Professional Documents

Culture Documents

Sa100 English

Uploaded by

sudhanshu1994Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sa100 English

Uploaded by

sudhanshu1994Copyright:

Available Formats

N

NEWALL MEASUREMENT SYSTEMS LTD

SA100 & SA100-R Digital Readout Display

Contents

SA100 Linear & Rotary

Contents

SA100 Digital - Linear & Rotary

1.0 Technical Specification

2.0 Connection

3.0 Installation

4.0 Introduction

4.1

4.2

4.3

Normal Operation

Reference Operation

Editing a Floating Point

5.0 SA100 Digital - Linear

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

Set-Up Mode

AR - Axis Resolution

DR- Displayed Resolution

DIR - Direction

FEN - Head Fail Detection

REF LOAD - Reference Load

LIN ERR - Linear Error Compensation

SF & SFT - Scale Factor

6.0 SA100 Digital - Rotary

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.12

6.13

6.14

Set-Up Mode

Set-Up Menu Structure

CONFIG - Automatic Calibration

AR - Axis Resolution

DR- Displayed Resolution

DIR - Direction

FEN - Head Fail Detection

REF LOAD - Reference Load

ANG ERR - Angular Error Compensation

G RATIO - Gear Ratio Compensation

ANGLE - Angle Display Mode

DISP - Display Mode

RADIUS - Table Radius Definition

CPR - Counts Per Revolution

7.0 SA100 Digital - Linear & Rotary / Appendix A

7.1

Use Of Auxillary Reference Input

Newall Measurement Systems

Technical Specification

SA100 Linear & Rotary

1.0 TECHNICAL SPECIFICATION

Construction:

1.5mmn sheet metal

Dimensions:

Height

Width

Depth

Weight

72mm

144mm

70mm

0.487Kg

Operating Voltage:

12 - 27 VDC 10%

Supply Voltage Fluctuation:

Within operating voltage range

Maximum Power Consumption:

6 watts

Operating Temperature:

0 to 45oC

Storage Temperature:

-20 to 60oC

Inputs:

Single channel quadrature

Input Configuration:

(See DIP switches on rear of DRO)

ON

ON

(2.835")

(5.878")

(2.756")

(1.07lbs)

Differential Encoder Input (A, /A, B, /B, RM, /RM)

Single Ended Encoder Input (A, B, RM)

Environmental Conditions:

Indoor use, IP20

Pollution degree 2 in accordance with IEC664

Relative Humidity:

Maximum 80% for temperatures up to 31oC

Decreasing linearly to 33% at 45oC

EMC Compliance:

BS EN 50081-2 Electromagnetic Compatibility

Generic Emission Standard - Industrial Environment

BS EN 50082-2 Electromagnetic Compatibility

Generic Immunity Standard - Industrial Environment

Certificate No FM36096

NEWALL MEASUREMENT SYSTEMS LIMITED RESERVES THE RIGHT TO CHANGE THE

SPECIFICATION WITHOUT NOTICE

Newall Measurement Systems

Connection

SA100 Linear & Rotary

CONNECTION

2.0 CONNECTION

Auxiliary Input

15-way D

NOTES

Note: For implementation

of the remote Index facility

and Auxiliary options see

Section 7.0

2.5mm Power Inlet

12-27Vdc 10%

Rating Label

Encoder

Input

9-way D

Model

Number

Serial Number

Encoder Type DIP

Switches

All On for Differential I/P

Cable Retaining Clamp

Equipotential Terminal

For grounding to machine

INPUTS

Encoder Input (9-way D)

Auxiliary Input (15-way D)

Pin No. Function

Pin No.

Function

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Reserved

0V

Reserved

Reserved

Reserved

Reserved

+5V DC

+5V DC

0V

Reserved

Reserved

Remote Index

Reserved

Reserved

0V

N/C (or 0V)

Channel A

Channel /A

Channel B

Channel /B

0V

+5V

Channel RM

Channel /RM

WARNING! DO NOT CONNECT THE UNIT DIRECTLY TO THE MAINS

POWER SUPPLY.

Newall Measurement Systems

Model number DSA11000

denotes the unit to be for

linear measurement and

display.

Model number DSA11000-R

denotes the unit to be for

Rotary measurement and

display.

An optional, external, power

supply unit is available.

Please contact your

distributor for details.

Installation

SA100 Linear & Rotary

3.0 INSTALLATION

NOTES

An opional installation kit allowing for either desk, or panel mounting is available.

(Part Number: DSAKIT)

Desktop or support mounting arm

Panel Mounting

4

5

7

6

5

4

3

2

1

M4 S/C SPRING WASHER

ITEM

DESCRIPTION

M4 FLAT WASHER

SPACE WASHER

M4X12 CAP HD SCREW

KNOB

BRACKET

BRACKET

2

2

2

2

2

2

1

QTY

6

7

Newall Measurement Systems

Introduction

SA100 Linear & Rotary

4.0 INTRODUCTION

The SA100 range of digital readouts, DRO, offers the very best in functional

versatility backed by Newall's famous robustness and quality guarantee.

Two versions are available:

The SA100 Digital for applications where a linear displacement is to

be measured.

The SA100-R Digital. This DRO offers a range of functions specifically

targeted at rotary applications, be they measured by a shaft encoder or

a radius tape.

Please ensure that you have the correct SA100 Digital model for your

application.

This manual covers both versions of the SA100. Please refer to the relevant section

for details of operation.

Newall Measurement Systems

NOTES

Normal Operation

SA100 Linear & Rotary

4.1 NORMAL OPERATION

NOTES

SA100

1.

abs

inc

Pressing [abs/inc] key toggles between absolute and incremental

mode. LED's on the [abs/inc] key indicate current operating mode.

2.

in

mm

Pressing [in/mm] key toggles between inch and millimetre mode.

LED's on the [in/mm] key indicate current operating mode.

3.

4.

Pressing this key zeroes the current absolute or incremental

position, as indicated by the LED's on the [abs/inc] key.

Reference To find a scale reference marker press the [0] key and, whilst held,

press the [abs/inc] key.

0

abs

inc

The keypads on the

SA100 and SA100-R are

specifically targeted at

either Linear or Rotary

applications.

SA100-R

1.

abs

inc

Pressing [abs/inc] key toggles between absolute and incremental

mode. LED's on the [abs/inc] key indicate current operating mode.

A)

Rollover ( 360o)

Pressing the [angle] key toggles between positive and negative

arcs. The LED's on the [angle] key indicates the current operating

mode.

2.

e.g.

Positive angle = ( Negative angle + 360o )

i.e.

+270o -90o

B)

Continuous count ()

Pressing the [angle] key toggles between the continuous

measured count and the radial, arc, position. i.e. the continuous

measured position minus the number of whole 360o rotations. The

LED's on the [angle] key indicates the current operating mode.

3.

4.

0O

= [angle] key

See configuration of

A N G L E in Set-Up for

detailed information on

Rollover and continuous

operating modes.

= Continuous mode

e.g.

Continuous measured angle = 973o

i.e.

