Professional Documents

Culture Documents

90 Dakota Wiring

Uploaded by

dodgerulzes100%(3)100% found this document useful (3 votes)

3K views107 pagesMaster WIRING DIAGRAMS contain the latest information available at time of publication. Diagrams contain various wires, wire routing, wire color codes, switches components, fuses, splices, connectors, connector cavities and other information. Each wire also contains a code (Fig. 3) which identifies main circuitidentification, part of a main circuit, COLOR OF WIRE which is shortened to two letters.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMaster WIRING DIAGRAMS contain the latest information available at time of publication. Diagrams contain various wires, wire routing, wire color codes, switches components, fuses, splices, connectors, connector cavities and other information. Each wire also contains a code (Fig. 3) which identifies main circuitidentification, part of a main circuit, COLOR OF WIRE which is shortened to two letters.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(3)100% found this document useful (3 votes)

3K views107 pages90 Dakota Wiring

Uploaded by

dodgerulzesMaster WIRING DIAGRAMS contain the latest information available at time of publication. Diagrams contain various wires, wire routing, wire color codes, switches components, fuses, splices, connectors, connector cavities and other information. Each wire also contains a code (Fig. 3) which identifies main circuitidentification, part of a main circuit, COLOR OF WIRE which is shortened to two letters.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 107

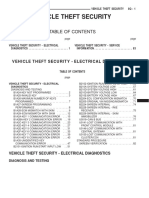

ELECTRICAL WIRING DIAGRAMS §8W - 1

1990 Dodge Dakota

ELECTRICAL WIRING DIAGRAMS

e INDEX

Page

CHARTS: Locating a System or Com 2

Fusible Link Chart. cieteeeeeees Main Circutt Identification . mie

Wire Color Code Chart Splice Locations... PIII 8

Master Wiring Diagrams. Electrical ard ‘and Components”

General information . Identification Index - = bese?

Fusible Links Electrical Wiring Diagram Wire Fiouting and ©

Fusible Links Replacement | weamegnent Lecation Index”. . ae

‘Multiple Fusile Link Replécomient’ vee STIS

Splice Location index 121220222 3

Single Fusible Link Replacement ||: SRS LOgation Inde. ois 3

MASTER WIRING DIAGRAMS

GENERAL INFORMATION

Master wiring diagrams contain the latest informa-

tion available at time of publication. These diagrams

contain various wires, wire routing, wire color codes,

switches components, fuses, splices, connectors, con-

nector cavities and other information except distrib- ©———_

uutor secondary wiring, see (Figs. 1 and 2). Most main

e@ circuts are identified by a main circuit identification

code. Some codes will not apply to all vehicles. Sec-

ondary codes are not shown. See main circuit codes

Each wire also contains a code (Fig. 3) which identi-

fies main circuit identification, part of a main circuit,

color of wire which is shortened to two letters soe b }

wire color code chart and if used a colored tracer

identified by a slash(/) followed by two letters and an

asterisk or an asterick by itself.

Wiring harnesses that have substitute wires of a DISTR NER ENGINE on

different color then called out on wiring diagrams TIRING ORDER I-5-3-4-0-2 pa7ss

should have an identifying tape with specified wire

color code (Fig. 4) Fig. 2—Distributor Secondary Wiring 3.91. Engine

ate

| ofa conn

sant

@ cancomenssa2

DISTRIBUTOR-CLOCKWISE ROTATION RPS

Fig. 1—Distributor Secondary Wiring 2.5L Engine Fig. 3—Wire Color Codes identification

8W-2 ELECTRICAL WIRING DIAGRAMS:

LOCATING A SYSTEM OR COMPONENT

In order to locate a system or component use al-

phatical index to determine dingram sheet number

and turn to that sheet for wiring diagram.

Sheet numbers for each wiring diagram are located

at lower right or left hand corner of each sheet. Page

numbers at top of page do not apply to diagram

IDENTIFICATION TAPE

NOTE: SHOULD COLOR CODE OF WIRE

NOT CORRESPOND TO MASTER

sheets. WIRING DIAGRAM SEE

INDENTIFICATION TAPE AS

[_—naarcororcoorenanr 7 SHOWN.

