Professional Documents

Culture Documents

Vernier Design

Uploaded by

RakeshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vernier Design

Uploaded by

RakeshCopyright:

Available Formats

United States Patent [191

[111

4,375,722

Nishikata et al.

[45]

Mar. 8, 1983

[54] VERNIER CALIPER

4,077,129

3/1978

4,136,455

1/1979 Owsen

Nishikata ........................ .. 33/147T

33/147 F

[75] Inventors: Goro Nishikata; Kozo Shibukawa,

both of Kawasaki, Japan

FOREIGN PATENT DOCUMENTS

[73] Assignee: Kabushiki Kaisha Mitutoyo

54681 12/1921

Seisakusho, Tokyo, Japan

[21] Appl. No.: 221,509

[22] Filed:

[63]

632671 11/1949

33/143 M

33/ 143 M

United Kingdom ........... .. 33/143 K

Primary Examiner-Harry N. Haroian

Attorney, Agent, or FirmBrisebois & Kruger

Dec. 30, 1980

Related US. Application Data

Continuation of Ser. No. 56,609, Jul. 11, 1979, aban

doned.

[51] Int. Cl.3

Sweden ........... ..

7454 of 1902 United Kingdom .

G01B 5/02

[57]

ABSTRACT

A vernier caliper includes a main beam body consisting

of two round rods parallel to each other and connected

together at one end by a jaw, and at the other end by a

rear frame. A vernier is supported freely and slidably on

[52]

[58]

US. Cl. ...................... .. 33/143 M; 33/147 T

Field of Search ........... .. 33/143 M, 143 R, 143 J,

the rods. The rods can be hollow and can have their

rear frame and secured in the openings with adhesive,

[56]

33/143 K, 147 R, 147 H, 147 G, 147 T, 147 J,

158, 159, 169, 170

References Cited

U.S. PATENT DOCUMENTS

respective ends inserted into openings of the jaw and

solder, or screws. A rack can be formed on one of the

rods to drive, for example, a dial indicator, and gradua

tions can be provided on a rod to read the measurement

taken with the vernier. This construction provides a

more accurate vernier caliper which can be precisely

2,531,334

1,515,266 11/1950

11/1924 Grenat

Mitchell...... ..

assembled without grinding, for example, jaw faces,

2,741,848

4/1956

Livingston .... ..

after assembly to calibrate the caliper.

3,302,294

3,228,287

2/1967

1/1966

Eguchi

Bizzoco ................................

et a1. .

.. 33/147

3 Claims, 12 Drawing Figures

U.S. Patent

Mar. 8, 1983

Sheet 1 of 5

4,375,722

U.S. Patent

Mar. 8, 1983

FIG. 4

Sheet 2 of5

4,375,722

US. Patent

Mar. 3, 1983

Sheet 3 of5

4,375,722

US. Patent

Mar. 8, 1983

Sheet4 of5

4,375,722

U.S. Patent

Mar. 8, 1983

Sheet 5 of5

4,375,722

4,375,722

suring faces of the measuring jaws after the vernier is

VERNIER CALIPER

assembled to the main beam.

Still another object of the invention is to provide a

This is a continuation of application Ser. No. 56,609,

?led July ll, 1979, now abandoned.

vernier caliper in which the ends of the round rods

inserted into the stopper and/or the external jaw of the

BACKGROUND OF THE INVENTION

The present invention relates to a vernier caliper with

unique features in the construction of its main beam.

The main beam in the conventional vernier calipers

usually consists of a main beam body made from thin

plate material with an external jaw and an internal jaw

main beam are adhered or soldered by ?xing means

such as an adhesive or a soldering material, thereby

integrally connecting the two rods without producing

strain in the surfaces of the two rods.

