Professional Documents

Culture Documents

En 39-2001

Uploaded by

qoolshabiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En 39-2001

Uploaded by

qoolshabiCopyright:

Available Formats

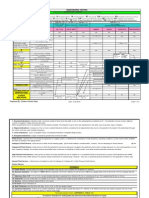

EN 39 2001

TUBE TYPE Outside Dia. of Black / Galvanized Tube Weight of Black / Galvanized Tube

SIZE Minimum Maximum Wall thickness Plain Ends Pieces

NB (mm) Inches mm Inches mm Inches mm Inches Kg./Ft. Kg./Mtr. per bundle

3 40 11/2 47.8 1.882 48.8 1.921 3.2 0.126 1.090 3.56 61

4 40 11/2 47.8 1.882 48.8 1.921 4.0 0.157 1.332 4.37 50

1. TOLERANCE :a) On Specified OD + 0.5mm (Ovality 0.5mm)

:b) The Inside Diameter of ubes shall allow insertion of a guage of 37.7mm dia for a minimum length of 200mm.

:c) On Wall thickness -10%

:d) The mass deviation on a single tube shall not exceed -7.5% of the specified mass.

2. ENDS : Cut cleanly and nominally square with the axis of the tube and free from excessive burrs.

3. PROPERTIES :a) Chemical (Maximum) C - 0.20%, SI - 0.05%, MN - 1.40%, P - 0.04%, S - 0.045%, AL - Min. 0.02%.

:b) Mechanical = UTS - 340 to 520 N/mm2, YS - 235 N/mm2 (minimum) & %Elongation on 5.65 S0 - 24% (minimum).

4. FLATTENING TEST WELD AT 90 DEGREES (COLD)

a) For weld : Distance between the platens, measured under load is not greater than 75% of the OD of tube.

b) For Material :Distance Between the platens, measured under load is not greater than 60% of the OD of tube.

5. STRAIGHTNESS : 1 in 500 (In 1 meter it should not exceed 3mm).

6. ZINC COATING : Minimum local coating thickness on the outside surface 40 microns.

(GALVANIZING)

7. MARKING : a) We can emboss mill sign "EN 39 UTP 3 or 4." online at every one meter interval over the length of pipe.

b) We can do online stencilling as per customer needs.

8. PACKING : Hexagonal type.

9. MILL TEST CERTIFICATE :We can issue a MTC, certifying that the tubes supplied comply with this Standard.

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Astm A 53 BDocument4 pagesAstm A 53 BLauren BowenNo ratings yet

- Astm A53Document2 pagesAstm A53joseocsilvaNo ratings yet

- Specifications Bruney Tandem 3 Seater With Cushion (Set of 3 Chairs) 1. Tubular Steel FrameDocument2 pagesSpecifications Bruney Tandem 3 Seater With Cushion (Set of 3 Chairs) 1. Tubular Steel Framesai kumarNo ratings yet

- Reg. 338 Boiler and Super Heater Tubes, Headers and Other Pressure Parts TubesDocument4 pagesReg. 338 Boiler and Super Heater Tubes, Headers and Other Pressure Parts TubesWASIM MAKANDARNo ratings yet

- Commercial Spec 3 Standard WMDocument4 pagesCommercial Spec 3 Standard WMAli KhaniNo ratings yet

- D-22 المواصفة المحدثة للاعمدة المدورةDocument12 pagesD-22 المواصفة المحدثة للاعمدة المدورةAhmed Al-BaghdadiNo ratings yet

- BS 1387-85Document2 pagesBS 1387-85mullanjiNo ratings yet

- Tubing PDFDocument20 pagesTubing PDFTheEdgeNo ratings yet

- Astm A 500Document3 pagesAstm A 500LuckySingh100% (2)

- British StardardDocument9 pagesBritish StardardSagubar SathikaliNo ratings yet

- Astm A106 A106mDocument4 pagesAstm A106 A106mmahamad AziNo ratings yet

- M3382 Spec (Fusible Link)Document4 pagesM3382 Spec (Fusible Link)DamonNo ratings yet

- Specification of Steel Tubular Poles 4009Document2 pagesSpecification of Steel Tubular Poles 4009Akshay DharNo ratings yet

- Standard HFRW PDFDocument3 pagesStandard HFRW PDFGuidoColomboNo ratings yet

- Astm A557 A557mDocument3 pagesAstm A557 A557mارفع راسك فوق انت يمنيNo ratings yet

- Top Circular Slab DesignDocument4 pagesTop Circular Slab DesignAbiyotNo ratings yet

- Instrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- Method of SwagingDocument4 pagesMethod of Swagingjcarlos7411No ratings yet

- Ts-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMDocument2 pagesTs-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMmohd darusNo ratings yet

- RT Acceptance CriteriaDocument3 pagesRT Acceptance CriteriaAndry Rimanov89% (18)

- Tata Steel Bulb Flats BroDocument11 pagesTata Steel Bulb Flats BroMd. Rafique HassanNo ratings yet

- 1 Triad AbcDocument4 pages1 Triad AbcAnamulKabirNo ratings yet

- BCE - H2SO4 Tower InternalsDocument3 pagesBCE - H2SO4 Tower InternalsDũng LêNo ratings yet

