Professional Documents

Culture Documents

Adp-Me-Spe-0576-000 C5 PDF

Uploaded by

diaccessltd_171729610 ratings0% found this document useful (0 votes)

58 views51 pagesOriginal Title

ADP-ME-SPE-0576-000 C5.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

58 views51 pagesAdp-Me-Spe-0576-000 C5 PDF

Uploaded by

diaccessltd_17172961Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 51

[BP ANDREW AREA DEVELOPMENT

‘TOPSIDE DETAILED DESIGN

ANDREW AREA DEVELOPMENT

DETAILED DESIGN

SPECIFICATION FOR COATING OF

STRUCTURAL STEEL, PIPING AND VESSELS

Document No: 37AND-F041G7001-Y-SD-0011-000

‘BP Document No: ADP-ME-SPE 0576-000

Wooo anoUP ENaWEERNG (NORTH

Beato ‘a Conant 7000

‘veoumweoiecr omer

2}e]=}e}=] fff

9] #/ 8] 2] 9/9) a} ala

WOOD GROUP ENGINEERING LTD

‘BP Andrew rea Development TOPSIDES DETAILED DESIGN, Page 20 52

Tie: Speciation for Coating of Stuctua Sea, Piping and Vessels

Contract No, 878ND Job No: Fos1G7001

‘Document No: 37AND-F041G700"-Y:S0-0011-000 Rev CS

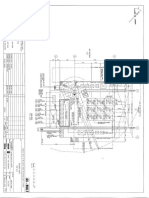

REVISION RECORD

Current revisions ar dented onthe relevant page(s) by a revision wiangle

REV. | DATE REVISION DETAILS

| osioze0 MENT

10

Be) 130420 ‘APPROVED FOR DESIGN

10

er | vains20 REISSUED APPROVED FOR DESIGN

10

G1 | eacere0 REASSUED APPROVED FOR DESIGN

12 | amended to reference painting of stainless steels under PFPn section

72 an Appa |

2 | 1ar0220 EISSUED APPROVED FOR CONSTRUCTION

13

Notechnical changes,

3 | cana REASSUED APPROVED FOR CONSTRUCTION

13 | section 1.1: Added reference to NSSPU specs, Added "HOLD" to BP

ETP and NSSPU references

Section 5, Table §: Removed System B14, Added System Bt.

Sution 7.2: Removed section related to PFP responsi, updated

section numbering and romoved related Appendix 2 rte

‘Appendix 1: Removed System B14. Addod Systom Bt,

ca | aanans WUCTION

Seation 1.1: Add references to NSSPU specs (Removed hod

Deleted GP relerences.

Section 1.5: final paragraph added fr cary,

Seation 1.7 abbreviation lst madi to rele current document.

Seation 2.6: BS 5488 removed specication superseded wih ISO

yo

‘Section 4: Amended to reflect requirements of NSSPU 06-60. Sections

4.2.4.5 remaved,

WOOD GROUP ENGINEERING LTD

'BP Andrew Area Development: TOPSIDES DETAILED DESIGN Page Sot 52

Tie: Specteation for Coating of Stuctural Stoo, Piping and Vessels.

Contract No. 37AND

sob No: FourG700%

Document No: STANO-F0616700'-¥:S0-0011-000 Rev C5

‘Seaton 5. Table 6.0 and associated text deleted, Reference to appendix

1 added to reduce potential contusion.

‘Sections: section 6.2 amended to incorporate the folloing text”

Blasting media for use on

oss steel shall be free from chordes,

‘Secton7.1: Last paragraph added for laity.”

‘Section 7.2: Reinistatatement of section to cover PFP and paint

supplier.

‘Appendix. 1: table fom NSSPU GP 06-60 added Pant system

‘nomenclature amended to System B-14a NS.1.c

0s | arias

{SUED APPROVED FOR CONSTRUCTION

‘Systems amended to provide manufacturers recommended coatings

‘and thicknesses In table 1 of append A,

WOOO GROUP ENGINEERING LTD

‘BP Andrew Area Development TOPSIDES DETAILED DESIGN Page do 52

Tite: Speciation for Coating of Sructural Stee, Piping and Vessels.

CConract No. S7AND Job No: Fou 700%

[Document No: 37AND-F041G700'-Y:0-0011-000 Rev C5

‘SPECIFICATION FOR COATING OF STRUCTURAL STEEL, PIPING & VESSELS.