Still another object of the invention is a vernier cali

per in which both ends of the round rods inserted into

the stopper or the external jaw are ?xed in their holes

formed integral with the main beam body. The main

beam is made by punching out a sheet metal blank

roughly to its shape with a press machine; then machin

ing and grinding the blank.

by a ?xing means such as screws or other similar parts,

But the main beam made in this way has to be ma

Still another object of the invention is a vernier cali

per in which a bush is slidably ?t on each of the two

thus connecting the rods to them to form one body

without producing strain in the surfaces of the rods and

allowing disassembly of the rods.

chined on all its faces; and because its shape is compli

cated because of the external jaw and the internal jaw

on it, and since the main beam is made of highly wear

resistant metal, machining of the main beam body is

dif?cult and laborious. Furthermore, because the metal

of the main beam body is relatively thin, there devel

rods, the bushes are loosely inserted into two parallel

holes made in the vernier, and the bushes are ?xed in the

two vernier holes with an adhesive or solder, thus al

lowing the vernier to be slidably supported on the main

beam body that consists of two round rods, even if a

oped the problem of warpage of the body that is caused

by the heat generated in the machining. There has been

also the problem in the conventional vernier calipers

25 small error exists in parallelism of the two vernier holes.

vernier caliper in which the main beam body slidably

supporting the vernier consists of two pieces of round

rods, thus reducing machining processes and, further

eliminating the groove previously required to be

Still another object of the invention is a vernier cali

per in which a transparent scale plate mounted on the

that error in reading the measured value is liable to

vernier has a scale groove with arch-shaped cross-sec

develop because, in order to ?t the vernier on the main

tion that is adjacent to and facing the scale of a round

beam body to slide, some play is provided between 30 rod and extends along its length, and the scale groove

them in the directions of the plate thickness and width

has vernier graduations, thus allowing scale readings

of the main beam.

without parallax error.

Still another object of the invention is a vernier cali

SUMMARY OF THE INVENTION

per in which a depth bar is installed between the two

The object of the present invention is to provide a

round rods that make up the main beam bodies, thus

formed on the main beam body for accommodating the

depth bar.

more, making exact and accurate machining easy, and

Still another object of the invention is a vernier cali

which is not liable to bend as a result of heat generated 40 per in which a rack is formed on one of the two round

in its machining.

rods of the main beam body, and the rack is in mesh

Another object of the invention is a vernier caliper

with the pinion of a device to indicate the amount of

that has light weight main beam body portions in the v vernier shift, whereby the rack is easily and simply

form of hollow pipes or tubes.

provided for the main beam body with no necessity of

Still another object of the invention is to provide a 45 forming a rack independently of the main beam body

vernier caliper in which a stopper or rear frame is

pierced with two parallel holes and ends of the two

pieces of round rods are inserted into the two holes and

?xed in the holes by a ?xing means to form a rigid

assembled body. When connecting, in this way, the two

pieces of round rods to the stopper, the position of the

stopper relative to the rods is adjusted so that in the

?xed position, the end face of the stopper that is to be

the standard plane for measuring depth will be precisely

positioned. Therefore, the amount of projection of the

depth bar from the standard plane for measuring depth

can be easily matched and preset to the graduation on

and fastening it in a groove, etc. in the main beam body.

These objects, features and advantages of the inven

tion will become more apparent by consideration of the

detailed speci?cation that follows and the accompany

ing drawings.

BRIEF DESCRIPTION OF THE DRAWINGS

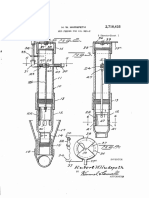

FIG. 1 is a plan view of a ?rst embodiment of the

55

invention;

FIG. 2 is a view in section taken along the line II-II

of FIG. 1;

FIG. 3 is an enlarged partial view of a portion of

the scale of the main beam without grinding the depth

FIG. 2;

bar and the standard plane.

Still another object of the invention is to provide a 60 FIG. 4 is an enlarged view in section taken along line

IV-IV of FIG. 1;

vernier caliper in which an external measuring jaw of

FIG. 5 is an enlarged view in section taken along line

the main beam is pierced with two parallel holes, and

VV of FIG. 1;

ends of the two pieces of round rods are inserted into

FIG. 6 is a plan view of a second embodiment of the

these two holes and ?xed to connect the two ends to the

external jaw on the main beam. When connecting the 65 vernier caliper of the invention with portions cut away

for illustration;

two round rods, the measuring faces of the external jaw

FIG. 7 is a view in section taken along line VIIVII

and vernier are set together and aligned, thus eliminat

of FIG. 6;

ing the previously required grinding of these two mea

4,375,722

FIG. 8 is a plan view of a third embodiment of a

faces 4c and 9a together while the rods 7, 8 are held in

vernier caliper of the invention with portions cut away

parallel.

for illustration;

The measuring jaw 4 and the stopper 6 can be joined

FIG. 9 is a view in section taken along line IXIX of

to the ends of the rods 7 and 8 by screws, so that the

FIG. 8;

rods can be disassembled.

