Professional Documents

Culture Documents

Chemical Engineering Laboratory Ii: /DT Term Is Zero Since

Uploaded by

Kayathre RaveendranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Engineering Laboratory Ii: /DT Term Is Zero Since

Uploaded by

Kayathre RaveendranCopyright:

Available Formats

CHEMICAL ENGINEERING LABORATORY II

10

Title of Experiment: Continuous Stirred Tank Reactor (CSTR)

20

Objectives of Experiment

The objectives for this experiment were to observe and control the operation a continuous-stirred tank reactor and to determine the effects of flow rate on conversion rate in a continuous-stirred tank reactor.

30

Introduction

Continuous Stirred Tank Reactor (CSTR) is used to conduct the whole experiment. The CSTR is an easily constructed, versatile and cheap reactor, which allows simple catalyst charging and replacement. This reactor permits straightforward control over temperature and pH of the reaction and the supply or removal of gases due to its well-mixed nature. CSTRs tend to be larger in size as the need for the efficiently mixed. There are some basic assumptions which can be made. For example, this reactor runs at steady state, i.e. all the time derivations go to zero. Besides, none of the variables are function of position, i.e. all of the spatial derivatives go to zero. The conditions that exist at the exit are the same as those everywhere in the reactor. dNA/dt term is zero since steady state us assumed. rA is set to be the rate term and the equation can now be solved for the volume to yield VCSTR= FA0- FA-rA

where, VCSTR volume of the reactor

FA0 FA -rA

inlet molar flow rate outlet molar flow rate rate of reaction

40

Materials and Equipment Beaker: 2L 2 Measuring Cylinder: 100 mL 1 Volumetric Flask 1 L 1 Glass rod Stopwatch 15 L of 2.3 % sodium hydroxide (NaOH) solution 15 L of 5 % ethyl acetate (Et(Ac)) solution 500 mL of 0.5 M sodium acetate, Na(Ac) 1 L of deionised water, H2O A Main Power Switch B - Conductivity and Temperature Meters C - Hot Water Pump D - Sump Tank E - Hot Water Tank F - NaOH Feed Tank G - Et(Ac) Feed Tank H - Reactor Vessel I - Dosing Pumps J - Tank Drain Valves K - Hot Water Valves L Pump Bypass Valve Figure 4.1: Continuous Stirred Tank Reactor

5.0

Results and Calculations Table 5.1: Results for Experiment 1

Conversion (%) 0 25 50 75 100

Conductivity (mS) 7.81 6.44 5.06 3.97 2.84

Table 5.2: Results for Experiment 2(a) Speed of Dosing Pumps: 15% Time Measured (min) 2 4 6 8 10 Reaction Temperature (C) 38.1 39.7 40.8 41.6 42.1 Conductivity (mS/cm) 1 22.0 22.0 22.1 22.1 22.1 2 1.2 1.2 1.2 1.2 1.2 Conversion of Reactants (%) 1 83.49 83.49 83.41 83.41 83.41 2 99.84 99.84 99.84 99.84 99.84

Table 5.3: Results for Experiment 2(b) Speed of Dosing Pumps: 30% Time Measured (min) 2 4 6 8 Reaction Temperature (C) 42.7 42.9 43.1 43.3 Conductivity (mS/cm) 1 24.7 26.1 27.1 28.3 2 1.2 1.3 1.4 1.4 Conversion of Reactants (%) 1 81.37 80.27 79.48 78.54 2 99.84 99.76 99.69 99.69

10 43.5 28.6 1.4 78.30 99.69 Table 5.4: Results for Experiment 2(c) Speed of Dosing Pumps: 50% Time Measured (min) 2 Reaction Temperature (C) 44.1 Conductivity (mS/cm) 1 26.6 2 1.9 Conversion of Reactants (%) 1 2 79.87 99.29

