Professional Documents

Culture Documents

UCS 67 84 Flow Chart

Uploaded by

Prashant RaneCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UCS 67 84 Flow Chart

Uploaded by

Prashant RaneCopyright:

Available Formats

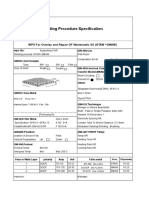

Impact testing Requirments UCS67 (for PQR) and UG 84i(Production test)

UCS 67

Impact test on Weld

procedure and Production

testing not required

Is impact testing exempted by UG20(f), UCS-66, and UCS-68

YES

NO

The MDMT used shall be either the

MDMT stamped

on the nameplate or the exemption

temperature of the welded

component before applying the

temperature reduction permitted by

UCS-66(b) or UCS-68(c).

Weld Procedure Require Impact tests on

Weld Metal and HAZ as per UG84 at

MDMT

UCS 67 (b)

Welds Made WITHOUT FILLER Metal.

WHEN ANY OF BELOW IS TRUE IMPACT IS REQUIRED

This clause is NOT Applicable for part of the material

specification (i.e. for Sec II material)

UCS 67 (a)

Welds Made WITH FILLER METAL

WHEN ANY OF BELOW IS TRUE IMPACT IS

REQUIRED

Impact

Exempted

UCS 67 (a)(1)

EITHER base metal is

required to be Impact

tested

NO

Weld procedure impact

Required.

Further analysis not

required

YES

UCS 67 (b)(1)

EITHER base metal is

required to be Impact

tested

YES

NO

UCS 67 (a)(2)

thickness of any individual weld pass

exceeds 13 mm and the MDMT is

colder than (21C)

YES

Weld procedure impact

Required.

Further analysis not

required

YES

UCS 67 (b)(2)

thickness at the weld exceeds 13 mm

Regardless of MDMT

UCS 67 (a)(3)

If base metals exempt from impact testing by

UCS66(g) or Fig UCS66, Curve C & D AND

NO

MDMT is between -29 to -48 Deg C.

Impact

Weld procedure with impact is not required if no

Exempted

individual pass is greater than 6 mm & each

batch of filler metal is impact tested as per SFA

at temp. not less than MDMT. Testing beyond

scope of SFA is acceptable

UCS66(j) When the base metal is

exempt from impact testing by

UCS66(g) or by Fig UCS-66

Curves C or D, 29C is the

coldest MDMT to be assigned for

OR

welded components that do not

meet the requirements of UCS67(a)(3).

NO

NO

Impact

Exempted

OR

OR

Impact

Exempted

Impact

Exempted

OR

OR

Impact

Exempted

NO

UCS 67 (a)(4)

When joining base metals exempt from

impact by UCS66(g) and MDMT is

greater than -48 Deg C

YES

Weld procedure impact

Required.

Further analysis not

required

YES

UCS 67 (b)(3)

thickness at the weld exceeds 8 mm

And MDMT is Colder than 10 Deg C

NO

Impact

Exempted

OR

YES

Weld procedure impact

Required.

YES

UCS 67 (a)(4)

When joining base metals exempt

from impact by UCS66(g) and

MDMT is greater than -48 Deg C

NO

Impact

Exempted

Since Weld Procedure Impact test is REQUIRED as per UCS 67.

PRODUCTION Test Plate is REQUIRED as per UG 84 (i) (2) for ALL joints.

Extent of testing will be as per weld procedure i.e. UG84(h) [Weld metal & HAZ]

UG 84 (i)(3) Number of Vessel Impact Test Plates Required

UG84 (i) (1)

UG 84 (h) details testing requirement for weld procedure

UG 84 (g) details sampling and acceptance criteria

Test will be for each weld procedure used on each vessel or group

of vessels as defined in UG 84 (i) (3)

Test plate shall be from one of the heats of steel used.

Cat A joints, test plate shall where practicable, extension to the end

of a production joint (as nearly as practicable the quality and type

of welding in vessel joint).

Cat B joints, that are welded using a different weld procedure than

Cat A, test plate shall be welded under production welding

conditions used for the vessel, using same type of equipment and

at the same location, same procedures used for joints. This

shall be welded concurrently with the production welds or as close

to the start of production welding as practicable.

