Professional Documents

Culture Documents

Apparel Check List

Uploaded by

vikkasverma.in0 ratings0% found this document useful (0 votes)

24 views2 pagesDAILY CHECK LIST FOR APPARELS AND BASIC RECORDS TO BE MAINTAINED

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDAILY CHECK LIST FOR APPARELS AND BASIC RECORDS TO BE MAINTAINED

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views2 pagesApparel Check List

Uploaded by

vikkasverma.inDAILY CHECK LIST FOR APPARELS AND BASIC RECORDS TO BE MAINTAINED

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

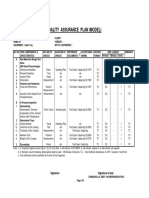

DAILY CHECK LIST

1.

THINGS TO CHECK IN P.O COPY:

a.

b.

c.

d.

e.

f.

g.

h.

i.

2.

QUANTITY

STYLING

ACCESSORY DETAILS

BUTTONS

THREAD SHADE/COUNT

INTERLININGS AT DIFFERENT PARTS

FABRIC INSPECTION REPORTS

ALL TEST REPORTES

FUSING TEST

SHRINKAGE LINING AND FABRIC

BUTTON HOLE DENSITY

BUTTON SEW

BOWING AND SCEW

CENTER SELVADGE

TEMPERATURE FUSING

LINING G.S.M

IRONABLITY

SPCM

FOLDING STANDARDS

THINGS TO CHECK IN TECH FILE :

a.

b.

c.

d.

FUSING AND IRONING PARAMETERS

BUTTONS/ LABELS POSITIONINGS

SEAM SPECIFICATIONS

MATCHING PARAMEETERS

OTHERS

CONSTRUCTION DETAILS IN TECHNICAL PACKAGE

APPROVEL FOR FIRST PIECES

PATTERN

CHECK FOR ACTUAL AND PPS SAMPLE.

THREADS SHADE

FUSING APPROVEL

BUTTONS/ LABELS POSITIONS AS PER TECH. PACK

SPECIAL QUALITY INSTRUCTION IN CASE OF DIFFICULT FABRICS

FABRIC HANDLING

CRITICAL MEASUREMENTS

PRESSING APPROVEL

TEMPLATES FOR COLLAR / CUFF POCKET ARE ASPER THE STYLE AND

MEASUREMENTS ARE MATCHING WITH THE APPORVED PATTERNS.

SPCM

PUCKERING STANDARD

NEEDLE AND BLADE ACCORDING TO FABRIC

FOLDERS SET AT CORRECT SPECIFICATIONS

MACHINE SETTINGS ARE CORRECT (ENSURE THREAD SETTING OF NDL AND BBN)

CHECK FABRIC INSPECTION SHEETS IF ANY FABRIC DEFECTS ARE THERE, SO

THOSE FABRICS CAN BE CHECKED FOR COFIRAMATION OF USAGE.

P.O TRACKING

CLEARING BALANCE ,ALTERATION,SECONDS,REJECTED PIECES

CHECK FOR M/C CLEAN AND MAINTANANCE

APPROVEL FOR PENDING ISSUES

PRIMARY,MID,FINAL INSPECTION

DISCUSE WITH Q.CS AGAINST DAILY ISSUES

PPS AND OTHER SAMPLES APPROVEL

TECH PACK FOLLOW UP

RECORDS

DAILY Q.C REPORT AND UPDATE

SAMPLE

PARTS ONLINE AND ENDLINE

ASSEMBLY ONLINE AND END LINE

FINAL

FABRIC INSPECTION

ALTERATION

SECONDS AND REJECTIONS

You might also like

- 34510193Document4 pages34510193gutmontNo ratings yet

- Sunrise Process Equipments: Quality Assurance PlanDocument8 pagesSunrise Process Equipments: Quality Assurance Plansushant_jhawerNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- ITP New Pressure VesselDocument2 pagesITP New Pressure Vesselyosafateden60% (5)

- Inspection Checklist Platformer Reactor Vessel PDFDocument5 pagesInspection Checklist Platformer Reactor Vessel PDFsebas_vNo ratings yet

- How To Make Garment Spec SheetDocument32 pagesHow To Make Garment Spec SheetKumera Haileyesus100% (1)

- Piping Specialty Item Design GuideDocument3 pagesPiping Specialty Item Design GuideCivil Friend67% (3)

- ThermocouplesDocument8 pagesThermocouplesRakesh NayakNo ratings yet

- FormP 4Document2 pagesFormP 4Mohamed Ahmed MaherNo ratings yet

- Piping SpecDocument355 pagesPiping Speclcaron44100% (1)

- MDR Form A-1Document2 pagesMDR Form A-1Yuvraj ThoratNo ratings yet

- Inspection Checklist Platformer Reactor VesselDocument5 pagesInspection Checklist Platformer Reactor VesselNaiyer Karimi100% (1)

