Professional Documents

Culture Documents

Acceptance Criteria Asme B31 3

Uploaded by

Hadi Allouche100%(9)100% found this document useful (9 votes)

20K views1 pageOriginal Title

ACCEPTANCE CRITERIA ASME B31 3(2)

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(9)100% found this document useful (9 votes)

20K views1 pageAcceptance Criteria Asme B31 3

Uploaded by

Hadi AlloucheCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

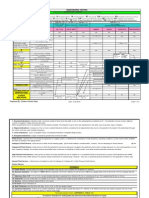

ACCEPTANCE CRITERIA FOR EXAMINATED WELDS

ACCORDING TO ASME B31 3

Table 341.3.2 (continued)

Symbol Measure Acceptable Value Limits [Note (6)]

A Extent of imperfection Zero (no evident imperfection

B Depth of incomplete penetration ≤ 1 mm (1⁄32 in.) and ≤ 0.2Tw

Cumulative length of incomplete penetration ≤ 38 mm (1.5 in.) in any 150 mm (6 in.) weld length

C Depth of lack of fusion and incomplete penetration ≤ 0.2Tw

Cumulative length of lack of fusion ≤ 38 mm (1.5 in.) in any 150 mm (6 in.) weld length

and incomplete penetration

D Size and distribution of internal porosity See BPV Code, Section VIII, Division 1, Appendix 4

E Size and distribution of internal porosity For Tw ≤ 6 mm (1⁄4 in.), limit is same as D

For Tw > 6 mm (1⁄4 in.), limit is 1.5 3 D

F Slag inclusion, tungsten inclusion, or elongated indication

Individual length ≤ Tw /3

Individual width ≤ 2.5 mm (3⁄32 in.) and ≤ Tw /3

Cumulative length ≤ Tw in any 12Tw weld length

G Slag inclusion, tungsten inclusion, or elongated indication

Individual length ≤ 2Tw

Individual width ≤ 3 mm (1⁄8 in.) and Tw /2

Cumulative length ≤ 4Tw in any 150 mm (6 in.) weld length

H Depth of undercut ≤1 mm (1⁄32 in.) and Tw /4

I Depth of undercut ≤1.5 mm (1⁄16 in.) and [Tw /4 or 1 mm (1⁄32 in.)]

You might also like

- ASME B31.3 Acceptance Criteria - Tab 341.3.2ADocument2 pagesASME B31.3 Acceptance Criteria - Tab 341.3.2Avsnaiduqc90% (21)

- NDT ACC. CriteriaDocument6 pagesNDT ACC. CriteriaBalakumar100% (5)

- Saudi Aramco: Company General UseDocument8 pagesSaudi Aramco: Company General UseMasudhBashaNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesMidhun K Chandrabose96% (24)

- RT Acceptance CriteriaDocument3 pagesRT Acceptance CriteriaAndry Rimanov89% (18)

- API 1104 Defects Acceptance Criteria FinalDocument9 pagesAPI 1104 Defects Acceptance Criteria Finalazizieh5701No ratings yet

- ASME B31 3 Acceptance Criteria Tab 341-3-2ADocument2 pagesASME B31 3 Acceptance Criteria Tab 341-3-2Aadel100% (1)

- Asme Viii d1 Ma Appendix 4Document8 pagesAsme Viii d1 Ma Appendix 4Chihiya Fitria Nurhayati100% (1)

- VT Acceptance Criteria PDFDocument10 pagesVT Acceptance Criteria PDFKalaivel ThandavarayanNo ratings yet

- Evaluation of RadiographDocument40 pagesEvaluation of Radiographoki karyadi100% (2)

- TWI Radiographic Interpretation. (Weld Defects & Repair)Document61 pagesTWI Radiographic Interpretation. (Weld Defects & Repair)jar_2100% (3)

- Api 1104 Acceptance CriteriaDocument6 pagesApi 1104 Acceptance CriteriaWillykateKairu75% (4)

- API 1104 Defects Acceptance Criteria FinalDocument4 pagesAPI 1104 Defects Acceptance Criteria FinalHendry AriosNo ratings yet

- Weld Metal RT Film InterpretationDocument10 pagesWeld Metal RT Film Interpretationsekarsanthanam95% (22)

- Defects Acceptance CriteriaDocument1 pageDefects Acceptance CriteriahakamaffaqNo ratings yet

- Asme b31.3 Acceptance RT TabulatedDocument86 pagesAsme b31.3 Acceptance RT TabulatedWalter Trajada100% (2)

- API 1104 Acceptance CriteriaDocument1 pageAPI 1104 Acceptance CriteriaMekhman100% (1)

- API 1104 Acceptance CriteriaDocument2 pagesAPI 1104 Acceptance CriteriaEngr Arfan Ali Dhamraho79% (14)

- API 1104 Defects-Acceptance-Criteria FinalDocument4 pagesAPI 1104 Defects-Acceptance-Criteria Finaljegathesmsjs86% (44)

- Cswip 3.2.2 Questions and AnswersDocument8 pagesCswip 3.2.2 Questions and AnswersZakirUllah0% (1)

