Professional Documents

Culture Documents

Terminal Points (TBWES & Toshiba) JSPL, 8 X 660 MW

Uploaded by

punitg_2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Terminal Points (TBWES & Toshiba) JSPL, 8 X 660 MW

Uploaded by

punitg_2Copyright:

Available Formats

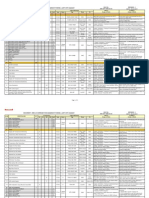

ATTACHMENT: I-A: TERMINAL POINTS FOR MAIN PLANT EQUIPMENT SUPPLIER

10 x 660 MW- JSPL (Jindal Power), Date 05-03-2012

Equipment/ System

Terminal points

Resolutions

TBWES)

(Toshiba

Inlet of Bunker

TBWES noted & confirmed.

&

MECHANICAL

Steam Generator

1

Coal

Ash

(a) Bottom ash

Outlet of

assembly

boiler

seal

plate

TBWES noted & confirmed.

(b) Fly ash

Outlet flanges of knife edge gate

valve of

air preheater,

economizer, ESP , hoppers

TBWES noted & confirmed.

Flue gas

Approx

1

meter

outside

chimney.

Note - Expansion compensator

in boiler scope.

TBWES noted & confirmed.

Fuel oil

One meter away from boiler for

supply and return line(in

the pipe rack)

TBWES noted & confirmed.

Boiler filling lines/

deaerator emergency /

initial filling line

Inlet of CST

Boiler filling system including

associated piping (between CST

and Economiser) by TBWES.

Terminal point shall be the inlet

nozzle on CST.

One point at first column of

boiler for each boiler

Terminal point for ACW system

shall be 1.0 m from boiler 1 st

row column. However, DMCW

pumps and PHEs shall be

separate of boiler cooling water

requirement and supplied by

boiler.

6

(a) CCW/SW

Also, for owners BOPs cooling

water requirement (DMCW),

terminal

point

shall

be

discussed with owner.

(b) AH Washing

One point at last column of

boiler for each boiler

TBWES noted & confirmed.

(c) Fire fighting for

APH

One point at last column of

boiler for each boiler

TBWES noted & confirmed.

One point at first column of

boiler for each boiler

TBWES noted & confirmed for

their scope.

Instrument Air /Service

Air

Service Air and Instrument Air

Supply shall be made

available by the Owner at two

points (one at Boiler and

other at Turbine area) with

isolation valve.

8

Equipments and Piping

Drains

Terminal

at

nearest

tundish/station drains at zero

elevation

TBWES noted & confirmed.

Blow Down

IBD Boiler blow down up to

nearest effluent pit. Cooling of

hot blow down prior to disposal

in boiler scope.

TBWES noted & confirmed.

10

Mill reject system

Outlet of mill pyrite hopper.

TBWES noted & confirmed.

11

Steam vent

1m above boiler roof including

silencer.(Note: Each vent is to be

provided

with

individual

silencer)

TBWES noted & confirmed.

12

Counter flanges

All flange interface terminals

should be provided with counter

flanges, nuts, bolts, gaskets etc.

by bidder.

TBWES noted & confirmed.

13

Feed Water

From the inlet of Feed Control

Station (FCS) (FCS to be

supplied by Boiler Vendor)

14

Steam Output

15

CRH , HRH and Auxiliary

Steam line( as applicable)

-

At the outlet of the main steam

valve of the boiler.

1 meter away from the

connecting

point

of

the

respective Equipments of the

Boiler.

Terminal point shall be inlet of

check valve near economizer

inlet header. Flow element shall

be issued as Free-Issue-Item

(FIM)

to

Toshiba

for

installation in upstream feed

water piping.

For MS piping terminal point

shall be the ESV inlet.

For CRH,TP shall be Turbine

Exhaust (QCNRV shall be

supplied by Toshiba as free

issue item)

For HRH, TP shall be inlet of

IV.