- P&ID ChecklistDocument4 pagesP&ID ChecklistMeoNo ratings yet

- Pip CL 009Document2 pagesPip CL 009Arindom KunduNo ratings yet

- Test Certificate-Pressure RegulatorsDocument2 pagesTest Certificate-Pressure RegulatorsJonathan Griffin100% (1)

- 0-WD380-EP200-00005 - Rev - A) Bolt and Nuts Tech. Spec.Document24 pages0-WD380-EP200-00005 - Rev - A) Bolt and Nuts Tech. Spec.carlos tapia bozzoNo ratings yet

- Dyeing Section Process Control of Rope Dyeing (Part I) (Pure Indigo/Bottoming/Topping)Document10 pagesDyeing Section Process Control of Rope Dyeing (Part I) (Pure Indigo/Bottoming/Topping)buttamanatNo ratings yet

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- Material Requisition For Bolt and Nuts-Rev0Document5 pagesMaterial Requisition For Bolt and Nuts-Rev0altipatlarNo ratings yet

- Form P-8 Manufacturer'S or Assembler'S Certificate of Conformance For Pressure Relief ValvesDocument1 pageForm P-8 Manufacturer'S or Assembler'S Certificate of Conformance For Pressure Relief ValvesMohamed Ahmed MaherNo ratings yet

- 7.4.1 D+list of Specification 7.4Document4 pages7.4.1 D+list of Specification 7.4Moizuddin SyedNo ratings yet

- Technical Specifications BAMULDocument133 pagesTechnical Specifications BAMULjaya100% (1)

- Process Equipment DesignDocument27 pagesProcess Equipment DesignVivek NairNo ratings yet

- TDC - CS PipeDocument1 pageTDC - CS PipetrushalpanchalNo ratings yet

- Exhibit 2 Condensate Drain SystemDocument59 pagesExhibit 2 Condensate Drain SystemJavier Jaya CamachoNo ratings yet

- SECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesDocument4 pagesSECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesMunir RasheedNo ratings yet

- Identification For Plumbing Piping and EquipmentDocument5 pagesIdentification For Plumbing Piping and EquipmentEN LeedNo ratings yet

- Technical Specification For Level Control ValvesDocument13 pagesTechnical Specification For Level Control ValvesAylaNo ratings yet

- Basic Checks For Shell & Tube Heat Exchanger: IBR Minimum Design Metal TemperatureDocument4 pagesBasic Checks For Shell & Tube Heat Exchanger: IBR Minimum Design Metal TemperaturesanjayNo ratings yet

- Bes 800-101Document25 pagesBes 800-101jfferrog100% (1)

- 16 JRTP 02 ITP - Rev01Document13 pages16 JRTP 02 ITP - Rev01khsaeed100% (1)

- 23 05 19 Manual Meters and GaugesDocument6 pages23 05 19 Manual Meters and GaugesolivaresjhonNo ratings yet

- Check List For Reviewing of Shell Tube Heat Exchanger Drawings PDFDocument4 pagesCheck List For Reviewing of Shell Tube Heat Exchanger Drawings PDFRakesh KumarNo ratings yet

- Sample Leak Testing Report For Ast TankDocument1 pageSample Leak Testing Report For Ast TankArimoro Cyril Obuse43% (7)

- QA For Butt FusionDocument9 pagesQA For Butt Fusionjimbox88No ratings yet

- Piping Inspection ProcedureDocument9 pagesPiping Inspection ProcedureImam Buchairi100% (2)

- Wi Insp 02 Heat ExchangerDocument6 pagesWi Insp 02 Heat ExchangerSamir Chaudhary100% (1)

- GAIL Metering SkidDocument36 pagesGAIL Metering SkidSimbu ArasanNo ratings yet

- SOP For Assigning of Identification Numbers To EquipmentsDocument10 pagesSOP For Assigning of Identification Numbers To EquipmentsGencay ErginNo ratings yet

- ,, Packoff / Seal: 8 SEP 2015 8 SEP 2015 03Document4 pages,, Packoff / Seal: 8 SEP 2015 8 SEP 2015 03Arjun PrajapatiNo ratings yet

- Progress Report 1 - ProcessDocument1 pageProgress Report 1 - ProcessrutujaNo ratings yet

- Packaging Component Specification: General InformationDocument3 pagesPackaging Component Specification: General InformationSandeepNo ratings yet

- BHEL Standards For Cable TraysDocument18 pagesBHEL Standards For Cable TraysLokesh Kumar KoshtiNo ratings yet

- Indicate If (1) Seamless (2) Fusion Welded. Indicate If (1) Flat (2) Dished (3) Ellipsoidal (4) HemisphericalDocument3 pagesIndicate If (1) Seamless (2) Fusion Welded. Indicate If (1) Flat (2) Dished (3) Ellipsoidal (4) HemisphericalmsuidNo ratings yet

