Professional Documents

Culture Documents

13.10 Last Year The Diamond Manufacturing Company Purchased Over $10 Million Worth of

Uploaded by

Jara TakuzawaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

13.10 Last Year The Diamond Manufacturing Company Purchased Over $10 Million Worth of

Uploaded by

Jara TakuzawaCopyright:

Available Formats

13.

10 Last year the Diamond Manufacturing Company purchased over $10 million worth of

office equipment under its special ordering system, with individual orders ranging from

$5,000 to $30,000. Special orders are for low-volume items that have been included in a

department managers budget. The budget, which limits the types and dollar amounts of

office equipment a department head can requisition, is approved at the beginning of the

year by the board of directors. The special ordering system functions as follows:

Purchasing A purchase requisition form is prepared and sent to the purchasing

department. Upon receiving a purchase requisition, one of the five purchasing agents

(buyers) verifies that the requester is indeed a department head. The buyer next selects

the appropriate supplier by searching the various catalogs on file. The buyer then phones

the supplier, requests a price quote, and places a verbal order. A prenumbered purchase

order is processed, with the original sent to the supplier and copies to the department

head, receiving, and accounts payable. One copy is also filed in the open-requisition file.

When the receiving department verbally informs the buyer that the item has been

received, the purchase order is transferred from the open to the filled file. Once a month,

the buyer reviews the unfilled file to follow up on open orders.

Receiving

The receiving department gets a copy of each purchase order. When

equipment is received, that copy of the purchase order is stamped with the date and, if

applicable, any differences between the quantity ordered and the quantity received are

noted in red ink. The receiving clerk then forwards the stamped purchase order and

equipment to the requisitioning department head and verbally notifies the purchasing

department that the goods were received.

Accounts Payable Upon receipt of a purchase order, the accounts payable clerk files it in

the open purchase order file. When a vendor invoice is received, it is matched with the

applicable purchase order, and a payable is created by debiting the requisitioning

departments equipment account. Unpaid invoices are filed by due date. On the due date,

a check is prepared and forwarded to the treasurer for signature. The invoice and

purchase order are then filed by purchase order number in the paid invoice file.

Treasurer

Checks received daily from the accounts payable department are sorted into

two groups: those over and those under $10,000. Checks for less than $10,000 are machine

signed. The cashier maintains the check signature machines key and signature plate and

monitors its use. Both the cashier and the treasurer sign all checks over $10,000.

a. Describe the weaknesses relating to purchases and payments of special orders by the

Diamond Manufacturing Company.

b. Recommend control procedures that must be added to overcome weaknesses identified

in part a.

c. Describe how the control procedures you recommended in part b should be modified if

Diamond reengineered its expenditure cycle activities to make maximum use of

current IT (e.g., EDI, EFT, bar-code scanning, and electronic forms in place of paper

documents).

(CPA Examination, adapted)

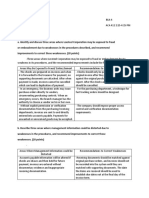

Weakness

1. Buyer does not verify that

the department heads request

is within budget.

2. No procedures established

to ensure the best price is

obtained.

Control

Compare requested amounts

to total budget and YTD

expenditures.

Solicit quotes/bids for large

orders.

Effect of new IT

System can automatically compare the

requested amount to the remaining

budget.

EDI and Internet can be used to solicit

bids.

3. Buyer does not check

vendors past performance.

4. Blind counts not made by

receiving.

5. Written notice of

equipment receipt not sent to

purchasing.

6. Written notice of

equipment receipt not sent to

accounts payable

7. Mathematical accuracy of

vendor invoice is not verified.

8. Invoice quantity not

compared to receiving report

quantity.

9. Notification of

acceptability of equipment

from requesting department

not obtained prior to

recording payable.

10. Voucher package not sent

to Treasurer.

11. Voucher package not

cancelled when invoice paid.

12. No mention of bank

reconciliation.

Prepare a vendor performance

report and use it when

selecting vendors.

Black out quantities ordered

on copy of Purchase Order

sent to receiving

Provide incentives if

discrepancies between

packing slip and actual

delivery are detected.

Send written notice of

equipment receipt to

purchasing.

