Professional Documents

Culture Documents

Lab Report Fiber Optics

Uploaded by

ArvinBautistaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Report Fiber Optics

Uploaded by

ArvinBautistaCopyright:

Available Formats

Laboratory Activity: Fiber Optics and Optical Power

Measurements

J. A. D. Bautista

A. A. M. Castillo

Abstract— This laboratory report will discuss the characteristics

of optical fibers, specifically, the single-mode fiber (S MF) and the

multi-mode fiber (MMF). The report will go into the power

measurements of both types of fibers and will also observe the

power outputs for the mechanical splicing combinations using

the two fibers. Furthermore, the characteristics of a 50/50 fiber

coupler is also observed and discussed.

Fig. 1. Optical Fiber Structure

I. CONCEPT AND THEORY

There are basically two types of fibers: stepped index and

In 1854 a British physicist by the name o f John Tyndall graded index. Graded index fibers has a h igh index of

discovered that light could be bent around a corner through a refract ion at the center of the fiber and exh ibits a gradual

curved spout of running water. In this experiment he permitted decrease of the index as one moves away from the center. On

water to spout from a tube, the light on reaching the limit ing the other hand, step-index fibers have an abrupt and distinct

surface of air and water was totally reflected and seemed to be difference between the fiber core and cladding. The graded

washed downwards by the descending liquid [1] . Tyndall index fiber and the step index fiber are illustrated in Fig. 2 and

discovered the idea of total internal reflection (TIR) and it is Fig. 3, respectively.

fro m this concept where optical fiber co mmun ication is built

on.

Like any other fo rm o f co mmun ication, fiber optic

communicat ion is co mposed of three elements, a light source

which acts as the sender of informat ion, a fiber media which

acts as the transmission mediu m, and a light detector for the

receiving end [2]. Most light sources emit light with Fig. 2. Multi-mode Graded index fiber.

wavelengths of 1300n m and 1550n m since these are the points

when the least attenuation is experienced, as will be discussed

in depth later.

For this activity, the focus is on the transmission mediu m

known as the optical fiber.

Optical Fibers

Fig 3. Multi-mode Stepped index fiber.

Optical fibers are the actual media that guides the ligh t [2].

The fibers can either be made of glass or plastic, but glass The stepped index fiber is further classified into two types:

fibers are more preferred because they exh ibit less attenuation. the single mode and the multi-mode fiber. The mu lti-mode

The typical fiber structure is usually made up of a core center stepped index fiber has, mult iple paths for the light to travel,

where the light actually propagates in; a cladding of lower as shown in Fig. 2 and Fig. 3 while the single mode fiber only

index of refract ion that allows the light to undergo TIR and allows a single light ray to propagate as shown in Fig. 4 [2].

propagate down the fiber; and the buffer coating which serves

as protection for the other parts of the fiber. A typical

structure for an optical fiber is shown in Fig. 1.

Fig. 4. Single Mode Fiber

attenuation of silica fiber is shown in Fig. 7. As shown in the

Refractive Index and Total Internal Reflection graph, three “windows” are identified as ideal wavelengths for

light sources. Nowadays, the 1300n m and 1550n m windows

Optical fiber communication relies on the concept of Total are co mmonly in use. These are the points where the

Internal Reflection (TIR) for light to properly propagate down attenuation of silica is at a local minima [3]. The most

the media to its destination. TIR is achieved when light goes significant factors contributing to the attenuation are Rayleigh

from a medium of higher refractive index to a lower refractive scattering and material absorption.

index and the angle of the reflected beam exceeds 90 degrees

from the normal of the interfaces. This property is governed Material absorption occurs as a result of the imperfect ion

by Snell’s law given below, and Fig. 5. illustrates the concept and impurities in the fiber. The most common impurity is the

of TIR. hydroxyl (OH-) mo lecule, which remains as a residue fro m

manufacturing of the fiber [4]. The absorbed light particles are

lost to the impurities thus causing a loss in power.

where n 1 and n 2 are refractive indexes of material 1 and Rayleigh scattering is the result of elastic collisions between

material 2, while θ 1 and θ 2 are angles of the incident ray and the light wave and the silica mo lecules in the fiber [4].When

the reflected ray, respectively, with respect to the normal of th elastic collisions occer, the light scattered in all directions.

the interface. If the scattered light continues to propagate down the fiber, no

attenuation occurs but there is also the chance that the

scattered light is unable to continue down the fiber.