Table of Content

1.0 INTRODUCTION...

1.4 Scope

12 Safety

1.3 Equipment

1.4 Personnel

1.5 Hazardous Matorals/Substances

1.6 Definitions,

1.7 Abbreviations. Se "

2.0 APPLICABLE CODES AND STANDARDS.

2.1 Revisions 4 ts

22 Confit of Information —— 13

23 Referenced Documents i 13

24 Codes and Standard nnn 13

25 American Standards.cx.oonn soo 18

26 British Standards. 13

2.7 Intemational Organization for Standardization, soos 4

28 _Nomegian Standards. —— 15

29° Others. a 18

3.0. GENERAL REQUIREMENTS. 16

3.1 Procedures . 16

8.2 Qualification of CONTRACTORS and Personnel. 16

33 Responsibilities. sen nae

WOOO GROUP ENGINEERING LTD

‘BP Andrew ra Dovolopnent TOPSIDES DETAILED DESIGN, Page Sot 52

“Tie: Specification for Coating of Structural Stoo, Piping and Vessels

(Contract No. 37AND Job No: Foe1e7001

‘Document No: 37AND-F041G700"-Y-S0-0011.000 Rev CS

40° MATERIALS,

44 General . 18

42. Materials Control and Usage =)

43. Spectc Compositional and Matrial Requirements see 18

44 MANUFACTURER’: Representative = 18

5.0 COATING SYSTEMS.

51 Specie Cotng S168 9

52 Fished Cong Cotours 10

53. Stencing and Colour locks, so 18

6.0 SURFACE PREPARATION, 21

61 onl nn | 2

62 Blast Cleaning | a

63. Adtonal Preparation. sn 88

7.0 COATING APPLICATION.

7.4 General — 23

7.2. Passive Fie Protection - 23

7.3 Coating Thickness son 24

7A Wield Areas, 24

75 Flanges and VANES sons 85

7.6 Protection of Applied Coatings 28

80 COATING REPAIRS ~ a7

8.1 Gonora se BT

82 Damage to Coatings During Fabrication... ee BF

8.3 Insufficient Thickness. : - ar

WOOD GROUP ENGINEERING LTD

{8P Anren ra Dovelopment TOPSIDES DETAILED DESIGN. Page ot 82

Tie: Speciation for Coating of Stuctura Stoo, Piping and Vessels

(contrat No. 37AND ob No: Foare7001

Becument No: 37AND-F0416700"-Y-S0-0011.000 Rev CS

9.0 INSPECTION AND TESTING OF COATINGS 28

8.1 General 28

92 Environmental Condtons. er]

8.3 Abrasive inspection nn 28

84 Inspection of Prepared Suraces — 23

95 Visual Inspection of Suraces ss 29

96 Sat Test svn 29

97 Coating Thickness Measurement 2

9.8 Holiday Detection nn. —

8.9 Adhesion Tests 30

8.10 Additional Tests. ss 4

100 QUALITY ASSURANCE & QUALITY CONTRO

101 Gener

102 Nanutacur and Tet Quay Pan

103. Spec Process Procodes

104 Quay Recad, oe :

185. Fentbepesion =n .

108. Vsieson :

11.0 DOCUMENTATION & CERTIFICATION.

11.1 Certication Requirements sone

11.2 Documentation with Delivery 95,

11.8 Manufacturing Record Book 38

APPENDIX 1 ~ SPECIFIC COATING SYSTEMS FOR OFFSHORE (NEW CONSTRUCTION)

WOOD GROUP ENGINEERING LTD

BP Androw Area Dovelopmt: TOPSIDES DETAILED DESIGN Page 7 of 52

“Tile: Spectcation or Coating of Sructual See, Pping and Vessels

Contact No. S7AND Job No:Fou@700%

Document No: S7AND-FO41G7001-¥-S0-0011-000 Rev CS

"APPENDIX 2— FINISHED COATING COLOURS

[APPENDIX 3- INSPECTION AND TESTING REQUIREMENTS

WOOD GROUP ENGINEERING ETD

{BP Andrew ra Development TOPSIDES DETAILED DESIGN Page 8 of 2

Tie: Specification or Coating of Srucual Sea, Peng and Vessels,

Contract No. 37AND Job No: Fost 7001

Document No: 37AND-F041G700"-¥:S0-001 1-000 Rev CS

10 INTRODUCTION

14 Scope:

“This spectication when read in conjunction withthe referonoed standards, specication,

Cther listed documents and relevant AFC drawings, defines the minimum technical

‘requirements forthe coating of structural ste piping and vessels. Pumps associated with

the various piping systems shall be coated in accordance with this specication

Instruments and electrical equipment may be supplied with the Manufacturers own pint

specication, provided that the Manufacturer can domonstate the sultebilly of the

proposed coating system for the design conditions in an offshore environment, and for @

minimum design life of 18 years. Manufacturers paint specication shall be submited for

COMPANY review and approval prior to coating application,

+ NSSPU GP 05-60 (Issue 1, December 2007) ~ Painting of Metal Surfaces for

Offshore Facilites and Onshore Plant

‘+ NSSPU GPO6.60-1 Paining of Motal Suraces for Offshore Facies and

‘Onshore Plant." December 2008)

‘The CONTRACTOR shall be responsible forthe application and testing ofthe coating() in

accordance with this speciation

12 Satety

Safety is paramount. All risks to personnel and the environment resulting fon the Project

‘hall bo As Low As Reasonably Practical (LARP).

CONTRACTOR shall subject all procedures to Risk Assessments, HAZOP and HAZID

analysis as appropriat, as an integral pat of the review process prior t procedure

approval and the mobilisation of resources to perform the work, COMPANY shall be

Invited to attend all such reviews. CONTRACTOR shal sue a Risk Aesaserrent, HAZOP

‘or HAZID Report and ensure that all recommendations are implemented and detaled in

revised procedures prior tothe work commencing.

rojb briefings or Too! box talks shall be undertaken, Including al personnel invoived in

the activity, prior to an operation commencing and at reguar intervals througheut execution

ofthe procedure. As a minimum they shall be undertaken at shit changes, A record shall

bbe maintained of al such briefing, including attendees.

‘BP Andrew Area Development TOPSIDES DETAILED DESIGN Page 9ot 52

Tie: Speciation or Coating of Stuctual Stool, Png and Vessel.

(Contract No. 37AND ob No: Fo4sG700%

Document No: S7AND-FO61G700"-¥.S0-0011-000 Rev C5

‘CONTRACTOR shall provide support to COMPANY in responding to actions delegated

{tom other safety assessments and reviews.

1.3 Equipment

‘AL temporary equipment provided to comple

appropriate legislative and COMPANY requirements

the work shall fully comply with al

Pressured hoses shall have test certificates stating the maximum safe working pressure

tobe used, They shall also be inspected once a wok to ensure ne damage has occurred

to them and a log of these ealety inepections kept The “doad man’ handle shal only be

‘manually held in poston bythe operator. Al pressurised hoses shall have the appropriate

test certificate available for verification purposes,

1.4 Personnel

‘Al personnel engaged on the project shall be experianced, qualified, competent and

appropriately supervised inorder to discharge the dutis delegated ina safe and efficient

1.5 Hazardous Materils/Substances

‘Al materials or substances classified as hazardous, or potentially hazerdous, shall

Undergo an HSE assessment and be handled, used and discharged in accordance with

legislative and COMPANY requirements. Appropriate safety precautors, including

contingency, emergency and fist ald, procedures and PPE to be worn by personnel using

‘any such materials shall be detalled in the Project Spectic Procedure, The PPE

appropriate forthe activities to be undertaken shal be addressed in each Tool Box Talk

Unused materials or substances and those collected for disposal, racyeling or re-use shall

be packaged appropriately and accompaniod by all relevant and necessary documentation,

CONTRACTOR shall take all appropriate measures to remove the uso of hazardous

‘materaisfsubstances in the work area(s) whore reasonably practicable.

Maacieas shall a taken to enue areata vetiation and contal the qualty af breathing

ir uring coating operations,

‘Tho CONTRACTOR shall pay due regard to local and statutory regulations in respect to

personnel safety. CONTRACTOR'S attention is drawn to the potential fie and explosion

hazards which may exist due to the presence of solvent vapours or abome dust, and to

‘BP Andrew Area Development TOPSIDES DETAILED DESIGN Page 100152

Tie: Specteation for Coating f Stucural See, Pigng and Vesses.