Send written notice of

equipment receipt to accounts

payable

Verify mathematical accuracy

of vendor invoice.

Compare/verify invoiced

quantity with quantity

received.

Obtain confirmation from

requisitioner of the

acceptability of equipment

ordered prior to recording

payable.

Send voucher package

(purchase order and receiving

report) to Treasurer along

with approved invoice.

Treasurer should mark

voucher package as PAID

when check is signed.

Bank account should be

reconciled by someone other

than Accounts Payable or the

treasurer.

Vendor performance ratings can be

updated automatically and made

available to buyer.

Do not permit receiving clerks to access

quantities on purchase orders.

Request bar coding or RFID tagging of

all items and use readers to check in all

deliveries.

Still provide incentives to detect

discrepancies.

Receiving data and comments entered

via on-line terminals and routed to

purchasing.

Configure system to notify accounts

payable automatically of equipment

receipt.

Automatic verification of mathematical

accuracy of vendor invoice.

System verifies invoice quantity with

quantity received.

Configure system to require confirmation

of equipment acceptability prior to

approving invoice for payment.

Configure system to match invoices

automatically with supporting

documents.

Configure system to mark supporting

documents as used when invoice is paid.

Bank account should be reconciled by

someone other than Accounts Payable or

the treasurer.

10.8

(CMA Examination, adapted)

a. O'Brien Corporation: Internal control weaknesses and recommended improvements:

Weaknesses and Potential Problem(s)

Recommendation(s) to Correct Weaknesses

1. Orders received over the telephone are

not confirmed by customers in writing.

This could result in errors or in filling

bogus orders.

Require a written customer purchase order

as confirmation of telephone orders.

2. Customer credit histories are not

checked before approving orders. This is

resulting in excessive late collections and

uncollectible accounts.

Customers credit should be checked and

no sales should be made to those that do

not meet credit standards.

3. Sales orders are filed by date in the

Marketing Department. This leads to

difficulty in handling customer questions

and complaints.

Establish customer files and file sales

orders by customers.

4. Only two copies of sales orders are

prepared. This is not enough to insure a

proper matching in the Billing Department.

Prepare, at a minimum, a three-part sales

order, sending one to Shipping and one to

Billing. Billing should match its copy with

a signed copy from Shipping before

preparing a sales invoice.

5. Items that are out of stock are merely

noted. Inaction in these cases could cause

lost sales.

Establish procedures to schedule

production for back orders and to ship and

bill the product once it is available.

6. There is no reconciliation of inventory

amounts shipped with billings. This could

result in undetected underbilling.

Billing and shipping records should be

integrated on the computer system to

provide for reconciliation of inventory

amounts shipped and billed.

7. The Receiving Department and the

Shipping Department share a computer

terminal. In addition, the personnel in both

departments have access to the physical

inventory and can update the perpetual

inventory records through the terminal.

This could result in theft of inventory with

no means of tracing the theft.

Each department should have its own

terminal and the terminals should be for

inquiry purposes only. The physical

custody and recordkeeping of inventory

should be separated (perpetual records

should be updated on the computer by

Purchasing/Accounts Payable and Billing).

Access to the physical inventory should be

limited to Receiving; it would add

incoming goods to the physical inventory

and select the goods from the warehouse

for shipping.

8. The Receiving Department does not

compare incoming deliveries to purchase

orders. This may lead to the acceptance of

unordered goods.

Copies of purchase orders without quantity

information should be sent to Receiving.

Receiving should match the shipment to the

purchase order and indicate the quantity

received.

9. A complete inventory listing is printed

only once a year. Errors in the perpetual

inventory records may remain undetected

for too long a time period.

Inventory listings should be printed

periodically throughout the year, and

physical counts compared to the listing on

a cycle basis.

b.

How O'Brien Corporation could use its new computer system to improve control and

efficiency:

Maintain an online master file for customer account and credit data in addition to

inventory data.

Use online terminals to enter sales order data into the system as orders are received.

Have the system check inventory availability as order data are entered; if the customer is

on the phone at this time, inventory availability may be confirmed directly to the

customer.

Have the system perform a credit check as order data are entered, and reject orders from

customers who are not credit-worthy.

