Professional Documents

Culture Documents

Material Schematic Caterpillar 950h 962h It62h Wheel Loader Hydraulic System

Uploaded by

Ganapati HegdeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Schematic Caterpillar 950h 962h It62h Wheel Loader Hydraulic System

Uploaded by

Ganapati HegdeCopyright:

Available Formats

C

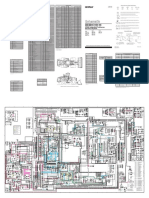

BASIC COMPONENT SYMBOLS

28

31

FLUID POWER SYMBOLS

MAIN AUX.

PUMP or MOTOR

CONTROL VALVES

SPRING

FLUID CONDITIONER

J

MM

49

TWO POSITION

ONE POSITION

VALVE PORTS

NN

BOTTOM VIEW

PRESSURE

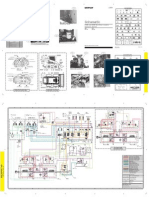

The Following components are not referenced on the Hydraulic System Schematic:

Case drain filter (31)

Hydraulic oil fluid sampling valve (SOS)

Hydraulic systems kidney loop filter (28)

Brake system accumulators (49)

950H, 962H and IT62H Wheel Loader

Hydraulic System

The Following components are not referenced on the Hydraulic System

Schematic:

- Pressure differential relief valve (A)

- Head end solenoid valve (ride control) (B)

- Signal relief valve (C)

- Tilt anti-drift valve (D)

- Rod end solenoid valve (ride control) (E)

- Ride control balance solenoid valve (F)

- Pilot pressure reducing valve (G)

- Lift cylinder head end pressure tap (H)

- Lift cylinder head end pressure sensor for Payload Control System and Autodig (J)

- Hydraulic lockout solenoid valve (K)

INFINITE POSITION

962H:

N4A1-UP

M3G1-UP

K6K1-UP

J6J1-UP

950H:

N1A1-UP

M1G1-UP

K5K1-UP

J5J1-UP

- Power train oil fluid sampling valve (A)

- Power train oil filter (B)

- Ecology drain for the hydraulic tank (C)

IT62H:

M5G1-UP

FLOW

12

VENTED

RETURN ABOVE FLUID LEVEL

PRESSURIZED

COMBINATION CONTROLS

SOLENOID

or MANUAL

SOLENOID

EE

MANUAL SHUTOFF

GENERAL MANUAL

EXTERNAL RETURN

SIMPLIFIED

CROSSING AND JOINING LINES

Item

Number

Description

Part

Number

Schematic

Location

HMU STEERING CIRCUIT

1

Hand Metering Unit

230-4176

A-4

Connector - Orifice

122-2340

B-3 , B-4

Cylinder Gp - Steer

163-0324

B-1

Valve Gp - Neutralizer

146-7571

B-3 , B-4

Valve Gp - Steer

142-4000

B-2

Valve Gp - Neutralizer

8J-1553

D-3

Valve Gp - Steer

124-8635

D-1

Cylinder Gp - Steer

163-0324

E-1

Valve Gp - Check

111-7775

D-3

10

Valve Gp - Pilot

147-1790

D-4

8J-6875

C-3

154-2883

E-2

11

Valve Gp - Shuttle

12

Screen Gp

MAIN SCHEMATIC

13

Pump Gp - Steering

241-9299

A-6

14

Pump Gp - Implement

254-4108

A-7

Cylinder - Tilt

242-4220

F-8

Cylinder - Tilt (Mid Lift)

247-0497

F-8

Cylinder - Tilt (High Lift)

245-7491

F-8

Cylinder - Tilt (Logger)

245-7487

F-8

20

Cylinder - Lift (LH)

242-4272

F-7

21

Cylinder - Lift (RH)