Contract No, AND sob No Fosta700r

Document No: S7AND-FO41G700'-Y-S0-0011-000 Rev C5

‘the potential dangers to personnel in the vicinity of equipment operating at high nozzle

pressure and using materials which may be ether toxe or tant tothe ekn, eyes or lungs,

‘The MANUFACTURER's safety data shoots shall be obtained and shall be made

conruet aval ao wr acs.

\hen cain ssomls raat te flog decent shale prowied

+ Chama rane ste an chen

+ OAR mba sco othe cur egos:

+ VoCcomtentingt:

+ Lown epr corte lea weg < 700;

+ Conan tharos stance

+ syeleton tharos homal dado comport

+ combust

«| Sell ning preaton ae pamela,

MANUFACTURER'S instructions on handling and storage shall be folowed. Flammable

products are to be stored in accordance with the curent Flammable Liquids Regulations,

‘way from combustible materials and all precautions taken to avoid creating ate hazard,

[MANUFACTURER and all patos responsible for supply and application of insulation and

Pint shall be consulted it insulation isto cover paint coating regarding physical sutabiy

‘and chemical compatibility between the paint and coating prior to config selection

Definitions

COMPANY BBP Exploration Oporating Company Lid or any of is

subsilarles or representative agents,

CONTRACTOR ‘The Parly contracted by the COMFANY to be

responsible fo the coating actos,

shat Indicates mandatory requirements

May Verbal form used to indicate a course of acton

permissible within th itso he standard

1 Andrw Avon Dovelopmen: TOPSIDES DETAILED DESIGN Page 11 of 52

“Tile: Spectcaton or Coating of Structural Stel, Pping and Vessel,

‘Contact No. S7AND Job No: Foa1a7001

Document No: S7AND-FO41G700"-Y.S0-0011-000 Rev C5

can Verbal form used for statements of possibilty and

capabilly, whether mati, physical or ces

Approval Consent given in wring, on behalf ofthe COMPANY

in advance of an event, by a person wir appropiate

authority. Approval by the COMPANY doos not

relieve the CONTRACTOR from any of is contractual

joblgations nor fram having to make goed any part of

COMPANY BP Exploration Operating COMPANY

Lid or any ofits subsiiavis or represenative agents.

Manufacturer ‘A. supplier proving goods or equipment to

COMPANY.

1.7 Abbreviations

ALARP As Lowas Reasonably Practcable

arc = Approved for Construction

8s = Bish Standard

cs = Carbon Stet

Fr = Dry Film Thickness

en = European Nom

cs = Group instruction for Supply

op = Group Practice

iso = Intemational Organization for Standardization

ut = Lowest astronemical ido

ue = Low Temperature Cure

NACE = National Assocation of Corosion Engineers

NOFT = Neminal Dry Film Thickness

NORSOK = Norsk Sokkels Konkuransepession

NSSPU = Neth Sea Strategic Performance Unt

oR = Occupational Air Requirements

BP Ancow Arca Development: TOPSIDES DETAILED DESIGN.

“il: Speciation for Coating of Stucturl Stel, Pping and Vessel

Contact No, S7AND

Document No: S7AND -FO#1G7001-Y-SD-0011-000 Rev GS

Page 120852

Job No F416 7001

00

PrP

PP

on

oc

RP

sP

ss

voo

‘Outer Diameter

Passive Fire Protection

Personne Potton

Quality Assurance

Qualty Control

Recommended Practice

Standard Practice

Stanioss Sto!

Volatile Organic Component

'P Andrew Aven Development: TOPSIDES DETAILED DESIGN, Page 190 52

‘Tile: Speciation or Coating of Stucural Ste, Piping and Vessel

‘Contact No, S7AND 4b No: F041 7001

Document No: STAND -FO81G7001-¥-S0:0011.000 Rev CS

20 APPLICABLE CODES AND STANDARDS

24 Revisions

‘The latest ives forthe relevant standards, codes, statutory regulations and specications

referenced herein shall bo applid to the work unless stated otherwise,

22 Conflict of Information

In the event of any conf, inconsistency or ambiguity between the contact decuments, this

‘specication or any other specication and associated data sheets, or with any of the

applicable codes, standards and regulations the CONTRACTOR shal immediately inform the

‘COMPANY in witing and receive wren clarification fram the COMPANY before proceeding

with the werk,

23 Referenced Documents,

It is the responsibilty of the CONTRACTOR to ensure that he has receted fram the

COMPANY all specications, ete which are referenced within applicable specications to

nee ered a omy ot mpc of wor tbe pred rn

‘COMPANY.

24 Codes and Standards

‘The CONTRACTOR is responsible for the quality of the work and comptance with the

requirements ofthe appbcabe International Codes, Statutory Regulations and Spectcations

as listed. The folowing Codes, Standards and Speciicatione with thelr latest published

amendments shall ply

25. Ameriean Standards

NACE RP0287 Standard Recommended Practice ~ Field Measurement of Surfaco

Profle of Abrasive Blast Glsaned Stee! Surfaces Using a Roplca Test

NACE P0188 —_Discontinuty Testing of New Protective Coatings On Conductive

Substrates

26 Biitsh Standards

BS 3900 Methods of Test for Pints

Bs 5378 Satety Signs & Colours

Bs 2042 Whiting Hygrometer

‘BP Arrow ra Development TOPSIDES DETAILED DESIGN Page 14052

Tie: Specification for Coating of Stucural Stel, Piping and Vessel

(Contract No, 37AND ob No: F04x67001

‘Document No: STANO-FO41G7001-¥-S0.001 1-000 Rev C5

185 4800 Painting Colours for Bulaing Purposes

Bs 729 Speciation for hot aip galvanized coatings on in and stee!

aricles

2.7 International Organization for Standardization

150 1461 Hot dp galvanised coatings on fabricated ion and stel ait.