Immediately following approval of a sales order, have the system (1) print or display a

shipping order for Shipping Department use, (2) print a packing slip and mailing label

for use in shipping the goods to the customer.

Once the order has been shipped, the system should generate a customer invoice.

Maintain order data online to facilitate response to customer inquiries re order status.

Use password access controls to restrict access to the customer and inventory files, and the

operations that can be performed on these files, to appropriate personnel.

12.7

OBrien Corporation is a midsize, privately owned, industrial instrument manufacturer

supplying precision equipment to manufacturers in the Midwest. The corporation is 10

years old and uses an integrated ERP system. The administrative offices are located in a

downtown building and the production, shipping, and receiving departments are housed

in a renovated warehouse a few blocks away.

Customers place orders on the companys website, by fax, or by telephone. All sales are on

credit, FOB destination. During the past year sales have increased dramatically, but 15%

of credit sales have had to written off as uncollectible, including several large online

orders to first-time customers who denied ordering or receiving the merchandise.

Customer orders are picked and sent to the warehouse, where they are placed near the

loading dock in alphabetical sequence by customer name. The loading dock is used both

for outgoing shipments to customers and to receive incoming deliveries. There are ten to

twenty incoming deliveries every day, from a variety of sources.

The increased volume of sales has resulted in a number of errors in which customers were

sent the wrong items. There have also been some delays in shipping because items that

supposedly were in stock could not be found in the warehouse. Although a perpetual

inventory is maintained, there has not been a physical count of inventory for two years.

When an item is missing, the warehouse staff writes the information down in log book.

Once a week, the warehouse staff uses the log book to update the inventory records.

The system is configured to prepare the sales invoice only after shipping employees enter

the actual quantities sent to a customer, thereby ensuring that customers are billed only

for items actually sent and not for anything on back order.

Identify at least three weaknesses in OBrien Corporations revenue cycle activities.

Describe the problem resulting from each weakness. Recommend control procedures that

should be added to the system to correct the weakness.

(CMA Examination, adapted)

Weaknesses and Potential Problem(s)

Recommendation(s) to Correct Weaknesses

1. Orders from new customers do not

require any form of validation, resulting in

several large shipments being sent and

never paid for.

Require digital signatures on all online

orders from new customers.

2. Customer credit histories are not

checked before approving orders, resulting

in excessive uncollectible accounts.

Customers credit should be checked and

no sales should be made to those that do

not meet credit standards.

3. Outgoing shipments are placed near the

loading dock door without any physical

security. The loading dock is also used to

receive incoming deliveries. This increases

the risk of theft, which may account for the

unexplained shortages in inventory.

Separate the shipping and receiving docks.

4. Physical counts of inventory are not

made at least annually. This probably

accounts for the inaccuracies in the

perpetual inventory records and may also

prevent timely detection of theft.

Physical counts of inventory should be

made at least once a year.

5. Shipments are not reconciled to sales

orders, resulting in sending customers the

wrong items.

The system should be configured to match

shipping information to sales orders and

alert the shipping employees of any

discrepancies.

6. The perpetual inventory records are only

updated weekly. This contributes to the

unanticipated shortages that result in

delays in filling customer orders.

The warehouse staff should enter

information about shortages as soon as

they are discovered.

Require a written customer purchase order

as confirmation of telephone and fax

orders.

Physically restrict access to the loading

dock area where customer orders are

placed.

Inventory records discrepancies should be

corrected and investigated.

You might also like

- Jawaban SIDocument8 pagesJawaban SIfhadli kunNo ratings yet

- Audit 14-25 Dan 15-25Document6 pagesAudit 14-25 Dan 15-25Diza Andriyani100% (1)

- SIA - Soal Dan JawabanDocument7 pagesSIA - Soal Dan JawabanRano Kardo SinambelaNo ratings yet

- HOBO Accounting BeamsDocument34 pagesHOBO Accounting BeamsAmr Ramadhan100% (1)

- CH 6Document6 pagesCH 6Natsu DragneelNo ratings yet

- Audit of PPE Case StudyDocument1 pageAudit of PPE Case Studyvenice cambryNo ratings yet

- Jpia Cup p1Document65 pagesJpia Cup p1RonieOlarte100% (1)

