Professional Documents

Culture Documents

Abstract CEng

Uploaded by

Fernando Beer FrenkelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abstract CEng

Uploaded by

Fernando Beer FrenkelCopyright:

Available Formats

Production and Utilization of High Test Molasses in Fermentation Industry

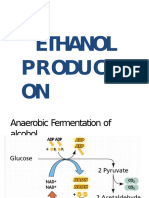

Abstract Experiments were conducted in the laboratory as well as the sugar Processing steps involved milling, clarification, evaporation, inversion and concentration. water. The product obtained was a heavy mill to produce high test molasses from sugarcane. inverted

brown syrup, containing 76.06% total sugars, 2.85% ash and 15.09% The utilization of high test molasses for the production of

ethanol was carried out at laboratory scale to provide information on the most suitable yeast strain for alcohol fermentation, and expected yield.

a pilot-scale process, such as methods of processing, selection of The production of ehtanol from high test molasses was also The processing methods employed are presented The data indicate that the high test

evaluated on a pilot-plant scale using blackstrap molasses as a control substrate. and the results compared.

molasses has proved to be more advantageous as a raw material for alcohol fermentation than the blackstrap molasses due to the formers higher sugar content and less ash content.

From the

process, 422 litres of ehtanol were obtained from one tonne of the

high test molasses as against 259 litres of ethanol derived from the same amount of the blackstrap molasses. The production of high test molasses from sugarcane will be High test

beneficial for both farmers and sugar mills specially when sugarcane is in surplus and the world sugar price is extremely low. molasses could be used in place of blackstrap molasses with more in available sugar mills with only; minimal addition of equipment.

advantages due to its superior quality. Besides it can be produced

You might also like

- Sugarcane-based Biofuels and BioproductsFrom EverandSugarcane-based Biofuels and BioproductsIan O'HaraNo ratings yet

- HPLC Cafeina y TeobrominaDocument12 pagesHPLC Cafeina y TeobrominaJhimmy Saucedo CercadoNo ratings yet

- Significance of The Study - BiochemDocument3 pagesSignificance of The Study - BiochemCarlos Miguel DacaimatNo ratings yet

- IBG 202 LAB 6 Production of EthanolDocument5 pagesIBG 202 LAB 6 Production of EthanolLow Pik KuanNo ratings yet

- 15jan12 - 163611 - Kunchada SingasintuDocument4 pages15jan12 - 163611 - Kunchada SingasintuRizka Rinda PramastiNo ratings yet

- Samara UnverstyDocument12 pagesSamara UnverstyMekoninn HylemariamNo ratings yet

- Optimization of Mashing Process in Beer Production Using RiceDocument4 pagesOptimization of Mashing Process in Beer Production Using Rice_juliogsNo ratings yet

- Rethinking The Cane Sugar Mill by Using Selective Fermentation of Reducing Sugars by Saccharomyces Dairenensis, Prior To Sugar CrystallizationDocument8 pagesRethinking The Cane Sugar Mill by Using Selective Fermentation of Reducing Sugars by Saccharomyces Dairenensis, Prior To Sugar CrystallizationZohaib RanaNo ratings yet

- Sugar FactoryDocument23 pagesSugar Factorysandys8754No ratings yet

- Bioethanol Production From Sugarcane Bagasse Using Fermentation ProcessDocument7 pagesBioethanol Production From Sugarcane Bagasse Using Fermentation ProcessM Syafiq SamadNo ratings yet

- Fed-Batch Alcoholic Fermentation of Palm Juice (Arenga Pinnata Merr) : Influence of The Feeding Rate On Yeast, Yield and ProductivityDocument5 pagesFed-Batch Alcoholic Fermentation of Palm Juice (Arenga Pinnata Merr) : Influence of The Feeding Rate On Yeast, Yield and ProductivityindriNo ratings yet

- Cacao PaperDocument5 pagesCacao Papercentro surcolombiano de investigación en café uscoNo ratings yet

- Nutrients For Molasses FermentationDocument7 pagesNutrients For Molasses FermentationItezaz AhsanNo ratings yet

- Cinetica Fermentacion 1Document21 pagesCinetica Fermentacion 1Santiago OrtizNo ratings yet