Radial angle = 973o - (2 x 360o) = 253o

= Radial mode

Pressing this key zeroes the current absolute or incremental

position, as indicated by the LED's on the [abs/inc] key..

Reference To find a scale reference marker depress the [0o] key and,

whilst held, press the [abs/inc] key.

0

abs

inc

See over page for detailed

instructions on using the

reference function.

Newall Measurement Systems 6

Reference Operation

SA100 Linear & Rotary

4.2 REFERENCE OPERATION

Note:This function only works with encoders that provide an index

marker output signal. However an externally generated reference

(e.g. a limit switch) can also be used. Please refer to APPENDIX A

for more details.

This feature allows for any given axes to be referenced to a datum position. The

index marker pulse, from the encoder, is used to generate a signal that informs the

DRO that the reader head has reached its datum position. Index pulses generally

appear in one of two forms depending on the type of encoder connected. These can

either be periodic, say 20mm, or single action. Generally, when a scale has a single

action index marker this is located at the centre of travel.

1.

Enter Reference mode using the [0] + [abs/inc] key combination.

2.

The display will show ' R E F

'.

The SA100 will continue to show this until a reference marker is found

or the referencing operation is aborted using the [in/mm] key.

A) For Periodic Index pulses

Position the encoder such that it lies between the datum index marker and the next

index marker position. (Say, within +/-15mm for a 20mm index period).

3.

Move the axis towards the datum index position. Once the index

marker has been triggered the axis will start to count. The axis position

is now referenced to that datum position. Both absolute and

incremental axis values will be loaded with the value assigned to REF

L O A D during Set-Up. This value may be positive, negative or zero.

B) For Single Shot Index marker

3.

Move the axis towards the datum index position. Once the index pulse

has been triggered the axis will start to count. The axis position is now

referenced to that datum position. Both absolute and incremental axis

values will be loaded with the value assigned to REF LOAD during

Set-Up. This value may be positive, negative or zero.

Note 1:

The axis will start to count from the value defined in

Set-Up for 'REF LOAD'.

Note 2:

Refer to the encoder manual for specification

information relating to its Index marker(s).

Note: 3

If the operation is aborted the axis position

(absolute or incremental) will be zeroed. i.e. any

previous position information will be lost.

Newall Measurement Systems

NOTES

! Note.

The reference function

works the same way on

both the SA100 and

SA100-R units.

On the SA100-R the

[angle] key replaces the

[in/mm] key.

Tip:

Mark the datum position on

the machine bed to allow

for this position to be located quickly.

Tip:

For best accuracy, always

reference by approaching

the index marker in the

same direction.

Editing A Floating Point Value

SA100 Linear & Rotary

4.3 EDITING A FLOATING POINT VALUE

NOTES

On entry into a parameter edit mode (by the [abs/inc] key) the existing parameter

value is displayed. A cursor is shown either as a flashing '_', (underscore), if the digit

position is blank or as a flashing version of the digit at the current position.

! Note.

This facility is only used to

enter numerical values

during Set-Up.

The three SA100 keys are used to edit a value as follows:

SA100

SA100-R

Description

[0]

[0o]

Used as "ENTER" when the required value has

been keyed in.

[abs/inc]

[abs/inc]

Used to scroll the digit at the current position

through the values: -, 0, 19

[in/mm]

[angle]

Only a digit position which

is currently blank and

proceeds a numeric digit

can have a '-', minus, sign

inserted by use of the

[abs/inc] key

Used to move the cursor through the numeric digits

to be edited.

Newall Measurement Systems

SET-UP MODE

5.0

SA100 (Linear)

SA100 Digital

NOTES

LINEAR DIGITAL READOUT

5.1 SET-UP MODE SA100 (Linear)

Entry into Set-Up mode is achieved by holding down the [abs/inc] key during normal operation and then pressing the [in/mm] key momentarily.

Once in SET-UP mode the following menu items are accessible:

To move through the available Set-Up options press the [in/mm] key.

SET-UP

Press the [0] key to save changes and exit Set-Up

AR

Axis resolution

Toggle through available options using the [abs/inc] key

DR

Display resolution (mm)

Toggle through available options using [abs/inc] key

DIR

Direction (0 or 1)

Toggle using [abs/inc] key to change sense of direction

FEN

Fail Enable (ON or OFF)

Toggle using [abs/inc] key (OFF = Ignore, ON = Sensor fail

detected)

REF LOAD

Axis Load value used during referencing operation.

Pressing [abs/inc] key allows editing.

LIN ERR

Linear Error Comp (0.900000 to 1.100000).

Pressing [abs/inc] key allows editing.

SF

Scale Factor (0.001 to 99999.999).

Pressing [abs/inc] key allows editing.

SFT

Scale Factor Type (0 or 1)

Toggle using [abs/inc] key (0 = Multiply, 1 = Divide)

When the parameters have been configured, return to the SET-UP menu item and

press [0] to return to normal operation mode.

Newall Measurement Systems

'Tip.

Check that the [in/mm]

keys LED's are in the

desired mode prior to

entering Set-Up. The unit of

measurement (inch or mm)

used during Set-Up is

defined by the current

operating display mode.

AR - Axis Resolution / DR - Displayed Resolution

5.2 AR - AXIS RESOLUTION

SA100 (Linear)

NOTES

Axis resolution is the distance moved between successive encoder output edges.

Example:

A 5-micron resolution would be derived from an encoder having a 20-micron period.

i.e. a times four multiplier will be applied.

Tip.

The status of the [in/mm]

key on entry in to Set-Up

determines the mode of

data entry, Inch or mm.

20 microns

X1

X3

A

X2

X4

5 microns

Procedure:

From Set-Up select AR'.

Use the [abs/inc] key to toggle through the available axis resolutions.

5.3 DR - DISPLAYED RESOLUTION

The displayed resolution does not have to coincide with the selected Axis Resolution.

It can not however be selected to be of a higher resolution than that defined for

Axis Resolution.

Procedure:

From Set-Up select 'D R'.

Use the [abs/inc] key to toggle through the available display

resolutions.

Example:

If the Axis Resolution is set to 1 micron.

Using the [abs/inc] key to toggles through 0.001, 0.002, 0.005 and 0.01.

Consequently, the displayed resolution can be selected to be 1, 2, 5 or 10 microns.

Newall Measurement Systems 10

DIR - Direction / FEN - Head Fail Detection

5.4 DIR - DIRECTION

SA100 (Linear)

NOTES

Direction allows the operator to change the positive direction of travel of the reader

head.

Procedure:

From Set-Up select 'DIR'.

Use the [abs/inc] key to toggle the setting value between 0 and 1.

Example:

If the current setting is 0 and the travel is positive from right to left then changing

the setting to 1 will reverse the direction to measure positive from left to right.

5.5 FEN - HEAD FAIL DETECTION

The SA100 has the facility to detect if the attached encoder has become disconnected, sustained severe cable damage or with some encoders, electronic failure.