For Auxiliary steam, TP shall

be at 1.0 meter from Boiler first

row column.

For HP Bypass, the piping shall

be by TBWES.HP Bypass

valves shall be free issue item

by TBWES to Toshiba.

16

Steam input ( as

applicable) Steam Turbine:

1

Condenser Cooling Water

(a) Closed loop DM

Cooling Water for

equipments (Primary

Circuit)

(b) ACW (Secondary

Circuit)

Condenser Make-up water

Instrument Air / Service

Air

Equipment and Piping

Drains

At the outlet of the main steam

valve of the boiler.

For LP Bypass, Upstream

piping of LP Bypass valve by

TBWES.

Refer Sl. N-14 above.

Upto the Condenser side flange

of the Butterfly valve ( scope of

Owner) including counter flange

At 1 meter away from TG

building column. (TG Vendor to

consider the requirement of DM

cooling water of the Boiler area

while sizing their PHE and

Pumps.) for Closed loop DM

Cooling Water for equipments

(Primary Circuit)

At Condenser Hot well Nozzle

Not Applicable to Boiler

Piping with isolation valve will

be provided at single point near

TG building. Further distribution

by vendor

Terminal at nearest tundish /

station drains at zero elevation.

Not Applicable to Boiler

Steam Vent

At suitable location, 1 m above

Turbine building roof including

silencer as required.

Not Applicable to Boiler

Carbon-di-oxide and

Hydrogen

Outlet manifold and subsequent

distribution under

bidders scope.

Not Applicable to Boiler

Steam Input

Refer Sl. N-14 above.

CRH, HRH and Auxiliary

Steam

Line (as applicable)

At the outlet of Main steam

valve of the Boiler

1 meter away from the

connecting point of the

Refer Sl. N-6a above for Boiler

scope.

Not Applicable to Boiler

Not Applicable to Boiler

Refer Sl. N-15 above.

respective Equipments of the

Boiler

10

Feed water

Up to the Inlet of Feed Control

Station (FCS). FCS

Supplied by the Boiler Vendor.

Refer Sl. N-13 above.

Electrical & Instrumentation:

1

Generator

Both phase and neutral side

flanges for connection with

IPBD. Generator Line and

Neutral side seal off bushing

terminals

suitable

for

termination

of

Purchaser's

Isolated

Phase

Generator

Busduct.

Not Applicable to Boiler

Neutral Grounding

Transformer & Resistor

(NGTR)

At the panel flange for

connection with IPBD. Seal off

bushing terminal of the Neutral

Grounding Equipment Cubicle

suitable for termination of

Purchaser's

Isolated

Phase

Generator Busduct.

Not Applicable to Boiler

Surge Protection and

Voltage Transformer

Cubicle

Seal off bushing terminals of the

Surge Protection and Voltage

Transformer Cubicle suitable for

termination

of

Purchaser's

Isolated

Phase

Generator

Busduct's tap-offs.

Not Applicable to Boiler

Lightening arrester

potential transformer

(LAPT) Cubicle

At the panel flange

connection with IPBD. .

Emergency DC Drives

At the incoming power supply

terminals of DC starters to be

located locally near the drives.

Power Cable interconnection

between DC starter and Motor

by Purchaser.

for

At the incoming power supply

terminals of DC starters

to be located locally near the

drives. Power Cable

interconnection between DC

starter and Motor is BTG

package scope

6

Cable & Cabling for

(1)

At

the

terminals

of

For TBWES scope.

For DC scanner air fan, TP

shall be motor terminal box.

For Local DC junction box ,TP

shall be local incoming

terminal.

For TBWES scope

BTG, except for ESP and

Soot Blower.

Instrument rack /JB mounted

locally near the equipment.

(2) At motor terminals

1.TBWES Noted & confirmed

2. TBWES Noted & confirmed

ESP

Power supply at 415 V level at

the incoming flange of ESP

PMCC for Busduct connection.