4 6 8 10 12

44.4 44.5 44.5 44.4 44.1

24.8 24.1 24.1 24.0 24.2

1.7 1.6 1.7 1.7 1.7

81.29 81.84 81.84 81.92 81.76

99.45 99.53 99.45 99.45 99.45

Calculations for Conversion of Reactants (%) X= 1- (k-ke)(ko-ke) 100% = 1- (22-1)(128.2-1) 100% = 83.49 % where, X k kO ke extent of conversion measured value for conductivity (mS/cm) initial conductivity for 2.3% sodium hydroxide solution (128.2 mS/cm) conductivity of the end product (1 mS/cm for a 5% sodium acetate solution)

Table 5.5: Table of Conductivity versus Conversion Dosing Pump (%) 15 30 50 Conductivity (mS/cm) C1 22.1 28.6 24.2 C2 1.2 1.4 1.7 Conversion (%) X1 83.41 78.3 81.76 X2 99.84 99.69 99.45

Figure 5.1: Graph of Conductivity versus Dosing Pump

Figure 5.2: Graph of Conversion versus Dosing Pump

6.0

Discussion

Based on Figure 5.1, Series C1 represents the conductivity for mixture at the inlet of CSTR while C2 represents the conductivity for mixture at the outlet of the CSTR. Increase of dosing pump, increases the conductivity of the mixture solution. This is because increasing the dosing pumps increases the flow rate of raw reactants into the CSTR, and hence the residence time of reactants in the reactor is lesser. The reactant does not have sufficient time to react and transform into product before being overflow to the tank drain where the conductivity of mixture is measured. So, the amount of NaOH remained in the fluid coming out from the CSTR is higher. Therefore, the conductivity is high due to the large amount of hydroxide ion (from NaOH) remaining in the outlet stream. By referring to Figure 5.2, Series X1 represents the conversion for mixture at the inlet of CSTR while X2 represents the conversion for mixture at the outlet of the CSTR. Increase of dosing pump, increases the conductivity of the mixture solution. The percentage conversion of the saponification reaction is dependent on the conductivity measured from the product. Therefore, from Figure 5.2 the percentage conversion is high at low percentage dosing pump. As the percentage dosing pump or flow rate increases, the resulting percentage conversion of NaOH decreases. This is due to less residence time of reactants in the CSTR, which does not give ample time for the saponification reaction to take place. Hence, lower percentage conversion of NaOH results. In short, the conversion of NaOH is inversely proportional to the percentage of dosing pump. The results proved that this theory applies on this experiment. The residence time of a chemical reactor is the average amount of time a particle spends inside the reactor, with the general formula of =VQ

where, V Q residence time, volume of fluid in reactor, m3 volumetric flow rate, m3/min

To calculate the residence time in a CSTR, first the volume of the CSTR has to be determined. Since the volume of CSTR in this experiment is set to be constant (the amount of fluid is maintained at a per-determined level by a level adjustor in the CSTR), so we can assume that the volume of fluid is around 20% of the volume of reactor. To get the volumetric flow rate of fluid into the reactor, multiply the dosing pump percentage to the total flow rate as the dosing peristaltic pumps are fitted with speed control to adjust the feeding rate. Therefore, for this experiment, the higher the dosing pump, the higher the volumetric flow rate and hence lower the residence time (as the volume of fluid, V is constant). By referring to the equation below, V=FAOXA-rA where, V FA0 XA rA volume of reactor initial feed rate of A extent of conversion of A rate of reaction

we know that as the volume of a CSTR increases, the conversion of reactant A increases as well. To be more precise, with higher volume of reactant fluid in the reactor and fixed volumetric flow rate, the residence time of the reactant in the reactor increases. Therefore, the reactant has more time to react in the reactor and hence the conversion will be higher. Temperature in the reactor affects the conversion and the conversion rate. By heating the mixture, the kinetic energy of the reactants molecules in a reactor increases. This promotes the movement of the molecules and more collisions between the