FIG. 10 is a plan view of a fourth embodiment show

Since, as mentioned above, the rods 7 and 8 are ?xed

ing a vernier caliper with portions cut away;

FIG. 11 is a view in section taken along line XIXI

of FIG. 10; and

FIG. 12_is a view in section taken along line XIIXII

to the stopper 6 and the measuring jaw 4 by ?xing

means such as adhesive pasting, soldering material, or

screws, no strain is produced in the round rods 7, 8

when they are ?xed to the external jaw 4 or the stopper

of FIG. 10.

6.

An external measuring jaw 9 and an internal jaw 10

are integrally formed with the vernier 2. In the middle

section of the vernier 2 there is a square depression in

DETAILED DESCRIPTION OF THE

PREFERRED EMBODIMENTS

The following description explains embodiments of

the present invention shown in the accompanying

[5 the form of a recess 11 that is open on one side. A pair

of spaced apart longitudinal holes 12 and 13 penetrate

through the ends of the vernier 2 at certain intervals

FIGS. 1 to 5 show a ?rst embodiment of the present

(FIG. 4). Bushes 14 and 15 are inserted into and ?xed in

invention. In FIG. 1, 1 is a main beam of a vernier

the parallel holes 12 and 13 in the vernier with an adhe

caliper and 2 is a vernier. The main beam 1 consists of a 20 sive and the like, and the round rods 7 and 8 are slidable

main beam body 3 extending longitudinally, an external

through the bushes. At the time of assembly, a clearance

measuring jaw 4 ?xed on one end of the main beam

is provided between the bushes 14, 15 and the holes 12,

body 3, an internal jaw 5' integral with the external jaw

13. In this way, even if there is a little error in the paral

drawings.

and a stopper or rear frame ?xed on the end of the main

beam body 3. The stopper or rear frame 6 prevents the

vernier 2 from coming off the main beam body 3.

The main beam body 3 consists of two round rods 7

lelism between the holes 12 and 13, or there is a rough

ness in the machining inside the holes, the vernier can

be precisely slidably assembled to the main beam body

3, by ?xing the bushes 14, 15 in the vernier 2 while the

round rods 7 and 8 pass through the bushes 14 and 15.

and 8 which extend lengthwise and parallel to each

other. Because the external measuring jaw 4 and the

The depression 11 of the vernier 2 is covered by a

stopper 6 ?x both ends of the rods 7 and 8, the distance 30 transparent scale plate 16 which is made of resin mate

between the round rods 7 and 8 and their parallelism are

rial and cemented to the vernier 2, (FIGS. 25). The

kept constant. The round rods may be either solid or

surface of the scale plate 16 that lies facing the round

hollow, but their outer diameter and their right-angled

rod 7 is formed with a scale groove 17 which extends

degree are made to be accurate.

longitudinally of the rod 7 and has the cross section of

The main beam body 3 can be made light in weight by 35 an arch, (FIG. 5). This scale groove 17 is adjacent to the

using hollow pipes or tubes for the rods 7 and 8. The

material of the rods is wear resistant hard metal.

Because round rods can be easily ground with a

grinding machine, simple and exact machining can be

achieved by only one grinding of their outer round 40

rod 7. In the scale groove 17, vernier scales 18 are pro

vided in the longitudinal direction with certain inter

vals. On the surface of the round rod 7 facing the scale

groove, scales 19 of the main beam are provided, in the

longitudinal direction of the rod 7, with certain inter

surfaces. Since the caliper body 3 consists of the round

rods 7 and 8 only, the bending of the rods 7, 8 due to

heat generated in grinding them can be prevented.

scales will not occur between the scales 18 and 19.

caliper body scale by adjusting the installed position of

and is indicated as a measured value on the vernier 2.