150 4824 Points and Varnishes: Pul-off Tes for Adhesion

Iso as01-1 Preparation of Stee! Substrates before Applicaton et Paints and

Flatod Products ~ Visual Assessment of Surface Cleaniness;

180 8800-3 Preparation of Ste! Substrates before Apoliaton ef Paints and

Related Products. Tests forthe Assessment of Surface Cleanliness,

Part 8: Assessment of Dust on Steel Surfaces Prepared for Painting

(Prossure-Sensive Tape Method)

10 8502-6 Preparation of Stee! Substrates before Application cf Paints and

Related Products. Tests forthe Assossment Of Surface Cleaniiness

~ Patt 6: Extraction of Sluble Contaminants for Analysis, The Brosle

Method

150 8502-9 Preparation of Steo! Substrates before Application cf Paints and

Related Products. Tass fr the Assessment of Surtace Cleaniness

~ Part 9: Field Method for the Conductometic Determination of

‘Water Soluble Sats

180.9001 (Qualty Managoment Systems ~ Requirements

180 11126 tion of steel substrates before application of paints and

related products ~ Speoiication for non-metalle bast cleaning

abrasives.

180 12044 Paints & Varnishes, Corrosion protection of steel structures by

protective paint systoms.

180 19840, Paints and Varnishes - Corrosion Protection of Stoel Sructures by

Protective Pint Systems - Measurement of, and Accoplance Crt

for, the Thickness of Dry Fis on Rough Surfaces

'BP Ancrow Area Develpment TOPSIDES DETAILED DESIGN, Page 15.152

Tie: Spectication for Coating of Stuctural Stee, Piping and Vessels

Contract No. S7AND Job Na Foeta7001

[Document No: a7AND-F041G700"-Y-S0-0011-000 Rew C5

28 Norwegian Standards

NORSOKW-001 Materials Selection

NORSOK™M-501 Surface Preparation and Protective Coating

29° Others

EN 10206 Metalic Produts~ Type a Inspection Documents

SS7AND-F04167001-V-S0.0009-000

Material Specification for Freproofing Equipment, Pipework, Riser

Pipework, Vessels and Structural Stelwork

'P Andrew Area Development: TOPSIDES DETALED DESIGN, Page 160 52

Tite: Speciation for Coating of Stucual Stes, Peng and Vessels,

Contract No, 37AND ob No: Foa1G7001

[Document No: 37AND-F0416700"-Y:S0-0011-000 Rev CS

30. GENERAL REQUIREMENTS

31 Procedures

Prior tothe! commencement of the work, CONTRACTOR'S fully comprehensive coating

procedures shall bo submited to the COMPANY for approval. The approved procedures

shall bo folowas for al the work for which the CONTRACTOR is responsible.

‘The detalled procedures submitted for approval shall include, but not necessarly be limited

to, the flowing

‘© Method and equipment for surface preparation, consumable and other parameters;

‘= Coating ning application and curing methed and equipment;

+ Coating / lining materials data (MANUFACTURER'S product data sheets and

application notes)

+ Ranges of temperature and relative humidty contol methods for surface preparation

‘and coating ning work;

+ Tne ee ac proprio ncn and eubeeqer con rings

+ be tin nd ian ta yn ess

+ Processor est danse costs rings

+ Matos trees an testing ing ccna ite:

+ Frege of en. hapecon and tts

+ surtcerpaatn an cots ns en shoots

‘All coating procedures shall be qualified in accordance withthe requirements of Ciause

10.3 of NORSOK M-501. However the tests, frequency and acceptance aiteria of tis

Specification shall apply.

3.2 Qualification of CONTRACTORS and Personnel

CONTRACTOR shall provide to COMPANY historical data in organising, planning and

‘exocution of work wth similar size and complexity.

[BP Anew Area Development TOPSIDES DETAILED DESIGN. Page 170 52

“Tie: Speciation for Coating af Stuctural Stel, Piping and Vessels.

‘Contact No, 37AND 4 No: 0417001

Document No: STAND FO81G7001-Y-S0:0011.000 Rev C5

Paint operators qualifications along with qualification of suporisors, foremen and QC)

Personnel in accordance with Clause 102 of NORSOK NASO1 shall be provided for

COMPANY's review,

33 Responsibilities

‘The CONTRACTOR shal be responsible for the procurement, application and guarantoed

time forall coatings and itis his responsibilty to ensure that they comply with tis

‘Spectcation and MANUFACTURER'S recommendations and data shests

“The proposed coating system shall be sulable for the design conditions nan offshore

environment and for a minimum design We of 15 years.

During the coating / ining work the CONTRACTOR shal be responsible for he protection

fall structure and equipment surfaces trom mechanical damage or paint over spray and

oppings.

Examples of surfaces to be protected from damage are vale spindes, glass facod

ot ure gauges, delicate machinery, electrical cables, stainless stool, gratings, name

plates, instrument panels, sacifclal anodes, machined washer recesses of flanges and

‘sealing surfaces of tanges.

Bearing areas for ruts on flange faces and flange sealing surfacas shal remain uncoated

te ensure 100% metal to metal contact on assembly of flanges.

‘Atul reporting / recording system shall be maintained by the CONTRACTOR who shall

‘comprehensively log the following data: air and steol tomporatures, relative humidity,

painting progress, fm thickness measured, batch no and any other information pertinent 1

the work

‘BP Andrew Area Development: TOPSIDES DETAILED DESIGN, Pago 18.0852

Tie: Spectcation for Coating of Stuctura Sto0,Plpng and Vessels

Consract No. STAND, 4b No: F041 7001

Document No: STAND FO81G7001-Y-SD-0011-000 Rev C5

40° MATERIALS

41 Ga

Accoptance of the coating systems shall be subjected to satisfactory resus from the

‘qualification tot

42

‘The CONTRACTOA shal obtain from COMPANY approved manufacturers, all abrasives,

coating and thinners o cary out the work.

‘The materials shall bo delivered tothe site, or CONTRACTOR's premises, eddressed for

th ob, in the vignal containers with labels Intact andthe seals unbroken

Materials that have lered, golled or otherwise deteriorated during storage shall not be

Used. Thixotropic materials that must be stired to obtain normal consistency are

‘acceptable,

1 coating material requires the atkition of a catalyst, the pot life under application

Cortions shal te clary stated onthe label and shall not be exceeded irrespective ofthe

‘apparent conlton of the material, When the pote limit is reached, the spray pot shall be

‘emptied, material ciscarded, the equipment cleaned and new material catalysed

4.3 Specific Compositional and Material Requirements

Epoxy coatings shall be two-pack products formulated to provide the specfed tlm build

without sagging or running. They shall contain polyamide or amine adduct curing agents,

although other curing agents may be acceptable for low temperature use subject to specific

COMPANY approval. Pigments shall be solectod to provide maximum environmental

resistance.