- RT InterpretationDocument16 pagesRT InterpretationRavindra S. Jivani100% (1)

- CSWIP 3.2 Course Material For Radiographic InterpretationDocument52 pagesCSWIP 3.2 Course Material For Radiographic InterpretationSrinivasa100% (7)

- Technical Inquiries To API 1104Document20 pagesTechnical Inquiries To API 1104Rey Fiedacan92% (12)

- IQIDocument9 pagesIQIalouisNo ratings yet

- IQI SelectionDocument3 pagesIQI Selectioncisar0007No ratings yet

- Paut Procedure - Asme 31.3 Process PipingDocument26 pagesPaut Procedure - Asme 31.3 Process PipingKarthikeyan Ganesan100% (3)

- ASME - B31.3 - Table 341.3.2Document2 pagesASME - B31.3 - Table 341.3.2Biju_PottayilNo ratings yet

- Post Weld Heat Treatment (PWHT) Inspection Question and AnswersDocument2 pagesPost Weld Heat Treatment (PWHT) Inspection Question and AnswersShajin Mohammed Shamsudhin100% (17)

- RADIOGRAPHY INTERPRETATION-Rev1Document41 pagesRADIOGRAPHY INTERPRETATION-Rev1OktayKul80% (5)

- Satorp TR Interview Questionnar (Welding)Document21 pagesSatorp TR Interview Questionnar (Welding)abyNo ratings yet

- RT Film InterpretationDocument20 pagesRT Film InterpretationMOhammed PatelNo ratings yet

- Cswip 3.2 BookDocument316 pagesCswip 3.2 Bookzahidned90% (21)

- OI For UT of Laminations-BasicDocument8 pagesOI For UT of Laminations-Basicperogami100% (1)

- RT in WeldingDocument35 pagesRT in WeldingSapan KansaraNo ratings yet

- Twi Ut Level 11Document229 pagesTwi Ut Level 11Vijayananda Ananda70% (10)

- RT Acceptance Criteria: Asme Sec Viii Div-1 API-650 Ansi/ Asme B 31.3 ASME B 31.1 Asme Sec Ix CodesDocument1 pageRT Acceptance Criteria: Asme Sec Viii Div-1 API-650 Ansi/ Asme B 31.3 ASME B 31.1 Asme Sec Ix CodesEr Md AamirNo ratings yet

- Ut Calibration Blocks DetailsDocument44 pagesUt Calibration Blocks Detailsmdsajidalam100% (4)

- AWS D1.1 Acceptance StandardsDocument2 pagesAWS D1.1 Acceptance StandardsAlper Çakıroğlu92% (12)

- NDT ACC CriteriaDocument6 pagesNDT ACC Criteriavsnaiduqc100% (1)

- RT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Document20 pagesRT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Oscar Iván Duque DiazNo ratings yet

- NDT AcceptanceDocument62 pagesNDT Acceptancebommakanti srinivasNo ratings yet

- Defect ASME Sec. I ASME B31.1 ASME Sec. VIII, Div. I, Para. UW-51 API 650 Asme Sec Viii Div. I, Paragraph UW-52Document7 pagesDefect ASME Sec. I ASME B31.1 ASME Sec. VIII, Div. I, Para. UW-51 API 650 Asme Sec Viii Div. I, Paragraph UW-52AnilNo ratings yet

- RT AccepDocument1 pageRT AccepEILA545 QAQCNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesDudy Pindayana FirdausNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesShubham ShuklaNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesNavanitheeshwaran Sivasubramaniyam100% (3)

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesShankar Pl GowdaNo ratings yet

- Acceptance Criteria of Weld DefectsDocument17 pagesAcceptance Criteria of Weld DefectsvikasNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesTanveer Rajput EngrNo ratings yet

- Acceptance Criteria Radiography Test 2018 PDFDocument7 pagesAcceptance Criteria Radiography Test 2018 PDFSigit Pratikno100% (1)

- NDT-Acceptance Various CodesDocument17 pagesNDT-Acceptance Various CodesShanmuga NavaneethanNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesdhasdjNo ratings yet

- Radiography Acceptance Criteria As Per B 31.3Document2 pagesRadiography Acceptance Criteria As Per B 31.3mohamedNo ratings yet

- Weld Acceptance Criteria1Document1 pageWeld Acceptance Criteria1sankarNo ratings yet

- Tabla D-5 DNV ST-F101 2021Document2 pagesTabla D-5 DNV ST-F101 2021Gabriel HernándezNo ratings yet

- RT Acceptance CriteriaDocument3 pagesRT Acceptance CriteriaRanjan Kumar100% (2)

- Acceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEDocument18 pagesAcceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEEngineersEDGE CoimbatoreNo ratings yet

- Acceptance Criteria For RTDocument3 pagesAcceptance Criteria For RTrajeshmohana100% (2)

- DNVGL-ST-F101 Submarine Pipeline Systems-415-416 PDFDocument2 pagesDNVGL-ST-F101 Submarine Pipeline Systems-415-416 PDFJeganeswaranNo ratings yet