242-4271

F-7

22

Valve - Choke Check

276-9072

D-9

23

Valve Gp - Manual Lowering

112-1817

E-9

24

Accumulator - Pilot Oil

245-2975

F-5

25

Pump Gp - Fan

254-5146

B-8

26

Motor Gp - Fan

246-6152

D-6

27

Valve Gp - Cooler Bypass

244-1426

B-9

28

Filter Gp - Return Oil

244-1031

B-9

15

30

Manifold Gp - Fan & Brake Charge

242-1307

C-8

31

Filter Gp - Case Drain

249-2334

A-8

32

Valve Gp - Breaker Relief

220-0814

A-8

33

Tank Gp - Hydraulic Oil

237-2742

A-8

34

Valve Gp - Secondary Steer Diverter

141-2597

B-6

35

Pump Gp - Secondary Steer

Valve Gp - Control

(2 Function Standard)

275-8544

A-6

261-4171

D-9

Valve Gp - Control

(2 Function W/RC)

261-3682

D-9

Valve Gp - Control

(3 Function)

261-4172

D-9

Valve Gp - Control

(2 Function W/RC)

261-3683

D-9

Valve Gp - Control (Snow Removal)

(3 Function W/RC)

274-8055

D-9

41

Accumulator - Ride Control (RC)

245-2973

F-6

42

Valve Gp - Control & Relief

263-5832

C-7

43

Motor Gp - Reversing Fan

228-8527

C-6

36

BRAKE SYSTEM

25

Pump Gp - Fan

254-5146

F-2

30

Manifold Gp - Fan & Brake Charge

242-1307

F-2

45

Control Gp - Foot Brake

193-1448

F-3

46

Switch As - Foot Brake Limit

105-6117

F-3

47

Sensor Gp - Foot Brake

214-4863

F-3

48

Valve Gp - Foot Brake

215-3687

F-3

49

Accumulator - Service Brake

213-8773

F-2

50

Actuator As - Parking Brake

129-8090

F-1

51

Valve Gp - Parking Brake

106-1774

F-2

52

Switch As - Parking Brake Pressure

174-4312

F-1

53

Switch As - Brake Pressure

175-3244

F-3

LINES CROSSING

HYDRAULIC PUMPS

FIXED

DISPLACEMENT

HYDRAULIC AND PNEUMATIC CYLINDERS

SINGLE ACTING

LINES JOINING

VARIABLE DISPLACEMENT

NON-COMPENSATED

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

UNIDIRECTIONAL

BIDIRECTIONAL

BIDIRECTIONAL

DOUBLE ACTING

INTERNAL PASSAGEWAYS

HYDRAULIC MOTORS

INFINITE

POSITIONING

CROSS

FLOW

PARALLEL

FLOW

FLOW IN ONE

DIRECTION

TWO

POSITION

THREE

POSITION

FLOW ALLOWED IN

EITHER DIRECTION

Printed in U.S.A.

- Steering pump outlet pressure (EE)

- Brake system accumulator pressure (PP)

This photo shows a left rear view of the implement control valve (36). The following

components can be seen in this view:

Electrical Symbols Table

The Following components are not referenced on the Hydraulic

System Schematic:

XX

YY

Hydraulic Symbols (Electrical)

15

- Implement control valve supply pressure tap (GG)

- Transmission reverse clutch (A)

- Transmission forward clutch (B)

- Transmission fourth speed clutch (C)

- Transmission third speed clutch (D)

- Transmission second speed clutch (E)

- Transmission first speed clutch (F)

- Torque converter inlet pressure (G)

- Transmission lubrication pressure (H)

- Transmission pump outlet pressure (J)

- Torque converter outlet pressure (K)

- Steering cylinder rod end grease fittings (L)

- Rear axle oscillation bearing grease fittings (M)

The Following components are not referenced on the Hydraulic System Schematic:

COMMAND CONTROL STEERING

6

GAS CHARGED

INTERNAL

SUPPLY PRESSURE

COMPLETE

The following remote pressure taps are located inside the panel on the

frontside of the service center:

Component Locations

SPRING

2006 Caterpillar

All Rights Reserved

PEDAL

REMOTE SUPPLY PRESSURE

INTERNAL RETURN

SPRING LOADED

CC

DETENT

THERMAL

PUSH BUTTON

PP

COMMAND CONTROL STEERING

SERVO

SOLENOID and

PILOT or MANUAL

SOLENOID

and PILOT

MANUAL CONTROL SYMBOLS

RIGHT SIDE MACHINE VIEW

RETURN BELOW FLUID LEVEL

PILOT CONTROL SYMBOLS

BIDIRECTIONAL

RELEASED PRESSURE

F

LL

UNIDIRECTIONAL

FLUID STORAGE RESERVOIRS

ACCUMULATORS

KK

PILOT

CONTROLLED

ROTATING SHAFTS

TEMPERATURE

PUSH-PULL LEVER

SHUTTLE

SPRING

LOADED

BASIC

SYMBOL

MEASUREMENT

The service center is located on the right side of the machine below the cab.

The Following components are located in the service center:

- Pilot accumulator (24)

- Pilot supply pressure tap (GG)

P T

SHIFTED POSITION

P T

NORMAL POSITION

This photo shows a front view of the implement control valve (36) in the loader frame.

The following components can be seen in this view:

CHECK VALVES

AB

AB

24

GG

FOUR-WAY

THREE-WAY

CONTROL VALVES

ATTACHMENT

LINE RESTRICTION

VARIABLE and PRESSURE

COMPENSATED

TWO-WAY

THREE POSITION

PUMP: VARIABLE and

PRESSURE COMPENSATED

2-SECTION PUMP

HYDRAULIC

PNEUMATIC

ENERGY TRIANGLES

VALVES

VALVE ENVELOPES

PRESSURE

COMPENSATION

LINE RESTRICTION

(VARIABLE)

SPRING

(ADJUSTABLE)

VARIABILITY

LINE RESTRICTION

(FIXED)

RESTRICTION

- Tilt anti-drift valve (A)

- Signal relief valve (B)

- Signal duplication valve (C)

- Return to tank port (D)

- Supply port from pump (E)

- Signal line to pump (F)

- Tank line (G)

- Screen (H)

- Tilt back pilot solenoid valve (J)

- Tilt back pilot (K)

- Tilt cylinder rod end line relief (L)

- Ride control balance solenoid valve (M)

- Rod end solenoid valve (ride control) (N)

G

Transducer

(Fluid)

Transducer

(Gas / Air)

Pressure Switch

(Adjustable)

Pressure Switch

SERVICE CENTER

Generator

Electric Motor

Electrical Wire

Temperature Switch

Electrical Symbols (Electrical)

DD

Pressure

Symbol

CC

RR

Temperature

Symbol

FF

Wire Number Identification Codes

48

Electrical Schematic Example

Hydraulic Schematic Example

Current Standard

Current Standard

XX

Harness identification code

This example indicates

wire 135 in harness "AG".

YY

15

Wire Color

Wire Color

Wire Gauge

Previous Standard

Wire Color

Wire

- Hand metering unit (1)

- Foot service brake valve (48)

- Steer pump load sense test port (FF)

- Front sercive brake test port (QQ)

- Rear service brake test port (RR)

IMPLEMENT CONTROL VALVE

Circuit Number

Identification

325-PK

Circuit Identification

Number

The following components are located under the front of the cab.