- Hall Chapter 3Document7 pagesHall Chapter 3Daphne0% (1)

- Improving Expenditure Cycle EfficiencyDocument21 pagesImproving Expenditure Cycle EfficiencyJuan Rafael FernandezNo ratings yet

- Expenditure Cycle Case - GARCIADocument2 pagesExpenditure Cycle Case - GARCIAARLENE GARCIANo ratings yet

- Mini Case Study: Expenditure CycleDocument2 pagesMini Case Study: Expenditure CycleShenShen LynwellNo ratings yet

- Quiz 5 Acc 401Document10 pagesQuiz 5 Acc 401EML0% (1)

- Fraud Tutorial 3 Solution - ACL 9Document2 pagesFraud Tutorial 3 Solution - ACL 9ExequielCamisaCrusperoNo ratings yet

- Tugas Audit Forensik Week 14Document11 pagesTugas Audit Forensik Week 14juppa Saroha Purba100% (2)

- Strategic Costing and Management SystemsDocument21 pagesStrategic Costing and Management Systemsambrosia96No ratings yet

- Quantitative TechniquesDocument18 pagesQuantitative TechniquesPing PingNo ratings yet

- Sistem Informasi Akuntansi Tugas Kelompok Sesi 4 Assignment 5Document4 pagesSistem Informasi Akuntansi Tugas Kelompok Sesi 4 Assignment 5patrecia 1896No ratings yet

- FarDocument5 pagesFarMaria Fatima AlambraNo ratings yet

- Accounting Information System Chapter 6Document59 pagesAccounting Information System Chapter 6Mohd Nur Ali FizrieNo ratings yet

- Revenue Cycle Activities & Business ProcessesDocument6 pagesRevenue Cycle Activities & Business ProcessesJanica GaynorNo ratings yet

- Problem VI - Combined Income Statement and Balance Sheet for Home Office and BranchDocument4 pagesProblem VI - Combined Income Statement and Balance Sheet for Home Office and BranchxxxxxxxxxNo ratings yet

- Chapter 8 Solutions and ExercisesDocument25 pagesChapter 8 Solutions and ExercisesCliff StewardNo ratings yet

- 10 3Document1 page10 3David TampiNo ratings yet

- Accounting Information System Chapter 5 Case 5Document1 pageAccounting Information System Chapter 5 Case 5Ms ShellNo ratings yet

- Appendix11A Transfer Pricing Quality Costs and Service Department Cost AllocationDocument29 pagesAppendix11A Transfer Pricing Quality Costs and Service Department Cost AllocationLSNo ratings yet

- Ans To Exercises Stice Chap 1 and Hall Chap 1234 5 11 All ProblemsDocument188 pagesAns To Exercises Stice Chap 1 and Hall Chap 1234 5 11 All ProblemsLouise GazaNo ratings yet

- POS System Streamlines Inventory and Billing for Mang Cha-aDocument1 pagePOS System Streamlines Inventory and Billing for Mang Cha-aJenifer CanlasNo ratings yet

- Chapter 09 Indirect and Mutual HoldingsDocument12 pagesChapter 09 Indirect and Mutual HoldingsNicolas ErnestoNo ratings yet

- TBChap 005Document278 pagesTBChap 005Anonymous Vf6qSieNo ratings yet

- Logical Models Communicate Business RequirementsDocument27 pagesLogical Models Communicate Business RequirementsAdam OngNo ratings yet

- Answered - BCD Company Offer Its Investors Option - BartlebyDocument1 pageAnswered - BCD Company Offer Its Investors Option - BartlebyTrisha AgraamNo ratings yet

- Philippine School of Business Administration: Auditing (Theoretical Concepts)Document5 pagesPhilippine School of Business Administration: Auditing (Theoretical Concepts)John Ellard M. SaturnoNo ratings yet

- Group Assignment 1Document5 pagesGroup Assignment 1pushmbaNo ratings yet

- Accounting Information System Chapter 12Document3 pagesAccounting Information System Chapter 12Novita WardaniNo ratings yet

- Audit of Other Income Statement ComponentsDocument7 pagesAudit of Other Income Statement ComponentsIbratama Sukses PratamaNo ratings yet

