Professional Documents

Culture Documents

C9704 Bladder Tank

Uploaded by

kalimutu2010Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C9704 Bladder Tank

Uploaded by

kalimutu2010Copyright:

Available Formats

Fire Fighting Industry

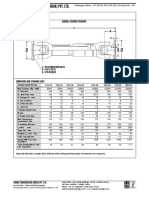

BLADDER TANK

GENERAL INFORMATION

Design conform and certified to ASME Code by local authorized agent (DEPNAKER). Two

type tank design from horizontal and vertical to meet a specific end user requirement. Started

from as small as 200 ltr foam capacity to 5000 ltr foam capacity. Bigger size are available

upon request. The bladder tank used together with a MGF Foam Proportioner, that will allow

accurate mixing of foam agent. (1-6%)

The most important feature of this bladder tank and system is the design, based upon non

moving parts. The force of water pressure inlet goes in, mean the bladder system star in

operation. By pressurizing a rubber bladder and allowing foam agent to mix into the main line

at the preset proportioning rate. As long as the MGF Bladder tank design with no further

utilities involved in working system except main water flow, a MGF bladder tank proportioning

will work safe without fail and safe operation.

TECHNICAL DATA

Design : ASME Section VIII

Design Pressure : 12.1 bar / 175 psi

Hydrotest : 19 bar / 275 psi

Vessel Material : Carbon Steel

Rubber Bladder : Thermoplastic rubber

Strength : 16 kg/cm2

Elongation : 450%

Connection : ASNI standard

Finishing : external primer and red epoxy

Internal primer coating

TANK DIMENSION & WEIGHT --- VERTICAL

Model Volume Height Diameter Appr Weight Connection

Ltr mm mm kg

MGF500S 500 1650 800 470

MGF750S 750 2340 800 530

MGF100B 1000 1910 1100 765 2” ANSI

MGF120B 1200 2110 1100 823 150lbs, RF

MGF150B 1500 2410 1100 910

MGF200B 2000 3010 1100 1077

MGF250B 2500 2520 1400 1400

MGF300B 3000 2870 1400 1552

MGF350B 3500 3170 1400 1683 3” ANSI

MGF400B 4000 3570 1400 1857 150lbs, RF

MGF450B 4500 3870 1400 1990

MGF500B 5000 4170 1400 2118

rd

Sentra Latumenten AA#18, 3 floor – Jakarta 11460 – T : (+62 21) 56941933 – F : (+62 21) 56944397 – www.mgf.co.id

You might also like

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- HVAC B.O.Q Cost Breakdown Master Sheet For Construction ProjectsDocument6 pagesHVAC B.O.Q Cost Breakdown Master Sheet For Construction ProjectsSanjeevan KrishnasamyNo ratings yet

- Lehry MRPDocument67 pagesLehry MRPvinayak abhaleNo ratings yet

- FRP Centrifugal: BlowerDocument8 pagesFRP Centrifugal: BlowerKanupriya JainNo ratings yet

- Comparison of 20 Ton ClassDocument7 pagesComparison of 20 Ton ClassFredy_AndiLoloNo ratings yet

- Air CellDocument3 pagesAir CellSathish Kumar ANo ratings yet

- General MEP (BOQ & COST)Document21 pagesGeneral MEP (BOQ & COST)Skill IndiaNo ratings yet

- LHP Price LIst - LP007 PDFDocument28 pagesLHP Price LIst - LP007 PDFRavichandran S100% (1)

- Marine Eng Est Time Between OverhaulsDocument6 pagesMarine Eng Est Time Between OverhaulsagvassNo ratings yet

- Venturi Flow Test Meter / Model AYV: Fire Pump Flowmeter SystemDocument2 pagesVenturi Flow Test Meter / Model AYV: Fire Pump Flowmeter Systemdekra abdoNo ratings yet

- Flowmeter Venturi Incendio Sala de Bombas PDFDocument2 pagesFlowmeter Venturi Incendio Sala de Bombas PDFCris YañezNo ratings yet

- Flowmeter Venturi Incendio Sala de Bombas PDFDocument2 pagesFlowmeter Venturi Incendio Sala de Bombas PDFCris YañezNo ratings yet

- V Anular - SGP (Eng)Document8 pagesV Anular - SGP (Eng)John lercariNo ratings yet

- Permanent Magnetic Lifter - Specification Table - ENDocument2 pagesPermanent Magnetic Lifter - Specification Table - ENSunil GurubaxaniNo ratings yet