molecules happen in the reactor. When two chemicals react, their molecules have to collide with each other with sufficient energy for the reaction to take place. The collision theory explains that two molecules will only react if they have enough energy. By heating the mixture, you will raise the energy levels of the molecules involved in the reaction. According to kinetic theory, molecules move faster and increase the frequency of collision under higher temperature. Hence, the conversion of a reaction will be higher in a reactor with higher temperature. The reaction between nitrogen gas and hydrogen gas to produce ammonia gas is exothermic, releasing 92.4kJ/mol of energy at 298K (25oC). N2 g + 3H2 g heat, pressure, catalyst 2NH3 g H= -92.4 kJ/mol where, N2 H2 H nitrogen gas hydrogen gas change of enthalpy in the system Le Chateliers principle states that: If a chemical system at equilibrium experiences a change in concentration, temperature, volume or partial pressure, then the equilibrium shifts to counteract the imposed change and a new equilibrium is established. To increase the conversion: Removing the product constantly to decrease the concentration of product. This helps to shift the equilibrium to the side with fewer moles of component (product side). Changes in the initial concentrations of the substances only affect the amount of product produced but not the conversion. Decreasing the temperature causes the equilibrium position to move to the right resulting in a higher yield of ammonia since the reaction is exothermic (releases heat). Le Chateliers Principle states that the system will react to remove the added heat, thus the reaction must proceed in the reverse direction, converting

NH3 ammonia gas

the products back to the reactants. Reducing the temperature means the system will be adjusted to minimise the effect of the change, that is, it will produce more heat since energy is a product of the reaction, and will therefore produce more ammonia gas as well. Reducing the volume or increase in pressure. By increasing the pressure, the distance between molecules decreases, the frequency of collision will be higher. So, more products will be formed and consequently the conversion will be higher. It is important to note that adding catalyst will not affect the conversion of the reaction. It only speeds up the rate for the reaction to reach equilibrium. Apart from that, the rate of the reaction at lower temperatures is extremely slow, so a higher temperature must be used to speed up the reaction which results in a lower yield of ammonia. Theoretically, after increasing the dosing pump, the product conductivity has to be higher due to more NaOH molecules remained in the solution. However, the conductivity does not change much. This is because the conductivity meter is measuring the fluid with the previous set of condition (lower dosing pump percentage) since the solution in the CSTR is mixture of product from current dosing pump and previous dosing pump. So, the conductivity shown does not represent the actual case. Recommendation for future work: The solution in the CSTR has to be drained completely before changing dosing pump. Prepare enough solution to ensure constant feed concentration Develop more accurate rotameter calibration for CSTR Research conductivity probe calibration more carefully to determine actual effects of all components Precaution steps: 7.0 Always wear gloves when filling up the feed tank with chemicals and taking out the waste from the sump tank. Hold the apparatus tightly so prevent them from slipping and fell down. Conclusion

In a CSTR, the fluid reagents are introduced into a tank reactor equipped with an impeller while the reactor effluent is removed. By increasing the flow rate into the CSTR, the residence time of reactant in the CSTR decreases, hence the conversion of ethyl acetate and sodium hydroxide decreases as well since the reactants do not have sufficient time to transform into the product which are ethanol and sodium acetate.

8.0

References

Anonymous. (n.d.). Chapter 2 Flowing Reactors: Continuous Stirred Tank Reactors CSTRs. Retrieved February 19, 2011, from http://unix.eng.ua.edu/~checlass//che354/Che354Site/Library/Modules/Chapter1/ C!CSTR.pdf Chaplin, Martin. (20 December, 2004). Continuous flow stirred tank reactors. Retrieved February 19, 2011, from LONDON SOUTH BANK UNIVERSITY website: http://www.lsbu.ac.uk/biology/enztech/cstr.html Coulter (2009). Factors That Affect Chemical Equilibrium. Retrieved February 18, 2011 from http://www.mrcoulter.com/LECTURES/08_equilibrium3.pdf David N. Blauch (2009). Chemical Equilibria Le Chateliers Principle. Retrieved February 19, 2011 from http://www.chm.davidson.edu/vce/equilibria/temperature.html Purchon N. (2006). Rates of reaction. Retrieved February 18, 2011 from http://www.purchon.com/chemistry/rates.htm#temperature Wikimedia Foundation Inc. (2011). Chemical Kinetics. Retrieved February 18, 2011 from http://en.wikipedia.org/wiki/Chemical_kinetics

