Professional Documents

Culture Documents

While: FOS3 2 T t+.0001 Count Count+1

Uploaded by

Michael KinneyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

While: FOS3 2 T t+.0001 Count Count+1

Uploaded by

Michael KinneyCopyright:

Available Formats

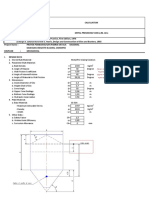

M E 360: Project 1 Michael Kinney

Dan McCormick

T.J. Kupetz

Hand Calculations: Pressure vessel with NO inlet hole.

𝑷𝒓 𝑷𝒓

𝝈𝒉𝒐𝒐𝒑 = 𝟐𝒕

; 𝝈𝒂𝒙𝒊𝒂𝒍 = 𝒕

were used to calculate the hoop and axial stresses. Radius of the tank was

obtained using the formula for volume vs. energy stored for a pressure vessel.

The von Mises stress at a given point was calculated with:

𝝈′ = 𝝈𝒂𝒙𝒊𝒂𝒍 𝟐 + 𝝈𝒉𝒐𝒐𝒑 𝟐 − 𝝈𝒂𝒙𝒊𝒂𝒍 𝝈𝒉𝒐𝒐𝒑

Note: since we were given a factor of safety of 2, and the loading was type III, we had to use

given material properties to iteratively solve for the thickness of the tank. This was done in

MATLAB:

while FOS3 <= 2

t=t+.0001;

count=count+1;

%von Mises Calculation

sigma_long=P*r/t;

sigma_hoop=P*r/(2*t);

von_Mises=(sigma_long^2+sigma_hoop^2-sigma_hoop*sigma_long)^(1/2);

FOS3=(Sf*Sut)/((von_Mises*Sut)+(von_Mises*Sf));

end

This incremented thickness by 0.1mm until the factor of safety reached 2.0. The optimal thickness was

found to be 2.6mm.

Going back to the hoop and axial stresses with this thickness, the von Mises stress was calculated to be

51.79 Mpa.

SolidWorks confirmed our hand calculations (see attached figure).

Our final values for Length, Radius, and Tank thickness are as follows:

Tank length (end-to-end): 2.073m

Tank radius (all round parts): 0.3455m

Tank thickness (uniform): 2.6mm

To reinforce the tank by the inlet hole, we gradually increased the thickness (from the body of the tank

moving towards the end where the hole was) from 2.6mm to 3.5mm. This drastically reduced the stress

in the inlet hole, so the factor of safety remained the same as it was without the hole.

You might also like

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Solution Manual For Materials Engineering Science Processing and Design Ashby Shercliff Cebon 3rd Edition Full DownloadDocument9 pagesSolution Manual For Materials Engineering Science Processing and Design Ashby Shercliff Cebon 3rd Edition Full Downloadkimberlyromeroxfmtcqakeb100% (40)

- UTS Comp MathematicsDocument2 pagesUTS Comp MathematicsRiyan D'forbiddenNo ratings yet

- Design Calculation Report For CCT Tank: TitleDocument15 pagesDesign Calculation Report For CCT Tank: TitleghansaNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- A Common Mistake in Design of Water TankDocument4 pagesA Common Mistake in Design of Water TankKhagesh AkreNo ratings yet

- Structures and Materials Section 7 Stress ConcentrationDocument21 pagesStructures and Materials Section 7 Stress ConcentrationAdi Adams AndaroffsaNo ratings yet

- Design of Steel Structures 46 69Document34 pagesDesign of Steel Structures 46 69Devika shettyNo ratings yet

- Linear Actuator DesignDocument6 pagesLinear Actuator DesignMaida AscicNo ratings yet

- Wood ArmerDocument14 pagesWood ArmerMarek100% (1)

- Design of A Cantilever Beam Under Nonuniform Distributed LoadDocument34 pagesDesign of A Cantilever Beam Under Nonuniform Distributed LoadJoni Carino SuniNo ratings yet