[staNDARD [STANDARD] roe

JEOLOR| conor | reactn |Qser'| coor | TRACER

t cOLOR CODE. Fig. 4—Identification of Substitute Wiring Circuits

BK OR

ex fac} wr | pk | rink | Pye

se [erown] wr | mo | a> | wt

DARK

ve | OAR] we [om | an | wr

DARK

oc | BARK | owe | vr | out] wr

ey | ory] ax | wr | ware} ax

UGHT

w [UST ae | we vuow) aK

usHT .

use| ax WIM TRACER

on Jorance] ak

Lf’

Cora

MAIN CIRCUIT IDENTIFICATION CODES

al Positive Circuit, L.__ Lighting Cirevit Faed (Exterior Lomps)

a2 Negative Circuit. JAI Lighting Circuit Feed (Interior Lamps}.

B_ Back Up Lamp Circuit. M2 _ Lighting Circuit Ground (Interior Lamps).

B3_Horard Warning Flasher Feed. P__ Brake Checking Circuit.

€ Air Conditioning and Heater Circuits, Heoted —»«@Z_Accossory Buss Bar Feed (Fuse Block).

Reor Window, Radiator Fan Molor. Q3 Battery Buss Bar Foed (Feed)

D_ Emergency, Stop Lamp and Tum Signal Circuits, 3 Alternotor Circuit to Electronie Regulator (Fial)

Lamp Outage, Brake Pad Sensor, Diagnostic RB Alternator Circuit Feed.

Connector. > Starter Motor and Starter Reloy Cireutt.

E__ Instrument Panel Cluster, Switches and T Tachometer.

IMlurnination Circuits ¥ Windshield Wiper and Wesher Circuit

F Power Assist Systems, Seats, Windows, ond W Power Window Circuit.

Door Locks. X_ Grounds For Radio Speakers, Cigar Lighter,

G Gauges, Warning Lamp Circuits and Voice Lamps, Clock, Speed Control, Power Antenna,

Alor. Power Amplifier, Power Windows, Power

H Horn Circuit. Mirrors, Deck tid Release and Door Locks,

31 Ignition Swiich Food Ciecuit. YS. EFl or Turbo Ground.

32 Ignition System Run Circuit. ZT. Turbo Fuel Injectors EF! and Turbo Ignition Coil

33. Starter Relay 1o Bollost Resistor. cand Fuel Pump Motor.

310 Ignition Switch Accessory Feed.

KC Logic and Power Modules.

‘SPLICE LOCATIONS

Splice loations are indicated on master wiring dia

grams by a diamond with splice cireuit eode within it

(exaraple 1). If there is more than one splice per cir-

cuit splice code a small box will be connected to the

diamond with the splice number in it (example 2)

Fig. 5).

Oo 2

EXAMPLE 1 BCAMPLE 2

Fig. 5—Wiring Splice Examples

In order to locate a particulat splice determine

splice number from master wiring diagram. Refer to

pictorial splice index to find figure number then turn,

to that figure to determine splice location within a

wiring harness (Fig. 6).

RPS,

ELECTRICAL WIRING DIAGRAMS 68W - 3

insulation can be used or damage to the electrical

‘system wil occur. Also make sure correct gauge of

wiring Is used, Refer to Master Wiring Diagrams for

proper gauge size.

(2) When a fusible link blows it is very important

to find out why it blew. They are placed in vehicle

electrical systems for protection against dead shorts

to ground which can be caused by electrical compo-

nent failure or various wiring failures. Do not just

replace fusible link to correct probl

(2) When replacing fusible links that are connected

to battery terminal of starter relay, they are to be

serviced with the same type of prefabricated fusible

Bink.

All other fusible links are replaced with a piece of

fusible link wire cut from bulk reels, Care must be

taken that the same gauge and color wire as the

original fusible link be used (see Fusible Link

Chart).

