Professional Documents

Culture Documents

Loader & Unloader Valve

Uploaded by

Satyajeet SahuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Loader & Unloader Valve

Uploaded by

Satyajeet SahuCopyright:

Available Formats

TECHNICAL CONCEPT OF LOADER AND

UNLOADER VALVE.

So 1st question in mind is what is it?

Firstly let me clear that loader and unloader valve is very

different in reciprocating type than screw type. May be the same

functions but working principle is different from it.

And loader valve is also termed as intake valve and or an inlet

valve. It functions is to regulate the air intake to the air

compressor part. i.e to regulate the supply of air sucked up into

compressor part.

And it is one kind of pneumatic actuator valve which operates

with a feedback signal system and works on a principle of pilot

pressure which is the same pressure maintained by the MPV to

operate that valve.

It functions with two modes: Loading and unloading mode.

For unloading mode: when the desired pressure is reached, it

goes to unload mode and closes the supply of air intake to

compressor unit thus the compressor just rotates but do not

produces any compressed air further. In this way no more air to

be sucked in and get compressed.

But there still remains the air inside the compressor element.

This is then passed gently through Blow down valve (BDV).thus

get a sound like psccchhhhhhh.

Again a question rises in mind? If compressor element is

rotating so how does it gets the lubrication facility?

The answer is there is always a small hole called free hole of

1mm in unloader valve which never closes completely. This

maintains the minimum pressure to regulate the oil flow for the

lubrication of compressor element.

Selection of machine in terms of load:

The machine should be selected neck to neck capacity. But

practically if the selection done is more than the 90 percent of

loading capacity then its efficiency is good.

How to check this load and unload:

This is to be checked in load relay (Read parameter) in panel.

Let us understand this with an example:

If a machine is serviced with a new spare AOS installed, then in

read parameter note down the value =1000(assume); load relay

value

And in next changing time of AOS, the value is= 2000.(load relay

value).

So the difference is (2000-1000)/running hours.

Let say running hours is 250 hrs.

Then separator use is: (2000-1000)/250 = 1000/250 = 4.

Permissible:

1.

2.

Max unloads /load condition: 10nos/hrs.

But practically it is not possible for any industry to maintain

this limit.

Effect on AOS:

More the load and unload condition. More will be the hitting

effect to AOS since there is sudden flow released which impact

the AOS.and stress produced in it thus decreasing the AOS Life.

So we see baffle plate is used in Atlas copco to get rid from

direct hitting thus reduces the stress produced from impact.

But the effect is seen on Elgi/IR machine.

You might also like

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Air Compressor Inlet Valve (Or Intake Valve - Unloader Valve)Document6 pagesAir Compressor Inlet Valve (Or Intake Valve - Unloader Valve)anup_nairNo ratings yet

- CMCDocument9 pagesCMCChuma KhanNo ratings yet

- Minimum Pressure Valve MPVL65FH and MPVL65FHSDocument2 pagesMinimum Pressure Valve MPVL65FH and MPVL65FHSСергей КолесниковNo ratings yet

- User's Manual: AD/DA Conversion UnitDocument194 pagesUser's Manual: AD/DA Conversion Unitmgkso706No ratings yet

- Samson PRV Mounting and Operating InstructionDocument20 pagesSamson PRV Mounting and Operating InstructionRick CalaguiNo ratings yet

- SA英文使用手册NEWDocument49 pagesSA英文使用手册NEWBernad Orlando0% (1)

- Operating and Maintenance Instructions PDFDocument13 pagesOperating and Maintenance Instructions PDFshihabNo ratings yet

- Fuel Oil Meter ManualDocument89 pagesFuel Oil Meter ManualbouguerraNo ratings yet

- Bom Chan KhongDocument78 pagesBom Chan KhongKhổng C. PhongNo ratings yet

- SLAD-MXf ManualDocument10 pagesSLAD-MXf ManualReiky Aji ShaputraNo ratings yet

- 40 BAR OIL-FREE PET COMPRESSORSDocument8 pages40 BAR OIL-FREE PET COMPRESSORSСергей Колесников100% (1)

- Camcs L PlantairDocument20 pagesCamcs L PlantairSergio MoncadaNo ratings yet

- BD 330 Plus 3000 Plus Product Description EN Antwerp Ed01Document6 pagesBD 330 Plus 3000 Plus Product Description EN Antwerp Ed01влад камрNo ratings yet

- Pressurisation Systems for Dynamic Pressure MaintenanceDocument52 pagesPressurisation Systems for Dynamic Pressure MaintenanceLe Van Phong100% (1)

- Hertz Compressor Catalog enDocument57 pagesHertz Compressor Catalog enTaufan JustvandsNo ratings yet

- Pressure-Swing Desiccant Type Compressed Air Dryers: Instruction ManualDocument60 pagesPressure-Swing Desiccant Type Compressed Air Dryers: Instruction ManualToso Eko PurwantoNo ratings yet