4.4 MANUFACTURER'S Reprosentative

‘Tho MANUFACTURER shall Keep avaliable a technical representative for provision of

‘advice, instruction and assistance to CONTRACTOR. The technical representative shal

be fully familar wih requiromants ofthis Spectication and with application charactristios|

of the coating ning systam under consideration

'BP Andrew Area Dovelopment: TOPSIDES DETAILED DESIGN. Page 190 62

“ile: Speciation for Coating of Stuctural Steel, Pping and Vessels

Contact No, STAND Job No:F04x67001,

Document No: STAND FO81G7001-Y-S0:0011-000 Rev CS

50 COATING SYSTEMS:

5.1 Specitic Coating Systems

‘Tho spectc coating systems relating to the generic systems In Table 6:0 are contained in

Appendix 1

5.2 Finished Coating Colours.

Finish colour schedules forthe folowing tame are det

fone

Blocks shall be painted in a prominent and easily readable poston as directed by

COMPANY and shall be not lass than 600 mm (24 In) long and 600 mm 24 in) deep

Stonciling for corrosive contents shall be in yellow gloss corresponding to OBES (AS

44800} and for toxic contents in tangerine gloss corresponding to OBES (BS 4800),

Pipework contents shall be banded at intervals tobe agreed with COMPANY.

542 Stenilediters

4, Stencil eters shal be nots than 38 mm (1 in), but preferably 50 mm (2 igh,

rnd shal be black oss for bath eclour blocks and staigh.on stenting.

». Stoned information shall consist of he flloning:

1. Plant tem number.

2, Deseraton of plant itm,

{BP Andrew Area Development TOPSIDES DETAILED DESIGN Page 2001 52

Tie: Speciation or Coating of Stuur Stoo, Piping and Vessels.

(Contract No. S7AND ob No: Fost7a01

Document No: S7AND-F041G70-S0-0011-000 Rev CS

'. Name of contents -corosive and tonic contents only, May be omied f covered by plant

item description,

WOOD GROUP ENGINEERING ETD

1 Andrew rea Development: TOPSIDES DETAILED DESIGN

Tie: Speciation for Coating of Stuctura See, Ping and Vessels

‘Contract No. S7AND Job No: Foexa7001

[Document No: 37AND-F041G7001-Y-S0-0011-000 Rew C5

60 SURFACE PREPARATION

6.1 General

Unless specifically excluded herein, sto! surlaces chal be prepared prior to coating by dey

abrasive blast cleaning, o the MANUFACTURER's standard and that spestied for the

appropriate system in Appendix 1

Surfaces not to be coated shall be masked to protect from damage by abrasive blast

cleaning. Boltholes shall be plugged and threaded studs shall have protective caps ited,

62

last Cleaning

Blast cleaning is defined as the removal of mil scale, rust, rust scale, foreign material of

‘coatings from a surface by the use of abrasives propeled through nezzes or by contitugal

wheels

Blast cleaning shal be carried out using dry gi to provide a visual standard ofSa2¥ or Sa

3 in accordance wih ISO 6501-1 as specie fr the appropiate system In Append 1

‘Blasting media for use on stainless steel shall be fae from chlorides. |

Where used, re-usable abrasives shall be regulatly checked and sieved to remove dint and

‘contamination. COMPANY may at its discretion require virgin grit, only, tobe used on any

application where It Is considered that the used of recycled git could impair coating

performance.

The CONTRACTOR shall have avaliable for review by COMPANY full details of the

proposed abrasive.

{An aluminium oxide or calcium silicate abrasive shall be used fr stainless steel and othor

noble surfaces. Abrasive containing soluble chlorides or ferrous material shall not be used

‘The CONTRACTOR shall exercise adequate segregation control to prevent carbon steel

‘contaminations of stainloss alloys. This shall be proven by regular fextoxy testing,

Surface preparation comparators complying with ISO 8501-1 shall be used at all tes to

‘ensure the spected surface prota is achieved and that the profle is sharp and angula.

“The photographic plates in ISO 8501-1 shall be used o ensure thatthe speced degree of

‘surface cleanness is achioved. The appropriate grade of Testex Tape or equal surface

proflle measurement fims shall be used and be appended tothe surface preparation and

coating work record sheets to provide a permanent record ofthe achieved surtae pf

'P Andrew Area Development TOPSIDES DETAILED DESIGN, Page 220 52

“Tile: Speciation for Coating of Structural Stel, Pping and Vesss.

Contract Na, AND Job No: Foata@7oot

[Document No: 37AND-F041G700"-:S0-0011-000 Rev CS

‘Grit blasting shall not be done in areas close to coating operations and / er wet coated

‘surfaces in order to prevent dust or git contamination,

Welded areas and appurtenances shall be given special attention for the removal of

\elding flux in crevices. Welding sliver, laminations and underying mil scale exposed

bore and during gt basting operations shal be removed by the bast mechanical m

and the adges smoothed or rendered flush

'No acd or inhibitor solutions shall be used on blast cleaned surtaces,

Propared surfaces shall be kept fr from any contamination and shall be completely fee

‘rom bast residues, dust or git

6.3 Additional Preparation

Intended weld areas shall be masked toa di

after blast cleaning and before coating

08 of SOmm to either side of te weld area,

‘100mm wide stip of uncoated bast leaned surface shal bel Betweon coated and

ut es pe og» ety eta ia sg

is done. When bast laring is rsimed, the 100mm stip of previously std sutace

shal equi ony aight brush bast remove any rs hat might remain,

‘When rectification has baen necessary on abrasive blast cleaned or previously coated

surfaces, the dressed areas shall be re-basted to remove all rut and contaminants and to

Provide adequate key. Blasting shal overlap a minimum of 25mm into the adsining coated

surace.

'8P Andrew rea Davelopment: TOPSIDES DETAILED DESIGN Pago 230 52

Tie: Speciation for Coating of Stuctual Stoel, Png and Vessel.

Contract No 37AND sob No:Foare700%

‘Document No: S7ANO-F061G700"-:S0.0011-000 Rev CS

7.0 COATING APPLICATION

74 General

‘All appicaton procedures and equipment shall be avaiable for review by the GOMPANY.