TBWES Noted & confirmed

Soot Blower MCC

Power supply at 415 V level at

the incoming terminals of Soot

Blower

MCC

for

cable

connection.

TBWES Noted & confirmed

UPS Supply (230 V AC, 1

phase, 50 Hz)

At the incoming power supply

terminals of Panels.

TBWES Noted & confirmed for

their scope as applicable.

10

Non UPS AC Supply

At the incoming power supply

terminals of Panels.

TBWES Noted & confirmed for

their scope as applicable.

11

DC Supply (220 V DC)

Redundant supply at each panel.

TBWES Noted & confirmed for

their scope as applicable.

12

Earthing

At the earth pad of MP

Equipment / Earth bus of Panels.

TBWES Noted & confirmed for

their scope.

At the earth riser 300 mm above

ground level

13

DCS ( including other PLC, Turbine Governor & BMS

systems)

TBWES confirmed

input for BMS.

for

the

13.1

UPS Supply

Redundant supply at DCS UPS

distribution board ( in MP

Vendor's scope)

Refer Sl. N-9 above.

13.2

Non UPS AC Supply

Supply at DCS ACDB ( in MP

Vendor's scope)

Refer Sl. N-10 above.

13.3

DC Supply

Redundant supply at DCS

DCDB ( in MP Vendor's scope)

Refer Sl. N-11 above.

13.4

Gateway cables

At the terminal point of gateway

module/marshalling.

TBWES Noted & confirmed for

their scope as applicable.

13.5

Electronic Earthing

At the Copper busbar of each

panel.

TBWES Noted & confirmed for

their scope as applicable.

14

VFD Drive

At the incoming power supply

terminals.

TBWES Noted & confirmed for

their scope as applicable.

15

Cable Tray & Support

Branch cable tray from Owners

TBWES Noted & confirmed for

16

AC Motor & Actuator

main cable trays/rack

their scope as applicable.

Motor Actuator Terminal Box

TBWES Noted & confirmed for

their scope.

CIVIL:

Base plate/sole plate, special and additional packers for all equipment

in BTG vendor scope. Supply of all foundation bolt for all equipment

in BTG scope shall be in scope of BTG vendor. Templates/ anchor

frames, if required, shall also be in Contractors scope.

TBWES Noted & confirmed for

their scope.

GENERAL:

All overflow drain connection, equipment drains, piping drains and

effluent discharge connections up to nearest effluent pit.

TBWES Noted & confirmed for

their scope.

Note: For the total BTG Package Vendor, the T.P for M.S., CRH, HRH, Feed water and

Auxiliary Steam Lines are not applicable

You might also like

- ACC - Offer 000984 Rev PDFDocument31 pagesACC - Offer 000984 Rev PDFMohamed SaaDNo ratings yet

- Coiled Tubing Introduction-Part 1Document109 pagesCoiled Tubing Introduction-Part 1qazim786100% (3)

- Fresh Oil Specs of Nateria MP-40 Vs Mobil 705Document1 pageFresh Oil Specs of Nateria MP-40 Vs Mobil 705bilalNo ratings yet

- Schematic Diagram of Sealing & Cooling Water For CepDocument12 pagesSchematic Diagram of Sealing & Cooling Water For Cepjp mishraNo ratings yet

- UntitledDocument8 pagesUntitledPMG Bhuswal ProjectNo ratings yet

- HP Bypass Valve Data SheetDocument8 pagesHP Bypass Valve Data Sheetcasno4427No ratings yet

- 13 Internal Walkway and PerformanceDocument24 pages13 Internal Walkway and PerformanceDSGNo ratings yet

- Once Through: Steam GeneratorsDocument21 pagesOnce Through: Steam GeneratorsrajrampallyNo ratings yet