FUSIBLE LINK CHART

i ce fice tol

auge je olor

master

seuct’ cove Pane Sage 72a, aK Back

4 Ga, RD Fed

22 \e081 16 Ga. 06. Dark Be

6 Ga GY Gray

20 Ga. OF Orange

22 Ga, Wr Wiite

Multiple Fusible Link Replacement

Fig. 6—Locating a Wiring Harness Splice

FUSIBLE LINKS

Vehicle wiring harnesses are equipped with fusible

links to protect against harness damage in the event

of a short in the electrical system.

Fusible links are color coded as to wire gauge size.

See fusible link chart.

FUSIBLE LINK REPLACEMENT

CAUTION: Do not replace blown fusible links with

standard wire. Only fusible type wire with hypalon

(1) Disconnect negative battery cable.

(2) Cut off any remaining portion of blown fusible

link flush with multiple connection insulator, taking

care not to cut into other fusible links (Fig. 7)

(8) Remove 1 inch of insulation from main harness

wire about 1 inch from multiple connection insulator

Gig. 7

(MAIN HARNESS.

STRIP ONE INCH INSTALL ANY. STRIPONE INCH

OF INSULATION EXISTING. ‘OF INSULATION

FROM BOTH WIRES TIE WRAPS. FROM BOTH WIRES.

-FUSIBLE LINK

Fig. 7—Fusible Link Repair

You might also like

- GM Chassis Application 1986-2004view PDFDocument376 pagesGM Chassis Application 1986-2004view PDFMotonetas de Antes100% (1)

- GM MasterToolDocument102 pagesGM MasterToolalejandro sanchez100% (1)

- Shop ManualsDocument45 pagesShop ManualsChris Herrington26% (31)

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualFrom EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualRating: 4.5 out of 5 stars4.5/5 (2)

- 2004 57 Hemi Engine PDFDocument50 pages2004 57 Hemi Engine PDFJay AndrewsNo ratings yet

- Ford Coyote Engines - Revised Edition: How to Build Max Performance: How to Build Max PerformanceFrom EverandFord Coyote Engines - Revised Edition: How to Build Max Performance: How to Build Max PerformanceRating: 5 out of 5 stars5/5 (1)

- Chevrolet Small-Block Parts Interchange Manual - Revised EditionFrom EverandChevrolet Small-Block Parts Interchange Manual - Revised EditionRating: 5 out of 5 stars5/5 (31)

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Chevelle Performance Projects: 1964-1972From EverandChevelle Performance Projects: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (2)

- Fuel System Dakota Dodge 1995Document94 pagesFuel System Dakota Dodge 1995Jorge MorenoNo ratings yet

- Chevy Nova 1968-1974: How to Build and ModifyFrom EverandChevy Nova 1968-1974: How to Build and ModifyRating: 5 out of 5 stars5/5 (15)

- Dodge Engine Controller Module Manual - Late 1980sDocument6 pagesDodge Engine Controller Module Manual - Late 1980ssquall814100% (1)

- MUSTANG - 03 Shop Manual Backup PDFDocument4,378 pagesMUSTANG - 03 Shop Manual Backup PDFAnonymous 9vLxWYUDQNo ratings yet

- Building 4.6/5.4L Ford Horsepower on the DynoFrom EverandBuilding 4.6/5.4L Ford Horsepower on the DynoRating: 5 out of 5 stars5/5 (1)

- ManualDocument20 pagesManualpepw67% (3)

- Vortec ManualDocument22 pagesVortec ManualArielNo ratings yet

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Dodge Interchange Parts ListDocument325 pagesDodge Interchange Parts ListArmoured CompNo ratings yet

- Dodge Dakota 1994 GroundDocument3 pagesDodge Dakota 1994 GroundGerar MuzNo ratings yet

- Chevy Engine GuideDocument94 pagesChevy Engine Guidesaltlydawg83% (6)