‘Coating shall only take place under conditions recommended by the MANUFACTURER,

900 series staniess that has an operating temperature greater than 50°C and Super

‘Duplex grades and 6% score re Paring Zn eh epry x00

Taeost2paepo9) | 1x28

\

ntr—2 pack opory 2x 100

Frish— Acyl mosted 2 pack porno | 1x50

Baz oS enna Pispae— Bas SORS0T Sa

sow rake Pang Zech epoy x50

oral areas, tush, to | er—2 pack opry 2x95

sons er stove cadeoatng

Fish— Aon esied pack poteratane (1X50

wore 83-1 was 68) oe oe

Be CS ara Pipa Bas SO RSHT SAS

taf'owase'c Paring Iara Zine Siete x60

Fish Modes Auminum sone x20

rat

[8 Arrow Ar Dovelopmant TOPSIDES DETAILED DESIGN

Tie: Specification or Coating of Srucural Stel, Pping and Vessel

Contact No, 37AND

‘Document No: S7AND-FO41G7001-¥:S0.0011-000 Rev C5

Page 390 52

Job No:Fo41G700%

vere scone SeECEATION conta

ries

more

tena

TS] ea aR — | P-BEETETET

reeset =e e Fo

eh Hener xm

stent iy ae

3 err STE

aowiste onto Poe x0

time

37 mas aeRO

roesite gn ee xe

iA Soe xm

55 ar ESS

pe | c

toeemne — (aeraeamart pat

aay ores FarageE rar OE

ea aoe

na Seer oso

a at epteoat aeanaaeanae

pate cts FS 725) ‘Priming ~2 pack low temperature cure epoxy

manemrotoncasane itm

sae ona ne

ue toe feu in coating gratings, tmayoo | *°?

ccomevonimtremtticere

Siorccamacnane —

(Micke gue xc peeiig)

‘BP Andrew Ara Dovelopment TOPSIDES DETAILED DESIGN

Tie: Specification for Coating of Sutra Se

‘Contact No, S7AND

‘Document No: S7AND-F041G700"-:S0-0011.000 Rev CS

Piping and Vessels,

Page 400t 52

Job No: Fosta7001

BT n= aay | oe Bas SORT SST

ning 20 er puck oy veo

Fri Seed mo ony ar, cov | xan

conspoing noe, oe any eas

Seat pk soy 1x80

Bie aaa — Rapa Ba SORT HTT

Pin -20 29 veo

Frit =2pckenoy ranaptingopeote | x280

Tenis

ara ars Fp = Bat BOT ET

scins200(seotunte | Prg- 2pckrputare’ 2 Pakepny | 1450

nso act -102 Pc pny vas

Eaeeae iy Fried pc pane

wow acter | a monte

de (58/6 rica

bone) cua reed

Big soreness — apes ETT eaa —[

susie SS, Ovi SP" | Coating — EponyPhanokc wih succes ack ‘etal 160

iene record on $5, Foster alas Neat resistant costing 57-

raped apt

TANK LINING

CI ea Fao Ba STEEN

fcc sonn ih-tamerenite pryorepyaterte|4x 50

{BP Andrew rea Dovelopent TOPSIDES DETAILED DESIGN Pago 4 of 82

Tie: Specification for Coating of Stuctural See, Piping and Vessel

Contact Ne. STAND ob No: 0487001

‘Document No: S7ANO-FO41.G7001-¥-$0.001 1-000 Rev C5

G42 | CS reconvene Pepa Ghat SOSSOT Sa

ooo tag Ping -Pabjetr xe

Frch—lue fate espeyestarorvintester |2X05mIm

al mm +50

Sound. of seconpresion may niet to be

cand dag acotan of caning fr his

CHS | CS Reeve Pepa Oa SORT SET

act bar Pinger xs

Fic Ge fat ince yee: 3x05

Speed of decompression may need 10 be| “tat Sam+

esate arg salaton of casings fr ths |50

Noi! 1

1. Aluminium epoxy primer can be applied to a damp surtaco provided its foe of water and that no

‘more than sight gingerng ofthe surface has taken place. Flash rusting must be no mare than as

Getined in the SSPC-SP1ZINACE ne

2. Blasting mea and pains for use of Stainless steal shall be foe from chlorides. Suiable blasting

‘medda are game, stonegtt and aluminium oxide.

3. For specification 1b an epoxy primer fish system may be acceptable Hf it is supported by

independent test data andor proven track ord

4. Manufacturers test data shall demonstrat suitably ofthe pant systom down to 100°.

{BP Ancow Arva Development: TOPSIDES DETAILED DESIGN

“Tie: Specification or Coating f Sutra Stee, Piping and Vessels

(Contact No, STAND Job No: Fosta7001

‘Document No: S7AND-F041G700"-

'$0.0011-000 Rev C5

APPENDIX 2~ FINISHED COATING COLOURS

1 Andrew rea Development TOPSIDES DETAILED DESIGN, Pago 480 52

Tie: Specification for Coating of Stuctural Ste, Pping and Vessel

Contact No. 37ANO ob No: F041 7001

‘Document No: S7AND-FO41G700-¥:S0-0017-000 Rev C5

‘R21 COLOUR SCHEDULE, EQUIPMENT AND STRUCTURAL SUPPORT (EXCLUDING

PIPING)

‘Al ejuipmentrequiing painting shall be fish painted to an off wile colour in accordance

with BS 4800-colour code 08 B15 unless noted otherwise below or where subject to

Mandatory Government Reguatons.

‘Safety equipment shal be painted as noted in Table A2.1. All acitional marnglcolours shall

confi to BS 4800.

‘STANDARD COLOUR SCHEDULE.

em, (Colour Bs 4800

Number

Exterior structural steelwork ofr White osBis

Flare tower, iling derrick, ‘YetlowiRed osEsi/

‘rae boom and A frame "Bands FESS

Pedestal cranes, oveibead Yellow OSES!

rans, chain boss et

‘Vessel, heat exchangers and On White oss

tanks (exluding elf ak)

Hifi tank Yellow OES

Firefighting equipment Red OES

‘Pumps (eluding Grewater servi) OFF white osBis

‘Motors, gemtor, compressors Bue 18ES3

Teetrament, lectrical igh Blue 1850

switchgear, transformers Semi gloss

Gear cases, couplings, guards Yellow O8ES

Inside of machinery guards Orange O6ES1

All elo valves Datk Grey ovAoo

Cc = ERTS] PRD SAT

15390 ag | pra aoa T_T

a

tant swaip | scan 2 am) i Goes

[BP Androw Area Development: TOPSIDES DETAILED DESIGN. Pago 45 0 52

Tie: Specteation for Coating of Stucual See, Pping and Vessel.