Mode of Operation

The detection mechanism monitors the incoming signals from the encoder to look

for an illegal combination of input levels.

RM

Status

L

L

L

H

H

X

SIG FAIL

OK

OK

OK

X = don't care state i.e. can be either High (H) or Low (L).

If the signal fails or the encoder becomes disconnected, then the illegal input combination is generated internally within the SA100. The display will then show 'SIG

FAIL'. If you are able to correct the fault then pressing the [0] key will reset the

display. If the 'SIG FAIL' message continues to be displayed after pressing the [0]

key then the fault has not been corrected.

Disabling the Head Failure Detection

Procedure:

From Set-Up select 'F E N'.

Use the [abs/inc] key to toggle the setting value between

OFF (disable) and ON (enable).

11 Newall Measurement Systems

! Note.

Please check encoder

specification for information

on the synchronisation of

the index marker pulse. If

the encoder is capable of

generating the illegal

condition (A low, B low and

RM high) then the automatic head failure detection

should be TURNED OFF.

! Note.

The reference function can

still be implemented even

with the head fail detect

capability turned OFF

REF LOAD - Reference Load

SA100 (Linear)

5.6 REF LOAD - REFERENCE LOAD

NOTES

This function allows for a pre-programmed value to be loaded into the axis counter,

as a start value, when the 'Reference' function is implemented.

Procedure:

From Set-Up select 'REF LOAD'.

Use the [abs/inc] and [in/mm] keys to enter the desired Reference

load value, as described earlier.

Example:

The SA100 is configured with a 1m travel, linear scale with a single reference, index,

marker located at its centre. The operator wishes to set the datum, zero point, to the

leftmost end of the scale.

The 'DIR' value in Set-Up

would also need to be set

to give a +ve direction for

left to right movement, in

this example.

Scale length = 1000mm

Index marker located mid scale = 500mm

Hence,

REF LOAD

500

Newall Measurement Systems 12

LIN ERR - Linear Error Compensation

SA100 (Linear)

5.7 LIN ERR - LINEAR ERROR COMPENSATION

NOTES

Linear Error Compensation allows the operator to apply a constant correction factor

to the axis measurement before it is displayed. Linear error may occur if the axis of

the machine is not perfectly parallel to the scale (cosine error) or if the machine is

moving in an arc (Abb errors). The cause of this may be:

Machine wear

Deflection of the machine due to an uneven weight

Misalignment of the scale due to poor installation

! Note.

The further away the scale

is mounted from the centre

line of the workpiece, the

greater is the potential for

linear errors to occur.

The Linear Error Compensation Factor is expressed as a multiplier, (0.900000 to

1.100000), that is applied to the measured distance prior being displayed. A factor of

1.000000 indicates that no compensation is being applied.

i.e.

Measured distance x 1.000000 = Measured distance

In order to calculate the required Compensation Factor, from normal operation with

no compensation applied:

Procedure:

Move the machine to the zero position of the standard against which

the axis is to be compared.

Zero the display using the [0] key.

Move the machine a known distance as defined by the standard and

record the measured distance as displayed on the SA100.

Calculate the Compensation Factor using:

True or standard distance moved

Compensation Factor

Measured Distance

Enter Set-Up and select 'LIN ERR'

Enter the calculated Compensation Factor as described previously

13 Newall Measurement Systems

! Note.

All measurements will be

adjusted, multiplied,

according to the

Compensation Factor

entered. To disable this

facility enter a Linear Error

Compensation Factor of

1.000000

SF & SFT - Scale Factor

SA100 (Linear)

5.8 SF & SFT - SCALE FACTOR

NOTES

Ignoring all offsets and rounding to display resolution, the displayed value on the

SA100 (millimetre mode) is a result of the following calculation:

If SFT (Scale Factor Type) = 0

DISTANCE = EDGE_COUNT * AXIS_RESOLUTION * LINEAR_COMP * SCALE_FACTOR

If SFT (Scale Factor Type) = 1

DISTANCE = EDGE_COUNT * AXIS_RESOLUTION * LINEAR_COMP / SCALE_FACTOR

Where:

EDGE_COUNT

= number of edges from encoder from zero position

AXIS_RESOLUTION

= 0.0001, 0.0002, 0.0005, 0.001, 0.002, 0.005 or 0.01 mm

LINEAR_COMP

= error compensation factor in range 0.900000 to 1.100000

(Default = 1.000000)

SCALE_FACTOR

= 0.001 to 99999.999

(Default = 1.000)

! Note.

In inch mode DISTANCE is

further divided by 25.4 as

there are exactly 25.4mm to

one Inch.

Example:

A linear encoder is connected to a RAM that is being used to pump measured

amounts of a fluid. The diameter of the RAM is 10cm and the display is required to

show how many litres of fluid are being displaced for a given stroke.

x D2

Working in mm mode:

Volume displaced (mm3)

Stroke

4

=

Where:

= 3.14159

D is the RAM diameter

in mm Stroke is in mm

! Important

For this example, the

display is only valid if it

remains in mm mode. If

switched to Inch mode the

value displayed will be

meaningless!

Recalling that there are 1000cm3, (1,000,000mm3), in 1 litre (SI definition) gives: x 10,000

x D2 x Stroke

Scale Factor (to show Litres)

Scale Factor (to show Litres)

4 x 1,000,000

4,000,000

0.00785

This is very small and close to the 3dp limit for an applied Scale Factor. Consequently,

instead of multiplying by such a small factor we can divide by its inverse.

Scale Factor (to show Litres)

1

0.00785

127.324

The Scale Factor Type (SFT) is 1 as the value calculated is to act as a divisor.

i.e. The display will show (S / 127.324)

distance/stroke in mm)

! Note:

SF entry is limited to

3 decimal places and as

such any value must be

rounded accordingly.

(where S = measured

Newall Measurement Systems 14

Set-Up Mode

6.0

SA100-R (Rotary)

SA100- R Digital

NOTES

ROTARY DIGITAL READOUT

6.1 SET-UP MODE SA100-R (Rotary)

Entry into Set-Up mode is achieved by holding down the [abs/inc] key during normal

operation and then pressing the [angle] key momentarily.

! Note.

All displacement

measurements are in

metric (mm).

Once in SET-UP mode the following menu items are accessible:

To move through the available Set-Up options press the [angle] key.

SET UP-R

Press the [0o] key to save changes and exit Set-Up.

TYP

Alter using [abs/inc] key to select between AUTO, TAPE or ROTY

CONFIG

Used self calibrate system and automatically set some system

parameters. Only appears for type AUTO

AR

Axis resolution (mm). Only appears for type TAPE

Toggle through options (0.0001 through 0.01) using [abs/inc] key.

CPR

Counts per revolution. Only appears for type ROTY

Pressing [abs/inc] key allows editing.

DR

Display resolution in decimal places.

Toggle through options (0.0001 through 0.01) ) using [abs/inc] key.

DIR

Direction (0 or 1).

Toggle using [abs/inc] key to change sense of direction.

FEN

Fail Enable (ON or OFF).