Splicing

Two optical fiber splicing methods are available for

permanent jo ining of two optical fibers. The optic cable fusion

splicing with an insertion loss of less than 0.1db is

imple mented using a special equip ment called fusion splicer.

The other type is mechanical splicing with an insertion loss of

Fig. 5. T otal Internal Reflection inside the Optical Fiber.

less than 0.5d B. Mechanical splicing uses a small mechanical

splice, that precisely aligns two bare fibers and secures them

mechanically [7]. Mechanical splicing is the splicing method

Optical Power in Watts and dBM

mentioned in this activity.

In optical co mmunicat ion, optical power measures the rate

Fiber coupler

at which photons arrive at a detector, it is a measure of energy

transfer per time and has a unit of Watts [5]. The power level

A fiber coupler is an optical fiber device with one or more

is too wide to be exp ressed on a linear scale. Thus, the

input fibers and one or several output fibers. Light fro m an

logarith mic scale known as decibel (dB) is used to express in

input fiber can appear at one or more outputs, with the power

optical co mmunicat ions [4]. The decibel does not give a

distribution potentially depending on the Wavelength and

magnitude of power, but it is a rat io of the output power to the

polarization [6].

input power, both in Watts, as expressed by,

dB = 10log(Pout /Pin ) (1) II. M ET HODOLOGY

The power level related to 1mW is noted as dBm and the

The activity calls for following safety guides for eye safety

power level related to 1µW is noted as dBµ. The dBm and

as well as proper handling of fiber optic cable. A paraphrased

dBµ equations are given as follows,

list of the guidelines is given below.

dBm = 10log(P/1mW) (2)

Eye Safety

Do not directly shine visib le and infrared radiation

dBµ = 10log(P/1µW) (3)

into your eyes.

Attenuation Turn off power source during manipulat ion and

concatenation of optical fiber.

The material most used in optical fibers is silica (SiO2) [3]. No bare fiber will be handled in this lab to

Silica fiber exh ibit d ifferent attenuation rates given different eliminate danger of serious eye injury due to

wavelengths for the source input. A graph of the spectral microscopic glass particles.

For the first part of the activity, the value of the optical

Proper fiber handling output power measured at the opposite end of the SM optical

fiber is read in dBm and it is converted to mW by isolating P

maintain optical quality and cleanliness of the in (2). The equation for dBm to mW is given by,

fiber endfaces and instrument connector interfaces.

(4)

Wash hands in soap before the activity.

Use a lint-free tissue and residue free isopropanol Computations from dBm to mW in Table I is as follows,

for cleaning optical surfaces .

Allow 15 seconds for surfaces to dry before (5)

mating. = 0.160mW

Always cap fiber end, bulkheads and mating

sleeves to percent contamination of optically clean = 0.133mW

surfaces.

List of Materials and Equipment A comparison of the values of the output power of the SMF

alone to when it was coupled with the MMF via the mating

single mode 2x2 fier coupler sleeve, gives the observation that the addition of the MMF

fiber semiconductor also added further attenuation or loss in power. The loss in

multimode fiber grade isopropyl power can be computed by simply, subtracting the dBm value

optical power alcohol of the SMF alone from the power of the SM-MMF power loss,

meter lint-free tissue given by,

optical source bulkhead caps

FC connector fiber connector (6)

( )