vals. By this scale arrangement, parallax in reading

In the vernier caliper with the above explained con

The ends of the rods 7, 8 go into parallel holes 6b and

struction, when moving the vernier 2 in the longitudinal

6c provided in the stopper 6, and they are there adhered 45 direction of the main beam body 3, the vernier 2 can

or soldered by a suitable ?xing material such as an adhe

shift or slide smoothly along the main beam body 3,

sive, solder, or the like, to the stopper 6. Accordingly,

because the round rods 7, 8 and the bushes 14, 15 are

no grinding to ?nish the end face 6a of the stopper 6,

smoothly and slidably contacted. When an object to be

which is to be the standard plane for depth measure

measured is held between the measuring jaws 4 and 9 of

ment, is required, and it becomes easy to match the 50 the vernier caliper, a metting point of the scale 19 of the

amount of projection of a depth bar (later mentioned)

main beam 1 and the scale 18 of the vernier 2 becomes

from the standard plane to the depth reading on the

an outer diameter or length of the object to be measured

the stopper 6 relative to the rods 7 and 8 at the time they

In the embodiment of the present invention so far

are joined, and ?xed together.

55 explained, a depth bar was not provided on the vernier

The other ends of the round rods 7 and 8 go into holes

2. As shown in FIGS. 6, 7, to the vernier 2 can be at

40 and 4b which are parallel to each other and are

tached a depth bar 20 which is positioned between the

pierced in the external measuring jaw 4. These ends are

round rods 7 and 8 and extends through a hole in the

?xed by an adhesive or solder or other ?xing materials

central portion of the stopper 6. In this case, the end

in the holes 40 and 4b. These holes 40, 4b are so dimen 60 face 60 of the stopper 6 becomes the standard plane for

sioned that there are clearances between the holes 40, 4b

the depth bar 20. By placing the depth bar 20 between

and the round rods 7, 8. Thus, when the other ends of

the round rods 7 and 8, there is no necessity of machin

the rods 7 and 8 are adhered or soldered to the holes 40.

ing a groove to accommodate it in the round bars 7 and

4b of the external measuring jaw 4, matching of the

8 of the main beam body 3.

measuring faces 4c and 9a of the external measuring 65 In the embodiment of FIG. 1 of the present invention

jaws 4 and 9 respectively can be easily achieved, with

above explained, measured values are read off from the

out additional grinding of the faces 4c and 90 after the

scale 19 of the main beam 1 and the scale 18 of the

external jaw 4 is ?xed to the rods 7, 8, by meeting both

vernier 2. The means to read the measured values are

4,375,722

nier, making it easy to precisely assemble the vemier

onto the main beam body, and giving good sliding

movement to the vemier. This advantage permits

smaller clearances at the fitting portions between the

vernier and the main beam body than in the conven

tional vemier calipers, which in turn improves accuracy

not necessarily limited to such scales. As shown in

FIGS. 6, 7, the scale 21 for reading the movement of the

vemier 2 in millimeter units is provided on the round

rod 8, and a rack 22 is formed on the round rod 7 along

its length, and a pointer 24 of a dial indicator 23

mounted on the vernier 2 is interconnected and inter

locked through a series of gears 25 with the rack 22 so

in the measurement.

Furthermore, a depth bar can be placed between the

two round rods, without requiring formation of a

groove to receive the depth bar in the main beam body

as to indicate the movement of the vemier 2 in 1/100

mil. units by the pointer 24 and the scale 26 of the dial

indicator 23. As shown in the construction of FIGS. 8

and 9, the movement of the vernier 2 in millimeter units

can be read from the counting device 27 interlocking

with the rack 22 and additionally the movement of the

as in the previous art of making vernier calipers, and the

weight of the vemier calipers is reduced by using round

bars, which can be hollow for the main beam body.

What is claimed is:

vemier 2 in l/ 100 millimeter units can be read from the

dial indicator 23 interlocking with the rack 22.

