Professional Documents

Culture Documents

Snap Through in A Reversed Dished Head

Uploaded by

matteo_1234Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Snap Through in A Reversed Dished Head

Uploaded by

matteo_1234Copyright:

Available Formats

08/06/2016

ReversedDishHead

ReversedDishedHead

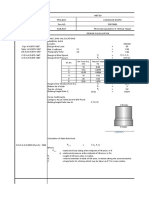

File:PVE407,LastUpdated:June2,2003,By:LB

TheProblem:

Theprocessinthisvesselrequiredareversedishedhead.The

reversedishedheadcouldnotbefabricatedthickenoughtomeet

theASMEVIII1rules.Thechosensolutionwastoreinforcethe

headwithribstopreventsnapthrough.

Variousalternatemethodsofanalysisareshownhere.Onlythe

plateanalysiswasusedfortheactualjob.However,the

comparisonofthevariousmethodsiseducational.

Theheaddiameterandthicknessanddesignpressureof75psiisthesameforalloftheexamples

bellow.Thematerialhasayieldstrengthof30,000psiandanalloweddesignstressof20,000psi.The

maximumallowedmembrane(tensile)stressis20,000psi,30,000atregionsofdiscontinuities.The

maximumallowedmembrane+bendingstressis30,000psi,60,000psiatdiscontinuities.

Analysis2DAxisymmetricwithLinearMaterialProperties:

Thisisoneofthesimplestmethodsofanalyzingthisvessel.Acrosssectionoftheheadwithout

reinforcementisanalyzed.Algorassumesthatthe2Ddrawingissymmetricalaboutanaxis

(axisymmetric).Theresultsshowthestressdistributionintheheadifthereisnomaterialyielding

(linearmaterialproperties).

Crosssectionofthereversedished

head(fromcentertoleftside).

Stressesareshownforaninterior

pressureinthisandthefollowing

shots.

Thepeakstressis54,000psiintheknuckleregion,wellabovethe30,000psiyieldpoint.Thishead

failstheASMEVIII1codecalculationsforexteriorpressure,butthestressesintheknuckleregionare

lessthanthediscontinuitystresslimitof60,000psi.Predicteddeflectionis0.15inches(notshown).

Perhapstheheadissafe?TheASMEcodecalculationsprovideasafepressureof57psiforaregular

dishedhead.Also,theuseofregulardishedheadexteriorpressurecalculationsisnotprovenfora

reversedishedhead.

Analysis2DAxisymmetricwithNonLinearMaterialProperties:

Thisanalysisallowsformaterialyielding.Thesamecrosssectionisanalyzed,butforthisanalysis,the

pressureisappliedinsteps,andthematerialwillbeallowedtoyield(NonLinear).Theresultscanbe

seeninthismovie.

Upto64psi,theheadcanbeseendeflectinglinearlyunderpressure.At69psisnapthroughis

beginning(andthedeflectionisgreaterthanthematerialthickness).Atthispointtheheadhasstarted

permanentdeformationitwillnotreturntotheoriginalshapeafterthepressureisremoved.Pressures

beyond72psishowrapidsnapthrough.Thefinalframeshowsthefullysnappedthroughshapeat72

psi.Thisshapeiskeptpermanentlyafterthepressureisremoved.

http://www.pveng.com/FEA/FEASamples/ReversedDishHead/ReversedDishHead.php

1/4

08/06/2016

ReversedDishHead

Defectionofthecenteroftheheadvs

pressure.Snapthroughstartsaround

66psi.

Originalandfinalshapeofhead.

Loadedto75psiandPressure

released.

Theheadsnappedthroughbeforethe75psioperatingpressurewasreached.Thetestpressureat1.3x

theoperatingpressurewouldalsonotbereached.Actualsnapthroughpressurestendtobelowerthan

calculatedpressuresduetomanufacturingtolerancesandmaterialvariations.Afactorofsafetywould

alsobeneeded.

Analysis3DPlateAnalysis:

Reinforcingribswereputontheheadtopreventsnapthrough.3Danalysisisrequiredtocalculatethe

stresses.AsurfacemodelwascreatedinSolidWorks.Thematerialthicknessisspecifiedattimeof

analysisintheAlgorFEAprogram.