- CHP 9Document3 pagesCHP 9rio octavianus yapieter100% (2)

- Analyzing Central Tendency and Measures in Statistical DataDocument5 pagesAnalyzing Central Tendency and Measures in Statistical DataBahauddin BalochNo ratings yet

- Purchase Order Errors Lead to Unauthorized PurchasesDocument3 pagesPurchase Order Errors Lead to Unauthorized PurchasestsziNo ratings yet

- AIS Tutorial 7 AnswersDocument16 pagesAIS Tutorial 7 Answersshaun100% (5)

- AIS10Document4 pagesAIS10XiaoMeiMei100% (1)

- EOQ inventory questionsDocument3 pagesEOQ inventory questionsPing Ping100% (1)

- Input Error Correction (Accounting Information System)Document14 pagesInput Error Correction (Accounting Information System)Rachel Garcia0% (1)

- ch02 Beams10e TBDocument22 pagesch02 Beams10e TBbabycatine100% (3)

- Audit Report AnalysisDocument9 pagesAudit Report AnalysisRey Aurel TayagNo ratings yet

- Auditing Chapter 4Document51 pagesAuditing Chapter 4Resselle Ann Solomon Soriano II80% (5)

- Chap 10 Transaction Cycle KEYDocument9 pagesChap 10 Transaction Cycle KEYLương Vân TrangNo ratings yet

- ApabkakakaDocument2 pagesApabkakakaDania Sekar WuryandariNo ratings yet

- What Is The Correct Amount of Inventory?: SolutionDocument3 pagesWhat Is The Correct Amount of Inventory?: SolutionSofia LaoNo ratings yet

- Mas Test Bank QuestionDocument3 pagesMas Test Bank QuestionEricka CalaNo ratings yet

- Tugas AKL ANNISA SHABIRA 3111801029Document7 pagesTugas AKL ANNISA SHABIRA 3111801029annisa shabiraNo ratings yet

- Master Budget-WPS OfficeDocument12 pagesMaster Budget-WPS OfficeRean Jane EscabarteNo ratings yet

- Breezy CompanyDocument2 pagesBreezy CompanychrisNo ratings yet

- Individual Business CaseDocument7 pagesIndividual Business CaseKatrina Belarmino100% (1)

- IFRS-15-Problem-Set 2Document4 pagesIFRS-15-Problem-Set 2FayehAmantilloBingcangNo ratings yet

- Business Combinations: Solution: DDocument17 pagesBusiness Combinations: Solution: Dbabycatine100% (1)

- ch09 PDFDocument40 pagesch09 PDFerylpaez100% (2)

- Solution PKP TutorialDocument6 pagesSolution PKP TutorialMohd HairiNo ratings yet

- Chapter 5Document6 pagesChapter 5Jane LubangNo ratings yet

- AIS Chapters 4 5Document3 pagesAIS Chapters 4 5Matthew Brian TajanlangitNo ratings yet

- Module - Revenue CycleDocument8 pagesModule - Revenue CycleGANNLAUREN SIMANGANNo ratings yet

- Paper 2 - WirawanDocument12 pagesPaper 2 - WirawanJara TakuzawaNo ratings yet

- Audit PlanDocument1 pageAudit PlanJara TakuzawaNo ratings yet

- Banking sector NPL ratiosDocument17 pagesBanking sector NPL ratiosJara TakuzawaNo ratings yet

- Excel All mj-2019-01Document195 pagesExcel All mj-2019-01Jara TakuzawaNo ratings yet

- Hilton 9E Global Edition Solutions Manual Chapter10Document65 pagesHilton 9E Global Edition Solutions Manual Chapter10Manish Pareta60% (10)

- Rais12 SM CH12Document46 pagesRais12 SM CH12Chris Search100% (1)

- Test Part III - ListeningDocument1 pageTest Part III - ListeningJara TakuzawaNo ratings yet

- CMA-Unit 1-Management Accounting 18-19Document25 pagesCMA-Unit 1-Management Accounting 18-19RahulNo ratings yet

- HO3Document2 pagesHO3raprapNo ratings yet

- As Accounting Manufacturing AccountsDocument12 pagesAs Accounting Manufacturing AccountsAlfred MakonaNo ratings yet