- Solution Tutorial - 1Document2 pagesSolution Tutorial - 1Akash FuryNo ratings yet

- Design of Steel Structures Formula Notes 59Document36 pagesDesign of Steel Structures Formula Notes 59Ayesha RubianaNo ratings yet

- Mechanical Design For Sieve Plate ColumnDocument14 pagesMechanical Design For Sieve Plate ColumnIan Zuhair II100% (1)

- Material Models and Modes of Failure - MM4MMM Fracture: ConvenorDocument17 pagesMaterial Models and Modes of Failure - MM4MMM Fracture: ConvenorSam WilcockNo ratings yet

- Stresses in A Flywheel RimDocument15 pagesStresses in A Flywheel RimSufiyan Mohammed0% (1)

- RwallDocument51 pagesRwallandualemNo ratings yet

- MD 5BDocument73 pagesMD 5Bctvd93100% (1)

- ChimneyDocument23 pagesChimneyUday KiranNo ratings yet

- PHY 171B Lab 1-1Document4 pagesPHY 171B Lab 1-1james50% (2)

- 04 Practical Application WeldingDocument6 pages04 Practical Application Weldingenrico.michelatoNo ratings yet

- Practice 3 4 and 5 - 240404 - 183255Document4 pagesPractice 3 4 and 5 - 240404 - 183255jeehwanryooNo ratings yet

- Plastic Collapse PDFDocument13 pagesPlastic Collapse PDFrajashrismdNo ratings yet

- Cep MosDocument27 pagesCep MosHuzi MalixNo ratings yet

- RC Retaining Wall Design Example ACIDocument9 pagesRC Retaining Wall Design Example ACIAnil kumar RNo ratings yet

- D Mec Frac Fatigue Part IIDocument38 pagesD Mec Frac Fatigue Part IIsure516vNo ratings yet

- Midterm Exam 2017 18Document2 pagesMidterm Exam 2017 18Ellarence RafaelNo ratings yet

- Design of Doubly Rectangular BeamDocument14 pagesDesign of Doubly Rectangular BeamAhmad HusnainNo ratings yet

- Api 650-2015Document29 pagesApi 650-2015tranceintt100% (2)

- Vjezbe Mjerne Tarke ExperimentDocument5 pagesVjezbe Mjerne Tarke Experimentdin10731367No ratings yet

- Learning Packet-3 CE 14 Singly Reinforced BeamDocument17 pagesLearning Packet-3 CE 14 Singly Reinforced BeamWalwal WalwalNo ratings yet

- Shear Wall DesignDocument10 pagesShear Wall DesignfaizanNo ratings yet

- Numerical SDocument4 pagesNumerical S009 Dhanush Gowtham HNo ratings yet

- Cal SiloDocument11 pagesCal SiloAnanda Azaria FebrianaNo ratings yet

- Mini Project 1.. 1Document15 pagesMini Project 1.. 1mohamed.hassan031No ratings yet

- Column Section Demand Capacity Ratio DeterminationDocument2 pagesColumn Section Demand Capacity Ratio DeterminationSandy YansikuNo ratings yet

- Tutorial 8Document13 pagesTutorial 8snoozermanNo ratings yet

- Retaining Wall Worked ExampleDocument12 pagesRetaining Wall Worked ExampleBhardwaj Kartik0% (1)

- Lecture 2 StrengthsDocument9 pagesLecture 2 StrengthsCarlos Augustus GonzalezNo ratings yet

- Mae (256F) - HW2 PDFDocument6 pagesMae (256F) - HW2 PDFClaireNo ratings yet

- CIE3150 2017 Case Study Beam V 03-2Document19 pagesCIE3150 2017 Case Study Beam V 03-2FerdiVKNo ratings yet