In another arrangement, to read the movement of the

1. A vemier caliper comprising

a first measuring jaw;

vemier 2, as shown in FIGS. 10 and 11, a slitted disc 29

a rear frame;

is rotatably supported on the vernier 2 interlocking

a main beam body comprising two round rods paral

through a series of gears 28. On the slitted disc 29, plural

lel to each other and extending between said mea

radial slits 30 are formed near the periphery and at

certain circumferential intervals. On the vemier 2, a

photoelectric convertor element 31 and a luminous

means securing a first end of each round rod to said

element 32 are attached facing each other with the slit

disc 29 in between them, and the photo-electric conver

tor element 31 and a liquid crystal digital indicator 34

are connected through a pulse counter 33 which counts

means securing the other end of each round rod to

said rear frame;

a slider having a second measuring jaw; and

means mounting said slider on said two round rods

the current pulses generated by the photo-electric con

for sliding movement along said rods between said

second jaw and said rear frame, and wherein

one of said rods has graduations,

suring jaw and said rear frame;

?rst measuring jaw;

vertor element 31, to thereby electrically indicate the

movement of the vernier 2 on the digital indicator 34.

As shown in FIGS. 6 to 10, forming a rack on the

a transparent scale plate with graduations is mounted

on the slider so as to face said round rod with grad

round bar 7 makes it unnecessary to use a rack bar made

independently of the main beam body 3 and to ?x it in

a groove formed in the main beam body 3, as in the

prior art.

In the embodiments of the present invention above 35

uations, and

a scale groove is formed in said scale plate in opposed

relation to said round rod with graduations and

extends axially of said rod, said groove having an

explained, the main beam body consists of two pieces of

round rods, which eliminates punching, and machining

arch-shaped cross-section, and vernier graduations

and grinding on many faces as has been required in the

2. A vemier caliper as claimed in claim 1, further

formed on said scale groove.

manufacture of conventional vernier calipers. The only

grinding required is of rotating round rods, which are 40

much easier to machine, and require less machining

than before. Furthermore, the round bar has higher

rigidity than bars of other shapes, which is an advantage

in resisting the bending due to heat generated in the

machining of the main beam body, and which heat has 45

comprising

caused bending of the thin main beam bodies of the

conventional vernier calipers. Thanks to the favorable

properties of the round rods, the measurement error due

3. A vemier caliper as claimed in claim 2 wherein a

rack is formed on one of said two round rods, said rack

meshes with a pinion supported on the Vernier, and an

to bending of the main beam body can be avoided.

By using round rods, bushes can be used at their

sliding contacts, and before assembly a slight gap can be

indicator for indicating movement of the vernier is

interlinked with said pinion and is mounted on the ver

nier.

a depth bar between said two round rods and extend

ing slidably through a central portion of said rear

frame,

means securing said depth bar on the vemier,

an outer end face of said rear frame comprising a

standard plane for depth measurement.

provided between the bushes and the holes of the ver

55

65

You might also like

- Vernier Caliper PatentDocument9 pagesVernier Caliper Patentmeinard angelesNo ratings yet

- United States Patent (191: BlakesleyDocument7 pagesUnited States Patent (191: BlakesleyRavindra JillepalliNo ratings yet

- US898276Document5 pagesUS898276Jacob LukaNo ratings yet

- Us3789638 PDFDocument13 pagesUs3789638 PDFjdanacayaNo ratings yet

- Us2996100 PDFDocument8 pagesUs2996100 PDFerzrzretgertfertgeNo ratings yet

- Tài liệu5Document12 pagesTài liệu5Hoàng ĐứcNo ratings yet

- Unlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973Document4 pagesUnlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973fgrt45No ratings yet

- Patent Application Publication (10) Pub. No.: US 2002/0153034 A1Document25 pagesPatent Application Publication (10) Pub. No.: US 2002/0153034 A1Paballo MontleNo ratings yet

- April 27, 1948. E. A. Bender 2,440,427: Filed Jan. 12, 1945 2 Sheets-SheetDocument6 pagesApril 27, 1948. E. A. Bender 2,440,427: Filed Jan. 12, 1945 2 Sheets-SheetAbu SayedNo ratings yet

- Mosler Safe & Lock Co. v. Mosler, 127 U.S. 354 (1888)Document6 pagesMosler Safe & Lock Co. v. Mosler, 127 U.S. 354 (1888)Scribd Government DocsNo ratings yet

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDocument7 pagesUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinNo ratings yet

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pages@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNo ratings yet

- United States Patent 1191 1111 3,956,085: Haas (45) May 11, 1976Document4 pagesUnited States Patent 1191 1111 3,956,085: Haas (45) May 11, 1976Alejandro Saravia AlcócerNo ratings yet