Contract No. STAND Job No: Fost 7001

‘Document No: STAND-FO41G700'-¥-$0-001-000 Rev OS

‘822. PIPEWORK COLOUR SCHEDULE AND INDENTIFICATION

A.22.1General

[All pipework pint colour coding and ientfcation shall be in accordance with this Appendix except

‘whee subject to mandatory UK or other Goverment Regulations. Unless saad athe, British

Standard Colours re refered to in BS 4800,

[All pipework and valves except for Grewse lines shal be punted off-vhite (BS 4800 colour code

(08 B15) and banded at strategic positions by PVC colour type specifically designed and manufactur

{er this purpose.

Firewater Hines and fitigs shal be pat rd (BS 4800 colour code O4 E $3) houghost their

Jeng.

ach sevice except Srewater sal be coded using two colors of PVC colour tap. The primary

colour band shall Henify the pie contents eg. water, at, oil The secondary edlour band shall

‘rovde additional deal to Frere he servic. Thus the sevice shal be fly enti bythe

cemmbination ofthe two banding colour.

A.2.2.2Colour Banding System

ach colour band system shall esis of:

1) Adhesive PVC met tape - the primary clout. This also indicates the dvcton of the pipe

eaten How witha a0.

1) Adhesive PVC masher tape =the secodaryeaout.

©) Adhesive text abel,

“The colour bands shal be appliod over the pipework paint coating. Prior othe band application the

paint coating shal be thoroughly cleaned ofall surfice contamination such aso, grea, sale dst.

by the application of en approved cleaning slvet compatible with he pant coating system ung only

ean rags or brushes, The cleaned aurface shal be allowed to completely dry out bef applying the

PVC colour bands

'P Androw ea Developmen: TOPSIDES DETAILED DESIGN, Page 460 52

Tie: Specteation for Coating of Stvetural Soe, Ping and Vessels

Constact No. S7AND Job No:Foex@7001

Document No: S7AND-FO81G7001-Y-S0-0011-000 Rev CS

“The PVC colour bands shall be appli tothe pipework immediatly the solvent cleaned surface i dry.

‘The banding eytom shal be applied as follows:

4) The length ofthe tapes nested shal be removed by applying a length of ape aroun! the pipework

‘withthe backing pape still atached. An overlap of SOmm shall be allowed for, andthe tapes cat

tothe desired length

1) The comer edges (opprox. 25mm) shall be cut of at an angle of 45°C a the overlap ed ofthe

tapes to prevent pel

9) The backing paper sal be removed from the primary band tape tothe extent that he arrow under

‘which the text strip eo be pico i cea. The arow sal point nthe dreton cf pipe contents

flow andthe txt strip shall be applied to the back face of the primary tape 9 atthe text is

‘early located and clearly visible within the transparent low arow window.

@ The tape shall be held wih both ands agnnst the pipe andthe low arrow adjusted into the best

reading poston forthe operations personel, The tape shall be applied by smooting ion to the

ipowork withthe ands, carefillyavidng tapping ac bubbles and without etching the tape.

‘Te ape shoal be a snug it on th pipework with SOmm overlap of the two tape nds the 45°C

cit comer ying ove the top onthe oven

©) The two secondary plain band tapes should be appli inthe same manner asthe primary band

tape

‘The PVC banding system shall be appli onal pipelines, ered so thatthe flow dietonalarow

nd label text would be clearly visible by operations personnel. The banding stem dal be appli

‘immediately ajacent

8) All vessel exchangers pumps et,

» Alvales

9) All pipework junctions

© Allservie appliances

9) Allwallfloceing penetrations

In addition to the above locations, the band sytem shall be appiod on pipework runs at + Im

interval

‘BP Andrew Area Development: TOPSIDES DETAILED DESIGN. age 47 of 62

“Tile: Speciation or Coating of Stuctural Stel, Ping and Vessels

Contact No, 87ND Job Ne:F0ex@7001

Document Na: S7AND-FO41G7001-Y-S0-0011-000 Rev CS

‘COLOUR SCHEDULES

‘BZ FLUID IDENTIFICATION COLOURS

SERVICE PRIMARY BAND S480) SECONDARY BAND BS4800 REF

AIR

Isrent Air Light Bae 20851

Plant Air Ligh Ble 20651

DRILLING RIG BULK SYSTEMS

an Bone Wise 27 Oven nas

a Cone visa 22037 Boe hes

Daling ed vise 2037 hewn scm

ak Vnng vise 203 Sanh wens

cuemicas |

Bie iu) Vii 22037 barpnly spas

Wer attr Vise 2C8 Ome seat

Deemer Voie nes Yaw woes:

Deane Vous 2C3 Datei oes

Stet Vii nen Bad woes

Nena Vets ne” te mos

Onecare) Vel RCH DkGreen hem

ness aise Via Rea White woes

Sele iaibitoe Violet 237 Gem nos

{> Andon Ara Development: TOPSIDES DETAILED DESIGN Page 4.0152

Tie: Speciation fr Casting of Stucral Set, Ping and Vessels

Coneat No. 378ND Job No: F0ss7001

Document No: S7ANO-F041G7001Y-S0.0011.000 Rev C5

DRAINS

Minas din Black coEsS Red Ess

Ding Drains ck CESS OFWie tosis

Din (open taarcus) Black ESS Gry A

Mod Dre ick (ESS omits 1081s

Din (open, no-tazarous) Black CESS Vie nen

vents

AamosplriBlowtown ick (OES Santwond oncss

HP fae Ssndaond —ORC3S-— Vike mss

LP tare Sundlvood —OBC3S-— Vit nos

DRILLING RIG SYSTEMS.