- ENG782S2Document8 pagesENG782S2Emperor RocaNo ratings yet

- FFT 3Document5 pagesFFT 3Avinash Kumar Jha 4-Year B.Tech. Mechanical EngineeringNo ratings yet

- Design and Analysis of An Aerial ScissorDocument4 pagesDesign and Analysis of An Aerial ScissorBảo Toàn LêNo ratings yet

- Worked Example - Retaining Wall Design - The Structural WorldDocument11 pagesWorked Example - Retaining Wall Design - The Structural WorldloishookiNo ratings yet

- Question: 5 A. A Hollow Circular Cylinder Is Made of Cast Iron and Has AnDocument2 pagesQuestion: 5 A. A Hollow Circular Cylinder Is Made of Cast Iron and Has AnMustafa KhudhairNo ratings yet

- 34 Design of Joints With Variable LoadingDocument8 pages34 Design of Joints With Variable LoadingPRASAD326100% (1)

- CE223 Fluid Mechanics Course AssignmentDocument6 pagesCE223 Fluid Mechanics Course AssignmentKing of KingsNo ratings yet

- Final Term Project PDFDocument44 pagesFinal Term Project PDFKevin BaxterNo ratings yet

- TR3011-2023-Compressible Aerodynamics Midterm Exam 152Document2 pagesTR3011-2023-Compressible Aerodynamics Midterm Exam 152Đăng PhạmNo ratings yet

- Stress Intensity Factor and Fracture Toughness TestingDocument31 pagesStress Intensity Factor and Fracture Toughness TestingShahrul Azmin0% (1)

- Structural Reinforced Concrete: Student Task 3-01Document17 pagesStructural Reinforced Concrete: Student Task 3-01Gleanna NiedoNo ratings yet

- ME328 Introduction to Design Cylinder Stresses: ldr + 2σ lr − 2l (σ dr term because it's theDocument3 pagesME328 Introduction to Design Cylinder Stresses: ldr + 2σ lr − 2l (σ dr term because it's theAndri IndriawanNo ratings yet

- Alcorcon Engineering Review Center: I. Machine FoundationDocument5 pagesAlcorcon Engineering Review Center: I. Machine FoundationReinzo GallegoNo ratings yet

- PE Cheat SheetDocument5 pagesPE Cheat Sheetdnl_vicars100% (1)

- Learning Packet 3 Partial01Document10 pagesLearning Packet 3 Partial01ronnie oraleNo ratings yet

- Three Hours: Structural IntegrityDocument21 pagesThree Hours: Structural IntegrityLi'sNo ratings yet

- Perhitungan Stabilitas Pondasi Bored Pile Pada Proyek Double-Double TrackDocument10 pagesPerhitungan Stabilitas Pondasi Bored Pile Pada Proyek Double-Double Trackandiny karlinaNo ratings yet

- Project4 Detailed Design ReportDocument36 pagesProject4 Detailed Design ReportMichael KinneyNo ratings yet

- Output Shaft Lube Nozzle Bearings Bolts RCM Face-Gear PMC Face-GearsDocument9 pagesOutput Shaft Lube Nozzle Bearings Bolts RCM Face-Gear PMC Face-GearsMichael KinneyNo ratings yet

- End of SummmerDocument2 pagesEnd of SummmerMichael KinneyNo ratings yet

- Process DescriptionDocument6 pagesProcess DescriptionMichael KinneyNo ratings yet

- Process DescriptionDocument3 pagesProcess DescriptionMichael KinneyNo ratings yet

- Michael A. Kinney: 115 Elm Ave. 215-718-7722 Churchville, PA 18966 Mak5202@psu - EduDocument1 pageMichael A. Kinney: 115 Elm Ave. 215-718-7722 Churchville, PA 18966 Mak5202@psu - EduMichael KinneyNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesFrom EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsFrom EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsRating: 5 out of 5 stars5/5 (1)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneFrom EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneRating: 4.5 out of 5 stars4.5/5 (5)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)