- TDS Jumbo Gabion P8+2.7 PolimacDocument2 pagesTDS Jumbo Gabion P8+2.7 PolimacszemianNo ratings yet

- FAMECADocument8 pagesFAMECADhimaz ZiroNo ratings yet

- TS - Helically Formed Fittings For 11 KV and LT LinesDocument17 pagesTS - Helically Formed Fittings For 11 KV and LT LinesAshim BhowmickNo ratings yet

- 1) Basic Data: Design of Simply Supported Doubly-Reinforced Beam Using IS 456-2000Document3 pages1) Basic Data: Design of Simply Supported Doubly-Reinforced Beam Using IS 456-2000Khaja100% (1)

- 10MB600 8ΩDocument2 pages10MB600 8ΩDiego PauloNo ratings yet

- Alambron CHQDocument4 pagesAlambron CHQJavier GranadosNo ratings yet

- Astm A556 A556mDocument3 pagesAstm A556 A556macount checkNo ratings yet

- 400PX3CHT33UEFLATDocument2 pages400PX3CHT33UEFLATjayesh95395No ratings yet

- Welded FinDocument7 pagesWelded FinNatarajan RavisankarNo ratings yet

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- 0 75px1tscnarmdDocument2 pages0 75px1tscnarmdnmpkumarNo ratings yet

- CD - Works: Salient FeaturesDocument8 pagesCD - Works: Salient FeaturesMuthusamy ArumugamNo ratings yet

- N1P 1.5 P1T2 BLK LDocument2 pagesN1P 1.5 P1T2 BLK LRijo RajanNo ratings yet

- Instrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- Three Core Cables To BS 6622Document8 pagesThree Core Cables To BS 6622rose chenNo ratings yet

- مواصفات الكابلاتDocument17 pagesمواصفات الكابلاتAdel FawziNo ratings yet

- TDS Jumbo Gabion P8+2.2 PVC - PubDocument2 pagesTDS Jumbo Gabion P8+2.2 PVC - PubszemianNo ratings yet

- Hmnjopl PDFDocument1 pageHmnjopl PDFAjay PrajapatiNo ratings yet

- NDT ACC. CriteriaDocument6 pagesNDT ACC. CriteriaBalakumar100% (5)

- International Standard For High Frequency Welded Fins DownloadDocument3 pagesInternational Standard For High Frequency Welded Fins DownloadPrasad Dhume50% (2)

- Terminal Blocks: Eurostyle P.C.B. TypeDocument77 pagesTerminal Blocks: Eurostyle P.C.B. TypeEngla ZikrillahNo ratings yet

- 5123BEUG (2016 2017) Tutorial Week16 AnswersDocument10 pages5123BEUG (2016 2017) Tutorial Week16 AnswerssalmanNo ratings yet

- PEM Self Locking Fasteners Nylon InsertDocument6 pagesPEM Self Locking Fasteners Nylon InsertAce Industrial SuppliesNo ratings yet

- NTPC TandaDocument14 pagesNTPC Tandazakir84md3639No ratings yet

- GTP 31X40MM & 51X63MMDocument6 pagesGTP 31X40MM & 51X63MMRaja AnzarNo ratings yet

- Installation StandardDocument6 pagesInstallation StandardDinanath SharmaNo ratings yet

- DS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstDocument3 pagesDS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstAppzNo ratings yet

- Datasheet For Cable: 1 Pair Overall Shielded Armoured Cable, Type F (Single Pair Cable Shall Have Only Overall Shielding)Document4 pagesDatasheet For Cable: 1 Pair Overall Shielded Armoured Cable, Type F (Single Pair Cable Shall Have Only Overall Shielding)AnamulKabirNo ratings yet

- Rockfall Protection Netting: Galvanized & Polymer Coated (10x12)Document2 pagesRockfall Protection Netting: Galvanized & Polymer Coated (10x12)Sudipto PaulNo ratings yet

- Fire Piping Astm A795Document3 pagesFire Piping Astm A795sinahimsNo ratings yet

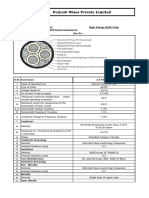

- No. KV SQMM No. Ohm/Km No. MM No. MM MM MM MM MM MM MM MM KG/KM Metre 10% KGDocument1 pageNo. KV SQMM No. Ohm/Km No. MM No. MM MM MM MM MM MM MM MM KG/KM Metre 10% KGadventure11111No ratings yet

- Pfevel12716 0-380139 (Uk)Document44 pagesPfevel12716 0-380139 (Uk)qoolshabiNo ratings yet

- Gear Cutting FormulaeDocument30 pagesGear Cutting Formulaeqoolshabi80% (5)

- Plane Sections Remain Plane. Y: CompressionDocument5 pagesPlane Sections Remain Plane. Y: CompressionakanyilmazNo ratings yet

- Scaffolding-Medical Cert.Document13 pagesScaffolding-Medical Cert.qoolshabiNo ratings yet

- BS5950 Load CasesDocument46 pagesBS5950 Load CasesthespecifierNo ratings yet