Professional Documents

Culture Documents

Lecture12 Oxidation PDF

Uploaded by

Fatimah Marwa NasutionOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture12 Oxidation PDF

Uploaded by

Fatimah Marwa NasutionCopyright:

Available Formats

Physics 9826b

Lecture 12

Mechanisms of Oxidation and Corrosion

12.1 Surface and Interface reactions in oxidation of metals

- thermal oxidation

12.2 Thermal oxidation of Si: Deal-Grove

12.3 Diffusion in metal oxide thin films

12.4 Corrosion (anodic oxidation)

- thermodynamics

- kinetics

References:

1) Zangwill, p.104-109

2) S.A. Campbell, The Science and Engineering of Microelectronic Fabrication, 1995

3) B. E. Deal and A. S. Grove, J. Appl. Phys., 36 (1965) 3770

4) C.Y. Chang, S.M. Sze, VLSI Technology, McGraw Hill

1

12.1 Mechanisms of Oxidation

When cations diffuse, the initially formed oxide drifts towards the metal

When anions diffuse, the oxide drifts in the opposite direction

2

Lecture 12

Physics 9826b

Microscopic oxidation pathways

J. Appl. Phys. 85 (1999) 7646

Lecture 17

Kirkendall effect

Marker at the diffusion interface move slightly in the opposite direction to the

most rapidly moving species vacancies can move!

Lecture 12

Physics 9826b

Thermal growth of aluminum oxide

Thick films (> 6000 ), Wagners theory:

Ultra-Thin films (< 30 ), Cabrera-Mott theory:

Cabrera-Mott theory

Electrons can cross the oxide

by tunneling mechanism

Electron transfer from metal

(Al) to the surface oxygen

establishes the Mott potential

V across oxide

Resulting uniform electric field

E=V/X is the driving force for

slow ionic transport, which

controls the height of the

potential barrier for ion jumps

Lecture 12

Physics 9826b

Diagram of potential energy maps for O2

There is thickness dependence of activation energy for ionic transport in the

opposite directions

Aside: Electrochemical oxidation of Al (Presentation 2)

7

Oxidation Rate (Kinetics)

During the oxidation of different metals, various empirical rate laws have

been observed

Linear law: w = kL t

Typical for metals with porous or cracked

oxide films ( transport of reactant ions

occurs at faster rates than the chemical

reaction), e.g., K, Ta

Parabolic law: w2 = kpt + C

Typical for metals with thick coherent

oxides, e.g. Cu, Fe

Logarithmic rate: w = ke log (Ct + A)

w weight gain

per unit area; or

oxide thickness

For oxidation at elevated temperature, e.g.,

Fe, Cu, Al; fast oxidation at the start, the rate

decreases to a very low value

Catastrophic at high T: rapid exothermal reactions, oxides are

volatile, e.g. Mo, W, V

8

Lecture 12

Physics 9826b

Oxidation of metals

Protective oxide films:

1. The volume ratio of oxide to metal after oxidation should be close to 1:1

or Pilling-Bedworth ratio = 1 (ration of oxide volume produced by oxidation to the volume

of metal consumed by oxidation)

2. The oxide film should have good adherence, high-temperature plasticity to

prevent fracture

3. The melting point of the oxide should be high

4. The oxide films should have a low vapor pressure and thermal coefficient of

expansion comparable to the one of the metal

5. Low conductivity and low diffusion coefficient for metal ions and oxygen are

desired

9

12.2 Thermal oxidation of silicon

Si grows a high quality oxide

Si(s) + O2 (g) = SiO2 (s)

Si(s) + H2 O (g) = SiO2 (s) +2H2

10

Lecture 12

Physics 9826b

Oxide growth calculator

Important parameters:

- initial SiO2 thickness

- temperature (700-1200oC)

