Professional Documents

Culture Documents

Polyester Double Braid Info Sheet

Uploaded by

Philip ImmoosOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polyester Double Braid Info Sheet

Uploaded by

Philip ImmoosCopyright:

Available Formats

POLYESTER DOUBLE BRAID

Polyester Double Braid provides an excellent combination of high strength, low stretch

excellent weathering and easy handling. Of all the popular fibers polyester has the best

weathering characteristics and the best wet abrasion resistance.

Polyester Double Braid comes standard with an overlay marine finish and is available on

special order with a spliceable polyurethane finish in clear or any of six colours.

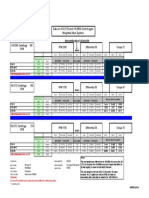

Approx Minimum

· Low stretch Code

Dia. Weight Tensile

(mm) (kg/ Strength

· High strength 100m) (tonne)

· Soft hand RDBPES06 6 3.6 1.09

· Torque free RDBPES08 8 5.4 1.63

· Excellent wet strength RDBPES09 9 7.1 2.18

· Meets MIL-DTL-24677B RDBPES11 11 9.4 2.85

RDBPES12 12 12.8 3.81

RDBPES14 14 16.5 4.87

RDBPES16 16 19.5 5.58

RDBPES18 18 28.0 7.89

RDBPES22 22 38.1 10.89

RDBPES24 24 49.9 14.15

RDBPES28 28 63.1 17.91

RDBPES30 30 77.8 21.81

RDBPES32 32 86.0 24.08

RDBPES36 36 112.2 29.15

RDBPES40 40 131.3 35.28

RDBPES44 44 153.3 40.45

RDBPES48 48 199.4 49.88

Specific Gravity 1.38* RDBPES52 52 224.7 56.23

Melting Point 250°C* RDBPES56 56 251.5 63.93

Critical temp 177°C* RDBPES60 60 311.0 77.08

Coefficient of friction 0.12 – 0.15* RDBPES64 64 343.8 84.34

Elongation at break 15% - 20% RDBPES68 68 394.4 93.40

Fibre water absorption 0% - 1% RDBPES72 72 447.9 107.46

UV resistance excellent RDBPES80 80 526.8 132.41

Wet abrasion excellent RDBPES88 88 654.8 157.80

Dry abrasion excellent RDBPES96 96 797.7 181.82

RDBPES104 104 900.4 205.86

* - value based on data supplied by the fibre manufacturer for

new, dry fiber

Tensile Strengths are determined in accordance with Cordage Institute 1500, Test Methods

2

for Fiber Rope. Weights are calculated at linear density under standard preload (200d )

plus 5%.

Head Office

Phone: +61 (0)8 9418 7500

Fax: +61 (0)8 9418 7511

Email: info@jeyco.com.au

E & OE

You might also like

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Veriflex Intercon 1.8-3kV Cable - 1Document2 pagesVeriflex Intercon 1.8-3kV Cable - 1anastasia abengoaNo ratings yet

- SUPA75Document1 pageSUPA75Roxxana Roxxana1990No ratings yet

- SUPA75 Slickline Rev 29 May 18Document1 pageSUPA75 Slickline Rev 29 May 18hoss mosafaNo ratings yet

- U PVC2 PDFDocument8 pagesU PVC2 PDFMohamed FarghalNo ratings yet

- Specifications & Typical Properties For Motiva Base OilsDocument1 pageSpecifications & Typical Properties For Motiva Base OilsMassimiliano VolaNo ratings yet

- PWL Series: A Super Long Life BatteryDocument2 pagesPWL Series: A Super Long Life BatteryTanveer AhmedNo ratings yet

- Upvc Pipe PDFDocument1 pageUpvc Pipe PDFSuman MaityNo ratings yet

- Data Sheet-H140A (1) (1) - WAZAMDocument2 pagesData Sheet-H140A (1) (1) - WAZAMdaniel.rabahdunordNo ratings yet

- 80315-01 r4 Technical Data Sheet PX-Q300Document1 page80315-01 r4 Technical Data Sheet PX-Q300JOSÉ VILLALOBOS CORALNo ratings yet