- Implement pump pressure tap (CC)

- Implement pump load Sense pressure tap (DD)

Wire

325-AG135 PK-14

This drawing shows a right side view of the wheel loader. The following components

can be seen in this view:

Flow

Symbol

Level

Symbol

325-PK-14

B

Circuit Number

Identification

HMU & SERVICE BRAKES

Wire Gauge

(EXAMPLE VALVE)

TILT CYLINDER LINES GROUP

33

32

32

Tap Locations

Pressure, Sampling, and Sensor

Tap

Number

Description

33

Schematic

Location

26

43

45 46

20

47 48

21

15

25

15

AA

AA

Fan Pump Discharge Pressure

B-8

CC

Implement Pump Charge Pressure

E-9

DD

Implement Pump Load Sense Pressure

B-7

EE

Steer Pump Pressure

FF

Steer Pump Load Sense Pressure

GG

Pilot Supply Pressure

E-5

HH

Fan Pump Load Sense Pressure

B-8

KK

Command Control Right Steer Pilot Pressure

D-2

LL

Command Control Left Steer Pilot Pressure

D-2

MM

Command Control Steering Neutral Pilot Press

D-3

NN

Command Control Steering Supply Pressure

D-3

B-7

A-4 or C-4

27

26

31

43

49

45 46

27

47 48

HH

42

PP

Service Brake Pressure

F-3

Front Service Brake Pressure

F-4

RR

Rear Service Brake Pressure

F-4

34

25 30 13

50 51

34

25

13

50

XX

Tilt Cylinder Rod End Pressure

F-8

35

53

52

35

30

14

51 12 23

YY

Tilt Cylinder Head End Pressure

F-8

Hydraulic Oil Sampling Port

B-9

42

53

49 52 28 31

SOS

20

21

28

23

14

REAR VIEW

FAN AND BRAKE HYDRAULIC SYSTEM

5 7

10

22 24

5 7 10

11

36 41

11 12 22

24 36 41

Machine Component Locations

FRONT VIEW

30

The fan and brake pump (25) is located on the front gear train of the engine, on the

right side of the machine. The fan and brake pump provides oil flow for the electronic

demand fan systemand the brake hydraulic system. The outlet pressure tap (AA) is

located on the fan and brake pump.

Also located on the engine on the right side of the machine is the fan control and

brake accumulator charging valve (30). The fan pump load sense pressure tap (HH)

is located above the brake charging valve.

FAN & BRAKE PUMP

30 Page

10

SOS

RENR8879-01

RENR8879-01

June 2006

41

TILT

15

49

51

20

XX

21

LIFT

24

H

B4

TO TRANSMISSION CONTROL

HITCH

A2

45

50

52

A1

30

PS

NO

A4

53

TO BRAKE

LIGHTS

NC

C

25

PP

RR

48

RACK

BACK

RAISE

HEAD

END

GG

To Fan Motor

T

LS

RACK

HEAD

END

BACK

RAISE

HOLD

HOLD

HOLD

LOWER

ROD

END

DUMP

HYDRAULIC

TANK

To Case Drain

Manifold

REAR AXLE

APPLY

46

23

RELEASE

AUX

YY

CC

FRONT AXLE

47

F

BRAKE SYSTEM

12

a1

FLOAT

8

10

CROSSOVER

RELIEF

KK

LL

CYL PORT "B"

CYL PORT "A"

SHUTTLE VLV

LOWER/

DUMP

LS

D

LOAD SENSING

PUMP PORT

ROD

END

FLOAT

DIRECTIONAL SPOOL

DR

PILOT PORT"A"

1

)(

22

26

FOR REVERSING

FAN SEE ITEM 42 & 43.

LINE PATTERNS

36

Pressure Line

Pilot / Load Sensing Pressure

NN

Component Group

A1

TO REAR

BRAKES

A2

42

43

REVERSING FAN

BACK UP

RELIEF

PRESSURE

REDUCING

VALVE

Air Line

CALLOUTS

YY

Taps (Pressure, Sampling,Sensor) by letter

52

Components by number

a1

REGULATED

PRESS. PORT

TO PILOT VALVE

11

e1

c1

T

C

IMPLEMENT PUMP OUTPUT

IMPLEMENT PILOT SUPPLY OIL

30

FF

d1

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

30 Page, Color 2

MM

COMMAND CONTROL STEERING

AND 3PC IMPLEMENT ATTACHMENT

PRIMARY STEERING PUMP CIRCUIT

STEERING CIRCUIT

SECONDARY STEERING CIRCUIT

IMPLEMENT PUMP LOAD SENSING CIRCUIT

MAIN RELIEF VALVE LOAD SENSING CIRCUIT

SUPPLY LINE

DRAIN / RETURN LINE

LIFT CYLINDER CIRCUIT

TILT CYLINDER CIRCUIT

AUXILIARY CIRCUIT

PILOT CONTROL SPOOL

PILOT PORT "B"