FC bulkhead caps

infrared sensor

fiber mating

sleeves

This additional loss could have been brought about by

To observe the different optical power behavior with the connector losses (caused by the mating sleeve). But the more

probable cause would be the fact that because there is a longer

SM and MM fiber several measurements are taken. In Part I of

fiber, the light travels a longer d istance, thus, being more

the activity, the SM fiber is coupled with a 1.3 micron light,

then measurements of the optical power at the opposite end of prone to Rayleigh scattering or absorption losses.

the fiber are taken. Next, the SM fiber is coupled w ith a

mat ing sleeve into a MM fiber, then optical power is T ABLE III

measured at the end of the MM fiber. A similar procedure is VALUES FOR P ART II OF THE ACTIVITY

done in Part II of the activity for the MM fiber, except that Fiber Type Power in dBm Power in mW

this time, it is the SM fiber that is coupled with the MM fiber, Multi-mode 0.170mW

and the power output is measured fro m the end of the SM

-7.69

fiber.

MMF-SMF splice -10.16 0.096mW

For the Part III of the activity, a 50/50 also called a 3 d B

fiber coupler is used and output power is measured fro m the Part II of the activ ity is essentially similar to the procedures

remain ing three ends. The characteristics and parameters of done for Part I, except that this time the MMF was used and a

the fiber coupler is then analyzed based on the observed data. MMF-SMF splice was created. Measure power values for Part

. II of the activity is shown in Table II. Co mputations using (4)

for converting dBm to mW for Part II are as follows,

III. RESULT S AND DISCUSSION

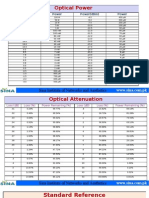

T ABLE I = 0.170mW

VALUES FOR P ART I OF THE ACTIVITY

Fiber Type Power in dBm Power (mW) = 0.096mW

Single Mode -7.94 0.160mW

SMF-MMF splice -8.75 0.133mW

For the additional loss of the MMF-SMF splice, the loss can Thus the experimental ratio is 46/ 54 (Port 3/ Port 4),

be calculated using (6) as in Part I, instead of 50/50.

( )

IV. A NSWERS T O QUEST IONS

The additional 2.47dB loss can again be attributed to loss 1. What is the core diameter of SMF-28 optical fiber?

caused by the mating sleeve or the Rayleigh scattering and

absorption because of the added length of the fiber, SMF-28 is manufactured to the most demanding

specifications in the industry and is widely used in the

transmission of voice, data and/or video. It has a core

T ABLE IIIII diameter o f 8.2u m a nu merical aperture of 0.14 and a

VALUES FOR P ART III OF THE ACTIVITY refractive difference of 0.36% [9].

Port Power in Power in Power in 2. What is the conventional color of singlemode fiber?

dBm mW µW

Port 2 -23.26 0.004 4 The fiber's jacket color is at times used to differentiate

Port 3 -9.97 0.101 101 mu lti-mode fibers (orange) fro m single-mode (yellow)

Port 4 -11.48 0.071 71 fibers [10].

3. Assuming 100% coupling efficiency of power into the

For the values in Part III, the measure power are converted

into mw and µW using a version (2) and (3). Co mputations optical power meter, how much optical power is lost in

are as follows, the SMF-MMF mechanical splice?

Port 2 As shown in (6), a loss of 0.81 dB is added when the

SMF-MMF splice was made. This translates to an

= 0.004mW additional 18% loss.

= 4µW 4. Assuming 100% coupling efficiency of power intothe

optical power meter, how much optical power is lost in

Port 3 the MMF-SMF mechanical splice?

= 0.101mW

Similar to question 3, the additional loss of the MMF-

SMF splice was already co mputed in the discussion

= 101µW and the results are about -2.47 d B wh ich translates to

an additional 43% loss.

Port 4

= 0.071mW 5. The measured output powers at 3 and 4 are consistent

with what launched input power(at port 1)?