- TTD PerformanceDocument5 pagesTTD PerformanceSriraja RajapNo ratings yet

- Ash Handling SystemDocument24 pagesAsh Handling Systemnetygen1No ratings yet

- 023 CepDocument12 pages023 Cepjp mishraNo ratings yet

- 8.water CirculationDocument33 pages8.water CirculationSatadru HalderNo ratings yet

- WH Vacuum in Steam TurbineDocument2 pagesWH Vacuum in Steam Turbinemiths_0087No ratings yet

- Bhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC BoilersDocument41 pagesBhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC Boilersrashm006ranjanNo ratings yet

- My Latest CV - EngineerDocument3 pagesMy Latest CV - EngineersasibhushanNo ratings yet

- CFCB Bed Ash CoolerDocument11 pagesCFCB Bed Ash CoolerUdhayakumar VenkataramanNo ratings yet

- HMBD Review Check ListDocument4 pagesHMBD Review Check Listctraminst_81No ratings yet

- Procedure For Condenser Vacuum PullingDocument4 pagesProcedure For Condenser Vacuum PullingPulkit AgarwalNo ratings yet

- WHRB Interlocks: S. No Boiler Equipment Logic For InterlocksDocument2 pagesWHRB Interlocks: S. No Boiler Equipment Logic For InterlocksAmeer MeerNo ratings yet

- Glaxo Vol IDocument164 pagesGlaxo Vol IPrakash WarrierNo ratings yet

- First Fill Bed Material Calculation For Bed Plate W DDocument3 pagesFirst Fill Bed Material Calculation For Bed Plate W DRAJKUMARNo ratings yet

- p101516-010 Rev.1 Gland Steam Condenser Specification Stg62Document2 pagesp101516-010 Rev.1 Gland Steam Condenser Specification Stg62Rais RijalNo ratings yet

- 57-62 1m809 - Eng72dpiDocument6 pages57-62 1m809 - Eng72dpiAbhinav TewariNo ratings yet

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDocument224 pagesBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadNo ratings yet

- DuctDocument3 pagesDuctRamalingam PrabhakaranNo ratings yet

- Title: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectDocument24 pagesTitle: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectRamalingam PrabhakaranNo ratings yet

- Condensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDocument8 pagesCondensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajNo ratings yet

- LPbypass SystemDocument43 pagesLPbypass Systemamulya1981No ratings yet

- Write Up On Aux PrdsDocument6 pagesWrite Up On Aux PrdsYousuf AliNo ratings yet

- Turbine Side PumpsDocument25 pagesTurbine Side PumpsPrakash Choudhary67% (3)

- History of Thermal Power PlantsDocument9 pagesHistory of Thermal Power PlantsAnonymous gr5Pr9AVNo ratings yet

- Flexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCDocument27 pagesFlexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCLakshmi NarayanNo ratings yet

- Design Calc - Cooling Tower Sizing - R1 - 15.10.2011Document1 pageDesign Calc - Cooling Tower Sizing - R1 - 15.10.2011AliAliNo ratings yet

- Regenerative Air PreheaterDocument19 pagesRegenerative Air PreheaterPrakash100% (1)

- Aux Steam SystemDocument14 pagesAux Steam SystemDipti BhanjaNo ratings yet

- CW Pumps Tripping On Over Load, 210 MW Unit, 02-03Document5 pagesCW Pumps Tripping On Over Load, 210 MW Unit, 02-03Charu ChhabraNo ratings yet

- Condenser Performance TestDocument16 pagesCondenser Performance TestAllan100% (1)

- Power Plant Familiar Is at Ion V - IIIDocument164 pagesPower Plant Familiar Is at Ion V - IIISiva Kumar Tutika100% (2)

- Vol-Ii B936Document113 pagesVol-Ii B936Anonymous uXdS9Y7No ratings yet

- 11V02 Acc SPC M 0001 V2 Part ADocument182 pages11V02 Acc SPC M 0001 V2 Part Asuparnabhose100% (1)