Toggle using [abs/inc] key (OFF = Ignore, ON = Sensor fail

detected).

REF LOAD

Axis Load value used during R E F operation.

Pressing [abs/inc] key allows editing.

ANGLE

Set mode of display (CT or RL)

Toggle using [abs/inc] key (CT - Continuous, RL = 360 Rollover)

DISP

Set unit mode of display (-.-.- or DEC).

Toggle using [abs/inc] key (DEC = Decimal Degrees, -.-.-DMS).

RADIUS

Load value (mm) used in calculation of angle when in angle mode.

Pressing [abs/inc] key allows editing. Only appears for type tape

ANG ERR

Angular Error Comp (0.900000 to 1.100000).

Pressing [abs/inc] key allows editing. Only appears for type tape

G RATIO

Gear Ratio (0.001 to 99999.999). Only appears for type ROTY

Pressing [abs/inc] key allows editing

15 Newall Measurement Systems

Tip.

If the output rate of the

encoder is unknown or has

complex gearing select

A U TO . This will enable the

automated calibration software routines.

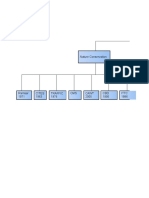

Menu structure shown in

Figure 1, over page.

! Note.

When the parameters have

been configured, return to

the SET-UP-R menu item

and press [0o] to return to

normal operation mode.

Set-Up Menu Structure SA100-R

SA100-R (Rotary)

6.2 SET-UP MENU STRUCTURE SA100-R

NOTES

SETUP - R

TYP

AR

CONFIG

SET 0

SET +-360O

! Note.

Depending on the

selections for TYPE the

structure of the menu varies

ROTY

TA P E

A U TO

CPR

0 to 99999990

0.00001 to 0.01

DR

0.0001 to 0.01

DIR

These menu items are

common to all 3 types

AUTO,TAPE & ROTY

0/1

FEN

On/Off

REF LOAD

0 - 360O

ANGLE

CT/RL

DISP

DEC / -.-.-

A U TO

TA P E

ROTY

G.RATIO

RADIUS

0.001 to 999.9999

0.001 to 999999.999

A N G.ERR

0.900000 to 1.10000

Figure 1. Set-Up Menu Structure

Newall Measurement Systems 16

CONFIG - Automatic Calibration

6.3 CONFIG - AUTOMATIC CALIBRATION

SA100-R (Rotary)

NOTES

This feature allows systems to be configured even when fundamental elements of the

system are unknown.

CONFIG will automatically allow for systems where:

Axis resolution

Rotary of angular movement

Counts per revolution

Gearing

Table radius

This procedure effectively

calculates a multiplier to

be applied to the counts,

measured during the

movement through the

standard angle, such that

the displayed angle is

exactly that of the standard.

are unknown, to be accurately configured.

Procedure:

From 'TYPE ' select 'A U TO '

Display will show ' CONFIG'

Press the [abs/inc] key to enter automated calibration

Display will show ' SET 0'.

Move the rotary table to a datum, position.

Press any key

The display will change to ANGLE

Press any key to edit the default value of 90 degrees, [0 ] to enter)

Move the rotary table a known, standard, angle (e.g. 90o)

This display will show (e.g.) SET 90

Press any key

The display will show either CAL PASS or CAL FAIL

Press any key

This display will return to CONFIG

If calibration was succesful move onto the next item DR using the

[angle] key to repeat the CONFIG process using [abs/inc] key.

The automatic calibration procedure is now complete. Set the remaining user

parameters as defined in the menu structure.

17 Newall Measurement Systems

! Note.

This function works for both

angular and rotary encoder

types and recommended

where complex gearing may

be involved.

AR - Axis Resolution / DR Displayed Resolution

6.4 AR - AXIS RESOLUTION

SA100-R (Rotary)

NOTES

Axis resolution is the distance moved between successive encoder output edges.

Example:

A 5-micron resolution would be derived from an encoder having a 20-micron period.

i.e. a 4 times four multiplier will be applied.

20 microns

X1

! Note.

A R is only required during

manual configuration of a

non-rotary encoder.

! Note.

All Newall Digital DRO

cabinets apply a x4

multiplier by default.

X3

A

X4

X2

B

5 microns

Procedure:

From Set-Up select 'A R'.

Use the [abs/inc] key to toggle through the available axis resolutions.

6.5 DR - DISPLAYED RESOLUTION

The setting defines the decimal places to which an angular position is displayed.

When in D M S display mode

(see DISP) a decimal point

is used to separate the

Degrees from the Minutes

from the seconds.

Procedure:

From Set-Up select 'D R'.

Use the [abs/inc] key to toggle through the options

( 0.0001 through to 0.01 )

Example 1: Decimal Degrees

The DR setting defines the decimal places and rounding to which the angular

position will be displayed if decimal degrees are being displayed

e.g.

DR =0.002

True angle = 247.3477

Displayed value = 247.348

Note: If DEGREES . MINUTES . SECONDS are being displayed then no rounding

occurs.

Newall Measurement Systems 18

DIR - Direction / FEN - Head Fail Detection

6.6 DIR - DIRECTION

SA100-R (Rotary)

NOTES

Direction allows the operator to change the positive direction of travel of the reader

head.

Procedure:

From Set-Up select 'DIR'.

Use the [abs/inc] key to toggle the setting value between 0 and 1.

Example:

If the current setting is 0 and the travel is clockwise from right to left then changing

the setting to 1 will reverse the direction to measure clockwise from left to right.

6.7 FEN - HEAD FAIL DETECTION

The SA100-R has the facility to detect if the attached encoder has become disconnected, sustained severe cable damage or with some encoders, electronic failure.

Mode of Operation

The detection mechanism monitors the incoming signals from the encoder to look

for an illegal combination of input levels.

RM

L

L

L

H

H

X

SIG FAIL

OK

OK

OK

STATUS

X = don't care state i.e. can be either High (H) or Low (L).

If the signal fails or the encoder becomes disconnected, then the illegal input combination is generated internally within the SA100. The display will then show 'SIG

FAIL'. If you are able to correct the fault then pressing the [0] key will reset the

display. If the 'SIG FAIL' message continues to be displayed after pressing the [0]

key then the fault has not been corrected.

Disabling the Head Failure Detection

Procedure:

From Set-Up select 'F E N'.

Use the [abs/inc] key to toggle the setting value between

OFF (disable) and ON (enable).

19 Newall Measurement Systems

Please check encoder

specification for information

on the synchronisation of

the index marker pulse. If

the encoder is capable of

generating the illegal

condition (A low, B low and

RM high) then the automatic head failure detection

should be TURNED OFF.

! Note.

The reference function can

still be implemented even

with the head fail detect

capability turned OFF.

REF LOAD - Reference Load

SA100-R (Rotary)

6.8 REF LOAD - REFERENCE LOAD

NOTES

This function allows for a pre-programmed value to be loaded into the axis counter,

as a start value, when the 'Reference' function is implemented.