= 71µW No, they do not add up, the sum of Port 3 and Port o f

are less than the input power. This is because of the

loss incurred by the ray as it p ropagated down the fiber

coupler.

Based on the values of the power fro m Port 3 and Port 4, it

can be seen that the theoretical coupling ratio of 50/50 is not 6. Given your data, what is the coupling ratio of the

followed, instead, the experimental coupling rat io is computed device?

by,

As computed in the discussion, the experimental

coupling ratio is 46/54 (Port 3/ Port 4), instead of

( ) 50/50.

7. Assuming a 4% reflection off the glass-air interface at

port 3 and 4, estimate the power that should be

( ) measured at port 2 (state in both dBm and mW or µW).

Explain why how this is consistent with your measured

value, and if there is no discrepancy, hypothesize

reasons for such by identifying possible other sources [9] http://www.photonics.byu.edu/FiberOpticConnectors

of loss in path. .parts/images/smf28.pdf

The computation for the experimental power at port 2 [10] www.tech-faq.com/multi-mode-fiber.ht m

given a 4% reflection is given by,

Power at Port 2 = (Power at Port 3(µW) + Power at

Port 4(µW)) x 0.04

Fro m the formu la the experimental power for Port 2 is

6.88 µW or .006mW o r -22.22 dB, which are values

greater than the experimental value meaning loss is

also experienced by the reflected beam that enters port

2.

V. CONCLUSION

Optical fibers are essential for optical co mmunicat ion. It is

important to understand the characteristics of the fiber

especially with how power is los t as light propagates down the

fiber. With an understanding of the attenuation characteristics

of the fiber, an efficient commun ication system can be

realized.

VI. REFERENCES

[1] Allan, W. B., Fiber Optics: Theory and Practice,

(Plenum Press, NewYork, 1973).

[2] http://www.openoptogenetics.org/images/f/fb/Funda

mentals_of_Fiber_Optics.pdf.

[3] http://lib.tkk.fi/Diss/2006/isbn9512282658/ isbn9512

282658.pdf.

[4] http://books.google.com/books?id=5LMp7y xfeDA C

&pg=PA53&dq=optical+power&h l=en&ei=u weCTe

SDNc3Ccdb

IAD&sa=X&oi=book_result&ct=result&resnum=2&

ved=0

DUQ6AEwAQ#v=onepage&q=optical%20power&f

=false

[5] http://books.google.com/books?id=hw1PFAr2L0s C&

pg=PA237&dq=optical+power+definition&hl=en&ei

=7weCTd3xCIO3cL65xaM D&sa=X&oi=book_resul

t&ct=result&resnum=2&ved=0CDYQ6A EwA Q#v=

onepage&q=optical%20power%20definition&f=false

[6] http://www.timbercon.com/Fiber-Opt ic-Coupler.ht ml

[7] http://www.fiberoptics4sale.co m/Merchant2/fiber -

optic-splicing-tutorial.php

[8] http://www.scribd.co m/doc/3942245/ Optical-fiber-

Structures

You might also like

- Characteristics of Cut-Off Shifted Single-Mode Optical Fibre and CableDocument24 pagesCharacteristics of Cut-Off Shifted Single-Mode Optical Fibre and CableDan BuruianaNo ratings yet

- AutoCAD Mechanical 2015 Overview Brochure - A4Document4 pagesAutoCAD Mechanical 2015 Overview Brochure - A4Raul ReynosoNo ratings yet

- Electrocraft EAD BLDC CatalogDocument16 pagesElectrocraft EAD BLDC CatalogElectromateNo ratings yet

- 2012.08.06 Osn - 1800 - R3 - CWDM & DWDMDocument45 pages2012.08.06 Osn - 1800 - R3 - CWDM & DWDMvictoriovegaNo ratings yet

- 2-Pengenalan Material SupportDocument14 pages2-Pengenalan Material Supportde suNo ratings yet

- Quidway AR19 Series Routers Product SpecificationDocument6 pagesQuidway AR19 Series Routers Product SpecificationAlexNo ratings yet