- Technical Diary-KMPCLDocument221 pagesTechnical Diary-KMPCLChandrahas SahuNo ratings yet

- Supercritical Boiler Cleanup Cycle: Ranjan KumarDocument23 pagesSupercritical Boiler Cleanup Cycle: Ranjan Kumarscentpcbarauni BARAUNINo ratings yet

- Air, Steam Vent Silencer - Enquiry Data SheetDocument1 pageAir, Steam Vent Silencer - Enquiry Data Sheetkishore1214No ratings yet

- Role of Instrumentation in Thermal Power Plant: Tejal K. Gote Batch: N62 NTC EklahareDocument23 pagesRole of Instrumentation in Thermal Power Plant: Tejal K. Gote Batch: N62 NTC EklahareAvishkar GoteNo ratings yet

- Poor Vacuum During Initial CommissioningDocument4 pagesPoor Vacuum During Initial CommissioningCharu ChhabraNo ratings yet

- Basics of Steam Turbine RollingDocument9 pagesBasics of Steam Turbine RollingLipika Ghosh BiswasNo ratings yet

- Bhel Pipe Color Code-Aa10630 1Document7 pagesBhel Pipe Color Code-Aa10630 1Vamsikrishna LakamsaniNo ratings yet

- VHB Presentation (Compatibility Mode) PDFDocument21 pagesVHB Presentation (Compatibility Mode) PDFhirenkumar patelNo ratings yet

- Furnace 01490Document83 pagesFurnace 01490JKKNo ratings yet

- Cold Start Up Check ListDocument6 pagesCold Start Up Check ListSreekanthMylavarapuNo ratings yet

- Turbine Bypass System - HORADocument11 pagesTurbine Bypass System - HORAhozipekNo ratings yet

- Over Water WingDocument7 pagesOver Water WingtsaipeterNo ratings yet

- Presentation of Kawasaki FGD and SCR SystemDocument20 pagesPresentation of Kawasaki FGD and SCR Systemjitendrashukla10836No ratings yet

- PRDS BasicsDocument4 pagesPRDS BasicsAvik Banerjee100% (2)

- MM M02 2Document347 pagesMM M02 2SamuelTrinandoNo ratings yet

- 500MW-Boiler - Salient FeatureDocument7 pages500MW-Boiler - Salient FeatureAhemadNo ratings yet

- Globe Valve Bs 1873 and Api 602: ASME B16.10Document7 pagesGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNo ratings yet

- Boiler AnnexDocument66 pagesBoiler Annexrenjithv_4No ratings yet

- 1.00.00 GENERAL Information: (For Vendor Registration Purpose)Document7 pages1.00.00 GENERAL Information: (For Vendor Registration Purpose)Rajendran SrnNo ratings yet

- Boiler OfferDocument10 pagesBoiler OfferManohar PandianNo ratings yet

- Materials and ComponentsDocument121 pagesMaterials and ComponentskishoreNo ratings yet

- BMS IO Summary For QC2 R1 20.02.2013Document9 pagesBMS IO Summary For QC2 R1 20.02.2013Nedunuri.Madhav Murthy100% (2)

- New Org Chart - LNT PowerDocument1 pageNew Org Chart - LNT Powerpunitg_2No ratings yet

- Project Director Head (Project Controls) Project ManagerDocument1 pageProject Director Head (Project Controls) Project Managerpunitg_2No ratings yet

- Project Director: Construction Manager EHS Manager Qa/Qc ManagerDocument1 pageProject Director: Construction Manager EHS Manager Qa/Qc Managerpunitg_2No ratings yet

- GEOJIT Equity Trading - Call and Trade Services - Free Online Trading ServicesDocument2 pagesGEOJIT Equity Trading - Call and Trade Services - Free Online Trading Servicespunitg_2No ratings yet

- Trading Account - ChargesDocument6 pagesTrading Account - Chargespunitg_2No ratings yet