- Bài Thí nghiệm SLSFD - 2023 - ELITECHDocument6 pagesBài Thí nghiệm SLSFD - 2023 - ELITECHVan VietNo ratings yet

- Bioprocess Engg Lab Assignment: Olivia Newton 119BT0433Document5 pagesBioprocess Engg Lab Assignment: Olivia Newton 119BT0433olivia6669No ratings yet

- Ethanol and Ethyl Acetate Production During The Cider Fermentation From Laboratory To Industrial ScaleDocument6 pagesEthanol and Ethyl Acetate Production During The Cider Fermentation From Laboratory To Industrial ScaleArif Hidayat100% (1)

- Obtención de Alcohol A Partir de RemolachaDocument11 pagesObtención de Alcohol A Partir de RemolachaJuan David BerrioNo ratings yet

- ANALYTICAL TECHNIQUES AND INSTRUMENTATION Rapid Method For Sugar Analysis of Doughs and Baked Products J. M. LANGEMEIER and D. E. ROGERS'Document3 pagesANALYTICAL TECHNIQUES AND INSTRUMENTATION Rapid Method For Sugar Analysis of Doughs and Baked Products J. M. LANGEMEIER and D. E. ROGERS'Tatjana BrankovićNo ratings yet

- Production of Ethanol From Cheap Substrates: FermentationDocument41 pagesProduction of Ethanol From Cheap Substrates: FermentationSrinivas RallapalliNo ratings yet

- Jurnal Gula Cair Jagung Manis (Bekti Dwisepti Mafiana)Document12 pagesJurnal Gula Cair Jagung Manis (Bekti Dwisepti Mafiana)BektiMafianaNo ratings yet

- Lab Report - SugarDocument7 pagesLab Report - SugarPeter AndrewNo ratings yet

- 3.body of ReportDocument54 pages3.body of ReportaregawiNo ratings yet

- 1996 Keskar Sugar Analysis of Molasses by HPLCDocument5 pages1996 Keskar Sugar Analysis of Molasses by HPLCGustavo CardonaNo ratings yet

- Bioethanol Production From Sugarcane Bagasse Using Fermentation ProcessDocument9 pagesBioethanol Production From Sugarcane Bagasse Using Fermentation ProcessHarsh DoshiNo ratings yet

- Ethyl Alcohol Production and OptimisationDocument5 pagesEthyl Alcohol Production and Optimisationakash sawarkarNo ratings yet

- ADI ReviewDocument1 pageADI Reviewana arroyoNo ratings yet

- Fermentation and Alcohol ProductionDocument24 pagesFermentation and Alcohol ProductionfanusNo ratings yet

- Non-Alcoholic Beer-A New Industrial ProcessDocument10 pagesNon-Alcoholic Beer-A New Industrial ProcessTrysh IoanaNo ratings yet

- Preparation of Ethanol From MolassesDocument14 pagesPreparation of Ethanol From Molassesfajar1232697No ratings yet

- UV Spectrophotometric Determination of Theobromine and Caffeine in Cocoa BeansDocument4 pagesUV Spectrophotometric Determination of Theobromine and Caffeine in Cocoa BeansIwanOne'ajjNo ratings yet

- Alcohol Fermentation: Prepared By:Prachi Patel Sem:Iii Saurashtra University RajkotDocument22 pagesAlcohol Fermentation: Prepared By:Prachi Patel Sem:Iii Saurashtra University RajkotBerlian SitorusNo ratings yet

- Supercritical Extraction of Cocoa Butter From Cocoa Seed, Using Pure Carbon Dioxide, Carbon Dioxide With Ethanol As Co-Solvent and EthaneDocument6 pagesSupercritical Extraction of Cocoa Butter From Cocoa Seed, Using Pure Carbon Dioxide, Carbon Dioxide With Ethanol As Co-Solvent and Ethanejmrozo3No ratings yet

- Appl. Environ. Microbiol. 2008 Dumbrepatil 333 5Document3 pagesAppl. Environ. Microbiol. 2008 Dumbrepatil 333 5DHENADANo ratings yet

- 7 LiewDocument6 pages7 LiewNovita SariNo ratings yet

- Laboratory Analytical ProcedureDocument10 pagesLaboratory Analytical ProcedureJovis IoanaNo ratings yet