- STP100 (Fiber Optic Characterization) OTDR - CD - PMD TestDocument40 pagesSTP100 (Fiber Optic Characterization) OTDR - CD - PMD TestnhlongdnNo ratings yet

- Jdsu Bert & RFC 2544 TestingDocument13 pagesJdsu Bert & RFC 2544 TestingRaviNo ratings yet

- Optical Fibre CommunicationDocument60 pagesOptical Fibre CommunicationN.ChanduNo ratings yet

- EXFO - Tnote017-Ang PDFDocument6 pagesEXFO - Tnote017-Ang PDFmnolasco2010No ratings yet

- DWDM 100GHz Spacing Single Channel OADM1Document3 pagesDWDM 100GHz Spacing Single Channel OADM1litoduterNo ratings yet

- Jdsu Mts 6000Document158 pagesJdsu Mts 6000munsureshNo ratings yet

- DWDM Lamda MappingDocument3 pagesDWDM Lamda MappingyouvsyouNo ratings yet

- Cisco Monitor Performance NCS 2000 DWDMDocument100 pagesCisco Monitor Performance NCS 2000 DWDMp4i9e8r5No ratings yet

- TM 2G3G4G Hardware Installation Guide V1.6 PDFDocument150 pagesTM 2G3G4G Hardware Installation Guide V1.6 PDFjacobus_louw4329No ratings yet

- Introduction To OSA / WDM Analyzer: Test & MeasurementDocument6 pagesIntroduction To OSA / WDM Analyzer: Test & MeasurementMahendra SinghNo ratings yet

- Fiber Optic Cable ProductsDocument48 pagesFiber Optic Cable ProductsUdriste DanielNo ratings yet

- Accessories: Europe/Middle East/Africa Product Selection GuideDocument68 pagesAccessories: Europe/Middle East/Africa Product Selection GuideShiela Monique FajardoNo ratings yet

- 12.5U Central MSAN - 2 Management and Switching Cards PlusDocument2 pages12.5U Central MSAN - 2 Management and Switching Cards PluswirelesssoulNo ratings yet

- FTTX Solutions: Mini Fiber Distribution Hub 3000Document5 pagesFTTX Solutions: Mini Fiber Distribution Hub 3000julianNo ratings yet

- Exfo in Band Osa MjerenjeDocument4 pagesExfo in Band Osa MjerenjeFatima MasloNo ratings yet

- Fiber Cable Distance CalculationDocument11 pagesFiber Cable Distance CalculationNgozi Henrietta EmiNo ratings yet

- FTTH PatDocument4 pagesFTTH Patsanjaya kumar sahooNo ratings yet

- Fiber Optics TutorialDocument46 pagesFiber Optics TutorialShahrukh KhanNo ratings yet

- 40-Channel Single Mudule ROADMDocument8 pages40-Channel Single Mudule ROADMAmos MakhubeleNo ratings yet

- Business Requirement For BizTalk ServerDocument13 pagesBusiness Requirement For BizTalk Serverapi-3815463No ratings yet

- Master Plan StepDocument43 pagesMaster Plan Stepnailclipperla100% (1)

- Fiber Distribution Outdoor CabinetDocument2 pagesFiber Distribution Outdoor Cabinetnkhoa123No ratings yet

- Optical NetworksDocument42 pagesOptical NetworksRavi DeveshNo ratings yet

- WDM networking technologies overviewDocument22 pagesWDM networking technologies overviewAbhishek SrivastavaNo ratings yet

- Gigabit Passive Optical Network: Ii. Theory A. FTTHDocument4 pagesGigabit Passive Optical Network: Ii. Theory A. FTTHarif100% (1)

- GPON: The Standard For PON Deployment and Service Evolution: OSI Confidential InformationDocument23 pagesGPON: The Standard For PON Deployment and Service Evolution: OSI Confidential Informationchaidar_lakareNo ratings yet