- LLLLLLLLLLL: United States Patent (191Document9 pagesLLLLLLLLLLL: United States Patent (191Mark EdowaiNo ratings yet

- Us 6131519Document4 pagesUs 6131519dgfhjsdg hfsdhyjNo ratings yet

- Description: (OCR Text May Contain Errors)Document6 pagesDescription: (OCR Text May Contain Errors)geeNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 6,450,269 B1Document8 pagesUnited States Patent: (12) (10) Patent N0.: US 6,450,269 B1Cường Nguyễn QuốcNo ratings yet

- United States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,121Document7 pagesUnited States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,12112348No ratings yet

- US6443044Document10 pagesUS6443044Sadia MoinNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- @et E7, 96? J. P. Yates: Filed March l2, 1965Document3 pages@et E7, 96? J. P. Yates: Filed March l2, 1965Ye PhoneNo ratings yet

- Us 5531545Document10 pagesUs 5531545Mark EdowaiNo ratings yet

- Iii Iihiii: United States Patent (19) 11 Patent Number: 5,732,772Document10 pagesIii Iihiii: United States Patent (19) 11 Patent Number: 5,732,772abodolkuhaaNo ratings yet

- July 7, 1936. H. F. Phillips 2,046,343: BY /0 %zedDocument3 pagesJuly 7, 1936. H. F. Phillips 2,046,343: BY /0 %zedfrank saruhanNo ratings yet

- United States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994Document6 pagesUnited States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994mohammadreza91No ratings yet

- Aug. 2, 1955 A. E. Atkinson 2,714,424: Ay 21 - Á-AsDocument3 pagesAug. 2, 1955 A. E. Atkinson 2,714,424: Ay 21 - Á-As12348No ratings yet

- Title - Wood Chipper ConstructionDocument4 pagesTitle - Wood Chipper Constructionمحمد عبدالدايمNo ratings yet

- Cementing Patent 2Document3 pagesCementing Patent 2Lara CitlalliNo ratings yet

- United States Patent (191: Yamamoto Et Al. (45) Date of Patent: Dec. 4, 1984Document11 pagesUnited States Patent (191: Yamamoto Et Al. (45) Date of Patent: Dec. 4, 1984Anonymous 6HADGUEXDNo ratings yet

- Patent DraftingDocument6 pagesPatent Draftingabhilasha singhNo ratings yet

- Us 4476409Document7 pagesUs 4476409Shankar PediredlaNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- Us4540334 PDFDocument9 pagesUs4540334 PDFJigar SutharNo ratings yet

- Nov. 24, 1953 I. Properz 2,659,948: Machine For The Continuous Casting of Metal RodsDocument3 pagesNov. 24, 1953 I. Properz 2,659,948: Machine For The Continuous Casting of Metal RodsmazaherramazaniNo ratings yet

- United States Patent 1111 3,595,128Document9 pagesUnited States Patent 1111 3,595,128rte678No ratings yet

- 915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWDocument15 pages915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWMetin MehelNo ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Tube Saport PDFDocument4 pagesTube Saport PDFjr110livecomNo ratings yet

- United States Patent (19) : B JornstadDocument4 pagesUnited States Patent (19) : B JornstadlfilippiniNo ratings yet

- Fig. Ib: Oct.8,1968 M - ,. - A. - KER - 3,404,545Document6 pagesFig. Ib: Oct.8,1968 M - ,. - A. - KER - 3,404,545Thiru MuruganNo ratings yet

- United States Patent (10) Patent No.: US 8,251,371 B2Document4 pagesUnited States Patent (10) Patent No.: US 8,251,371 B2shamsNo ratings yet

- US1908080Document3 pagesUS1908080reichanNo ratings yet

- US3448518Document4 pagesUS3448518liebersax8282No ratings yet

- US2091376 - Surface Test Indicator - Julius R (JR) Reich, 1937Document6 pagesUS2091376 - Surface Test Indicator - Julius R (JR) Reich, 1937devheadbotNo ratings yet

- Modern Blanking and Piercing DiesDocument58 pagesModern Blanking and Piercing DiesMustafa Sert100% (4)