CYL PORT "B"

BRAKE CHARGE VALVE AND FAN CONTROL CIRCUIT

BRAKE CONTROL CIRCUIT

27

LS

4

3

HH

DD

34

e1

28

AA

25

b1

PILOT PORT "A"

EE

SOS

Connection b1 only for Command Control Steering

B

CROSSOVER RELIEF

e1

d1

CYL PORT "A"

DIRECTIONAL SPOOL

PUMP PORT

14

1

29

MAKE-UP CHECKS

35

32

TANK PORT

Attachment

TO PARKING

BRAKE

PS

RENR8879-01

PILOT PORT"B"

b1

Drain / Return Lines

TO FRONT

BRAKES

MAKE UP

CHECK

31

BACK-UP RELIEF

c1

c1

HMU SUPPLY PORT

FF

HMU STEER AND 3PC IMPLEMENT

THIS SCHEMATIC IS FOR THE 950H AND 962H WHEEL LOADER

13

33

PART #: 241-0475 CHG 07 & BRAKE SYSTEM PART # 244-1398 CHG 00

Components are shown installed on a fully operable machine with the key and engine

off and transmission shifter in neutral.

d1

9

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations

You might also like

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- 950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringDocument2 pages950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringRodrigo Chacca100% (2)

- 938h Hyd SchematicDocument13 pages938h Hyd SchematicMahmud Maher80% (10)

- Diagrama Hidraulico 345 BDocument2 pagesDiagrama Hidraulico 345 BOmar Carrera50% (4)

- 330C Excavator Hydraulic System: Fluid Power SymbolsDocument2 pages330C Excavator Hydraulic System: Fluid Power SymbolsVictor Nunez100% (1)

- 330c Cap1 Up, Cgz1 UpDocument2 pages330c Cap1 Up, Cgz1 UpFabio Sierra50% (2)

- Hydraulic System Schematic 914-g PDFDocument2 pagesHydraulic System Schematic 914-g PDFpupoz100% (7)

- Cat 950g Electric DiagramDocument2 pagesCat 950g Electric DiagramLuis Eduardo Corzo Enriquez100% (3)

- D5M ElectricoDocument2 pagesD5M ElectricoHamilton MirandaNo ratings yet

- 966H 972H Hydraulic Schematic RENR8828Document2 pages966H 972H Hydraulic Schematic RENR8828Freddy Quispe100% (1)

- 330 BLDocument2 pages330 BLHenry Huayhua67% (9)

- Diagrama Hidraulico 962g CaterpillarDocument4 pagesDiagrama Hidraulico 962g CaterpillarRonald Gareca Rueda100% (1)

- CAT - 950G - SchematicDocument2 pagesCAT - 950G - Schematicssinokrot95% (20)

- 330D Hyd Schematic RENR9980Document2 pages330D Hyd Schematic RENR9980Energy Sun Biocar100% (5)

- A B C E D A B C E G F: Machine Harness Connector and Component LocationsDocument2 pagesA B C E D A B C E G F: Machine Harness Connector and Component LocationsJavier Omar R Portan100% (3)

- 345B Electrical SystemDocument2 pages345B Electrical Systemcbudkuley60% (5)

- 980g DiagramaDocument2 pages980g DiagramaLuis Emilio Santana Diaz100% (2)

- Transmission Pressures - Test and Adjust: NoticeDocument6 pagesTransmission Pressures - Test and Adjust: NoticeAbdelbagiNo ratings yet