(-a) For each vessel, one test plate shall be made for each welding procedure used for joints of

Cat A & B, unless the vessel is one of several as defined in

(-b) or (-c) below.

In addition, for Category A and B joints the following requirements shall apply:

(-1) If automatic, machine, or semiautomatic welding is performed, a test plate shall be made in

each position employed in the vessel welding.

(-2) If manual welding is also employed, a test plate shall be made in the flat position only,

except if welding is to be performed in other positions a test plate need be made in the vertical

position only (where the major portions of the layers of welds are deposited in the vertical

upward direction). The vertically welded test plate will qualify the manual welding in all

positions.

(-b) For several vessels or parts of vessels, welded

within any 3 month period at one location, the plate thickness of which does not vary by more

than 6 mm, or 25%, whichever is greater, and of the same specification & grade of material, a

test plate shall be made for each 400 ft (120 m) of joints welded by the same procedure.

(-c) For small vessels not exceeding the volume limitations defined in U-1(j) made from one

heat of material requiring impact tests, one welded test joint made from the same heat of

material and welded with the same electrode and the same welding procedure may represent

one lot of 100 vessels or less, or each heat treatment furnace batch, whichever is smaller.

UG 84 (j)

If vessel test plate fails to meet

the impact requirements, the

welds represented by the plate

shall be unacceptable. Reheat

treatment and retesting or

retesting only are permitted.

You might also like

- ASME VIII Div. 1 - 7 Impact TestingDocument21 pagesASME VIII Div. 1 - 7 Impact TestingYoucef ChorfaNo ratings yet

- Impact Testing RequirementsDocument24 pagesImpact Testing Requirementschuckhsu124850% (2)

- Inspection Requirements ASME VIII DIV 1 1673549276Document39 pagesInspection Requirements ASME VIII DIV 1 1673549276Mat Pustjens100% (1)

- Impact Test Requirements Enigma - ABSADocument13 pagesImpact Test Requirements Enigma - ABSASH1961No ratings yet

- Asme 9 DatosDocument47 pagesAsme 9 Datosvichu_villamarNo ratings yet

- MDMT & Impact Testing ExceptionsDocument13 pagesMDMT & Impact Testing ExceptionsSourav Sharma100% (2)

- ASME Code Section 8Document7 pagesASME Code Section 8wienslaw5804No ratings yet

- Artilce - Potential Detrimental Consequences of Excessive PWHT On Steel PropertiesDocument8 pagesArtilce - Potential Detrimental Consequences of Excessive PWHT On Steel PropertieswholenumberNo ratings yet

- Summary of ASME BPVC Section VIII Div 1 (Part 4) - Welding & NDTDocument11 pagesSummary of ASME BPVC Section VIII Div 1 (Part 4) - Welding & NDTTin Aung KyiNo ratings yet

- ASME Impact Test RequirementDocument3 pagesASME Impact Test Requirementapply19842371100% (4)

- ASME Impact Test RequirementDocument6 pagesASME Impact Test RequirementgaurangNo ratings yet

- Summary of Important Points in ASME Code Section 8Document3 pagesSummary of Important Points in ASME Code Section 8dhirendarjiNo ratings yet

- Pressure Vessel Dimension Inspection PDFDocument17 pagesPressure Vessel Dimension Inspection PDFEqubal KhanNo ratings yet

- 510 PC Oct04 Qas-Ex2 Open PSJDocument7 pages510 PC Oct04 Qas-Ex2 Open PSJCss SfaxienNo ratings yet

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 pagesQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীNo ratings yet

- SecVIII Div1 UW40Document2 pagesSecVIII Div1 UW40arianaseriNo ratings yet

- ASME 9 Multi Process Welding Procedures QW200Document2 pagesASME 9 Multi Process Welding Procedures QW200Teodor EzaruNo ratings yet

- Asme PWHT PreheatDocument135 pagesAsme PWHT PreheatWaqas WaqasNo ratings yet

- Tube To Tube Sheet WeldingDocument5 pagesTube To Tube Sheet WeldingGowrish Kumar100% (2)

- Hastelloy C-276 WeldingDocument4 pagesHastelloy C-276 WeldingClaudia MmsNo ratings yet