- QAP1Document33 pagesQAP1sanjiv66669No ratings yet

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- Polythene Pipes Fittings Specials and AccessoriesDocument15 pagesPolythene Pipes Fittings Specials and Accessoriestebodin_319100% (1)

- ITP For CS Is 1239 FittingsDocument1 pageITP For CS Is 1239 FittingsMaan RawatNo ratings yet

- 23 22 13 - Steam and Condensate PipingDocument21 pages23 22 13 - Steam and Condensate PipingOsamah AlzubadiNo ratings yet

- AMEC Specification For Titanium 01Document9 pagesAMEC Specification For Titanium 01cenkturkerNo ratings yet

- Ifs 607a R8 Las 6-2010Document17 pagesIfs 607a R8 Las 6-2010Heymonth ChandraNo ratings yet

- QP Transformer PDFDocument6 pagesQP Transformer PDFmanoj_2027No ratings yet

- HD - Planta de PVCDocument7 pagesHD - Planta de PVCDavid LapacaNo ratings yet

- Fit-Up Inspection BasicsDocument1 pageFit-Up Inspection BasicsAhmed HaridiNo ratings yet

- Boiler Remaining Life AssessDocument33 pagesBoiler Remaining Life AssessSSudhakar100% (1)

- VEDST003 - Shell and Tube Heat Exchanger Specification SheetDocument23 pagesVEDST003 - Shell and Tube Heat Exchanger Specification SheetyuganterNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- NHAI Manual For 6 LaningDocument70 pagesNHAI Manual For 6 LaningAbishek Kumar80% (5)

- Burberry Ethical Trading Policy:: Why These Dormitories Are Good PractiseDocument3 pagesBurberry Ethical Trading Policy:: Why These Dormitories Are Good Practisevikkasverma.inNo ratings yet

- Nestlé India PoSHDocument8 pagesNestlé India PoSHvikkasverma.inNo ratings yet

- Sharp Tool PolicyDocument3 pagesSharp Tool Policyvikkasverma.in100% (4)

- 27K StagesDocument7 pages27K Stagesvikkasverma.inNo ratings yet

- 08 Wall Roof Floor Framing inDocument12 pages08 Wall Roof Floor Framing invikkasverma.inNo ratings yet

- Sharp Tool PolicyDocument3 pagesSharp Tool Policyvikkasverma.in100% (4)

- Take Control of Your TimeDocument12 pagesTake Control of Your Timevikkasverma.inNo ratings yet

- Bengali Primark Code of Conduct PDFDocument13 pagesBengali Primark Code of Conduct PDFvikkasverma.in100% (1)

- Habit TrackerDocument1 pageHabit Trackervikkasverma.inNo ratings yet

- 5S Diagnostic ChecklistDocument6 pages5S Diagnostic Checklistvikkasverma.in50% (2)

- ISO 9001-2015 Transition Checklist C 01 Rev ADocument4 pagesISO 9001-2015 Transition Checklist C 01 Rev Avikkasverma.in100% (1)

- 5s ChecklistDocument4 pages5s Checklistvikkasverma.inNo ratings yet

- First Aid KitDocument1 pageFirst Aid Kitvikkasverma.inNo ratings yet

- A Good Teacher Is Like A CandleDocument1 pageA Good Teacher Is Like A Candlevikkasverma.inNo ratings yet

- Leadership Lessons From Lord ShivaDocument14 pagesLeadership Lessons From Lord Shivavikkasverma.inNo ratings yet

- File RecordsDocument1 pageFile Recordsvikkasverma.inNo ratings yet

- Management by Objective FormatDocument1 pageManagement by Objective Formatvikkasverma.inNo ratings yet

- Customer Care QuizDocument1 pageCustomer Care Quizvikkasverma.inNo ratings yet

- Advance PlanningDocument5 pagesAdvance Planningvikkasverma.inNo ratings yet

- Check List For Starting A SchoolDocument8 pagesCheck List For Starting A Schoolvikkasverma.in73% (11)

- Screen Printing ProcessDocument3 pagesScreen Printing Processvikkasverma.inNo ratings yet

- Retail Customer ServiceDocument10 pagesRetail Customer Servicevikkasverma.inNo ratings yet

- BPDocument4 pagesBPvikkasverma.inNo ratings yet

- 7 Principals of Good Practice in EduDocument7 pages7 Principals of Good Practice in Eduvikkasverma.inNo ratings yet

- Quality Manual: Fareedh TradersDocument1 pageQuality Manual: Fareedh Tradersvikkasverma.inNo ratings yet

- WineDocument3 pagesWinevikkasverma.inNo ratings yet

- Implementing ISO 9001 in Education Using ISO IWA2Document2 pagesImplementing ISO 9001 in Education Using ISO IWA2vikkasverma.inNo ratings yet

- 5s ChecklistDocument4 pages5s Checklistvikkasverma.inNo ratings yet