You might also like

- Lab 1 - CSTRDocument22 pagesLab 1 - CSTRnur athilahNo ratings yet

- Lab ManualDocument24 pagesLab ManualAasia FarrukhNo ratings yet

- CSTRDocument19 pagesCSTRAmir Al-AimanNo ratings yet

- 5 - (CSTR Bp143)Document12 pages5 - (CSTR Bp143)Aisyah Addia AzizanNo ratings yet

- CSTR 40LDocument16 pagesCSTR 40LhishamNo ratings yet

- Experiment CSTR 40LDocument18 pagesExperiment CSTR 40LSaber Minato Azrul100% (2)

- Lab Report CSTR 40LDocument26 pagesLab Report CSTR 40LAnonymous NyvKBW33% (3)

- CSTR Lab ReportDocument16 pagesCSTR Lab Reportleenzalal100% (5)

- Tubular ReactorDocument20 pagesTubular ReactorMuhamad Hafifi AjwadNo ratings yet

- CSTR 40LDocument17 pagesCSTR 40LMuhammad Affifudin100% (1)

- PFR Lab ReportDocument16 pagesPFR Lab Reportcog0812No ratings yet

- CSTR SeriesDocument14 pagesCSTR SeriesElina Nes100% (1)

- Stirred Tank Reactors in SeriesDocument25 pagesStirred Tank Reactors in SeriesChristopher Emeka Ominyi100% (1)

- CHE516 - Lab Report On Plug Flow Reactor PDFDocument25 pagesCHE516 - Lab Report On Plug Flow Reactor PDFCesarah Cabungcal100% (1)

- C4 Lab ReportDocument11 pagesC4 Lab ReportchaitanyaNo ratings yet

- CSTRDocument15 pagesCSTRbilisfreak100% (3)

- CSTRDocument12 pagesCSTRsamueloNo ratings yet

- Continuous Stirred Tank Reactor CSTR in Series PDFDocument15 pagesContinuous Stirred Tank Reactor CSTR in Series PDFMuhamad Hafifi AjwadNo ratings yet

- Abstract For CSTR Lab ReportDocument4 pagesAbstract For CSTR Lab ReportNabilah SyaheeraNo ratings yet

- Experiment: Batch Reactor Unit Operations Lab I (CHEGR3787L) Fall 2004Document5 pagesExperiment: Batch Reactor Unit Operations Lab I (CHEGR3787L) Fall 2004Janice YanNo ratings yet

- Lab RPRT (CSTR)Document21 pagesLab RPRT (CSTR)Black White80% (5)

- Continuous Stirred Tank Reactor (CSTR)Document6 pagesContinuous Stirred Tank Reactor (CSTR)Elaine PuiNo ratings yet

- CSTR FinalDocument36 pagesCSTR FinalMuhammad Yar KhanNo ratings yet

- CSTR ReportDocument21 pagesCSTR ReportJonathon Douglas100% (1)

- Experiment 7 Batch ReactorDocument5 pagesExperiment 7 Batch Reactorxyzabc9871230% (1)

- IYOHA COLLINS 16CF020531 Batch Reactor ReportDocument19 pagesIYOHA COLLINS 16CF020531 Batch Reactor ReportDavid OvieNo ratings yet

- Stirred Tank by MAUREENDocument27 pagesStirred Tank by MAUREENJimNo ratings yet

- Continuous Stirrer Tank Reactors in Series.Document54 pagesContinuous Stirrer Tank Reactors in Series.Farrukh Shahzad60% (5)

- CSTR in SeriesDocument16 pagesCSTR in SeriesAhmadAzriMohamad50% (2)