- Optec Catalogue PDFDocument98 pagesOptec Catalogue PDFVijay Lakshmipathy0% (1)

- Of ClassificationDocument33 pagesOf ClassificationManoj BorahNo ratings yet

- Blown Optical Fiber Mini CatalogDocument20 pagesBlown Optical Fiber Mini CatalogBDNo ratings yet

- IP Radio Presentation-Compiled2Document32 pagesIP Radio Presentation-Compiled2Ilham HidayatNo ratings yet

- OSN Spare PartDocument56 pagesOSN Spare PartAhmed M GomaaNo ratings yet

- Fiber Optic CommunicationDocument4 pagesFiber Optic Communicationeaglett100% (1)

- TCI 727 Spectrum Monitoring System PDFDocument8 pagesTCI 727 Spectrum Monitoring System PDFustamNo ratings yet

- Section 6 B2H SOPDocument91 pagesSection 6 B2H SOPDayaram SahNo ratings yet

- Fiber OpticDocument55 pagesFiber OpticabdussamihNo ratings yet

- User Guide Intelligent Optical Link Mapper FTB-1 English (1060268)Document131 pagesUser Guide Intelligent Optical Link Mapper FTB-1 English (1060268)mousa34No ratings yet

- I&M OTN Sept2016 PDFDocument64 pagesI&M OTN Sept2016 PDFnoircyNo ratings yet

- Reference Guide To Fiber Optic Testing: VIAVI SolutionsDocument104 pagesReference Guide To Fiber Optic Testing: VIAVI SolutionsDjnsilva Silva100% (1)

- Fiber Optic SpecificationsDocument3 pagesFiber Optic SpecificationsManish ChananaNo ratings yet

- Fibre Cabling Installation and Inspection GuideDocument24 pagesFibre Cabling Installation and Inspection Guidecarlosf_6No ratings yet

- FTTH Accessories PDFDocument10 pagesFTTH Accessories PDFdannyalcivarNo ratings yet

- OTNNPDocument1 pageOTNNPsrotenstein3114100% (1)

- 3 Optical FiberDocument15 pages3 Optical FiberDhyan PatelNo ratings yet

- Ensuring The Availability and Reliability of Dark-Fiber NetworksDocument6 pagesEnsuring The Availability and Reliability of Dark-Fiber Networksapi-19786391No ratings yet

- Wp-t-304-Fiber Testing Fundamentals Whitepaper BrownDocument24 pagesWp-t-304-Fiber Testing Fundamentals Whitepaper BrownMoss OuaddaRiNo ratings yet

- WDM Principle OverviewDocument67 pagesWDM Principle OverviewOtmane Ben AhmedNo ratings yet

- Guide Perimeter Intrusion Detection SystemsDocument17 pagesGuide Perimeter Intrusion Detection Systemss7502000800No ratings yet

- The Basics - Fiber Optic Fundamentals and Best Practices - Bicsi (PDFDrive)Document105 pagesThe Basics - Fiber Optic Fundamentals and Best Practices - Bicsi (PDFDrive)Emad Suliman AbusittaNo ratings yet

- Telecom GlossaryDocument206 pagesTelecom GlossaryAshish Mohapatra0% (1)

- The Basics of FTTHDocument36 pagesThe Basics of FTTHFanny TampubolonNo ratings yet

- Ason/Gmpls: Development and Deployment: Young Lee Huawei, USADocument25 pagesAson/Gmpls: Development and Deployment: Young Lee Huawei, USA7kkhsNo ratings yet

- Optical Network Monitoring System Onmsi Ensures Municipality Fiber Network Availability Case StudiesDocument2 pagesOptical Network Monitoring System Onmsi Ensures Municipality Fiber Network Availability Case StudiesgagaNo ratings yet

- WDM Technologies: Passive Optical ComponentsFrom EverandWDM Technologies: Passive Optical ComponentsAchyut K. DuttaNo ratings yet