- For Screw Compressor Minimum Pressure Valve Type MPVLDocument3 pagesFor Screw Compressor Minimum Pressure Valve Type MPVLhmltdt9221100% (1)

- 12 Air Starting of Diesel EnginesDocument26 pages12 Air Starting of Diesel EnginesCurtler PaquibotNo ratings yet

- Different Type Air DryerDocument9 pagesDifferent Type Air DryermishtinilNo ratings yet

- ABAC Formula 5.5 22kWDocument6 pagesABAC Formula 5.5 22kW1976gt500No ratings yet

- Brochure Secador NVCDocument7 pagesBrochure Secador NVCByron PanchiNo ratings yet

- Leonova Condmaster ManualDocument172 pagesLeonova Condmaster ManualThomas BembeNo ratings yet

- Commissioning Atlas Copco ZR900 VSD Air CompressorDocument9 pagesCommissioning Atlas Copco ZR900 VSD Air CompressorLeonardo SilvaNo ratings yet

- ARCA Evolution160 240 enDocument2 pagesARCA Evolution160 240 enadyturNo ratings yet

- GPS Heatless Regenerative Dryer ManualDocument20 pagesGPS Heatless Regenerative Dryer ManualfructoraNo ratings yet

- 2946 1186 00 Maintenance Procedure GA 11-30 (VSD)Document9 pages2946 1186 00 Maintenance Procedure GA 11-30 (VSD)Rui FortunaNo ratings yet

- Screw Compressor ManualDocument67 pagesScrew Compressor ManualHelmut SchaafNo ratings yet

- ZR-ZT55-90 VSD-FFDocument22 pagesZR-ZT55-90 VSD-FFrodrigodiazsilvaNo ratings yet

- User Manual: Screw Air Compressor Controller MAM-KY02SVF B - VF - Monitor-200Document23 pagesUser Manual: Screw Air Compressor Controller MAM-KY02SVF B - VF - Monitor-200Biplob MiaNo ratings yet

- High Efficiency Compressed Air Dryers: Adsorption Dryers Classical SystemDocument8 pagesHigh Efficiency Compressed Air Dryers: Adsorption Dryers Classical Systemneversig100% (1)

- IR Pegasus 15-37Document8 pagesIR Pegasus 15-37Didi IswantoNo ratings yet

- Fludex (Flender)Document50 pagesFludex (Flender)Waris La Joi Wakatobi100% (1)

- Manual FM160 CompressorDocument61 pagesManual FM160 CompressorSeekPTNo ratings yet

- Tri Sen Controle Surge Compressores TS160Document6 pagesTri Sen Controle Surge Compressores TS160Jimmy RumlusNo ratings yet

- DHRC Catalog - F164LR.Document28 pagesDHRC Catalog - F164LR.mdalt9180No ratings yet

- FD Dryers CatalogDocument13 pagesFD Dryers CatalogmasrooorNo ratings yet

- Operator Manual for Champion Screw CompressorDocument90 pagesOperator Manual for Champion Screw CompressorPrince NeroNo ratings yet

- Installation Operating Manual SewatecDocument82 pagesInstallation Operating Manual SewatecMouayed Zeadan100% (1)

- ARIEL Maint intervalSEK PDFDocument7 pagesARIEL Maint intervalSEK PDFMargaret Daugherty100% (1)

- Centrifugal CompressorDocument18 pagesCentrifugal CompressornisasoberiNo ratings yet

- Air Compressor ZR 160Document20 pagesAir Compressor ZR 160kattukoluNo ratings yet

- Field Performance Testing For Centrifugal CompressorsDocument7 pagesField Performance Testing For Centrifugal CompressorsRicardo BecNo ratings yet

- ELGI22Document9 pagesELGI22Ajans VictorNo ratings yet

- Spesifikasi Atlas Copco ZT 30Document5 pagesSpesifikasi Atlas Copco ZT 30Fithrul MubarokNo ratings yet

- CPVR60 Industrial Air CompressorsDocument17 pagesCPVR60 Industrial Air CompressorsIpenu Sujarwo100% (1)

- Schneider Air Compressor-Katalog 2011 enDocument291 pagesSchneider Air Compressor-Katalog 2011 envirgil guimanNo ratings yet

- Pump Wear RingsDocument1 pagePump Wear RingsLaxman Singh Sankhla100% (1)

- Operating manual for liquid ring vacuum pumps and compressorsDocument0 pagesOperating manual for liquid ring vacuum pumps and compressorsCorina PanfilNo ratings yet

- FE800 Bedienungsanleitung Standard 3297-80D1 1 ENGLDocument44 pagesFE800 Bedienungsanleitung Standard 3297-80D1 1 ENGLMantencion ProverdeNo ratings yet