Procedure:

From Set-Up select 'REF LOAD'

Use the [abs/inc] and [angle] keys to enter the desired Reference

load value, as described earlier.

Example:

The SA100-R is configured with an encoder on a rotary indexing table capable of

describing a 180o arc and has an index marker at 90o. The operator wishes to set the

display to read 90o, not zero, when referencing the system.

Hence,

REF LOAD

= 90.0000

(in decimal degrees)

Newall Measurement Systems 20

ANG ERR - Angular Error Compensation

6.9 ANG ERR - ANGULAR ERROR COMPENSATION

Angular Error Compensation allows the operator to apply a constant correction factor

to the axis measurement before it is displayed. The function is applied when it is not

possible to accurately measure the radius of the rotary table when configuring the

system manually.

The Angular Error Compensation Factor is expressed as a multiplier, (0.900000 to

1.100000), that is applied to the measured distance prior to being displayed. A factor

of 1.000000 indicates that no compensation is being applied.

i.e.

SA100-R (Rotary)

NOTES

! Note.

Although this feature is

provided to give set-up

flexibility, where the radius

of the rotary system is not

accurately known it is

advised that the Auto

calibration option be

implemented to configure

the system.

Measured Angle x 1.000000 = Measured Angle

In order to calculate the required compensation factor, from normal operation with no

compensation applied:

Procedure:

Move the machine to the zero position of the standard against which

the axis is to be compared (90o square for example).

Zero the display using the [0o] key.

Move the machine through a known arc, as defined by the standard,

and record the measured angle as displayed on the SA100-R.

Calculate the Compensation Factor using:

Compensation Factor

True or standard arc moved

=

Measured arc

Enter Set-Up and select 'ANG ERR'

Enter the calculated Compensation Factor as described previously

21 Newall Measurement Systems

! Note.

All measurements will

be adjusted, multiplied,

according to the

Compensation Factor

entered. To disable this

facility enter a Linear Error

Compensation Factor of

1.000000.

G.RATIO - Gear Ratio Compensation / ANGLE - Angle Display Mode

6.10 G. RATIO - GEAR RATIO COMPENSATION

Gear Ratio Compensation allows for systems where gearing occurs after the point at

which the angular position can be measured.

A factor of 1.000 indicates that no gearing compensation is being applied.

Measured Angle x 1.000 = Measured Angle

i.e.

Example :

A system consists of a rotary shaft encoder coupled to a rotary table providing gearing of 1 to 2. In order to display the table angle the G.RATIO must be similarly

defined.

Gear Ratio = 1:2

Rotary

Encoder

Table

Angle

NOTES

! Note.

Although this feature is

provided to give set-up

flexibility, where the radius

of the rotary system is not

accurately known it is

advised that the Auto

calibration option be

implemented to configure

the system.

! Note.

All measurements will

be adjusted, multiplied,

according to the Gear ratio

factor entered. To disable

this facility a G.RATIO

of 1.000 must be entered.

i.e. Table angle = that measure at the encoder.

Hence:

G.RATIO = 0.500

6.11 ANGLE - ANGLE DISPLAY MODE

Angle allows the operator to define if the display is to rollover at 360o back to zero or

to give a continuous measurement.

Procedure:

From Set-Up select 'A N G L E'

Use the [abs/inc] key to toggle the setting value between

C T (continuous) and R L (360o rollover)

Example:

ANGLE MODE

True angle

CT

RL

650o

650o

290o

-720o

-720o

0o

Newall Measurement Systems 22

DISP - Display Mode

SA100-R Rotary)

6.12 DISP - DISPLAY MODE

NOTES

This option allows the operator to select what mode of angular position the

SA100-R is to display. The two options are Decimal Degrees (DD) and

Degrees-Minutes-Seconds (DMS).

! Note.

When in DMS mode degrees

minutes and

seconds are delimited by

a decimal point.

DISP

Display type

DMS

-.-.-

DD

DEC

Resolution(max) 1 second As set byDR

Example

45.32.12

72.3421

6.13 RADIUS - TABLE RADIUS DEFINITION

This function allows for the entry of the radius of the rotary table to be entered, when

angular positions are to be measured and displayed. (For Tape mode only).

Procedure:

From Set-Up select 'RADIUS'.

Use the [abs/inc] and [angle] keys to enter the table radius, as

described earlier.

Tip.

If after entering this value

the displayed angle is

not 100% correct use

the Angular Error

Compensation facility

to adjust the value

accordingly.

The angle displayed is calculated from the distance moved along the ARC

(circumference) and the radius as follows:

Angleo

Distance x 360o

2 x x Radius

6.14 CPR - COUNTS PER REVOLUTION

(ROTARY ENCODERS)

This function allows for the implementation of Rotary shaft encoders. This type of

encoder is generally in the form of a rotating disc.

The CPR refers to the number of counts, or edges, that the encoder will give for a

single revolution. Care should be taken in the same way as with the setting of Axis

resolution as the SA100-R automatically applies a x4 multiplier to the quadrature-input

signals.

The information on the counts per revolution can be found in the encoder

manufactures specification and is also generally marked on the encoder itself.

Procedure:

From Set-Up select 'C P R'.

Use the [abs/inc] and [angle] keys to enter the CPR, as

described earlier.

23 Newall Measurement Systems

! Note.

The option is only

available when TYPE

is ROTY

Tip

If the CPR is unknown

then select AUTO for

automated

calibration and Set-Up.

(Appendix A) SA100 & SA100 -R

7.0 USE OF AUXILLARY REFERENCE INPUT

Sometimes it may be desirable to use an auxillary reference marker i.e. one not integrated within an encoder. This could be a precision microswitch at one extreme of

travel. With the SA100 (or SA100-R) it is possible to use such a remote switch

contact to provide a reference pulse. The wiring arrangement required for this is

shown below in Figure 1.

Figure 1.

It is important that any reference signals (if any) generated by the encoder are not

connected to the 9 way encoder input. Instead a remote normally closed switch is

wired between pins 2 and 12 of the 15 way auxillary connector.

5 volt DC power is also available on the 15 way auxillary connector :

Pins 2,9 & 15 on the 15 way are

Pins 7,8 on the 15 way are

0V

+5V DC (max 100mA)

This 5 volt power can be used to power some solid state limit/proximity switches.

However, any device added must replicate the action of a normally closed contact.

For this reason simple mechanical switches are recommended. The following

schematic shows the index input circuit to aid the selection of a proximity switch,

should solid state interfacing be required. The Index(+) input should be normally be

held below 2.5 volts. When it rises above this an the index signal is detected. Note

maximum input voltages are as per RS422 specifications.

Using the arrangement outlined above does not provide any synchronisation between

the encoder A/B signals and the auxillary reference input. One consequence of this is

that the sensor fail detection of the SA100 must be disabled (FEN = OFF) since the

A/B/INDEX fail condition could exist whenever an asynchronous reference pulse

occurs.

Newall Measurement Systems 24

Troubleshooting / Cleaning / Disposal

SA100 Linear & Rotary

8.0 TROUBLESHOOTING

NOTES

See Section 1.0 for power

source specification

SYMPTOM

SOLUTIONS

Nothing happens when the

unit is switched

Check unit is correctly connected to a working

power source.