- Results and Discussion of CSTR in SeriesDocument3 pagesResults and Discussion of CSTR in SeriesleenzalalNo ratings yet

- Stirred Tank in Series ReportDocument20 pagesStirred Tank in Series ReportEmonbeifo EfosasereNo ratings yet

- CSTR in SeriesDocument17 pagesCSTR in SeriesDhiyyah MardhiyyahNo ratings yet

- Lab CSTR in SeriesDocument13 pagesLab CSTR in SeriesKhairul Zakirin78% (9)

- Isothermal CSTR PDFDocument9 pagesIsothermal CSTR PDFprashant_cool_4_uNo ratings yet

- Reactor Lab ManualDocument33 pagesReactor Lab ManualAthinaNo ratings yet

- Batch ReactorDocument4 pagesBatch ReactorFoo Xiao BingNo ratings yet

- Experiment 9Document6 pagesExperiment 9Muzammil Iqbal100% (1)

- Continuous Stirred Tank Reactor: CHEN-410 Unit Operation LabDocument34 pagesContinuous Stirred Tank Reactor: CHEN-410 Unit Operation LabMohamad Abou DaherNo ratings yet

- CHE506 - Lab Report On Plug Flow ReactorDocument25 pagesCHE506 - Lab Report On Plug Flow Reactorfiorella50% (2)

- Lab 3 Plug FlowDocument29 pagesLab 3 Plug FlowHikaru MokaNo ratings yet

- RTD in CSTRDocument7 pagesRTD in CSTRRahul Pancholi100% (5)

- Intro CSTRDocument6 pagesIntro CSTREmmanuel PlazaNo ratings yet

- Vapour Liquid Equilibrium ExpDocument5 pagesVapour Liquid Equilibrium ExpAakash Sharma100% (1)

- PK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory IiiDocument21 pagesPK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory Iiibedirtupak92% (12)

- Bubble Cap Distillation ColumnDocument3 pagesBubble Cap Distillation Columnnhalieza1067No ratings yet

- CSTR Lab ReportDocument14 pagesCSTR Lab ReportAmy Farhana33% (3)

- Exp - 2 Bubble Cap Distillation ColumnDocument13 pagesExp - 2 Bubble Cap Distillation ColumnAdawiyah Al-jufri100% (1)

- Lab 1Document12 pagesLab 1JoeJeanNo ratings yet

- Batch Reactor PDFDocument29 pagesBatch Reactor PDFSaranya KannanNo ratings yet

- CSTRDocument11 pagesCSTRfarahanisiliasNo ratings yet

- S.no. Name of The Experiment Date of Conduction Date of Submission P2 Cascade CSTR 4 February, 2021 9 February, 2021Document14 pagesS.no. Name of The Experiment Date of Conduction Date of Submission P2 Cascade CSTR 4 February, 2021 9 February, 2021DEEPSHIKA DUTTANo ratings yet

- PFR Lab ReportDocument21 pagesPFR Lab ReportValentinoDullSatin100% (1)

- Modeling in Transport Phenomena: A Conceptual ApproachFrom EverandModeling in Transport Phenomena: A Conceptual ApproachRating: 3 out of 5 stars3/5 (2)

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsFrom EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsNo ratings yet

- Reaction Kinetics for Chemical Engineers: Butterworths Series in Chemical EngineeringFrom EverandReaction Kinetics for Chemical Engineers: Butterworths Series in Chemical EngineeringRating: 4 out of 5 stars4/5 (3)

- Thermodynamic Models for Chemical Engineering: Design, Develop, Analyse and OptimizeFrom EverandThermodynamic Models for Chemical Engineering: Design, Develop, Analyse and OptimizeNo ratings yet

- Skytrain Avia Services: Emergency Procedures ManualDocument32 pagesSkytrain Avia Services: Emergency Procedures ManualEndro RastadiNo ratings yet

- Computer Networking: A Top-Down Approach Featuring The InternetDocument27 pagesComputer Networking: A Top-Down Approach Featuring The InternetmssacNo ratings yet