- Paper1 - Improved SSF-cellulosic Ethanol Production by The Cellobiose Fermenting Yeast Kluyveromyces Marxianus G2-16-1 - KridsanaDocument12 pagesPaper1 - Improved SSF-cellulosic Ethanol Production by The Cellobiose Fermenting Yeast Kluyveromyces Marxianus G2-16-1 - Kridsanakridsana.krisomdeeNo ratings yet

- ConclusionDocument2 pagesConclusionAmirHakimRusliNo ratings yet

- Sugar Cane JuiceDocument5 pagesSugar Cane Juices.sabapathyNo ratings yet

- Utilization of Labneh Whey Lactose Hydrolyzed Syrup in Baking and ConfectioneryDocument8 pagesUtilization of Labneh Whey Lactose Hydrolyzed Syrup in Baking and ConfectioneryDollyNo ratings yet

- Bio-Ethanol Production in DetailDocument46 pagesBio-Ethanol Production in DetailSCIENCE EDUCATION BY PIYUSH HANSNo ratings yet

- Part 3 Operation Standards For Ethanol Production Process EdDocument12 pagesPart 3 Operation Standards For Ethanol Production Process EdabrhshNo ratings yet

- The Making of Pomegranate Wine Using Yeast Immobilized On SoDocument6 pagesThe Making of Pomegranate Wine Using Yeast Immobilized On SoNguyenThaiAnhNo ratings yet

- A Study On Some Efficient Parameters in Batch Fermentation of Ethanol Using SC1 Extracted From Fermented Siahe Sardasht PomaceDocument7 pagesA Study On Some Efficient Parameters in Batch Fermentation of Ethanol Using SC1 Extracted From Fermented Siahe Sardasht PomaceGaby RoblesNo ratings yet

- Raw Sugar Filterability ImprovementsDocument4 pagesRaw Sugar Filterability ImprovementsAndy TpNo ratings yet

- Alcohol FermentationDocument34 pagesAlcohol FermentationSaravana Bharathy ReddyNo ratings yet

- Ethanol Laboratory ManualDocument129 pagesEthanol Laboratory ManualYoni LoveNo ratings yet

- Production of Alcohol From Cassava Our Hydrolysate: July 2010Document8 pagesProduction of Alcohol From Cassava Our Hydrolysate: July 2010Simon LexsNo ratings yet

- GlucoseDocument12 pagesGlucoseشہریار شمسیNo ratings yet

- Invert Sugar From Cationinc SystemDocument5 pagesInvert Sugar From Cationinc SystemOsmar AlmeidaNo ratings yet

- BioethanolDocument13 pagesBioethanolROUHAN QURESHINo ratings yet

- D2-7 Antoine Charbonneau - AISC 2016 NOVASEPDocument26 pagesD2-7 Antoine Charbonneau - AISC 2016 NOVASEPhendrajobNo ratings yet

- Determination of SugarsDocument8 pagesDetermination of SugarsNatzi MonsalvoNo ratings yet

- Synthesisand Mass Balanceof Citric Acidfrom Sugarcane Molasses Using Bakers Yeastand Submerged Batch Fermentation TechniqueDocument5 pagesSynthesisand Mass Balanceof Citric Acidfrom Sugarcane Molasses Using Bakers Yeastand Submerged Batch Fermentation Technique19L1031099 LÊ THỊ THỦYNo ratings yet

- Manufacturing and Industrial ProcessDocument10 pagesManufacturing and Industrial ProcessTan TanNo ratings yet

- Industrial Alcohol ProductionDocument4 pagesIndustrial Alcohol ProductionSheraz AliNo ratings yet

- Ampas SaguDocument9 pagesAmpas Sagumardian azuraNo ratings yet

- I I M M: Experiment 12. High Performance Liquid Chromatography Determination of Caffeine in Coffee, Coke, or TeaDocument1 pageI I M M: Experiment 12. High Performance Liquid Chromatography Determination of Caffeine in Coffee, Coke, or TearamadakuNo ratings yet

- Soap-Making Manual. A practical Handbook on the RControl in the modern Soap PlantFrom EverandSoap-Making Manual. A practical Handbook on the RControl in the modern Soap PlantRating: 5 out of 5 stars5/5 (2)