- Si crystal orientation

- Wet or dry environment

Examples: Initial SiO2 thickness 25, 1000oC, Si(001), Dry O2

400 in 1 hour

initial SiO2 thickness 10, 1000oC, Si(111), Wet O2

~4500 in 1 hour

initial SiO2 thickness 10, 1000oC, Si(100), Wet O2

~3870 in 1 hour

http://www.cleanroom.byu.edu/OxideThickCalc.phtml

11

SiO2 growth stages

Initial

Lecture 12

Si wafer

Linear

Si wafer

Parabolic

Si wafer

In a furnace with O2 gas environment

Linear- oxide grows in equal amounts for

each time

< 500 thick

~ 500, in order for oxide layer to keep

growing, oxygen and Si atoms must be in

contact

SiO2 layer separate the oxygen in the

chamber from the wafer surface

- Si must migrate through the grown

oxide layer to the oxygen in the vapor

- oxygen must migrate to the wafer

surface

Physics 9826b

Thermal oxidation of silicon

Diffusivity of Si in SiO2 much smaller than that of O2

molecular O2 diffusion

(opposite to metal oxidation or anodic oxidation of Si , in which cations moves

out to surface)

gas

cg

SiO2

Si

c0

csurf

ci

F1

F2

F3

xo

Depth (x)

F1 incident flux to surface; F1=hg (Cg-Cs) hg mass transfer coefficient

F2 flux through the oxide; F3 reaction flux of oxide growth at interface

13

Deal-Grove model

Recall: from ideal gas law, Cg=pg /kT

Henrys law: C0=H ps

F1 = h(C*-C0), where h=hg/HkT

F2 = D(O2) [(C0-Ci)/x0] (from Ficks law)

If we let rate at interface be proportional to concentration of oxidant at the SiO 2/Si

interface, then:

F2 = ksCi

Assuming steady state approximation: F1 = F2 = F3

h(C*-C0) = D(O2) [(C0-Ci)/x0] = ks Ci

algebra then, solve for concentration at the interface

C

Ci

1

kS

h

k S x0

D

; Co

k x

*

C 1 S 0

D

kS

k S x0

1

h

D

B. E. Deal and A. S. Grove, J. Appl. Phys.,

36 (1965)

3770

Lecture

17

Lecture 12

14

Physics 9826b

Deal-Grove model (linear-parabolic regime)

Rate of growth

dx

F3

dt

, where N is the number of oxygen atoms incorporated

per unit volume (2.2 1022 cm-3 for SiO2)

dx

dt

F3

Hk

pg

k

k x

N 1 s s o

h

D

for x 0 x ( t 0 ) solution

x 0 Ax

2

1

1

A 2D

h

ks

For very t

x0

x 0 Ax

2 DC *

; B

;

N

B

hin oxides,

(t )

we can neglect

linear

quadratic

term,

and we have :

regime

For thick

oxides

x o B (t )

2

is

B (t )

parabolic

regime

15

Deal-Grove Model

Physical significance of 2 regimes:

- in linear regime for thin films, the

oxidant concentration is

assumed constant throughout

the system, C0 ~ Ci, rate is

controlled by interface (surface)

reaction;

- in the parabolic (thick film)

regime, Ci 0, and C0 ~ C* ;

and

B D, and diffusion through the

oxide dominates growth

kinetics

16

Lecture 12

Physics 9826b

Problems with DG model:

Steady state growth?

Interface growth assumes first order gas phase type

reaction, why?

What is the true O2 profile?

Is the interface a sharp well-phase-segregated plane

(strain in Si, suboxides, roughness?

No good physical interpretation of accelerated initial

growth

Ions, radicals, surface reaction/exchange?

17

The role of SiO formation during the SiO2 growth

Overall reaction route is dependent on the oxygen (water) pressure and

temperature used

- at low T, high po2 Si(s) + O2(g) = SiO2 (s) - passive oxidation regime

- at high T, low po2 Si(s) + O2(g) = 2SiO (g) active oxidation

Starodub D. Surf. Rev. Lett. 6 (1999) 45-52

Lecture 12

18

Physics 9826b

Oxygen reactions with oxide films

Some possible types of reactions:

(i) exchange without a change in

total oxygen concentration

(ii) Oxide growth with additional O

incorporation

oxide

O2

substrate

Exchange

Oxide growth

19

Oxygen transport mechanisms examined by ion

scattering and isotopes

16O

H+

18O

marker

tracer

(first)

(last)

Oxygen lattice

transport (O or

vacancy exchange)

Direct oxygen

transport (no Oexchange) to

interface

Energy

Concentration vs

depth

Lecture 12

Raw ion scattering

spectra (for two

20

isotopes)

10

Physics 9826b

Oxygen isotope experiments: SiO2 growth mode

Q: Why use isotopes?