- PWHT ProcedureDocument6 pagesPWHT ProcedurevictorbirlanNo ratings yet

- U1a - 735834Document2 pagesU1a - 735834Alex SimonNo ratings yet

- Duplex Stainless Steel Welding - Best PracticesDocument4 pagesDuplex Stainless Steel Welding - Best PracticesjosemiguelzuNo ratings yet

- Pressure Vessel, Asme CodeDocument10 pagesPressure Vessel, Asme Codeabhi_mohit2005100% (1)

- Asme Pressure Vessel JoiDocument4 pagesAsme Pressure Vessel JoiliamcsNo ratings yet

- Weld Joint EfficienciesDocument5 pagesWeld Joint EfficienciesMohd Idris MohiuddinNo ratings yet

- 2019 ASME Section IX SynopsisDocument31 pages2019 ASME Section IX SynopsisFaiez GhrabNo ratings yet

- Lethal Service - Quick GuideDocument3 pagesLethal Service - Quick GuideNasir Khan Jadoon0% (1)

- Pressure VesselsDocument45 pagesPressure Vesselsshiel175No ratings yet

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- Shell and Tube Heat Exchangers (API 660 vsTEMA)Document3 pagesShell and Tube Heat Exchangers (API 660 vsTEMA)Aravind MadhuNo ratings yet

- Welding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Document1 pageWelding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Lipika GayenNo ratings yet

- PWHTDocument79 pagesPWHTnguyenNo ratings yet

- Percentage Wall Reduction Is The Most FrequentlyDocument4 pagesPercentage Wall Reduction Is The Most Frequentlysanketpavi21No ratings yet

- Lesson 06 UW40 UW56.1 New2Document30 pagesLesson 06 UW40 UW56.1 New2Kandregula Mohan BabuNo ratings yet

- Preheat and Interpass TempDocument2 pagesPreheat and Interpass TempUche UrchNo ratings yet

- Asme Boiler and Pressure Vessel Codes: SectionsDocument68 pagesAsme Boiler and Pressure Vessel Codes: Sectionsajay thomasNo ratings yet

- National Iranian Gas Company IGAT 5 Gas Compressor Stations: 602-106-TSH-VD-015 Rev. 0 PWHT ProcedureDocument9 pagesNational Iranian Gas Company IGAT 5 Gas Compressor Stations: 602-106-TSH-VD-015 Rev. 0 PWHT ProcedurewiNo ratings yet

- Asme Sec 9Document12 pagesAsme Sec 9ckkashyap0007No ratings yet

- Welding Practice For Duplex-1 PDFDocument18 pagesWelding Practice For Duplex-1 PDFBipin Rohit100% (1)

- Asme Section Ix InterpretationsDocument72 pagesAsme Section Ix InterpretationsEmmanuelNo ratings yet

- Pressure Vessel Dimension InspectionDocument10 pagesPressure Vessel Dimension InspectionYetkin ErdoğanNo ratings yet

- Hydrotest Blind PDFDocument9 pagesHydrotest Blind PDFManu Jojo100% (1)

- HT Chart For ASME Material-B31.3Document1 pageHT Chart For ASME Material-B31.3MurugananthamParamasivamNo ratings yet

- Esab Inconel 625 InfoDocument1 pageEsab Inconel 625 InforinshadNo ratings yet

- Weld Repair Rate - MFJO542Document2 pagesWeld Repair Rate - MFJO542Salahuddin Farooqui100% (1)

- Fluid Service CategoriesDocument5 pagesFluid Service CategoriesKodali Naveen Kumar100% (1)

- ASME DIV 2 Class 1 Vs Class 2Document3 pagesASME DIV 2 Class 1 Vs Class 2Idris SiddiquiNo ratings yet

- Agenda Item: 650-2024: Coating Prior To Hydrostatic TestingDocument4 pagesAgenda Item: 650-2024: Coating Prior To Hydrostatic Testinggigiphi1No ratings yet

- WM PWHTDocument18 pagesWM PWHTFaiz IshakNo ratings yet

- Multi Process Welding Procedures QW200.4 (ASME IX)Document1 pageMulti Process Welding Procedures QW200.4 (ASME IX)HoangNo ratings yet