Platemodeltopviewcreatedin

SolidWorks.

Platemodelbottomview.

TheFEAanalysisoftheheadinAlgorshowedthatthestresseswereacceptable.Themaximumallowed

membrane(tensile)stressis20,000psi,30,000atregionsofdiscontinuities.Themaximumallowed

membrane+bendingstressis30,000psi,60,000psiatdiscontinuities.Peakstressesaroundstress

concentrationscanbelarger.

MembraneStresslimitedto20,000

psiexceptinareasofdiscontinuities.

Atareasofdiscontinuities,membrane

stresscanbe30,000psi.Thisplot

showsmaximummembranestresses

at42,000psiataconcentrationwhich

isacceptable.

TotalStress(Membrane+Bending)

limitedto30,000psiexceptinareas

ofdiscontinuities.Atareasof

discontinuities,membranestresscan

be60,000psi.Thetotalstressesare

acceptable.

Analysis3DSolidAnalysis:

AsolidmodelwascreatedinSolidWorksincludingthereinforcingribsandallweldfillets.Theactual

materialthicknesswasmodeled.Thiswasnotdonefortheoriginalanalysis,butisincludedherefor

educationalpurposes.

http://www.pveng.com/FEA/FEASamples/ReversedDishHead/ReversedDishHead.php

2/4

08/06/2016

ReversedDishHead

Solidmodelbottomview

Solidmodeldetailmeshedat1/8"

meshsize

Topsidestress

Bottomsidestressdetail

Thesolidmodelmaximumcalculatedstressesarefoundinthesamelocationasfortheplatemodel,but

aremuchlower.Thesolidmodelaccountsbetterforthestressesatconnections,andallowstheeffect

ofweldfilletstobeincluded.

Themaximumstressis28,000psi,foundinsmallpeakareas.Thisvaluecouldbeusedwithafatigue

analysisifrequired.Allofthegeneralstressesarebelowthe20,000tensilelimit,sonostress

linearizationisrequiredtoseparatemembraneandmembrane+bendingloads.

Snapthroughanalysisresultsforthe

solidbottomhead.pressureat1sec

is75psi.At3.5xoperatingpressthe

headstartstoyield.

Displacedheadat5xoperating

pressuredisplacementmagnified2x.

TheSolution:

Thedesignwiththereinforcingribswassuccessfullyused.Areportinterpretingtheresultsaccordingto

ASMEVIII2rulesallowedthevesseltoberegistered.Alatermodificationtotheprocessallowedaless

expensivedoublewallheadtobeusedinstead.

ComparisonofMethodsShown:

TheSolidandPlateanalysismethodshereproducedalmostidenticalstressresultsexceptat

attachments.TheSolidmodelwiththeweldfilletsgavemorerealisticandlowerstressresults.Thesolid

modelwasalsoeasiertomakethantheplatemodelwhichrequiredeachsurfacetobesplitatall

intersections.Ifthestresseswerehigherinthesolidmodel,stresslinearizationwouldhavebeen

requiredtoseparatethemembraneandmembrane+bendingstresses.Thesolidmodelstress

linearizationismoredifficultthanreadingthestressesoffoftheplatemodel.

Credits:

ThistankwasbuiltbyPriceSchonstromInc.,35ElmStreet,Walkerton,Ontario,Canada,N0G2V0

2016PressureVesselEngineeringLtd.

http://www.pveng.com/FEA/FEASamples/ReversedDishHead/ReversedDishHead.php

3/4

08/06/2016

ReversedDishHead

http://www.pveng.com/FEA/FEASamples/ReversedDishHead/ReversedDishHead.php

4/4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Bumax Material Presentation - 04!05!16Document49 pagesBumax Material Presentation - 04!05!16matteo_1234No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Structures Stiffness PDFDocument27 pagesStructures Stiffness PDFEric VillenasNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Material Groups and StandardsDocument1 pageMaterial Groups and StandardsJohn Rymar LameraNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Coeficiente de RozamientoDocument2 pagesCoeficiente de RozamientoThomasNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- SWG BrochureDocument36 pagesSWG BrochureMorteza Shakerien100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Radiograph Interpretation of Castings PDFDocument4 pagesRadiograph Interpretation of Castings PDFmatteo_1234No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Bolts Nuts Gasket TorqueDocument20 pagesBolts Nuts Gasket Torquematteo_1234No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 3D Printing Buyers GuideDocument19 pages3D Printing Buyers Guidematteo_1234No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Pvp2014-28980 Analysis and Testing of A Ring-Joint FlangeDocument15 pagesPvp2014-28980 Analysis and Testing of A Ring-Joint Flangematteo_1234No ratings yet