- Vehicle Compatibility ChartDocument9 pagesVehicle Compatibility ChartLilith MarieNo ratings yet

- GMC Sierra 1988-2005Document18 pagesGMC Sierra 1988-2005Adal Vera75% (4)

- 1995 Dakota Service ManualDocument1,430 pages1995 Dakota Service Manuallilfroger100% (4)

- Speedtweaks Tips and Tricks Dodge RamDocument0 pagesSpeedtweaks Tips and Tricks Dodge RamDarik OreskovichNo ratings yet

- Wiring DiagramsDocument9 pagesWiring DiagramsjulienfranceNo ratings yet

- WWW - Incar.tw-1989 Ford F250 Diesel Repair Manual PDFDocument5 pagesWWW - Incar.tw-1989 Ford F250 Diesel Repair Manual PDFkenneth0% (3)

- Engine TypesDocument4 pagesEngine TypesRoss GrimmettNo ratings yet

- Jeep Grand Cherokee 2005 2008 Sistem Antirobo PDFDocument94 pagesJeep Grand Cherokee 2005 2008 Sistem Antirobo PDFNORCOM SACNo ratings yet

- 2003 Expedition - Navigator Service ManualDocument4,603 pages2003 Expedition - Navigator Service Manualsc19605980% (15)

- Fisher Body Service Manual 1972 870550 IndexDocument13 pagesFisher Body Service Manual 1972 870550 IndexAnonymous DR7W37SeqNo ratings yet

- A Carter Thermo-Quad Guide: Contents..Document31 pagesA Carter Thermo-Quad Guide: Contents..Chris EvrardNo ratings yet

- Good Wrench ManualDocument146 pagesGood Wrench ManualPM82% (11)

- Dodge Dakota 2005 Service-Repair-Manual-FREE-PDF-DOWNLOADDocument80 pagesDodge Dakota 2005 Service-Repair-Manual-FREE-PDF-DOWNLOADsen tilNo ratings yet

- Chrysler MasterToolDocument84 pagesChrysler MasterToolEder0% (1)

- Car Shop ManualsDocument45 pagesCar Shop Manualselif nane50% (2)

- Jeep Engine and Cam SpecsDocument6 pagesJeep Engine and Cam Specsmnlwood25580% (1)

- Dodge Dakota 1991-2004 - Fiação para AlarmeDocument13 pagesDodge Dakota 1991-2004 - Fiação para Alarmecybersaloon100% (1)

- Xfer Case IdentificationDocument9 pagesXfer Case IdentificationErickMaki0% (1)

- Toyota Tacoma Service ManualDocument1,634 pagesToyota Tacoma Service ManualDiego Hernan Piñeiro100% (2)

- 2019 GMC Sierra Limited Denali Owners ManualDocument493 pages2019 GMC Sierra Limited Denali Owners ManualJhon MechanicNo ratings yet

- Chrysler Town and Country - Caravan - Voyager - 1998 - IntroductionDocument10 pagesChrysler Town and Country - Caravan - Voyager - 1998 - IntroductioneephantomNo ratings yet

- Rust Repair CatalogDocument64 pagesRust Repair CatalogTroy Bauer80% (5)

- Ac Delco 16229684 Ecu VortecDocument15 pagesAc Delco 16229684 Ecu VortecMarcin Baj73% (11)

- Dodge Ram Fault CodesDocument42 pagesDodge Ram Fault Codesnaismith1100% (4)

- Small Block Chevy Tuning TipsDocument4 pagesSmall Block Chevy Tuning Tipsmijaboot100% (4)

- 1974-2009 All Vehicles Parts Interchange List PDFDocument108 pages1974-2009 All Vehicles Parts Interchange List PDFcrawdoogie83% (6)

- 2002 Whatsnew FordDocument27 pages2002 Whatsnew FordHector Dongo Arrayan0% (1)

- Chevrolet+s 10+pickup+1983 2004Document16 pagesChevrolet+s 10+pickup+1983 2004Jorge Alexander Bazan Becerra100% (1)