- FM200 Filling System/ Equipment: Solution A: Filling Machine+ Vacuum Pump+ Weighing SystemDocument2 pagesFM200 Filling System/ Equipment: Solution A: Filling Machine+ Vacuum Pump+ Weighing Systemal boshia100% (1)

- Hibon Blower ManualDocument55 pagesHibon Blower ManualAulia RahmanNo ratings yet

- ALM Refrigeration Air DryerDocument34 pagesALM Refrigeration Air DryerJunaid AhmedNo ratings yet

- Hertz Piston Type Compressor ManuelDocument31 pagesHertz Piston Type Compressor Manueligor_sandulenkoNo ratings yet

- 360 CDE Atlas Copco Air Dryers ManualDocument38 pages360 CDE Atlas Copco Air Dryers Manualshamil130798100% (1)

- Mam 6090Document64 pagesMam 6090AmatorNikNo ratings yet

- Detroit Screw Compressor Manual A4 FINAL NocroDocument52 pagesDetroit Screw Compressor Manual A4 FINAL NocroDaniel Fernando Bernal PescaNo ratings yet

- Rotina de Inspeção em ManutençãoDocument11 pagesRotina de Inspeção em ManutençãoBrender VictorNo ratings yet

- Ingersoll Rand Oil Free CompressedAirTechnologyIAS 0701015 enDocument12 pagesIngersoll Rand Oil Free CompressedAirTechnologyIAS 0701015 envkees1987No ratings yet

- Petroleum Gas Compression Workbook 2 PDFDocument47 pagesPetroleum Gas Compression Workbook 2 PDFMahathir Che Ap100% (4)

- Air Filters for Mann Hummel EuropiclonDocument4 pagesAir Filters for Mann Hummel EuropiclonSatyajeet SahuNo ratings yet

- Air Filters for Mann Hummel EuropiclonDocument4 pagesAir Filters for Mann Hummel EuropiclonSatyajeet SahuNo ratings yet

- NTPC Air Filter QuoteDocument2 pagesNTPC Air Filter QuoteSatyajeet SahuNo ratings yet

- Investor Update Financial Performance Q1fy2018 19 PDFDocument35 pagesInvestor Update Financial Performance Q1fy2018 19 PDFSatyajeet SahuNo ratings yet

- Hydraulic Oil: Komatsu GenuineDocument4 pagesHydraulic Oil: Komatsu GenuineKattie ValerioNo ratings yet

- CSA (Print)Document4 pagesCSA (Print)Satyajeet SahuNo ratings yet

- Wind FiltersDocument4 pagesWind FiltersSatyajeet SahuNo ratings yet

- Tdtdo 50 MSDSDocument10 pagesTdtdo 50 MSDSSatyajeet SahuNo ratings yet

- Air Filters Support Long Compressor Life and Efficient OperationsDocument3 pagesAir Filters Support Long Compressor Life and Efficient OperationsSatyajeet SahuNo ratings yet

- Cat Elc (Extended Life Coolant) MdsDocument8 pagesCat Elc (Extended Life Coolant) Mdsharikrishnanpd3327No ratings yet

- KASA Consumable Pricelist February 2016 WebsiteDocument2 pagesKASA Consumable Pricelist February 2016 WebsiteSatyajeet SahuNo ratings yet

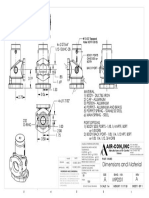

- Air-Con, Inc: Dimensions and MaterialDocument1 pageAir-Con, Inc: Dimensions and MaterialSatyajeet SahuNo ratings yet

- Ga 11Document39 pagesGa 11Satyajeet SahuNo ratings yet

- 2935 0724 30 - tcm30-1628027Document54 pages2935 0724 30 - tcm30-1628027Hossam Mohi EldinNo ratings yet

- KASA Consumable Pricelist February 2016 WebsiteDocument2 pagesKASA Consumable Pricelist February 2016 WebsiteSatyajeet SahuNo ratings yet

- KASA Consumable Pricelist February 2016 WebsiteDocument2 pagesKASA Consumable Pricelist February 2016 WebsiteSatyajeet SahuNo ratings yet

- MPV STEPDocument262 pagesMPV STEPSatyajeet SahuNo ratings yet

- Atlas Copco AftermarketDocument8 pagesAtlas Copco AftermarketSatyajeet SahuNo ratings yet

- Cross reference chart for MAKRA separator replacement partsDocument29 pagesCross reference chart for MAKRA separator replacement partsabvgdzolicNo ratings yet

- Atlas Copco AftermarketDocument8 pagesAtlas Copco AftermarketSatyajeet SahuNo ratings yet

- Elgi PG Series Diesel DrivenDocument8 pagesElgi PG Series Diesel DrivenSatyajeet Sahu100% (1)