A: To study processes,

not just structures!!

900 C

1.

18O

uptake at the surface!

2. Growth at the interface

3.

16O

4.

16O

800 C

loss at the surface

movement at the

interface!

21

Gusev, Lu, Gustafsson, Garfunkel, PRB 52, 1759 (1995)

Schematic model for ultra-thin films

Surface

exchange

SiO2

Transition zone,

Growth

SiOx

Si (crystalline)

Deal and Grove

Lecture 12

22

11

Physics 9826b

12.3 Diffusion in metal oxide thin films

Atomic oxygen (O) in metal oxide films

Oxygen (O2) transport in SiO2

O-exchange

in surface

layer

No O-exchange

in bulk of oxide

SiO2 growth +

O-exchange

at interface

O2 decomp.

at surface

O-diffusion and

exchange in bulk

of oxide

Si-substrate

O2

O2

MOx growth,

O-exchange

at interface

Substrate

MOx

SiO2 films:

amorphous after annealing

molecular O2 transport in SiO2

decomposition by SiO desorption

(Many) transition metal and lantinide films:

tend to crystallize at low T

high oxygen mobility

23

Plan-view HRTEM and HAADF-STEM

3042513A-12, HAADF-STEM

ZrO2 /Si(001)

As deposited

5 nm

5 n m

3042513A-12, HAADF-STEM

HRTEM shows no discrete crystallization, though

some regions do show lower-ordering structure

HAADF-STEM shows density variations

suggestive of either roughening or partial phaseseparation

2 nm

Lecture 12

24

12

Physics 9826b

Elementary steps during metal oxidation

25

Microscopic oxidation pathways

J. Appl. Phys. 85 (1999) 7646

Lecture 17

Lecture 12

26

13

Physics 9826b

Oxygen diffusion in ultrafine grained monoclinic ZrO2

Objective: find the difference in diffusivities of O in

crystalline ZrO2 and grain-boundary region

- prepare samples with different grain-to-grain

boundary ratio,

- analyze by SIMS

J. Appl. Phys. 85 (1999) 7646

18O

27

profiles in crystalline ZrO2

Dv= 2.5x10-7m2/s;

Db= 3.3x10-5m2/s;

28

Lecture 12

14

Physics 9826b

Comparison of 18O diffusion in metal oxides

J. Appl. Phys. 85 (1999) 7646

Lecture 17

29

12.4 Corrosion

Corrosion is the deterioration of a material resulting from chemical reaction with

its environment

- temperature, pressure

- concentration of the reactions and products

- mechanical stress and erosion

Can be regarded as reverse extractive metallurgy

Metallurgy,

reduction

Metal oxide (silicate, carbonate)

Lower energy state

Metal

Corrosion,

oxidation

Higher energy state

Spontaneous process

Metals: electrochemical process

Nonmetals: direct chemical reaction (with salts, water, organic solvents,

oxygen plus UV)

30

Lecture 12

15

Physics 9826b

Oxidation Reduction Reactions of Metals

Zn + 2HCl ZnCl2 + H2

Simplified ionic form:

Zn0 + 2H+ Zn2+ + H2

Two half reactions:

Zn0 Zn2+ + 2e- (oxidation half reaction)

2H+ + 2e- H2 (reduction half reaction)

1. Oxidation reaction: metals form ions that go into aqueous solution, also

called the anodic reaction; electrons are produced and remain in the metal

2. Reduction reaction: metals or nonmetals consume electrons and they are

reduced into zero-charge state, also called the cathodic reaction

Both oxidation and reduction reactions must occur at the same time

31

Standard Electrode Half-Cell Potential for Metals

Every metal has a different tendency to corrode in a particular environment

Standard Electrode Half-Cell Potential for metals gives a universal way to

compare the tendency for metals to form ions

if the potential is negative, metal oxidizes to ions

If the potential is positive, less tendency to corrode

measured against

standard hydrogen electrode

Assign 0V to the reaction:

2H+ + 2e- H2

32

Lecture 12

16

Physics 9826b

Standard electrode potentials at 250

33

Galvanic cells

Galvanic couple (cell): is constructed with two dissimilar metal electrodes

each immersed in a solution of their own ions, and separated by a porous

wall (membrane) to prevent their mechanical mixing and an external wire to

connect the two electrodes

Zn Zn2+ + 2e- Eo = -0.763 V

Cu Cu2+ + 2e-

Eo = +0.337 V

Overall reaction:

Zn + Cu2+ Zn2+ + Cu

Ecello = - 1.100 V

Recall: Nernst equation connects half-cell reaction

potentials with the metal ion concentrations

E E

0 . 0592

n

where

log C ion ,

C ion is molar

concentrat

ion of ions

34

Lecture 12

17

Physics 9826b

Galvanic Cells with NO metal ions present

Consider a galvanic cell in which Fe and Cu electrodes are immersed in an

aqueous acidic electrolyte (no metals ions present)

Fe Fe2+ + 2e-

Eo = -0.440 V

Cu Cu2+ + 2e-

Eo = +0.337 V

Fe has the more negative half-cell potential, will

oxidize

Fe Fe2+ + 2e-

(anodic half reaction)

If acidic:

2H+ + 2e- H2

(cathodic half reaction)

If neutral or basic solution:

O2 + 2H2O + 4e- 4 OH-

35

Common cathode reactions for aqueous galvanic cells

36

Lecture 12

18

Physics 9826b

Microscopic Galvanic Cell Corrosion

Electrochemical reactions for (a) Zn in dilute hydrochloric acid; (b) Fe immersed in

oxygenated neutral water solution (rusting of iron)

2Fe + 2H2O + O2 2 Fe2+ + 4OH- 2 Fe(OH)2

2 Fe(OH)2 + H2O + O2 2 Fe(OH)3 (rust)

37

Galvanic Cells created by differences in Composition,

Structure, and Stress

1. Grain grain-boundary galvanic cell (grain boundaries are typically

more chemically active (anodic) than the grain matrix)

2. Multiple-phase galvanic cells (e.g. Fe and Fe 3C in gray cast iron)

3. Impurity cells (higher corrosion resistance for purer metals)

Types of corrosion

Uniform chemical attack corrosion (whole surface area is affected)

Galvanic or two-metal pair corrosion

Pitting and perforation

Intergranular

Stress and Erosion

Cavitation

Selective leaching or dealloying

38

Lecture 12

19

Physics 9826b

Corrosion Rate (Kinetics)

So far we discussed equilibrium conditions and thermodynamic tendencies

of metals to corrode

Corroding systems are not at equilibrium

Kinetics - Faradays equation (electrochemistry)

w

ItM

nF

where

iAtM

w is weight

I curretn

flow,

n number

i curretn

nF

of corroded

A; M atomic

of electrons

density,

or electropla

A/cm

produced

2

ted metal

mass of the metal,

or consumed,

; A area of electrode,

in time

t;

g/mol;

F 96500C/mol

cm

How to measure corrosion rate:

- a weight loss per unit area;

- change in thickness of material per unit time;

- as a current density

39

Acceleration of Corrosion

Physical Characteristics

exposed area (less, increases corrosion rate)

time of exposure (more time, more corrosion)

Environmental Characteristics

acidic environment

sulfur gas environment

temperature (high temps, more corrosion)

moisture (oxygenated moisture)

40

Lecture 12

20

Physics 9826b

Passivation

A protective film in oxidizing atmospheres

chromium,nickel, titanium, aluminum

Metal oxide layer adheres to parent metal

barrier against further damage

self-healing if scratched

Sensitive to environmental conditions

passivated metal may have high corrosion rates

41

Corrosion Prevention

Coatings

Barrier films

Inhibitive pigments

Sacrificial treatments

Paint

Active cathodic protection

42

Lecture 12

21

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Extraction of Natural Dyes From Chick-Pea Husk and Optimization of Dyeing Parameters With Box-Behnken DiagramDocument26 pagesExtraction of Natural Dyes From Chick-Pea Husk and Optimization of Dyeing Parameters With Box-Behnken DiagramBhoolata PalNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Casting Material CF3 & CF8Document3 pagesCasting Material CF3 & CF8Arunprasad MurugesanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Abetong Tank c14 TryckDocument2 pagesAbetong Tank c14 TryckingemekanicalNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Chemistry Paper 1Document14 pagesChemistry Paper 1Ngai Ivan CHANNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Plenty Duplex Filter: 1" - 4"size.: Design PressureDocument2 pagesPlenty Duplex Filter: 1" - 4"size.: Design PressureAnkush VarshneyNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Research Topics: Awetehagn Tuaum, Stanley Muse Shitote, and Walter Odhiambo OyawaDocument2 pagesResearch Topics: Awetehagn Tuaum, Stanley Muse Shitote, and Walter Odhiambo OyawaMICHAEL MWONGANo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