- ASME VIII PreparationDocument2 pagesASME VIII PreparationSameh AminNo ratings yet

- Use of Appendices 1-9 and 1-10 of ASME Section VIII Division 1Document3 pagesUse of Appendices 1-9 and 1-10 of ASME Section VIII Division 1SachinNo ratings yet

- PWHTDocument13 pagesPWHTcv100% (2)

- QAPDocument31 pagesQAPlohitha100% (1)

- Spiral Wound GasketsDocument3 pagesSpiral Wound GasketsHarish GundaNo ratings yet

- U-Stamp QapDocument6 pagesU-Stamp Qapchonubobby100% (1)

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsDocument13 pagesThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25No ratings yet

- Weld Overlay Procedure For InconelDocument3 pagesWeld Overlay Procedure For InconelArash Mohamadi100% (2)

- Asme Sec Viii Ucs PWHTDocument35 pagesAsme Sec Viii Ucs PWHTMahesh KumarNo ratings yet

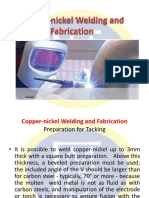

- Cuni Welding PresentationDocument13 pagesCuni Welding PresentationPrashant RaneNo ratings yet

- Interpretation VIII 1-16-85Document1 pageInterpretation VIII 1-16-85Prashant Rane100% (1)

- Calculation of Wind and Seismic LoadsDocument6 pagesCalculation of Wind and Seismic Loadsfaris11No ratings yet

- UCS 67 84 Flow ChartDocument1 pageUCS 67 84 Flow ChartPrashant RaneNo ratings yet

- Swami Vivekananda ThoughtsDocument1 pageSwami Vivekananda ThoughtsPrashant RaneNo ratings yet

- Guidance To Good Engineering Practices - Pressure TestingDocument27 pagesGuidance To Good Engineering Practices - Pressure TestingPrashant RaneNo ratings yet

- TTT Extension Piece WeldingDocument1 pageTTT Extension Piece WeldingPrashant RaneNo ratings yet

- CA Treatment ProcessDocument54 pagesCA Treatment ProcessPrashant RaneNo ratings yet

- EC3 - Offshore Padeye DesignDocument4 pagesEC3 - Offshore Padeye Designscaricatutto100% (1)

- ASME Sec VIII Div 1 Appendix 28Document2 pagesASME Sec VIII Div 1 Appendix 28Prashant RaneNo ratings yet

- Feroxyl and Copper Sulfate TestingDocument23 pagesFeroxyl and Copper Sulfate TestingPrashant RaneNo ratings yet

- Pipe Chart PDFDocument2 pagesPipe Chart PDFCarlos Rivera0% (1)

- Aws Welder Qualification Requirments Tyk JointsDocument2 pagesAws Welder Qualification Requirments Tyk JointsPrashant RaneNo ratings yet

- Z0-TS-P-04010 Table 3Document1 pageZ0-TS-P-04010 Table 3Prashant RaneNo ratings yet

- Pipe Schedule and Thickness PDFDocument2 pagesPipe Schedule and Thickness PDFskychurch100% (1)

- Dqsul-Cfs Info Iso 9001 2008 Vs 2015-1Document4 pagesDqsul-Cfs Info Iso 9001 2008 Vs 2015-1Prashant RaneNo ratings yet

- BIS 4503 1967 Shell and Tube Type Heat Exchangers PDFDocument72 pagesBIS 4503 1967 Shell and Tube Type Heat Exchangers PDFmahaveenNo ratings yet

- Dwdi PDFDocument54 pagesDwdi PDFm_seyedNo ratings yet

- ElectrodesDocument4 pagesElectrodesPrashant RaneNo ratings yet

- ThermoDocument25 pagesThermoJerryco AlviarNo ratings yet

- G7Document21 pagesG7Maame Ama FrempongNo ratings yet

- Introduction To Marine MachineriesDocument13 pagesIntroduction To Marine MachineriessrcattozziNo ratings yet

- Climbing Film EvaporatorDocument8 pagesClimbing Film Evaporatorsaz140% (1)