- Umted States Patent (19) (11) Patent Number: 4 957 424: Mitchell Et A1. (45) Date of Patent: Sep. 18, 1990Document17 pagesUmted States Patent (19) (11) Patent Number: 4 957 424: Mitchell Et A1. (45) Date of Patent: Sep. 18, 1990adrianomc25No ratings yet

- Dumbbell Handle Bar Assembly and Method of Production Is PresentedDocument14 pagesDumbbell Handle Bar Assembly and Method of Production Is Presentedamitims3350No ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Document5 pages11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91No ratings yet

- 1944 Even Distribution of Concrete in PipesDocument4 pages1944 Even Distribution of Concrete in PipesAdeel FaisalNo ratings yet

- Hollow Lateral Extrusion Stuttgart Rudolf Ifu StuttgartDocument7 pagesHollow Lateral Extrusion Stuttgart Rudolf Ifu StuttgartjoaopedrosousaNo ratings yet

- Us4173933 PDFDocument10 pagesUs4173933 PDFRizki Fajar NovantoNo ratings yet

- 6ave. E: Sept. 13, 1966 F. Rompelen Etal 3,273,061Document4 pages6ave. E: Sept. 13, 1966 F. Rompelen Etal 3,273,061mohamed hemdanNo ratings yet

- United States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsDocument8 pagesUnited States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsUvxtalNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- Ep 0679137B1Document11 pagesEp 0679137B1daveNo ratings yet

- US2125697Document3 pagesUS2125697davarniyaalirezasepehrelectricNo ratings yet

- Dynamic KeysDocument46 pagesDynamic KeysRakeshNo ratings yet

- Pen HolderDocument8 pagesPen HolderRakeshNo ratings yet

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 pagesSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNo ratings yet

- Cooler Warm SeasonDocument13 pagesCooler Warm SeasonRakeshNo ratings yet

- Cigar Holding ApparatusDocument1 pageCigar Holding ApparatusRakeshNo ratings yet

- Rechargable Cigrett LighterDocument6 pagesRechargable Cigrett LighterRakeshNo ratings yet

- Comb FilterDocument5 pagesComb FilterRakeshNo ratings yet

- Froth Flotation Deinking Process For PaperDocument16 pagesFroth Flotation Deinking Process For PaperRakeshNo ratings yet

- Testing-Paper and Method of Making SameDocument2 pagesTesting-Paper and Method of Making SameRakeshNo ratings yet

- Ornamenting A PaperDocument2 pagesOrnamenting A PaperRakeshNo ratings yet

- Hybrid Topcoat Formulations For PaperDocument11 pagesHybrid Topcoat Formulations For PaperRakeshNo ratings yet

- Sol ShieldDocument9 pagesSol ShieldRakeshNo ratings yet

- Process For Surface Sizing PaperDocument7 pagesProcess For Surface Sizing PaperRakeshNo ratings yet

- Llo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterDocument3 pagesLlo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterRakeshNo ratings yet

- Buddhism VolDocument36 pagesBuddhism VolRakesh100% (1)

- KniDocument5 pagesKniRakeshNo ratings yet

- Toothbrush HolderDocument7 pagesToothbrush HolderRakeshNo ratings yet

- Err-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695Document3 pagesErr-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695RakeshNo ratings yet

- F PenDocument3 pagesF PenRakeshNo ratings yet

- MicDocument7 pagesMicRakeshNo ratings yet

- Sound Abs BarrDocument23 pagesSound Abs BarrRakeshNo ratings yet

- Sol StovDocument11 pagesSol StovRakeshNo ratings yet

- CalDocument48 pagesCalRakeshNo ratings yet

- PencilDocument1 pagePencilRakeshNo ratings yet

- Sol LampDocument6 pagesSol LampRakeshNo ratings yet

- Solar PlantDocument12 pagesSolar PlantRakeshNo ratings yet

- Solar PlantDocument12 pagesSolar PlantRakeshNo ratings yet

- Interconnected Solar CellsDocument13 pagesInterconnected Solar CellsRakeshNo ratings yet

- Solar HarnDocument11 pagesSolar HarnRakeshNo ratings yet

- A History of Our Ears by Peter SzendyDocument13 pagesA History of Our Ears by Peter Szendygraham_rapierNo ratings yet