- Birotor Plus Positive Displacement Meter: Technical DataDocument4 pagesBirotor Plus Positive Displacement Meter: Technical DataMiftahul FajriNo ratings yet

- Specification: Constant Current Discharge Characteristics Unit:A (25, 77)Document2 pagesSpecification: Constant Current Discharge Characteristics Unit:A (25, 77)Dhani DmjNo ratings yet

- Irrigation (Lamjung)Document18 pagesIrrigation (Lamjung)Laxu KhanalNo ratings yet

- NNV4S6-65S-F4 Product SpecificationsDocument3 pagesNNV4S6-65S-F4 Product SpecificationsTo VT3No ratings yet

- Grade Slate: Vistamaxx Performance PolymersDocument1 pageGrade Slate: Vistamaxx Performance PolymersSatish BindumadhavanNo ratings yet

- TDS-US-ParaWeb 2, Nov15Document1 pageTDS-US-ParaWeb 2, Nov15Saurabh ChandelNo ratings yet

- CBR Laboratorium PB - 0113 - 76 AASHTO T - 193 - 74Document2 pagesCBR Laboratorium PB - 0113 - 76 AASHTO T - 193 - 74Gung SuryaNo ratings yet

- TH Power Inductors - AGP4233: Click For Temperature Derating InformationDocument5 pagesTH Power Inductors - AGP4233: Click For Temperature Derating InformationMarc SugrueNo ratings yet

- Karumel Ex4412: KCC CorporationDocument4 pagesKarumel Ex4412: KCC CorporationABAID ULLAHNo ratings yet

- Macdrill TSSDocument2 pagesMacdrill TSSRaed fouadNo ratings yet

- FRPC Properties EN-RUDocument1 pageFRPC Properties EN-RUVahNo ratings yet

- Component Properties (Sheets: 1) 2. Molar Material BalancesDocument2 pagesComponent Properties (Sheets: 1) 2. Molar Material BalancesMohamed Sayed AbdoNo ratings yet

- M30Easycrete, Trial SheetDocument1 pageM30Easycrete, Trial Sheetabir senguptaNo ratings yet

- Teslin TableDocument1 pageTeslin TableEzequiel FernandezNo ratings yet

- Product Data Sheet: Apsco Technology LubricantsDocument1 pageProduct Data Sheet: Apsco Technology LubricantsMuhannadNo ratings yet

- Co. Material Samp. Batch No. Sample Id T (°C) G*/Sin (Δ) (Kpa 2.442 G* (Kpa) Δ (°) Η* (Mpa S) Ω (Rad/S) Γ* (%) Σ* (Kpa) G (Mm) Τ (N M) Ts (S) Texp (S) Dplate Notes Tcontroller Op. ResultDocument1 pageCo. Material Samp. Batch No. Sample Id T (°C) G*/Sin (Δ) (Kpa 2.442 G* (Kpa) Δ (°) Η* (Mpa S) Ω (Rad/S) Γ* (%) Σ* (Kpa) G (Mm) Τ (N M) Ts (S) Texp (S) Dplate Notes Tcontroller Op. ResultNaveen SinghNo ratings yet

- Sandvik Saf 2205Document4 pagesSandvik Saf 2205Matias Garcia LabrañaNo ratings yet

- HV19153C22PVCDocument1 pageHV19153C22PVCHiVoltageONo ratings yet

- 3-P Separator Design - 1Document10 pages3-P Separator Design - 1Naeem HussainNo ratings yet

- Data Sheet VDM Alloy 22 PDFDocument13 pagesData Sheet VDM Alloy 22 PDFAlberto LazzarettiNo ratings yet

- 8552Document6 pages8552staedtlerpNo ratings yet

- Powered By: SpecificationDocument2 pagesPowered By: SpecificationleninNo ratings yet

- 462 Standar10 PPMDocument1 page462 Standar10 PPMShendi SuryanaNo ratings yet

- 2510 Prepreg System: Industry Material Specification Industry DatabaseDocument5 pages2510 Prepreg System: Industry Material Specification Industry DatabaseChiranthanRameshNo ratings yet