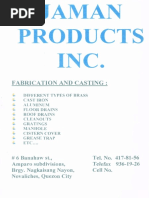

- Jaman Products Incorporated PDFDocument37 pagesJaman Products Incorporated PDFEppNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Oxidation of Azo DyesDocument245 pagesThe Oxidation of Azo Dyesglen dunnNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Cargo Tank Cleaning Guide EnglDocument1 pageCargo Tank Cleaning Guide EnglSat Partner100% (3)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Continuous Casting: Continuous Casting, Also Called Strand Casting, Is The Process WherebyDocument8 pagesContinuous Casting: Continuous Casting, Also Called Strand Casting, Is The Process Wherebysurendra ratreNo ratings yet

- Not Alloyed: Case-Hardening Steels C16EDocument1 pageNot Alloyed: Case-Hardening Steels C16Esafat parNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Photovoltaic CablesDocument12 pagesPhotovoltaic CablesAMARENDRA SINo ratings yet

- Shehata2000 PDFDocument10 pagesShehata2000 PDFMoe GyiNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 2014 Gibbbs - Book - Review - Ceramic - Petrography - The - Inte PDFDocument2 pages2014 Gibbbs - Book - Review - Ceramic - Petrography - The - Inte PDFBokaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Design of Free Standing Walls Feb 1984Document40 pagesDesign of Free Standing Walls Feb 1984Dale Stewart100% (4)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 4011 - Hit Re 500-SD PDFDocument1 page4011 - Hit Re 500-SD PDFBaterdene BaachkaNo ratings yet

- Activity 3 Metal and CorrosionDocument6 pagesActivity 3 Metal and CorrosionPUNDAVELA ANGELICANo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 3m 6000 Series Reusable Full Face Mask Respirator Technical DatasheetDocument5 pages3m 6000 Series Reusable Full Face Mask Respirator Technical DatasheetOviedo RocíoNo ratings yet

- Exam Style Questions 2 PDFDocument2 pagesExam Style Questions 2 PDFFernando AguasNo ratings yet

- Hvac SpecsDocument19 pagesHvac SpecsahmadNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Description of Damage: 4.3.2 Atmospheric Corrosion 4.3.2.1Document2 pagesDescription of Damage: 4.3.2 Atmospheric Corrosion 4.3.2.1Ajmi HmidaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Row Schott Technical Glasses View 2020-04-14Document80 pagesRow Schott Technical Glasses View 2020-04-14Oleg ChernovNo ratings yet

- 7 Dry Sand MoldingDocument3 pages7 Dry Sand MoldingFahri RamadhanNo ratings yet

- Class Never Goes Out of Style: List PriceDocument6 pagesClass Never Goes Out of Style: List Pricekarthikmr85No ratings yet

- ME123L FlatbackDocument14 pagesME123L FlatbackJosephNo ratings yet

- Concept Knitting LTD.: Masco Group Benmorle AM-300 Trail ReportDocument2 pagesConcept Knitting LTD.: Masco Group Benmorle AM-300 Trail ReportNahianNo ratings yet

- Trade ProjectDocument13 pagesTrade Projectjohn mwangi100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- CVNG 2006 Cement 2022 RevisedDocument127 pagesCVNG 2006 Cement 2022 RevisedshayndellNo ratings yet

- Atmospheric Transport and Deposition of Microplastics in A Subtropical Urban EnvironmentDocument8 pagesAtmospheric Transport and Deposition of Microplastics in A Subtropical Urban EnvironmentJhomara PalominoNo ratings yet

- Ctg. O-RingsDocument38 pagesCtg. O-RingsFelipe RamirezNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)