- Budgeting and Budgetary Control As Tools For Accountability in Government ParastatalsDocument115 pagesBudgeting and Budgetary Control As Tools For Accountability in Government ParastatalsPandak Gabriel Gwalang100% (2)

- EXERCISE NO 3 (Process Costing)Document9 pagesEXERCISE NO 3 (Process Costing)Arun kumarNo ratings yet

- Inventory Management Sample ChapterDocument33 pagesInventory Management Sample ChapterraamNo ratings yet

- 6 - Cost AccountingDocument29 pages6 - Cost AccountingNathalie GetinoNo ratings yet

- A-Level: AccountingDocument14 pagesA-Level: AccountingPrincess SevillaNo ratings yet

- Ch.13 SolutionDocument29 pagesCh.13 SolutionLastri Defani SinambelaNo ratings yet

- David Gidudi Choka b50-7229-2003Document76 pagesDavid Gidudi Choka b50-7229-2003fazliNo ratings yet

- Wal-Mart Walmart Case Study: Efficiency V/s ResponsivenessDocument9 pagesWal-Mart Walmart Case Study: Efficiency V/s ResponsivenessAmit royNo ratings yet

- Kanban: A Lean Manufacturing ToolDocument16 pagesKanban: A Lean Manufacturing ToolESMERALDA NERINo ratings yet

- Vol 2. SampleDocument23 pagesVol 2. SamplevishnuvermaNo ratings yet

- Final Project Inventory MGT at Malabar CementsDocument50 pagesFinal Project Inventory MGT at Malabar CementsMahaManthra100% (1)

- Notebook Demand ForecastDocument10 pagesNotebook Demand ForecastgauravNo ratings yet

- 4 Reporting and Analyzing Merchandising OperationsDocument45 pages4 Reporting and Analyzing Merchandising OperationsJenny HermosadoNo ratings yet

- Standard Sap Reports (SD & MM)Document15 pagesStandard Sap Reports (SD & MM)Gaurav Harimitter50% (2)

- Balbin, Ma. Margarette P. Assignment #1Document7 pagesBalbin, Ma. Margarette P. Assignment #1Margaveth P. BalbinNo ratings yet

- Buffalo Accounting Go-Live ChecklistDocument16 pagesBuffalo Accounting Go-Live ChecklistThach DoanNo ratings yet

- Materials Management in Primary Health Centre: A Process MappingDocument17 pagesMaterials Management in Primary Health Centre: A Process MappingAkansha JohnNo ratings yet

- Project Report on Ratio Analysis of Prism CementDocument68 pagesProject Report on Ratio Analysis of Prism Cementvickram jainNo ratings yet

- FIN 420 Chapter 3 (Financial Ratio and Analysis)Document20 pagesFIN 420 Chapter 3 (Financial Ratio and Analysis)Damia AlyaNo ratings yet

- CPFR ModelDocument10 pagesCPFR ModelUcheNo ratings yet

- Standard Costing - Solutions To Home Work Problems: Question No: 19 Reconciliation With Finished Goods InventoryDocument7 pagesStandard Costing - Solutions To Home Work Problems: Question No: 19 Reconciliation With Finished Goods InventoryDevi ParameshNo ratings yet

- How To Read and Interpret Financial Statements - A Guide To Understanding What The Numbers Really MeanDocument179 pagesHow To Read and Interpret Financial Statements - A Guide To Understanding What The Numbers Really MeanMushahid Aly Khan100% (5)

- Operation Management ReportDocument14 pagesOperation Management ReportClaudia SmithNo ratings yet

- COST ACCTNG - Chapters 5-6 ActivitiesDocument30 pagesCOST ACCTNG - Chapters 5-6 ActivitiesAnjelika ViescaNo ratings yet

- Case 6Document3 pagesCase 6maricar carongoyNo ratings yet

- Working Capital Management of INDIAN OVERSEAS bANK. Completed by Sarath NairdocDocument66 pagesWorking Capital Management of INDIAN OVERSEAS bANK. Completed by Sarath Nairdocsarathspark100% (5)

- Chapter 10 - Inventory Decision MakingDocument84 pagesChapter 10 - Inventory Decision MakingArman100% (1)