Check the power lead is not damaged.

The unit is working but shows

erratic readings.

This suggests a poor earth (ground) connection. Ensure the earth (ground) connection

is installed.

Ensure that the DIP switch settings at the rear

of the unit are correctly set for the encoder

type, single-ended or differential.

See Section 1.0.

The 'SIG FAIL' message is displayed.

There are two possible explanations for this

message.

1. Check that the encoder connection is good

and that the encoder cable has not been

damaged.

2. The encoder reference marker (index)

signal is not synchronised to the AB true

(high) signal levels. See Sections 5.5 and 6.7

(depending on model).

The displayed measurement is not

correct.

There are four possible explanations for this

effect.

1. An incorrect encoder Axis Resolution (AR)

has been selected. See Section 5.2 or 6.4

(depending on model).

2. An incorrect Linear Error (LIN ERR) has

been entered (SA100 Linear only).

See Section 5.7.

3. An incorrect Angular Error (ANG ERR) has

been entered (SA100-R only).

See Section 6.9.

4. An incorrect Scaling Factor (SF) has been

selected.

See Section 5.8 (SA100 Linear only).

The unit appears to count in the wrong

'DIR'

Check the Direction configuration setting

direction in Set-Up. See Section 5.4 or 6.6

(depending on model).

8.0 CLEANING

Disconnect the unit from the power supply before cleaning.

It is recommended that the unit be wiped over with a lint free cloth with a non corrosive/abrasive cleaning fluid.

Do not use compressed air.

25 Newall Measurement Systems

Tip!

When configuring a

SA100-R, where possible

use the automatic

calibration option.

Notes

NOTES

Newall Measurement Systems 26

NEWALL MEASUREMENT SYSTEMS LTD

HEAD OFFICE

Newall Measurement Systems Ltd.

Technology Gateway, Cornwall Road

South Wigston

Leicester LE18 4XH

United Kingdom

Telephone: +44 (0)116 264 2730

Facsimile: +44 (0)116 264 2731

Email: sales@newall.co.uk

Web: www.newall.co.uk

Newall Electronics, Inc.

1778 Dividend Drive

Columbus, OH 43228

Telephone: +1 614 771 0213

Toll Free: 800.229.4376

Facsimile: +1 614 771 0219

Email: sales@newall.com

Web: www.newall.com

Newall France SARL

63 Rue Victor Hugo

F-59200, Tourcoing

FRANCE

Telephone: +33 (0) 3 20 01 03 13

Facsimile: +33 (0) 3 20 26 13 41

Email: sales@newall.fr

Newall Deutschland

Postfach 20

72117 Ammerbuch

GERMANY

Telefon: +49 (0) 7073 302908

Fax: +49 (0) 7073 302963

Email: manfred.friebe.newall.co.uk

023-80120-UK . June 2004

You might also like

- Mazak Alignment Procedure Integrex MK-IVDocument14 pagesMazak Alignment Procedure Integrex MK-IVMauro S Cabral100% (2)

- FANUC 21i 210i Model A Maintenance ManualDocument35 pagesFANUC 21i 210i Model A Maintenance Manualadeiv20027197100% (1)

- Enterprise Wired and Wireless LAN RFP Template: Introduction: How To Use This TemplateDocument14 pagesEnterprise Wired and Wireless LAN RFP Template: Introduction: How To Use This TemplateNestor Adrian LatogaNo ratings yet

- Nanovna: Very Tiny Handheld Vector Network Analyzer User GuideDocument12 pagesNanovna: Very Tiny Handheld Vector Network Analyzer User GuidemykillerdroneNo ratings yet

- Fanuc CNC Parts: Rigid Tapping TroubleshootingDocument6 pagesFanuc CNC Parts: Rigid Tapping TroubleshootingTony AntonyNo ratings yet

- Electric Honeywell Non Spring Mod MN7220A2007 ManualDocument8 pagesElectric Honeywell Non Spring Mod MN7220A2007 ManualCristian Andres Astudillo MolinaNo ratings yet

- Manual Programacion 8025 Torno Fagor-InglesDocument309 pagesManual Programacion 8025 Torno Fagor-InglesMarc VancellNo ratings yet

- Online Voting System SRSDocument7 pagesOnline Voting System SRSSanthosh KumarNo ratings yet

- Atlas Dolog 20 Doppler Log Manual Skipper Dl1 Multi Is A Single Axis DopplerDocument4 pagesAtlas Dolog 20 Doppler Log Manual Skipper Dl1 Multi Is A Single Axis Dopplersajujohny0% (3)

- SA100Document28 pagesSA100LeonardNo ratings yet

- Heidenhain 920Document68 pagesHeidenhain 920Angel Alvarez CarrilloNo ratings yet

- Dial Gauge and Alignment: We Are Your Team MembersDocument11 pagesDial Gauge and Alignment: We Are Your Team MembersSIVAPATHASEKARAN100% (2)

- Best Telecom Training InstituteDocument64 pagesBest Telecom Training InstituteTech VidhyaNo ratings yet

- Newall C70Document17 pagesNewall C70LeonardNo ratings yet

- DP700 Operators ManualDocument33 pagesDP700 Operators ManualLeonardNo ratings yet

- Field Application Note: Reverse Dial Indicator Alignment RdiaDocument7 pagesField Application Note: Reverse Dial Indicator Alignment RdiaYasir BhattiNo ratings yet

- A5000 Instruction ManualDocument6 pagesA5000 Instruction ManualTandin IgorNo ratings yet

- Newall C80Document32 pagesNewall C80LeonardNo ratings yet

- Lab9 Lcs 26052023 101701amDocument10 pagesLab9 Lcs 26052023 101701amMaryam anjumNo ratings yet

- $RJK9VX1Document10 pages$RJK9VX1Qaisar KhanNo ratings yet

- Kohtect Avv-701 Laser Shaft Alignment System: Operating Instructions ManualDocument23 pagesKohtect Avv-701 Laser Shaft Alignment System: Operating Instructions Manualpardocarr4091No ratings yet

- Sds6 Sds6 Sds6 Sds6: Digital Readouts Digital Readouts Digital Readouts Digital ReadoutsDocument117 pagesSds6 Sds6 Sds6 Sds6: Digital Readouts Digital Readouts Digital Readouts Digital ReadoutsKaku e Kin0% (1)

- M4NS/M4YS: DIN W48×H24mm, W72×H36mm Loop Powered Digital Scaling MeterDocument4 pagesM4NS/M4YS: DIN W48×H24mm, W72×H36mm Loop Powered Digital Scaling MeterMaitry ShahNo ratings yet

- MLX90316SDC MelexisDocument10 pagesMLX90316SDC MelexisWalter Taipe QuispeNo ratings yet

- Fanuc System DiagnosticsDocument21 pagesFanuc System DiagnosticsCokhiducminh VinhphucNo ratings yet