- Activity No. 5 Capacitive Circuit ObjectivesDocument4 pagesActivity No. 5 Capacitive Circuit ObjectivesJohn Paul BaquiranNo ratings yet

- Measurement of SubstructureDocument24 pagesMeasurement of SubstructureAamaniVeeranam80% (10)

- Hospital Managemen T System: Oose LAB FileDocument62 pagesHospital Managemen T System: Oose LAB FileAASHNo ratings yet

- Research BulletsDocument18 pagesResearch BulletsVong Albios DogomeoNo ratings yet

- Nov. AbwDocument50 pagesNov. Abwjbyarkpawolo70No ratings yet

- Trenes de Engranajes - PresentaciónDocument17 pagesTrenes de Engranajes - PresentaciónPedro Jorge De los SantosNo ratings yet

- Composition, Thermal and Rheological Behaviour of Selected Greek HoneysDocument13 pagesComposition, Thermal and Rheological Behaviour of Selected Greek HoneyssyazaqilahNo ratings yet

- ISO 11957 1996 en PreviewDocument5 pagesISO 11957 1996 en PreviewHoang TraNo ratings yet

- Z 80 HelptopicsDocument5 pagesZ 80 HelptopicsEverly NNo ratings yet

- LAB REPORT-Rock Pore Volume and Porosity Measurement by Vacuum Saturation-GROUP - 5-PETE-2202Document13 pagesLAB REPORT-Rock Pore Volume and Porosity Measurement by Vacuum Saturation-GROUP - 5-PETE-2202Jeremy MacalaladNo ratings yet

- Alkali MetalsDocument12 pagesAlkali MetalsSaki Sultana LizaNo ratings yet

- Digital Image Processing TechniquesDocument34 pagesDigital Image Processing Techniquesaishuvc1822No ratings yet

- Selection: Open-Type Reciprocating Compressors: Input ValuesDocument1 pageSelection: Open-Type Reciprocating Compressors: Input ValuesYuli RahmawatiNo ratings yet

- Department of Computer Engineering Academic Year 2020-21 Class: SE Computer & IT Subject: 22226 PCI (Programming in C) MCQ Unit 1: Program Logic Development MCQ Question Bank With AnswersDocument8 pagesDepartment of Computer Engineering Academic Year 2020-21 Class: SE Computer & IT Subject: 22226 PCI (Programming in C) MCQ Unit 1: Program Logic Development MCQ Question Bank With AnswersVooovoNo ratings yet

- Ice o Matic - Cim0436faDocument2 pagesIce o Matic - Cim0436faJean RamosNo ratings yet

- Understanding Process ConditionsDocument41 pagesUnderstanding Process ConditionsIbrahim Al-HammadiNo ratings yet

- Writing Iap Smarten Up in Maths Age 7 8Document38 pagesWriting Iap Smarten Up in Maths Age 7 8lphoune100% (1)

- Matrix Inversion Note in Mathematics MagazineDocument2 pagesMatrix Inversion Note in Mathematics Magazinejuan carlos molano toroNo ratings yet

- Earth and Life Science Test ReviewDocument3 pagesEarth and Life Science Test Reviewmerlyn m romerov100% (1)

- Barrels & Actions by Harold HoffmanDocument238 pagesBarrels & Actions by Harold HoffmanNorm71% (7)

- Plasma CuttingDocument12 pagesPlasma Cuttingpavi32No ratings yet

- Ee242 Lect06 TwoportsDocument32 pagesEe242 Lect06 TwoportsZyad IskandarNo ratings yet

- Jm-10 Operation Manual Rev02 UnlockedDocument121 pagesJm-10 Operation Manual Rev02 UnlockedAlan Jimenez GonzalezNo ratings yet

- No.1 PrestressedDocument10 pagesNo.1 PrestressedKristin ArgosinoNo ratings yet

- MCB and ELCB PDFDocument35 pagesMCB and ELCB PDFChris AntoniouNo ratings yet

- Auditing The Usage of Therapeutic Footwear in Diabetic Foot Patients Through Amit Jain's Extended SCC' Classification For Therapeutic FootwearDocument6 pagesAuditing The Usage of Therapeutic Footwear in Diabetic Foot Patients Through Amit Jain's Extended SCC' Classification For Therapeutic FootwearJosé MorenoNo ratings yet

- Molecular Cell Biology Lodish 7th Edition Solutions ManualDocument8 pagesMolecular Cell Biology Lodish 7th Edition Solutions ManualmarisorbornewwssNo ratings yet

- Welding Machine CatalogueDocument12 pagesWelding Machine CatalogueRodney LanagNo ratings yet

- Ukur KadasterDocument21 pagesUkur KadasterMuhammad NajmiNo ratings yet

- (It Bus) Computer HistoryDocument6 pages(It Bus) Computer HistoryRica Elaine LubasanNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)