- Forensic Materials Engineering Case Studies 2004 PDFDocument464 pagesForensic Materials Engineering Case Studies 2004 PDFRodolfo Arias100% (2)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- AMR Review 2005Document17 pagesAMR Review 2005nightshadow2250No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- AMR Review 2005Document17 pagesAMR Review 2005nightshadow2250No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Real Time Radiography Course BookletDocument48 pagesReal Time Radiography Course Bookletmusaismail8863No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A More Realistic Approach To Equivalent Pressure Method ASME BPVC Code Case 2901Document1 pageA More Realistic Approach To Equivalent Pressure Method ASME BPVC Code Case 2901matteo_1234No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Process Heat Transfer - KernDocument878 pagesProcess Heat Transfer - Kernalvinia100% (5)

- PVP2014-28729 Large Openings in Cylindrical Pressure Vessels-An Assessment Based On Absolute Size 2014 PDFDocument6 pagesPVP2014-28729 Large Openings in Cylindrical Pressure Vessels-An Assessment Based On Absolute Size 2014 PDFmatteo_1234No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- PVP2014-28265 Burst Test of B16.9 Welded TeesDocument10 pagesPVP2014-28265 Burst Test of B16.9 Welded Teesmatteo_1234No ratings yet

- A FEA Study of Shell and Solid Elemnts in Impact or Crash Box SimulationsDocument57 pagesA FEA Study of Shell and Solid Elemnts in Impact or Crash Box Simulationsmatteo_1234No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- PVP2014-28958 Writing and Reviewing FEA Reports Under ASME Div 1 and 2 Design PDFDocument5 pagesPVP2014-28958 Writing and Reviewing FEA Reports Under ASME Div 1 and 2 Design PDFmatteo_1234No ratings yet

- Vibration of A Cantilever Beam in Ambient FluidDocument10 pagesVibration of A Cantilever Beam in Ambient Fluidmatteo_1234No ratings yet

- Contact Update AnsysDocument32 pagesContact Update AnsyslumasNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Analysis of Bolted Joints SAMPE2011 Collier Automated Space VesselDocument13 pagesAnalysis of Bolted Joints SAMPE2011 Collier Automated Space Vesselmatteo_1234No ratings yet

- Bolted FRP Flange Joints For Pipelines - A Review of Current Practice and Future Changenlles BuenisimoDocument33 pagesBolted FRP Flange Joints For Pipelines - A Review of Current Practice and Future Changenlles Buenisimomatteo_1234No ratings yet

- Avesta Welding ManualDocument300 pagesAvesta Welding Manual66apenlullenNo ratings yet

- Nickel Aluminium Bronce SB-148 C95800Document2 pagesNickel Aluminium Bronce SB-148 C95800matteo_1234No ratings yet

- The Effect of Induced Imperfecfections On The Formation of The First Lobe Buckling in TubesDocument14 pagesThe Effect of Induced Imperfecfections On The Formation of The First Lobe Buckling in Tubesmatteo_1234No ratings yet

- Review Seismic AnalysisDocument8 pagesReview Seismic AnalysisSanjay DeshpandeNo ratings yet

- Influence of Imperfections On Axial Buckling Load On CompositesDocument11 pagesInfluence of Imperfections On Axial Buckling Load On Compositesmatteo_1234No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Efficient Finite Element Modelling and Simulation of WeldingDocument112 pagesEfficient Finite Element Modelling and Simulation of Weldingmatteo_1234No ratings yet

- Nickel Al Bronze Guide Engineers PDFDocument100 pagesNickel Al Bronze Guide Engineers PDFSenakeNo ratings yet

- Deflection and Member DeformationDocument7 pagesDeflection and Member DeformationChristopher LattaNo ratings yet

- Dirt & Air Separ Ators: Models Das-2 To DAS-12Document2 pagesDirt & Air Separ Ators: Models Das-2 To DAS-12Lee ChorneyNo ratings yet