- General MEP (BOQ & COST)Document27 pagesGeneral MEP (BOQ & COST)MEGAWATT CONTRACTING AND ELECTRICITY COMPANYNo ratings yet

- HVAC - BOQ, Cost Estimate & ProcurementDocument6 pagesHVAC - BOQ, Cost Estimate & Procurementsunkk0369No ratings yet

- MS 400, MS 650: Series Submersible MixerDocument25 pagesMS 400, MS 650: Series Submersible MixerAnonymous CMS3dL1TNo ratings yet

- SKUM Bladder Tank MTB Vertical - FDS14306 0214 LRDocument2 pagesSKUM Bladder Tank MTB Vertical - FDS14306 0214 LRLupiNo ratings yet

- Drip Sampler IIDocument1 pageDrip Sampler IIEnrique BarriosNo ratings yet

- General MEP (BOQ & COST)Document21 pagesGeneral MEP (BOQ & COST)projects.nptsuae.comNo ratings yet

- Butterfly ValvesDocument4 pagesButterfly ValvesrahulNo ratings yet

- Mad G SeriesDocument4 pagesMad G SeriesKali Dass KMNo ratings yet

- Kranti List Feb 2021Document1 pageKranti List Feb 2021Himank Gupta0% (1)

- AHP Critical Spares ListDocument2 pagesAHP Critical Spares ListVikasShuklaNo ratings yet

- HitachiDocument66 pagesHitachiNay Soe100% (2)

- Flexible Coupling PDFDocument4 pagesFlexible Coupling PDFSatNo ratings yet

- Coupling Catalog oDocument3 pagesCoupling Catalog oGanesh KhandareNo ratings yet

- GP100S-Crusher-Parts-Manual 373083390 PDFDocument2 pagesGP100S-Crusher-Parts-Manual 373083390 PDFАлександрNo ratings yet

- Pneumatic AC Spot Welding Machine-HWASHI 001Document8 pagesPneumatic AC Spot Welding Machine-HWASHI 001Juan OrtegaNo ratings yet

- Universal Joint Drawing - 1Document2 pagesUniversal Joint Drawing - 1patelchiragisNo ratings yet

- Screw Press Technical Data: Nominal ProdDocument1 pageScrew Press Technical Data: Nominal ProdRobby PutraNo ratings yet

- GB Double Scissors VDocument2 pagesGB Double Scissors VCostescuAdrianNo ratings yet

- BOQ - Bill of Quantities and Cost Sheets For MEP ProjectsDocument21 pagesBOQ - Bill of Quantities and Cost Sheets For MEP ProjectsChaithanya100% (5)

- 16-400 enDocument145 pages16-400 enluis_erf22No ratings yet

- Lampiran Surat Perubahan Retail Price SGP Periode June 2019Document6 pagesLampiran Surat Perubahan Retail Price SGP Periode June 2019Istiqomah khaeriyyah100% (1)

- Gate - Globe - Check - Strainer - Dual CheckDocument32 pagesGate - Globe - Check - Strainer - Dual CheckSacre EwaNo ratings yet

- Pinbush - Tyre Coupling 2014Document4 pagesPinbush - Tyre Coupling 2014Priyam NandwanaNo ratings yet

- Revised Offer Consoliadted BOQ-Jio PointDocument9 pagesRevised Offer Consoliadted BOQ-Jio PointPankaj ChaddaNo ratings yet

- ELGi AIRLUBE 500 HRS & ELGi AIRLUBE PLUS 750 HRSDocument1 pageELGi AIRLUBE 500 HRS & ELGi AIRLUBE PLUS 750 HRSANILNo ratings yet

- Gtec Transfer SwitchesDocument4 pagesGtec Transfer SwitchesthiagobrenoNo ratings yet

- Process Pump Technical OfferDocument53 pagesProcess Pump Technical OfferHisham ElsayedNo ratings yet

- Product Datasheet: Finish: Dimensions: Weight: 2.114 G IeeDocument6 pagesProduct Datasheet: Finish: Dimensions: Weight: 2.114 G IeeKATHERINE MEJIANo ratings yet

- 1LES100025 ZD Low Voltage Transformers PDFDocument4 pages1LES100025 ZD Low Voltage Transformers PDFDiego Peña100% (1)

- Footing Steel Quantity of Morarka CollegeDocument21 pagesFooting Steel Quantity of Morarka CollegeHANISHNo ratings yet

- Code of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Document11 pagesCode of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Sarbendu PaulNo ratings yet