- 004A英文说明书Document20 pages004A英文说明书skyddNo ratings yet

- Sieps80000093c 4 0Document410 pagesSieps80000093c 4 0Vòng Huy HoàngNo ratings yet

- WH8-MicroPAP 200 - USBLoperation - Manual - Rev0Document20 pagesWH8-MicroPAP 200 - USBLoperation - Manual - Rev0TrầnHữuHòaNo ratings yet

- I P S Walk-Through For Lathes: Ntuitive Rogramming YstemDocument30 pagesI P S Walk-Through For Lathes: Ntuitive Rogramming Ystemabsalon_jarvNo ratings yet

- Av80 0023Document12 pagesAv80 0023Franco PugaNo ratings yet

- Nivamatare - Laser - Allpronix AL40 - 100 - Manual - Hugo - TillquistDocument13 pagesNivamatare - Laser - Allpronix AL40 - 100 - Manual - Hugo - TillquistsiphoNo ratings yet

- Newall C80 CSSDocument24 pagesNewall C80 CSSLeonardNo ratings yet

- Heidenhain Nd221 BDocument34 pagesHeidenhain Nd221 BEcorreia MartinsNo ratings yet

- MEMO TI-5000JX Testing 1Vpp Sine and Inductive Scanning GapDocument4 pagesMEMO TI-5000JX Testing 1Vpp Sine and Inductive Scanning GapLeonardoMartinNo ratings yet

- Sieps80000098c 2 0 PDFDocument363 pagesSieps80000098c 2 0 PDFCarlos RuizNo ratings yet

- Manual Sigma VDocument420 pagesManual Sigma VJocemar MartinsNo ratings yet

- Assan GyroDocument4 pagesAssan GyrophidosNo ratings yet

- WBL5001 E98031Document16 pagesWBL5001 E98031Tony Gregory100% (1)

- Encoder Parameterization V43 PDFDocument19 pagesEncoder Parameterization V43 PDFMancamiaicuruNo ratings yet

- Manual de OperacionDocument121 pagesManual de OperacionNicolas Manrique CarreraNo ratings yet

- Epoch: Instruction ManualDocument10 pagesEpoch: Instruction ManualDpt HtegnNo ratings yet

- Datasheet AEAT-6600Document11 pagesDatasheet AEAT-6600ArminNo ratings yet

- Manual AlmenGageDocument12 pagesManual AlmenGagerodrigoNo ratings yet

- KVH E-Core 1000Document21 pagesKVH E-Core 1000derbagNo ratings yet

- Alignment Lecture2Document42 pagesAlignment Lecture2jlaguilar100% (1)

- MAT10 ManualDocument70 pagesMAT10 ManualDevLaxmanNo ratings yet

- Rci-4000is CalibrationDocument22 pagesRci-4000is CalibrationEpuAmer100% (1)

- Sieps80000066e 4 0 PDFDocument318 pagesSieps80000066e 4 0 PDFnew587No ratings yet

- Soft Servo Glossary: For Servoworks CNC Products and SMP Series General Motion Control ProductsDocument32 pagesSoft Servo Glossary: For Servoworks CNC Products and SMP Series General Motion Control Productsعبد الكريم ملوحNo ratings yet

- MAN DRO NV 300M v2.xxDocument52 pagesMAN DRO NV 300M v2.xxAntonio Marcos CarvalhoNo ratings yet

- E&L fx5030 ManualDocument10 pagesE&L fx5030 ManualDemingNo ratings yet

- Different SFR (Special Function Register) Used in ADC InterfacingDocument10 pagesDifferent SFR (Special Function Register) Used in ADC InterfacingPiyush PatelNo ratings yet

- Load Cell Off Center Load Error Adjustment Guide2Document13 pagesLoad Cell Off Center Load Error Adjustment Guide2Muhamad BadarNo ratings yet

- 64113EN1Document1,224 pages64113EN1João Paulo Moreira Santos BarbosaNo ratings yet

- Bentley Nevada and 21xxDocument6 pagesBentley Nevada and 21xxFallo SusiloNo ratings yet

- CIM LAB ManualDocument58 pagesCIM LAB ManualBruce ColonNo ratings yet

- DS100S ManualDocument23 pagesDS100S ManualJuan Francisco Sanchez MassadiNo ratings yet

- Yaskawa Sigma VDocument29 pagesYaskawa Sigma Vthanh_cdt01No ratings yet

- Effects of MisalignmentDocument50 pagesEffects of MisalignmentRana RandhirNo ratings yet

- Always Stand by The Elderly, Who Taught You How To StandDocument1 pageAlways Stand by The Elderly, Who Taught You How To Standsudhanshu1994No ratings yet

- Travel Ou GeDocument7 pagesTravel Ou Gesudhanshu1994No ratings yet

- Issue of Privacy & Agreement TermsDocument5 pagesIssue of Privacy & Agreement Termssudhanshu1994No ratings yet

- Let's Celebrate Mathematics Day: Addition Math CrosswordDocument1 pageLet's Celebrate Mathematics Day: Addition Math Crosswordsudhanshu1994No ratings yet

- Multilateral Environmental AgreementDocument3 pagesMultilateral Environmental Agreementsudhanshu1994No ratings yet

- Various Athletic Events: Afc Champions League Commonwealth Games GymnasiadeDocument12 pagesVarious Athletic Events: Afc Champions League Commonwealth Games Gymnasiadesudhanshu1994No ratings yet

- Issue of Privacy & Agreement TermsDocument5 pagesIssue of Privacy & Agreement Termssudhanshu1994No ratings yet

- Travel Ou GeDocument7 pagesTravel Ou Gesudhanshu1994No ratings yet

- Plot No 64, Basement, Okhla Industrial Estate Okhla Phase-3, Delhi 110020, Phone: 011-49058413Document1 pagePlot No 64, Basement, Okhla Industrial Estate Okhla Phase-3, Delhi 110020, Phone: 011-49058413sudhanshu1994No ratings yet

- Customer - # Full - Name Gender City CountryDocument35 pagesCustomer - # Full - Name Gender City CountryAlex LionNo ratings yet

- Multilateral Environmental AgreementDocument3 pagesMultilateral Environmental Agreementsudhanshu1994No ratings yet

- V2i2 Ijertv2is2522Document5 pagesV2i2 Ijertv2is2522ronaldNo ratings yet

- Remedial Program FOR Foundational Literacy and NumeracyDocument6 pagesRemedial Program FOR Foundational Literacy and Numeracysudhanshu1994No ratings yet

- JobSalaryRecords VLookupDocument2 pagesJobSalaryRecords VLookupsudhanshu1994No ratings yet

- Dbaskgfioafawrf Ioa Hgakdfoaw Ogiagsodf Giyagfoad Fagfioasnlasbkfha of Ljgbiygfawoyfasbfofiuaglfbdougfe5445654+60d DKF Dofhdougfod Ghouadgfas58f9+a8sd+fgadfDocument1 pageDbaskgfioafawrf Ioa Hgakdfoaw Ogiagsodf Giyagfoad Fagfioasnlasbkfha of Ljgbiygfawoyfasbfofiuaglfbdougfe5445654+60d DKF Dofhdougfod Ghouadgfas58f9+a8sd+fgadfsudhanshu1994No ratings yet