- Plano Electrico 330L 9ml00410Document2 pagesPlano Electrico 330L 9ml00410Keiber Bastos100% (1)

- 345b Excavator Electrical System Schematic Used in Service Manual Renr1900 - Caterpillar Machinery Repair & TroubleshootingDocument5 pages345b Excavator Electrical System Schematic Used in Service Manual Renr1900 - Caterpillar Machinery Repair & TroubleshootingWilliams Burgos67% (3)

- Plano Hidraulico 330d ExcavadoraDocument2 pagesPlano Hidraulico 330d ExcavadoraIsmael Romero DeLarios50% (2)

- Electric Diagram System Caterpillar CLD 325CDocument10 pagesElectric Diagram System Caterpillar CLD 325CcmhNo ratings yet

- 320 C RAW ElectricDocument2 pages320 C RAW ElectricRudolph Prieto M100% (2)

- Esquema Cat 330Document2 pagesEsquema Cat 330Francisco Iniesta67% (6)

- Diagrama Electrico 315l CaterpillarDocument2 pagesDiagrama Electrico 315l CaterpillarEdwin Carrera75% (4)

- Transmission Hydraulic SystemDocument4 pagesTransmission Hydraulic SystemA Ramos Gaby100% (4)

- 322BL-2 - Schematic - Hydraulic SystemDocument2 pages322BL-2 - Schematic - Hydraulic SystemHelar W. Cutipa Machaca100% (3)

- 345c Excavator Electrical SchematicDocument16 pages345c Excavator Electrical SchematicJeremy Martin83% (6)

- Caterpillar D6R Tractor (Electronic Clutch Brake) Electrical System PDFDocument2 pagesCaterpillar D6R Tractor (Electronic Clutch Brake) Electrical System PDFdothao80% (10)

- 320C Hydraulic Excavator Electrical SchematicDocument2 pages320C Hydraulic Excavator Electrical Schematicluiscampos7792% (12)

- Cat 6cr 320b Diagrama ElectricoDocument12 pagesCat 6cr 320b Diagrama ElectricoHarlinton descalzi100% (1)

- 950H Wheel Loader Hydraulic SystemDocument2 pages950H Wheel Loader Hydraulic Systemwtn2013100% (16)

- Renr8879renr8879-04 Sis PDFDocument2 pagesRenr8879renr8879-04 Sis PDFMAQUINARIAPESADA100% (1)

- 950H, 962H, and IT62H Wheel Loader Hydraulic System: Command Control SteeringDocument2 pages950H, 962H, and IT62H Wheel Loader Hydraulic System: Command Control SteeringPacoNo ratings yet

- 16m Hydraulic r9hDocument11 pages16m Hydraulic r9hqwureyquweryNo ratings yet

- Plano Hidrulico de 272cDocument4 pagesPlano Hidrulico de 272cMaría Felisa López QuintoNo ratings yet

- Diagrama Hidraulico 420E CATERPILLARDocument4 pagesDiagrama Hidraulico 420E CATERPILLARjulio cesar100% (6)

- 994F HydrDocument4 pages994F HydrF Diaz BarreraNo ratings yet

- Cat 14h Sistema HidraulicoDocument2 pagesCat 14h Sistema HidraulicoJuan Pablo Barron Marin100% (3)

- Planos Hidráulicos Moto Cat 140MDocument4 pagesPlanos Hidráulicos Moto Cat 140Mjuafe100% (2)

- 420E Sist HidrDocument4 pages420E Sist HidrRodolfo BaccagliniNo ratings yet

- Plano Hidraulico 16m CatDocument2 pagesPlano Hidraulico 16m CatLuis Ramos100% (2)

- Retroexcavadora 416D B2DDocument4 pagesRetroexcavadora 416D B2Denrique_13_14100% (7)

- 416 eDocument2 pages416 ehfgskrNo ratings yet

- Renr8838renr8838 SisDocument2 pagesRenr8838renr8838 SisYvan Vidal Calapuja MachacaNo ratings yet