- Answer Key Grade 6 - 2023Document7 pagesAnswer Key Grade 6 - 2023ALKHANSAA ELOBEIDYNo ratings yet

- dp0 PDFDocument4 pagesdp0 PDFSimonNo ratings yet

- OracleDocument23 pagesOracleriza arifNo ratings yet

- DbintfcDocument80 pagesDbintfchnr.uninstallNo ratings yet

- Green Synthesis of Zinc Oxide Nanoparticles: Elizabeth Varghese and Mary GeorgeDocument8 pagesGreen Synthesis of Zinc Oxide Nanoparticles: Elizabeth Varghese and Mary GeorgesstephonrenatoNo ratings yet

- Bottazzini RiemannDocument36 pagesBottazzini RiemanncedillaNo ratings yet

- Canalis KDP-KBA-KBB-KNA-KSA-20-1000A-2014Document324 pagesCanalis KDP-KBA-KBB-KNA-KSA-20-1000A-2014Rubén González CabreraNo ratings yet

- Java10 PDFDocument137 pagesJava10 PDFswarup sarkarNo ratings yet

- Dynamic model of manipulatorsDocument20 pagesDynamic model of manipulatorsbalkyderNo ratings yet

- Superconductivity in RH S and PD Se: A Comparative StudyDocument5 pagesSuperconductivity in RH S and PD Se: A Comparative StudyChithra ArulmozhiNo ratings yet

- Ey-H3l Yh1576Document44 pagesEy-H3l Yh1576jorgeNo ratings yet

- Water Reducing - Retarding AdmixturesDocument17 pagesWater Reducing - Retarding AdmixturesAbdullah PathanNo ratings yet

- EET422 EMC Intro-Banana Skins 2011-2012 MSWDocument6 pagesEET422 EMC Intro-Banana Skins 2011-2012 MSWVeeradasan PerumalNo ratings yet

- Introduction To Curve FittingDocument10 pagesIntroduction To Curve FittingscjofyWFawlroa2r06YFVabfbajNo ratings yet

- Cephalometric Evaluation of The Airway Dimensions in Subjects With Different Growth PatternsDocument6 pagesCephalometric Evaluation of The Airway Dimensions in Subjects With Different Growth PatternsJuán A. Nina LeonNo ratings yet

- CobolDocument224 pagesCobolrahulravi007No ratings yet

- San Unit-Wise QuestionsDocument6 pagesSan Unit-Wise QuestionsSushmitha KodupakaNo ratings yet

- Zarlino-On The ModesDocument150 pagesZarlino-On The ModesPartituraDireccion100% (1)

- Data AnalysisDocument7 pagesData AnalysisAndrea MejiaNo ratings yet

- TIM Fungsi 1Document40 pagesTIM Fungsi 1lilikNo ratings yet

- CI SetDocument18 pagesCI Setতন্ময় ঢালি Tanmay DhaliNo ratings yet

- ASTM D 1510 - 02 Carbon Black-Iodine Adsorption NumberDocument7 pagesASTM D 1510 - 02 Carbon Black-Iodine Adsorption Numberalin2005100% (1)

- Instrumentation Design UTHMDocument5 pagesInstrumentation Design UTHMAnis AzwaNo ratings yet

- SubNetting Practice LabDocument3 pagesSubNetting Practice LabOdoch HerbertNo ratings yet

- 1 05 Lab Crime Scene Sketch GADocument2 pages1 05 Lab Crime Scene Sketch GAthis is hardly gonna be usedNo ratings yet

- Product Presentation Nova Blood Gas AnalyzerDocument38 pagesProduct Presentation Nova Blood Gas Analyzerlaboratorium rsdmadani100% (1)

- Bab 8Document29 pagesBab 8Nurul AmirahNo ratings yet

- Operational Guidelines For VlsfoDocument2 pagesOperational Guidelines For VlsfoИгорьNo ratings yet