Md and el il eye Vile 2037 Brom 05039

Conca cement aitives Vit mcs Bhe ESS

FIREFIGHTING SERVICES | |

IPE TO BE FULLY COATED WITH PRIMARY COLOUR

carte oxi at 04859 Emerald Gre Mess

Fam Re OES PaleGreen ocs3

Wate Re HESS

Forts

Dice! Brown 0639 White woes

Foal Gas Sandia o8c35 white 0085s

‘Aviation Fa Bick ESS white OOESS

(mL NON PROCESS)

Ayo SaincoPink 433

Late os Brows 06039 Emerald Green MES

‘bP Androw Area Development: TOPSIDES DETAILED DESIGN

Tis: Spocteation for Coating of Stctua Stee, Piping and Vessels

Contact No, 37ND

Document No: S7AND-F081G7001-¥-S0-0011-000 Rev CS

Page 490 52

ob No: Fos1700%

PROCESS

Hydrocarbon Gas Sandalwood

Hydrocarbon Liquid Sandalwood

Cadence Sandalwood

Produced Water Groen

UTILITIES GAS FLUID

itegen Blue Green

WATER

Water injection (tare)

Potable Water

osc3s

o8c3s

o8c3s

npas

WES

uc39

npas

npas

FEE

Wess

2051

Ess

O4ES3

O4ES3

WES

'BP Andrw Area Developmen: TOPSIDES DETAILED DESIGN Page 50052

Tile: Spectcation lor Coating of Stutura Soe, igng and Vessels

Contract No. S7AND Job No: Foa1G7001

Document No: 37AND-F08%G700-¥:S0-0011-000 Rev CS

| Aone 9-SPECTION AND TST REQUIREMENTS

'P Andrew Avea Development: TOPSIDES DETAILED DESIGN, Page 51 of 52

“Tile: Speciation or Coating of Structural Stel, Piping and Vessel

Contract Na. 87ND Job Ne: Fost 7001

[Document Na: 87AND-F04147001-Y-S0-0011-000 Rev CS

Appendix 3

INSPECTION AND TESTING REQUIREMENTS

TREGEPTANGE

estes | weTH00 rneguencr | SCSEPTANCE | consequence

Ermer | iaionanaee | Sate aaactecranh | neces wh |Nobatg cn

cmane™ |icpcac | Scemamceenn | es

tna | Sire

Yas | Waustormen. | onc erateaam | oaaacnin Goan eared

Bn |S la cee

me sci

= ‘aera

ee

tee, | a Sige |) eee

8 Sette ‘Sago

© twine, | Sob

como

Seong

Tea | oes Sanam Maman Reagan

'soescee eee, [st

Toagmes —RepeaTape | Nagamine | Aeeetes | Ptr

fect nor [poor ine |

eC

Seaton | Say oman, | cut fest | ace

Soa” | Stew TSoimmere, | ermutorate at

free eater

Serene

Sone ener |

om ie

| eset aun

Tati, Truceoina | so ewe _[ ohn Ppa

actin | ersoece | gatentrme enc! |" |

os Stexewoue |

twocsthesrtcs, | Sasso ne

Poco sadence |oesemte |

= |

Tiaras SO a | ea 1 es aca apr nais

Soom | arog

Srv

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Conserve RingDocument10 pagesConserve Ringdiaccessltd_17172961No ratings yet

- A Guide To Refinery ProcessDocument35 pagesA Guide To Refinery ProcessBalamurugan100% (3)

- Nit Xl3t 600 ManualDocument214 pagesNit Xl3t 600 Manualdiaccessltd_17172961No ratings yet

- 2408 001Document1 page2408 001diaccessltd_17172961No ratings yet

- Skerik Grey Scale Test (v.03)Document1 pageSkerik Grey Scale Test (v.03)diaccessltd_1717296175% (4)

- OmniSX - MX2 - Training - 16J TOFD Flaw Sizing and CharacterizationDocument35 pagesOmniSX - MX2 - Training - 16J TOFD Flaw Sizing and Characterizationaldeanucu100% (3)

- Masterclass Stopinspectie (TBV TA Neste) Deel 4Document6 pagesMasterclass Stopinspectie (TBV TA Neste) Deel 4diaccessltd_17172961No ratings yet

- MrutDocument1 pageMrutdiaccessltd_17172961100% (1)

- Article On Tofd WaveletDocument6 pagesArticle On Tofd Waveletdiaccessltd_17172961No ratings yet

- Corrosion Under Insulation - Initial Draft (21MAY04)Document8 pagesCorrosion Under Insulation - Initial Draft (21MAY04)diaccessltd_17172961No ratings yet

- Boiler RbiDocument65 pagesBoiler Rbidiaccessltd_17172961No ratings yet

- DMS Go Plus Operating Manual EnglishDocument264 pagesDMS Go Plus Operating Manual EnglishvrapciudorianNo ratings yet

- BOD-AM WI Pipe Stress Report - AshxDocument57 pagesBOD-AM WI Pipe Stress Report - Ashxdiaccessltd_17172961No ratings yet

- KND RP L 0026 - 2aDocument15 pagesKND RP L 0026 - 2adiaccessltd_17172961No ratings yet

- WPSDocument3 pagesWPSdiaccessltd_17172961No ratings yet

- Procedure Quality Record (PQR)Document37 pagesProcedure Quality Record (PQR)diaccessltd_17172961No ratings yet

- Electrical Diagram - LQDocument124 pagesElectrical Diagram - LQdiaccessltd_17172961100% (1)

- 37and F041G7001 I TS 0019 000 - IDocument1 page37and F041G7001 I TS 0019 000 - Idiaccessltd_17172961No ratings yet

- Test ReportDocument7 pagesTest Reportdiaccessltd_17172961No ratings yet

- 20090201102513Document160 pages20090201102513diaccessltd_17172961100% (1)

- ABS Coating GradingDocument64 pagesABS Coating Gradingdiaccessltd_17172961No ratings yet

- API5LX 65 Welding SummaryDocument25 pagesAPI5LX 65 Welding Summarydiaccessltd_17172961No ratings yet

- 37and F041G7001 I TS 0021 000 - IDocument1 page37and F041G7001 I TS 0021 000 - Idiaccessltd_17172961No ratings yet

- Boiler ChecksheetDocument5 pagesBoiler Checksheetdiaccessltd_171729610% (1)

- Adp-Me-Spe-8015-000 C1Document77 pagesAdp-Me-Spe-8015-000 C1diaccessltd_17172961No ratings yet

- 05Y - 610386 - J - Boiler - GADocument1 page05Y - 610386 - J - Boiler - GAdiaccessltd_17172961No ratings yet

- Adp-Me-Spe-8014-000 C1Document76 pagesAdp-Me-Spe-8014-000 C1diaccessltd_17172961No ratings yet

- BRB DR P 0002a Rev z1Document1 pageBRB DR P 0002a Rev z1diaccessltd_17172961No ratings yet

- 5 UOP Separex Membrane TechnologyDocument50 pages5 UOP Separex Membrane TechnologyCSNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)