- API600 API602 GATE VALVEMODEL GVT WebDocument14 pagesAPI600 API602 GATE VALVEMODEL GVT WebBakheit LayliNo ratings yet

- CHP SpecifictionDocument36 pagesCHP SpecifictionVaibhav Jain100% (1)

- 馬來西亞 說明書 PDFDocument6 pages馬來西亞 說明書 PDFChris TiongNo ratings yet

- Sil Technical Document GFRP PDFDocument5 pagesSil Technical Document GFRP PDFprashant patilNo ratings yet

- 0.S22180FES-Al Qiddiya Pump Station, KSA - WB - R60-SG-06.10.23Document7 pages0.S22180FES-Al Qiddiya Pump Station, KSA - WB - R60-SG-06.10.23Osama KheadryNo ratings yet

- Pan American Silver: MODEL:3700 10th Edition (ISO13709) LA SIZE:3x4-16S QTY: 2Document6 pagesPan American Silver: MODEL:3700 10th Edition (ISO13709) LA SIZE:3x4-16S QTY: 2wilsonNo ratings yet

- Progressing Cavity Pump (PCP) - Huaming EnergyDocument3 pagesProgressing Cavity Pump (PCP) - Huaming EnergyKevin XuNo ratings yet

- MB Series Spec Sheet 2014 v2Document3 pagesMB Series Spec Sheet 2014 v2Maurynho ChavezNo ratings yet

- Omega NH FuseDocument5 pagesOmega NH Fusevu leNo ratings yet

- Ductile Iron Gate Valve Acc - To BS Flanged PN 16Document2 pagesDuctile Iron Gate Valve Acc - To BS Flanged PN 16khai ruleNo ratings yet

- Unirub Techno India PVT 1Document5 pagesUnirub Techno India PVT 1BalajiYachawadNo ratings yet

- KATALOG KočnicaDocument4 pagesKATALOG KočnicaamirNo ratings yet

- 6cta8.3-C (CPR256)Document2 pages6cta8.3-C (CPR256)Dennis K ThomasNo ratings yet

- A 906 - A 906m - 99 - Qtkwni9bota2ts1sruqDocument8 pagesA 906 - A 906m - 99 - Qtkwni9bota2ts1sruqZam DresNo ratings yet

- C9723 Portable MonitorDocument1 pageC9723 Portable Monitorkalimutu2010No ratings yet

- C9721 MonitorDocument1 pageC9721 Monitorkalimutu2010No ratings yet

- C9725 Hydrant PillarDocument1 pageC9725 Hydrant Pillarkalimutu2010No ratings yet

- EDM & Genset CO2 SystemDocument2 pagesEDM & Genset CO2 Systemkalimutu2010No ratings yet

- C9722 Master NozzleDocument1 pageC9722 Master Nozzlekalimutu2010No ratings yet

- C9720 Hydrant ValveDocument1 pageC9720 Hydrant Valvekalimutu2010No ratings yet

- C9709 Foam ChamberDocument1 pageC9709 Foam Chamberkalimutu2010No ratings yet

- C9715 HD600BDocument2 pagesC9715 HD600Bkalimutu2010No ratings yet

- C9713 Foam Hose ReelDocument1 pageC9713 Foam Hose Reelkalimutu2010No ratings yet

- C9715 HD600BDocument2 pagesC9715 HD600Bkalimutu2010No ratings yet

- C9708 Fire HoseDocument1 pageC9708 Fire Hosekalimutu2010No ratings yet

- c9705 Comp BT-HDDocument1 pagec9705 Comp BT-HDkalimutu2010No ratings yet

- C9712 Hose ReelDocument2 pagesC9712 Hose Reelkalimutu2010No ratings yet

- C9706 2way MonitorDocument1 pageC9706 2way Monitorkalimutu2010No ratings yet

- C9701 Coupling WyesDocument1 pageC9701 Coupling Wyeskalimutu2010No ratings yet

- C9707 ENG MonitorDocument1 pageC9707 ENG Monitorkalimutu2010No ratings yet

- AFFF FoamDocument2 pagesAFFF Foamkalimutu2010No ratings yet

- BOQ Fountain Water Body (1) .XLSXBDocument6 pagesBOQ Fountain Water Body (1) .XLSXBPrashant Singh Chauhan60% (5)

- Hydrogen Fracturing Process Section 6Document8 pagesHydrogen Fracturing Process Section 6BillNo ratings yet