- Le22a1321 AocDocument130 pagesLe22a1321 AocEchefisEchefisNo ratings yet

- Quality ControlDocument10 pagesQuality ControlSabbir AhmedNo ratings yet

- State ManagementDocument16 pagesState Managementnegikamal703No ratings yet

- Online Examination System For AndroidDocument7 pagesOnline Examination System For AndroidSri Sai UniversityNo ratings yet

- BSR NH Circle Jaipur 2016Document103 pagesBSR NH Circle Jaipur 2016vikash kumar50% (4)

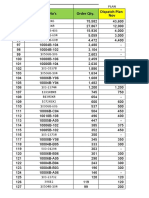

- Order Qty Vs Dispatch Plan - 04 11 20Document13 pagesOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNo ratings yet

- Shell Hazardous Area Classification FundamentalsDocument30 pagesShell Hazardous Area Classification Fundamentalsthekevindesai100% (17)

- Hot Air Oven Or Dry Oven: نﺎﺸﻄﻋ ﻦﻴﺴﺣ ﻲﻠﻋ G @a - nv19Document2 pagesHot Air Oven Or Dry Oven: نﺎﺸﻄﻋ ﻦﻴﺴﺣ ﻲﻠﻋ G @a - nv19حسين محمد مطرود كاظمNo ratings yet

- Standardization of Naoh 1Document3 pagesStandardization of Naoh 1api-309208977No ratings yet

- Module002 LaboratoryExercise002Document2 pagesModule002 LaboratoryExercise002Joaquin SmithNo ratings yet

- 01 GeoStrucAnal Cylinder Elastic PDFDocument12 pages01 GeoStrucAnal Cylinder Elastic PDFSiddhant KaushikNo ratings yet

- Genius Publication CatalogueDocument16 pagesGenius Publication CatalogueRaheel KhanNo ratings yet

- Jamesbury Polymer and Elastomer Selection GuideDocument20 pagesJamesbury Polymer and Elastomer Selection Guidesheldon1jay100% (1)

- The Right Stuff PDFDocument4 pagesThe Right Stuff PDFNeelank Tiwari100% (1)

- Materials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilDocument5 pagesMaterials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilBart MaxNo ratings yet

- Product Management Self-Learning ManualDocument261 pagesProduct Management Self-Learning ManualAbhishek Arekar100% (1)

- SIM BoxingDocument2 pagesSIM Boxingkrishnakant_75No ratings yet

- Psychrometric Chart - Us and Si UnitsDocument1 pagePsychrometric Chart - Us and Si UnitsRaden_Rici_Abi_1914No ratings yet

- G270han01 V0Document26 pagesG270han01 V0NemkoNo ratings yet

- CH 4 Data CommDocument4 pagesCH 4 Data CommHenna ShainaNo ratings yet

- 3-Axially Loaded Compresion Members PDFDocument37 pages3-Axially Loaded Compresion Members PDFKellen BrumbaughNo ratings yet

- Parallel Port Programming (PART 1) With CDocument13 pagesParallel Port Programming (PART 1) With ChertzoliNo ratings yet

- Slope Stability in Slightly Fissured Claystones and MarlsDocument25 pagesSlope Stability in Slightly Fissured Claystones and MarlsrullyirwandiNo ratings yet

- David Lowe Thesis PDFDocument201 pagesDavid Lowe Thesis PDFKRISHNA VAMSHINo ratings yet

- Fiber Optic Trainer/ Fiber & OSP TechnicianDocument7 pagesFiber Optic Trainer/ Fiber & OSP Technicianapi-78570706No ratings yet

- VXN150 Vixion Fuel Tank PDFDocument3 pagesVXN150 Vixion Fuel Tank PDFHarris Jum'aniandaNo ratings yet

- Softening N Penetration Test BitumenDocument11 pagesSoftening N Penetration Test BitumenEdwin LeonNo ratings yet

- 2019 All PDFDocument27 pages2019 All PDFvishesh bhatiaNo ratings yet