- Hfe Cambridge Audio 540p 640p ServiceDocument16 pagesHfe Cambridge Audio 540p 640p ServiceRufusyNo ratings yet

- Rociador Tyco Esfr-25Document4 pagesRociador Tyco Esfr-25Anonymous cSvj5fXxwNo ratings yet

- Understanding Psychology 10Th Edition Morris Test Bank Full Chapter PDFDocument25 pagesUnderstanding Psychology 10Th Edition Morris Test Bank Full Chapter PDFdaniel.rodriguez971100% (11)

- Johnson MotorDocument161 pagesJohnson Motorchrisbock100% (2)

- Mnda 20170325 2Document3 pagesMnda 20170325 2icaretooNo ratings yet

- Benedicte Vidaillet - Workplace Envy (2008)Document200 pagesBenedicte Vidaillet - Workplace Envy (2008)mp3elv1428100% (1)

- Sukhar v. State of U.P. ( (1999) 9 SCC 507) - Section 6Document6 pagesSukhar v. State of U.P. ( (1999) 9 SCC 507) - Section 6Sahil DhingraNo ratings yet

- D&D 5 0 CB7 Uncharted Journeys OEF, 2022 12 08 CB70600Document294 pagesD&D 5 0 CB7 Uncharted Journeys OEF, 2022 12 08 CB70600Renan RossiNo ratings yet

- Garlock Gylon Gasketing Brochure GSK3 3Document12 pagesGarlock Gylon Gasketing Brochure GSK3 3gholi100% (1)

- 1.ching Vs SalinasDocument17 pages1.ching Vs SalinasChristian John Dela CruzNo ratings yet

- Python-Nmap - Nmap From PythonDocument7 pagesPython-Nmap - Nmap From PythonpedrodotnetNo ratings yet

- Ammonia Analyser User ManualDocument125 pagesAmmonia Analyser User ManualABVSAINo ratings yet

- Brand ManagementDocument17 pagesBrand ManagementLeo PaulNo ratings yet

- HG-G4 Module 6 RTPDocument9 pagesHG-G4 Module 6 RTPGirlie Mae BalondoNo ratings yet

- Testing Cellular Glass Insulation Block: Standard Test Methods ofDocument4 pagesTesting Cellular Glass Insulation Block: Standard Test Methods ofArun UdayabhanuNo ratings yet

- The Man Who Made PuppetsDocument14 pagesThe Man Who Made Puppetshung.nguyenquoc89No ratings yet

- 0A-Training Manual Preface Template-4pDocument4 pages0A-Training Manual Preface Template-4pa2227 jglNo ratings yet

- CapSense Proximity DesignDocument12 pagesCapSense Proximity Design99SUPERDOG99No ratings yet

- Form No 3CEDocument3 pagesForm No 3CE123vidyaNo ratings yet

- Surface Vehicle Recommended PracticeDocument3 pagesSurface Vehicle Recommended PracticeVIGNESH KUMARNo ratings yet

- Nanya Technology Corporation'S Opposition To Rambus' Motion To Compel Nanya Technology Corporation To Produce DocumentsDocument7 pagesNanya Technology Corporation'S Opposition To Rambus' Motion To Compel Nanya Technology Corporation To Produce Documentssabatino123No ratings yet

- Bass Petition at AcordaDocument74 pagesBass Petition at AcordaActivist Shorts ResearchNo ratings yet

- Clouding IP LLCDocument6 pagesClouding IP LLCPriorSmartNo ratings yet

- Be Thou My VisionDocument5 pagesBe Thou My VisionrinaselviaNo ratings yet

- (John Man) Alpha Beta How 26 Letters Shaped The W PDFDocument320 pages(John Man) Alpha Beta How 26 Letters Shaped The W PDFCII-ShikshaNo ratings yet

- AWS Partner Network (APN) Messaging and Branding GuideDocument56 pagesAWS Partner Network (APN) Messaging and Branding GuideArun Mohan100% (1)

- DeepWork CompanionDocument26 pagesDeepWork Companionjijiki44% (39)

- Astm D 2481Document4 pagesAstm D 2481dorbarelNo ratings yet

- HVDCDocument246 pagesHVDCmajdoubNo ratings yet