- About Kotak Gold ETF (KGETF) Scheme FactsDocument3 pagesAbout Kotak Gold ETF (KGETF) Scheme Factspunitg_2No ratings yet

- 11 TradeDocument3 pages11 Tradepunitg_2No ratings yet

- Procedure For Installation Static Equipment For MSQ Upgradation UnitDocument7 pagesProcedure For Installation Static Equipment For MSQ Upgradation Unitpunitg_2No ratings yet

- Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011Document11 pagesLarsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011punitg_2No ratings yet

- The Overview of Gold Etfs and Its Various Positive Features: Mohdsaleem Matloobullah KhanDocument11 pagesThe Overview of Gold Etfs and Its Various Positive Features: Mohdsaleem Matloobullah Khanpunitg_2No ratings yet

- Securities Transaction Tax11234Document2 pagesSecurities Transaction Tax11234punitg_2No ratings yet

- Trading Holidays For The Calendar Year 2014Document1 pageTrading Holidays For The Calendar Year 2014punitg_2No ratings yet

- 01 Procedure For Structural SteelDocument9 pages01 Procedure For Structural Steelpunitg_2No ratings yet

- 30 1 Static Equipment Horizontal ErectionDocument2 pages30 1 Static Equipment Horizontal Erectionpunitg_2No ratings yet

- Larsen & Toubro Limited MSQ (Epcc-1) Upgadation Project: ContentsDocument5 pagesLarsen & Toubro Limited MSQ (Epcc-1) Upgadation Project: Contentspunitg_2No ratings yet

- Larsen & Toubro Limited MSQ (Epcc 1) Up Gradation: LT/MSQ/P/DPT//007Document4 pagesLarsen & Toubro Limited MSQ (Epcc 1) Up Gradation: LT/MSQ/P/DPT//007punitg_2No ratings yet

- 1 Procedure For Radiography TestingDocument9 pages1 Procedure For Radiography Testingpunitg_2No ratings yet

- Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: Procedure For Joint NumberingDocument3 pagesLarsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: Procedure For Joint Numberingpunitg_2No ratings yet

- NC 306 29JUL2010Document1 pageNC 306 29JUL2010punitg_2No ratings yet

- Contents:: Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) ProjectDocument3 pagesContents:: Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Projectpunitg_2No ratings yet

- 31 1 Static Equipment Vertical ErectionDocument2 pages31 1 Static Equipment Vertical Erectionpunitg_2No ratings yet

- Udhakar Chchasare: Total Experience:-THREE YEAR & ONE MONTH Experience in QA/QC & NDTDocument4 pagesUdhakar Chchasare: Total Experience:-THREE YEAR & ONE MONTH Experience in QA/QC & NDTpunitg_2No ratings yet

- ABRO Company ProfileDocument7 pagesABRO Company Profilepunitg_2No ratings yet

- PROC-OHS-INCIDENT-REPORTING - Procedure and Corrective ActionDocument6 pagesPROC-OHS-INCIDENT-REPORTING - Procedure and Corrective Actionpunitg_2No ratings yet

- FRM-OHS-HOT - WORK - PERMIT - Permit & GuidelinesDocument2 pagesFRM-OHS-HOT - WORK - PERMIT - Permit & Guidelinespunitg_2No ratings yet

- Purification Technologies For Biogas Generated by Anaerobic DigestionDocument24 pagesPurification Technologies For Biogas Generated by Anaerobic DigestionshazaNo ratings yet

- Dimensions: Guascor SFGLD 560 Lean Burn GensetDocument2 pagesDimensions: Guascor SFGLD 560 Lean Burn GensetTithy MoniNo ratings yet

- Diesel Engine: Transiting 210 KW Net Power RequirementDocument7 pagesDiesel Engine: Transiting 210 KW Net Power RequirementAlanNo ratings yet

- Hydraulic Brain TeasersDocument7 pagesHydraulic Brain TeasersabhijitmukhNo ratings yet