- Renr7387renr7387-05 SisDocument4 pagesRenr7387renr7387-05 SisJorgeNo ratings yet

- 248B SCL HidraulicDocument2 pages248B SCL Hidraulicalex ro100% (2)

- Component Locations: 966G and 972G Wheel Loader Hydraulic SystemDocument4 pagesComponent Locations: 966G and 972G Wheel Loader Hydraulic SystemAndrei Bleoju100% (3)

- Backhoe 420E y 430E Interactivo - SISDocument15 pagesBackhoe 420E y 430E Interactivo - SISIvanZavaleta100% (10)

- Hydraulic System 950H, 962H, and IT62H Wheel Loader: Front of Frame Hand Metering UnitDocument2 pagesHydraulic System 950H, 962H, and IT62H Wheel Loader: Front of Frame Hand Metering UnitMarcelino Huamani100% (1)

- Plano de Implementos d11tDocument2 pagesPlano de Implementos d11talexander_1985No ratings yet

- 784C Tractor and 785C Off-Highway Truck Hydraulic System: 784C: 2PZ1-105 785C: 1HW1-Up APX1-450 785C (HAA) : 5AZ1-399Document2 pages784C Tractor and 785C Off-Highway Truck Hydraulic System: 784C: 2PZ1-105 785C: 1HW1-Up APX1-450 785C (HAA) : 5AZ1-399Jorge SolisNo ratings yet

- Hydraulic System 420E, 430E PDFDocument23 pagesHydraulic System 420E, 430E PDFDavid100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsFrom EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsNo ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- EatonDocument143 pagesEatonBrayandPach100% (1)

- FP Diesel Caterpillar Engines - Digipubz PDFDocument578 pagesFP Diesel Caterpillar Engines - Digipubz PDFStar SealNo ratings yet

- Jumping Jack Mikasa MT-76D Parts ManualDocument11 pagesJumping Jack Mikasa MT-76D Parts ManualGanapati HegdeNo ratings yet

- Automatict RansmissionDocument34 pagesAutomatict RansmissionGanapati HegdeNo ratings yet

- OptimizedSystemforVehicleFleet MAintenance PAPERDocument9 pagesOptimizedSystemforVehicleFleet MAintenance PAPERGanapati HegdeNo ratings yet

- Parker F12 Series Motr Parts CatalogueDocument14 pagesParker F12 Series Motr Parts CatalogueGanapati HegdeNo ratings yet

- Tower Crane Handbook PDFDocument131 pagesTower Crane Handbook PDFGanapati Hegde100% (2)

- 4TNV88 Engine Parts Manual 917329Document97 pages4TNV88 Engine Parts Manual 917329Ganapati HegdeNo ratings yet

- GMK Features and Benefits ImperialDocument24 pagesGMK Features and Benefits ImperialGanapati HegdeNo ratings yet

- Dalal Street Investment Journal - August 07 2018 PDFDocument84 pagesDalal Street Investment Journal - August 07 2018 PDFGanapati HegdeNo ratings yet

- Manual Operation Maintenance Komatsu pc300lc pc350lc Hydraulic Excavators PDFDocument343 pagesManual Operation Maintenance Komatsu pc300lc pc350lc Hydraulic Excavators PDFGanapati Hegde100% (1)

- Eaton Illustrated Parts ListDocument24 pagesEaton Illustrated Parts ListGanapati HegdeNo ratings yet

- Bobcat Parts List PDFDocument3,533 pagesBobcat Parts List PDFGanapati Hegde40% (5)

- Donaldson Filter Product Specification GuideDocument319 pagesDonaldson Filter Product Specification GuidecivodulNo ratings yet

- Endress Product LineDocument72 pagesEndress Product LineGanapati HegdeNo ratings yet

- 320D & DL Parts ManualDocument1,023 pages320D & DL Parts ManualKeron Trotz95% (64)