- Bolier Inspection ReportDocument4 pagesBolier Inspection ReportHadi AlloucheNo ratings yet

- Ir Ir: Nuclide Safety Data Sheet Iridium-192Document2 pagesIr Ir: Nuclide Safety Data Sheet Iridium-192Hadi AlloucheNo ratings yet

- Asme Section II A Sa-106 Page 5Document1 pageAsme Section II A Sa-106 Page 5Hadi AlloucheNo ratings yet

- Acceptance Criteria Asme B31 3Document1 pageAcceptance Criteria Asme B31 3Hadi Allouche100% (9)

- Industrial Internet of Things: Presented To-Presented byDocument18 pagesIndustrial Internet of Things: Presented To-Presented byGaurav RaturiNo ratings yet

- Viscous Fluid Flow Frank M White Third Edition - Compress PDFDocument4 pagesViscous Fluid Flow Frank M White Third Edition - Compress PDFDenielNo ratings yet

- Intel Stratix 10 Avalon - MM Interface For PCI Express Solutions User GuideDocument173 pagesIntel Stratix 10 Avalon - MM Interface For PCI Express Solutions User Guideenoch richardNo ratings yet

- The Dry Bulk Management StandardDocument18 pagesThe Dry Bulk Management Standardamu_more44100% (1)

- Earth Science (Metamorphic Rocks)Document8 pagesEarth Science (Metamorphic Rocks)MA. ALEXIS LAURENNo ratings yet

- Chennai To Vishakhapatnam El6Vvd: Indigo 6E-6835Document3 pagesChennai To Vishakhapatnam El6Vvd: Indigo 6E-6835VENKATESH POONDRUNo ratings yet

- Chapter 1 (PLC)Document9 pagesChapter 1 (PLC)Kibria PrangonNo ratings yet

- Contact Inform 2002 PDFDocument24 pagesContact Inform 2002 PDFFrank AlmeidaNo ratings yet

- Math 202 Syllabus-Spring18 PDFDocument2 pagesMath 202 Syllabus-Spring18 PDFvonacoc49No ratings yet

- BECO UACE Chem2Document6 pagesBECO UACE Chem2EMMANUEL BIRUNGINo ratings yet

- Arts6,4, Week2, Module 2V4Document24 pagesArts6,4, Week2, Module 2V4Loreen Pearl MarlaNo ratings yet

- 20160323014547-16MnCr5 - 16MnCrS5Document1 page20160323014547-16MnCr5 - 16MnCrS5Chaitanya DattaNo ratings yet

- Table 1 Minimum Separation DistancesDocument123 pagesTable 1 Minimum Separation DistancesjhonNo ratings yet

- Reloved - October 2015Document116 pagesReloved - October 2015Barron Fields67% (3)

- Leadership Games and ActivitiesDocument38 pagesLeadership Games and ActivitiesWilliam Oliss100% (1)

- Food Biotechnology in Ethical PerspectiveDocument340 pagesFood Biotechnology in Ethical Perspectivemojtaba2500100% (2)

- Modern Myth and Magical Face Shifting Technology in Girish Karnad Hayavadana and NagamandalaDocument2 pagesModern Myth and Magical Face Shifting Technology in Girish Karnad Hayavadana and NagamandalaKumar KumarNo ratings yet

- Disectie AnatomieDocument908 pagesDisectie AnatomieMircea SimionNo ratings yet

- 1ST SUMMATIVE TEST FOR G10finalDocument2 pages1ST SUMMATIVE TEST FOR G10finalcherish austriaNo ratings yet

- Academic Reading: All Answers Must Be Written On The Answer SheetDocument21 pagesAcademic Reading: All Answers Must Be Written On The Answer SheetLemon MahamudNo ratings yet

- 09.tracheostomy Management by Speech Language Pathologists in SwedenDocument12 pages09.tracheostomy Management by Speech Language Pathologists in SwedenCarlonchaCáceresNo ratings yet

- Reactive Dyes For Digital Textile Printing InksDocument4 pagesReactive Dyes For Digital Textile Printing InksDHRUVNo ratings yet

- YellowstoneDocument1 pageYellowstoneOana GalbenuNo ratings yet

- Updating - MTO I - Unit 2 ProblemsDocument3 pagesUpdating - MTO I - Unit 2 ProblemsmaheshNo ratings yet

- Relationships, 365 Day Devotional Mylesunroe 377pgDocument377 pagesRelationships, 365 Day Devotional Mylesunroe 377pgEla100% (7)

- Top Coat-200 - Data PDFDocument4 pagesTop Coat-200 - Data PDFLiliana GeorgianaNo ratings yet

- S590 Machine SpecsDocument6 pagesS590 Machine SpecsdilanNo ratings yet

- ChipmunkDocument19 pagesChipmunkema.nemec13No ratings yet

- Science Involved in Floating Paper Clip Science Experiment GuidelinesDocument4 pagesScience Involved in Floating Paper Clip Science Experiment GuidelinesSHIELA RUBIONo ratings yet