- CS 088Document2 pagesCS 088chandu306No ratings yet

- Determining The Moisture Content of Jatropha Seeds, Iodine Vale and Peroxide Value of Jatropha OilDocument7 pagesDetermining The Moisture Content of Jatropha Seeds, Iodine Vale and Peroxide Value of Jatropha OilCalator Prin MuntiNo ratings yet

- 1 Feasibilty Study of Development of A Gas Fired Termal Power Facility in Sheberghan Volume 1Document54 pages1 Feasibilty Study of Development of A Gas Fired Termal Power Facility in Sheberghan Volume 1Nana Silvana AgustiniNo ratings yet

- PLTD - OkDocument121 pagesPLTD - OkDefrizalAlfatihNo ratings yet

- 01 Engines: Table of Contents (Continued)Document20 pages01 Engines: Table of Contents (Continued)Pablo De Miguel GonzálezNo ratings yet

- Draw WorkDocument4 pagesDraw WorkfahroerNo ratings yet

- Area 1Document62 pagesArea 1Blessie AgutoNo ratings yet

- Graco EcoQuip Brochure - December 28 2014Document7 pagesGraco EcoQuip Brochure - December 28 2014AshwinNo ratings yet

- Dw10 FC: EURO 6 Step 1 Diesel Engine Automotive Application VersionDocument2 pagesDw10 FC: EURO 6 Step 1 Diesel Engine Automotive Application VersionArturHeiseNo ratings yet

- Piping HandbookDocument3 pagesPiping Handbookbarlang12350% (4)

- Enerwaste Green HubDocument20 pagesEnerwaste Green Hubgaby.hernandez485703No ratings yet

- Baltic Supramax Index (BSI) : Route Definitions: Route 1BDocument3 pagesBaltic Supramax Index (BSI) : Route Definitions: Route 1BIvan OsipovNo ratings yet

- Flashback ArrestorDocument6 pagesFlashback ArrestorahmedNo ratings yet

- Science Notes For Class 10 Chapter 16 Management of Natural ResourcesDocument3 pagesScience Notes For Class 10 Chapter 16 Management of Natural ResourceswsgNo ratings yet

- Vehicle Refueling: City of Hamilton - Corporate Safety GuidelineDocument5 pagesVehicle Refueling: City of Hamilton - Corporate Safety GuidelineamalNo ratings yet

- V776-561-004S Air Dryer CheckDocument4 pagesV776-561-004S Air Dryer CheckWilson BuenoNo ratings yet

- Bosch Standard User ManualDocument20 pagesBosch Standard User ManualZian HennNo ratings yet

- Bir Form 0605Document2 pagesBir Form 0605John Louise Tan100% (1)

- FMDVSPLTR InstructionsDocument5 pagesFMDVSPLTR InstructionsFatosYañezNo ratings yet

- Kia Picanto 2004 GLS 5 Doors Hatchback 1.1L L4 Sohc 12V FWD Gasoline 5-Speed Manual Subcompact Car Passenger Car South KoreaDocument11 pagesKia Picanto 2004 GLS 5 Doors Hatchback 1.1L L4 Sohc 12V FWD Gasoline 5-Speed Manual Subcompact Car Passenger Car South KoreaBaroszNo ratings yet

- Checklist Inspeccion de TaladrosDocument4 pagesChecklist Inspeccion de TaladrosAdolfo AnguloNo ratings yet

- Piping Engineer Interview Questions (From 6 To 10 Year)Document2 pagesPiping Engineer Interview Questions (From 6 To 10 Year)RamanNegi100% (1)

- Textbook: Package P3: Kiln - Operation and Optimisation Fuel Types and Their CharacteristicsDocument35 pagesTextbook: Package P3: Kiln - Operation and Optimisation Fuel Types and Their CharacteristicsSantanu PachhalNo ratings yet

- PP FWpumpDocument10 pagesPP FWpumpMohammad MohseniNo ratings yet