- 管径计算表Document11 pages管径计算表Ascend032No ratings yet

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- Marathon Electric Motors (India) Limited: Rotating Machines Industrial Products UnitDocument3 pagesMarathon Electric Motors (India) Limited: Rotating Machines Industrial Products UnitHUNGNo ratings yet

- Condition Summary Hoheweg Eslpa MRNKCDocument36 pagesCondition Summary Hoheweg Eslpa MRNKCTrần Văn TiếnNo ratings yet

- Apc Materials Properties PDFDocument1 pageApc Materials Properties PDFnamyefNo ratings yet

- Centricast CL 1520 Data SheetDocument6 pagesCentricast CL 1520 Data SheetOlmer Romero MendezNo ratings yet

- Nap-Gard 7-2500 PDFDocument2 pagesNap-Gard 7-2500 PDFPietro ViganNo ratings yet

- XFL 4020Document3 pagesXFL 4020pkmzNo ratings yet

- Table: Frame Section Properties 01 - General Sectionname Material Shape Autotype Totalwt TotalmassDocument5 pagesTable: Frame Section Properties 01 - General Sectionname Material Shape Autotype Totalwt TotalmassJose Alejandrino MendozaNo ratings yet

- Uaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileDocument20 pagesUaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileABHIJITH M SNo ratings yet

- Python Compac27Document2 pagesPython Compac27Konstantinos SynodinosNo ratings yet

- Crystic Ve671Document2 pagesCrystic Ve671M Taufik WijayaNo ratings yet

- Inductor DataSheetDocument5 pagesInductor DataSheetniteshNo ratings yet

- ProctorDocument1 pageProctorAdnan YousafNo ratings yet

- Hit Welding Industry Co.,Ltd. (Changzhou Huatong Welding Industry Co.,Ltd.)Document2 pagesHit Welding Industry Co.,Ltd. (Changzhou Huatong Welding Industry Co.,Ltd.)loucho1487No ratings yet

- Brands You Trust.: CRANE® REVO® - Pneumatic Rack and Pinion ActuatorsDocument12 pagesBrands You Trust.: CRANE® REVO® - Pneumatic Rack and Pinion ActuatorsYamil Diaz SantosNo ratings yet

- HS-2172 Vs HS-5500 Test ComparisonDocument1 pageHS-2172 Vs HS-5500 Test ComparisonRicardo VillarNo ratings yet

- Texaco Meropa 320 Eng M0010Document2 pagesTexaco Meropa 320 Eng M0010Ady MihailaNo ratings yet

- Data Sheet A1 A15 BidimDocument2 pagesData Sheet A1 A15 BidimEmil ElkinNo ratings yet

- Compound Studies With Naphthenic, TDAE, and DAE Extender OilsDocument50 pagesCompound Studies With Naphthenic, TDAE, and DAE Extender OilsJicheng PiaoNo ratings yet

- Radius Jars - Broshure and Spec Sheets - 2020 - Eng Rev - 7057135 - 01Document18 pagesRadius Jars - Broshure and Spec Sheets - 2020 - Eng Rev - 7057135 - 01riadh kherarbaNo ratings yet

- Elec & I&C Cable Construction Progress (As of 21 June, 2018)Document7 pagesElec & I&C Cable Construction Progress (As of 21 June, 2018)Kharisma Pangeran LanangNo ratings yet

- IFB 2300 - BNZ MaterialsDocument2 pagesIFB 2300 - BNZ Materialsmiltone87No ratings yet

- Motiva Group II Base OilDocument1 pageMotiva Group II Base Oiliescobar0702No ratings yet

- The Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandThe Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Study of Subsonic Wind Tunnel and Its Calibration: Pratik V. DedhiaDocument8 pagesStudy of Subsonic Wind Tunnel and Its Calibration: Pratik V. DedhiaPratikDedhia99No ratings yet

- Dekker V Weida Amicus Brief by 17 AGsDocument35 pagesDekker V Weida Amicus Brief by 17 AGsSarah WeaverNo ratings yet