- Ace Plast Ram C Revised July 2016Document1 pageAce Plast Ram C Revised July 2016pulakjaiswal85No ratings yet

- Contoh BQ Kerja AwamDocument14 pagesContoh BQ Kerja Awamahsam shasNo ratings yet

- Teflon Based GasketsDocument2 pagesTeflon Based GasketsAndroidNo ratings yet

- Fire Rated DoorDocument43 pagesFire Rated Doorshwetha shweNo ratings yet

- ESAB Welding HandbookDocument31 pagesESAB Welding Handbookhooky1100% (4)

- Work Schedule TemplateDocument10 pagesWork Schedule TemplateShahab AliNo ratings yet

- Load Calculation As Per IS CodeDocument14 pagesLoad Calculation As Per IS Coderonnie_syncinNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Make A Good SIZE-UP-Tom BartschDocument97 pagesMake A Good SIZE-UP-Tom BartschMauricioRiffoNo ratings yet

- Construction Estimate GuideDocument70 pagesConstruction Estimate Guidejanetabunar100% (2)

- BROMEN™Pleated Cartridge FilterDocument1 pageBROMEN™Pleated Cartridge FilterCarlos BarriosNo ratings yet

- For Construction: 1 383-L-ISO-18003-00Document1 pageFor Construction: 1 383-L-ISO-18003-00Ranish P. KurianNo ratings yet

- What Is Laminate PCBDocument9 pagesWhat Is Laminate PCBjackNo ratings yet

- Material Specification SA - HSP Lampung - Lobby - 2nd FloorDocument2 pagesMaterial Specification SA - HSP Lampung - Lobby - 2nd FloorAnjani DwitaNo ratings yet

- C&P WITCHLINER Insulated U-Bolt With PTFE (Not To Grip)Document1 pageC&P WITCHLINER Insulated U-Bolt With PTFE (Not To Grip)Achraf BoudayaNo ratings yet

- Dynamic Models For Structural Plasticity (1993)Document296 pagesDynamic Models For Structural Plasticity (1993)Alem LoajnerNo ratings yet

- KA20903 - Lecture 1 Introduction To Mechanics of SolidsDocument6 pagesKA20903 - Lecture 1 Introduction To Mechanics of SolidsKit Meng LimNo ratings yet

- Deformation of SolidsDocument2 pagesDeformation of SolidsMukesh TiwariNo ratings yet

- Design Guidelines On Residential UnitsDocument19 pagesDesign Guidelines On Residential Unitspriyasankar7No ratings yet

- General MaterialsDocument10 pagesGeneral MaterialsShanica Rosaldo CariñoNo ratings yet

- Tugas Termo IDocument1 pageTugas Termo IAditia Syamputra TanjungNo ratings yet

- Project Sub Project Sipil Owner Date Revision Prepared by No Description Qty Unit Cost Total Cost RP RP Brand Part No. B Floor StrengtheningDocument6 pagesProject Sub Project Sipil Owner Date Revision Prepared by No Description Qty Unit Cost Total Cost RP RP Brand Part No. B Floor StrengtheningMas Ngabehi ErwinNo ratings yet

- Current RatesDocument17 pagesCurrent Ratessadiq_r2007No ratings yet

- Report On Junkers CalorimeterDocument5 pagesReport On Junkers CalorimeterSandip PatelNo ratings yet

- Properties of Concrete Containing Ground Granulated Blast Furnace Slag (GGBFS) at Elevated TemperaturesDocument8 pagesProperties of Concrete Containing Ground Granulated Blast Furnace Slag (GGBFS) at Elevated Temperaturesteguh widayatNo ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- Impact of Glass Facades On Internal Environment of Buildings in Hot Arid ZoneDocument13 pagesImpact of Glass Facades On Internal Environment of Buildings in Hot Arid ZoneMohamed FajarNo ratings yet

- 5fc5275d6e1cd14138c012f5 - Matsui MC BrochureDocument4 pages5fc5275d6e1cd14138c012f5 - Matsui MC BrochurePedro Del AngelNo ratings yet

- Nitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesDocument2 pagesNitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesKishore Nayak kNo ratings yet

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)