- Design and Fabrication of Oil Skimmer RobotDocument46 pagesDesign and Fabrication of Oil Skimmer RobotSathiya Udumalpet100% (2)

- Bhel Jhansi ReportDocument73 pagesBhel Jhansi ReportTarun VermaNo ratings yet

- 1001 Solved Problems in Electrical EngineeringDocument799 pages1001 Solved Problems in Electrical EngineeringMarlon Manalo92% (13)

- Fault Code 195 Coolant Level Sensor Circuit - Voltage Above Normal or Shorted To High SourceDocument13 pagesFault Code 195 Coolant Level Sensor Circuit - Voltage Above Normal or Shorted To High SourceAhmedmah100% (1)

- Week 5 Waste Management in Singapore Case Study For SSE1201 v6Document34 pagesWeek 5 Waste Management in Singapore Case Study For SSE1201 v6ZihNo ratings yet

- Technical Data Compressor: SC12CLDocument6 pagesTechnical Data Compressor: SC12CLKokoNo ratings yet

- 487.4-2013 Standard For The Electrical Protection of Communication Facilities Serving Electric Supply Locations Through The Use of Neutralizing TransformersDocument55 pages487.4-2013 Standard For The Electrical Protection of Communication Facilities Serving Electric Supply Locations Through The Use of Neutralizing Transformersjose eduardo mejia sanchezNo ratings yet

- Nhce Hydraulic Excavator E505c EvoDocument4 pagesNhce Hydraulic Excavator E505c EvoYew LimNo ratings yet

- Ismt LTD (2019-2020)Document150 pagesIsmt LTD (2019-2020)Nimit BhimjiyaniNo ratings yet

- Abdullah Project ReportDocument15 pagesAbdullah Project ReportHafiz AbdullahNo ratings yet

- AMOY StandardDocument4 pagesAMOY StandardHariyanNo ratings yet

- EPIV ValvesDocument2 pagesEPIV ValvesstomakosNo ratings yet

- Experiment #8 Title: Power Factor Correction: II. Wiring CircuitDocument13 pagesExperiment #8 Title: Power Factor Correction: II. Wiring CircuitNesleeNo ratings yet

- STD 149Document42 pagesSTD 149Pranav TalwarNo ratings yet

- TM 1-1520-256-23 PDFDocument522 pagesTM 1-1520-256-23 PDFEagle1968100% (1)

- Fuel, Lubricants and Fluids: en-GBDocument59 pagesFuel, Lubricants and Fluids: en-GBRuanNo ratings yet

- Thermal Pr0perties of CeramicsDocument5 pagesThermal Pr0perties of CeramicsaufaNo ratings yet

- Measuring The Pour Point of Crude Oils: Manual MethodDocument1 pageMeasuring The Pour Point of Crude Oils: Manual MethodSamuel OlonadeNo ratings yet

- Cover Page: Machine Design-II Semester: 8: in This Subject Student Are Learn About Below Given PointDocument8 pagesCover Page: Machine Design-II Semester: 8: in This Subject Student Are Learn About Below Given PointSp PatelNo ratings yet

- Electromagnetic Induction: Theory and Exercise BookletDocument62 pagesElectromagnetic Induction: Theory and Exercise Bookletabc9999999999No ratings yet

- LPG Co-MinglingDocument17 pagesLPG Co-MinglingderhgawenrahulNo ratings yet

- Environmental Impact Assessment by L.W. CanterDocument38 pagesEnvironmental Impact Assessment by L.W. CanterDewi Hadiwinoto33% (9)

- PB PDFDocument95 pagesPB PDFMisha KulibaevNo ratings yet

- Rengoera Lave Vaisselle Encastrable Ikea 300 - AA 2192023 3 1Document64 pagesRengoera Lave Vaisselle Encastrable Ikea 300 - AA 2192023 3 1adamNo ratings yet

- Vista Vista Ar Tech Data Sheet MalarkeyDocument2 pagesVista Vista Ar Tech Data Sheet MalarkeyHoeNo ratings yet

- ENDA-5000 HRE2406B- Gas Analyzer- Thiết Bị Phân Tích KhíDocument6 pagesENDA-5000 HRE2406B- Gas Analyzer- Thiết Bị Phân Tích KhíminhNo ratings yet