- Chapter 8 Ionic Chain PolymerizationDocument34 pagesChapter 8 Ionic Chain PolymerizationelnurorucluNo ratings yet

- The Effects of Different Debittering Methods On The Production of Lupin Bean Snack From BitterDocument16 pagesThe Effects of Different Debittering Methods On The Production of Lupin Bean Snack From BitterMalak BattahNo ratings yet

- Exercises: Sections 10.3, 10.4: The Gas Laws The Ideal-Gas EquationDocument6 pagesExercises: Sections 10.3, 10.4: The Gas Laws The Ideal-Gas EquationPcd MickeyNo ratings yet

- VOL-VCA EN Proefexamen PDFDocument15 pagesVOL-VCA EN Proefexamen PDFKonstantins Slatins100% (1)

- Tropical and Subtropical Agroecosystems 1870-0462: E-Issn: Ccastro@uady - MXDocument9 pagesTropical and Subtropical Agroecosystems 1870-0462: E-Issn: Ccastro@uady - MXFaisalNo ratings yet

- Laporan Obat Ed 2016: No. Nama Barang Unit ED Jumlah HPPDocument3 pagesLaporan Obat Ed 2016: No. Nama Barang Unit ED Jumlah HPPIeie MawonNo ratings yet

- Well Control MethodsDocument4 pagesWell Control MethodsVassilios KelessidisNo ratings yet

- Acids, Bases and Salts MCQS: (D) (Ii) and (Iv)Document12 pagesAcids, Bases and Salts MCQS: (D) (Ii) and (Iv)Atharva BhokareNo ratings yet

- Deal AMA NAMA 14.04.23Document26 pagesDeal AMA NAMA 14.04.23Afif SetiawanNo ratings yet

- 1100 XC Airless SprayerDocument28 pages1100 XC Airless SprayerR Fonseca GomezNo ratings yet

- Surface Water Treatment Operator Certification Manual - Tratamiento de Aguas ResidualesDocument311 pagesSurface Water Treatment Operator Certification Manual - Tratamiento de Aguas ResidualesJhon Jairo Mazuera GuzmanNo ratings yet

- Atomic Absorption Spectrophotometry (AAS)Document4 pagesAtomic Absorption Spectrophotometry (AAS)Kurnia JayantoNo ratings yet

- Code For Electrical Installations at Oil and Gas Facilities-2015 4edDocument58 pagesCode For Electrical Installations at Oil and Gas Facilities-2015 4edMarijan Utroša100% (1)

- CE8005 QB Air Pollution and Control Engineering PDFDocument13 pagesCE8005 QB Air Pollution and Control Engineering PDFRohini meeraNo ratings yet

- Explosives PDFDocument9 pagesExplosives PDFuttamksrNo ratings yet

- HamzaDocument20 pagesHamzaHamza KhakwaniNo ratings yet

- SISTO - Maintenance-Free Diaphragm Valves With and Without LiningDocument2 pagesSISTO - Maintenance-Free Diaphragm Valves With and Without LiningsharemwNo ratings yet

- Thermo-Lag 3000-P PDS PDFDocument7 pagesThermo-Lag 3000-P PDS PDFskNo ratings yet

- Lagermeister XXL-SDSDocument6 pagesLagermeister XXL-SDSPratik MoreNo ratings yet

- Bruice Organic Chemistry 6eDocument26 pagesBruice Organic Chemistry 6esdfasf asdasdasd100% (1)

- Abn Abwa 8s eDocument8 pagesAbn Abwa 8s efrancis eugenioNo ratings yet

- Us 4570540Document3 pagesUs 4570540erwerNo ratings yet

- Exam 3 Review Sheet Chem 1601 F17Document1 pageExam 3 Review Sheet Chem 1601 F17RossNo ratings yet

- Purestab Md1024: Technical Data SheetDocument2 pagesPurestab Md1024: Technical Data SheetHadyan AdliNo ratings yet

- Braskem Braskem PP PCD 0140BR Polypropylene Impact CopolymerDocument2 pagesBraskem Braskem PP PCD 0140BR Polypropylene Impact CopolymerBFCNo ratings yet

- History of Organic Chemistry 2Document2 pagesHistory of Organic Chemistry 2MiaNo ratings yet

- Mec 9000Document40 pagesMec 9000Dark Cenobite100% (1)

- Cellular Respiration Review WorksheetkeyDocument6 pagesCellular Respiration Review WorksheetkeyLiezel Cagais SanchezNo ratings yet