- Promoting The Conservation and Use of Under Utilized and Neglected Crops. 12 - TefDocument52 pagesPromoting The Conservation and Use of Under Utilized and Neglected Crops. 12 - TefEduardo Antonio Molinari NovoaNo ratings yet

- Lesson 3 - Adaptation AssignmentDocument3 pagesLesson 3 - Adaptation AssignmentEmmy RoseNo ratings yet

- Application of The Ritz Method To The Analysis of Non-Linear Free Vibrations of BeamsDocument12 pagesApplication of The Ritz Method To The Analysis of Non-Linear Free Vibrations of BeamsKuldeep BhattacharjeeNo ratings yet

- Suggestions On How To Prepare The PortfolioDocument2 pagesSuggestions On How To Prepare The PortfolioPeter Pitas DalocdocNo ratings yet

- Chapter 8 - Current Electricity - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatDocument123 pagesChapter 8 - Current Electricity - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatskjNo ratings yet

- Management of StutteringDocument182 pagesManagement of Stutteringpappu713100% (2)

- Vicente BSC2-4 WhoamiDocument3 pagesVicente BSC2-4 WhoamiVethinaVirayNo ratings yet

- Jurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIDocument9 pagesJurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIMarsaidNo ratings yet

- Pinterest or Thinterest Social Comparison and Body Image On Social MediaDocument9 pagesPinterest or Thinterest Social Comparison and Body Image On Social MediaAgung IkhssaniNo ratings yet

- Industry GeneralDocument24 pagesIndustry GeneralilieoniciucNo ratings yet

- Smashing HTML5 (Smashing Magazine Book Series)Document371 pagesSmashing HTML5 (Smashing Magazine Book Series)tommannanchery211No ratings yet

- NHD Process PaperDocument2 pagesNHD Process Paperapi-122116050No ratings yet

- New KitDocument195 pagesNew KitRamu BhandariNo ratings yet

- Test 1801 New Holland TS100 DieselDocument5 pagesTest 1801 New Holland TS100 DieselAPENTOMOTIKI WEST GREECENo ratings yet

- Unix SapDocument4 pagesUnix SapsatyavaninaiduNo ratings yet

- EQUIP9-Operations-Use Case ChallengeDocument6 pagesEQUIP9-Operations-Use Case ChallengeTushar ChaudhariNo ratings yet

- Aits 2122 PT I Jeea 2022 TD Paper 2 SolDocument14 pagesAits 2122 PT I Jeea 2022 TD Paper 2 SolSoumodeep NayakNo ratings yet

- CBSE Class 12 Informatics Practices Marking Scheme Term 2 For 2021 22Document6 pagesCBSE Class 12 Informatics Practices Marking Scheme Term 2 For 2021 22Aryan BhardwajNo ratings yet

- Fractional Differential Equations: Bangti JinDocument377 pagesFractional Differential Equations: Bangti JinOmar GuzmanNo ratings yet

- Rfis On Formliners, Cover, and EmbedmentsDocument36 pagesRfis On Formliners, Cover, and Embedmentsali tahaNo ratings yet

- STAB 2009 s03-p1Document16 pagesSTAB 2009 s03-p1Petre TofanNo ratings yet

- Madam Shazia PaperDocument14 pagesMadam Shazia PaperpervaizhejNo ratings yet

- How Should We Allocate Scarce Resources Over Our Business Portfolio?Document20 pagesHow Should We Allocate Scarce Resources Over Our Business Portfolio?Vivek AryaNo ratings yet

- 20150714rev1 ASPACC 2015Document22 pages20150714rev1 ASPACC 2015HERDI SUTANTONo ratings yet

- Week1 TutorialsDocument1 pageWeek1 TutorialsAhmet Bahadır ŞimşekNo ratings yet

- Growth Kinetic Models For Microalgae Cultivation A ReviewDocument16 pagesGrowth Kinetic Models For Microalgae Cultivation A ReviewJesús Eduardo De la CruzNo ratings yet

- Class 12 Unit-2 2022Document4 pagesClass 12 Unit-2 2022Shreya mauryaNo ratings yet

- SST Vs BBTDocument7 pagesSST Vs BBTFlaxkikare100% (1)