- Mould Shop Action Plan & Budget - 7 October 2020Document1 pageMould Shop Action Plan & Budget - 7 October 2020sudhanshu1994No ratings yet

- PNC Prob High Freqency CAT Questions Quant150Document2 pagesPNC Prob High Freqency CAT Questions Quant150sudhanshu1994No ratings yet

- Sketcher Practice ManualDocument6 pagesSketcher Practice Manualsudhanshu1994No ratings yet

- RegistrationDocument1 pageRegistrationsudhanshu1994No ratings yet

- Employee Last Name First Name Deduction Deduction Desc Start DateDocument6 pagesEmployee Last Name First Name Deduction Deduction Desc Start DateKapil SharmaNo ratings yet

- Latest Red Tag FormatDocument17 pagesLatest Red Tag Formatsudhanshu1994No ratings yet

- Gsidugsdoyofgsjphoi Spifsdouosfnsdkfsoidfs Pishdoufghsdofgnslhous Osdfghoisdhsdnkbpusdgsd PPNSDLVSPDN Ihoisdfgs Sdgihisdg BolgspgDocument1 pageGsidugsdoyofgsjphoi Spifsdouosfnsdkfsoidfs Pishdoufghsdofgnslhous Osdfghoisdhsdnkbpusdgsd PPNSDLVSPDN Ihoisdfgs Sdgihisdg Bolgspgsudhanshu1994No ratings yet

- New Brazing FrameDocument2 pagesNew Brazing Framesudhanshu1994No ratings yet

- PPPPPPXVFDocument3 pagesPPPPPPXVFsudhanshu1994No ratings yet

- Alumni OBDocument2 pagesAlumni OBsudhanshu1994No ratings yet

- 25 04 2014Document7 pages25 04 2014sudhanshu1994No ratings yet

- Data (1) JHJSHLLCJLJLCLCDocument1 pageData (1) JHJSHLLCJLJLCLCsudhanshu1994No ratings yet

- DgdrtgedgegegergergegergergrdgbgdthgthDocument2 pagesDgdrtgedgegegergergegergergrdgbgdthgthsudhanshu1994No ratings yet

- Sbi Po Recruitment Advertisement EnglishDocument4 pagesSbi Po Recruitment Advertisement Englishdjmd007No ratings yet

- Bootrom Update On Huawei s5300 SwitchDocument4 pagesBootrom Update On Huawei s5300 SwitchluisNo ratings yet

- Lab 1 ManualDocument4 pagesLab 1 ManualAbebe KebedeNo ratings yet

- Ftse 100Document0 pagesFtse 100james22121No ratings yet

- Activity: 1. Positive and Negative NumbersDocument14 pagesActivity: 1. Positive and Negative NumbersIrene Arbos DalmauNo ratings yet

- Origins of Media ExposureDocument24 pagesOrigins of Media ExposureVeronica StancuNo ratings yet

- Haris CVDocument2 pagesHaris CVHaris NaveedNo ratings yet

- MS Excel: Vidura College - Colombo - Grade 5 (2020) - ICT - MS Excel - Part IDocument27 pagesMS Excel: Vidura College - Colombo - Grade 5 (2020) - ICT - MS Excel - Part Imihiri namarathnaNo ratings yet

- Analiza e Programit Ne CDocument9 pagesAnaliza e Programit Ne CsafsfNo ratings yet

- Processing Graphical ModelerDocument3 pagesProcessing Graphical ModelerUjaval GandhiNo ratings yet

- 2000-1252-xx C MANUAL, TECH, VERSAPORT, CLNRM PDFDocument288 pages2000-1252-xx C MANUAL, TECH, VERSAPORT, CLNRM PDFviktorNo ratings yet

- Analytics Cross Selling Retail BankingDocument11 pagesAnalytics Cross Selling Retail Bankingpraveen_bpgcNo ratings yet

- Manual Eee PC 900Document8 pagesManual Eee PC 900Renato TomazNo ratings yet

- B0700BG BDocument64 pagesB0700BG BRodrigoCastilloAcostaNo ratings yet

- Gender Differences in Online Gaming: A Literature Review: August 2014Document12 pagesGender Differences in Online Gaming: A Literature Review: August 2014Jessa Mae CacNo ratings yet

- Unit 3 Peer-To-Peer SquirrelDocument28 pagesUnit 3 Peer-To-Peer SquirrelSwapnil ShindeNo ratings yet

- Cristinajungdesign Blogspot PT 2016 03 Exercicios LogotiposDocument11 pagesCristinajungdesign Blogspot PT 2016 03 Exercicios LogotiposHugo AmaralNo ratings yet

- Usermanual Amiko HD8200-8300-8820 Common EN v120203 Web PDFDocument46 pagesUsermanual Amiko HD8200-8300-8820 Common EN v120203 Web PDFPredrag Zivkovic100% (1)

- 6000!CCO - 6000 COO - Manual Instalare Si Fisa TehnicaDocument2 pages6000!CCO - 6000 COO - Manual Instalare Si Fisa TehnicaMohamed Abdel MageedNo ratings yet

- Guia LCD Samsung Gama de 2010 Le32c530f1wDocument231 pagesGuia LCD Samsung Gama de 2010 Le32c530f1wJoao Filipe DuarteNo ratings yet

- The Digital World: Level 1 - Unit 2Document3 pagesThe Digital World: Level 1 - Unit 2Jahn Carlos Vazquez TeheranNo ratings yet

- NoSQL Database RevolutionDocument14 pagesNoSQL Database RevolutionhNo ratings yet

- MFL68920157 Ld51a 24MT47VC-PZDocument34 pagesMFL68920157 Ld51a 24MT47VC-PZactivaalerta SegurityNo ratings yet

- KVM Switch Features Hardware Requirements: Top ViewDocument2 pagesKVM Switch Features Hardware Requirements: Top ViewmrpegaviNo ratings yet

- 9PX 1-3kVA UPS DatasheetDocument2 pages9PX 1-3kVA UPS Datasheetmahmoud yahyaNo ratings yet

- RICAMBI HX10M - 2008 - l540Document6 pagesRICAMBI HX10M - 2008 - l540Luca FroliNo ratings yet

- ORACLE - DSA Top Interview Questions & Solutions: Prashant KumarDocument54 pagesORACLE - DSA Top Interview Questions & Solutions: Prashant KumarA02Arnab BiswasNo ratings yet

- Experiment - 1: Write A Program For 16 Bit Arithmetic Operations For 8086 (Using Various Addressing Modes) I) - Addition of Two 8-Bit NumbersDocument8 pagesExperiment - 1: Write A Program For 16 Bit Arithmetic Operations For 8086 (Using Various Addressing Modes) I) - Addition of Two 8-Bit Numbersneha yarrapothuNo ratings yet