Professional Documents

Culture Documents

Lab 3 - Unsymmetrical Bending of A Cantil

Uploaded by

rodolfoordiguez_70Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab 3 - Unsymmetrical Bending of A Cantil

Uploaded by

rodolfoordiguez_70Copyright:

Available Formats

Laboratory Sheet 1 UNIVERSITI TEKNIKAL MALAYSIA MELAKA SOLID MECHANICS 3 UNSYMMETRICAL BENDING OF A CANTILEVER OBJECTIVE 1.

To construct a Mohrs Circle of deflections. 2. To establish values of the principle second moments of area from the Mohrs Circle. 3. To compare the principle second moments to theoretical values. THEORY Figure 1 shows a cantilever beam with a load applied at the free end. The beam has two principle axes, x and y, about which pure bending can take place. The principle axes pass through the centroid of the section but do not necessarily coincide with the arbitrary geometrical axes of the section.

No Dokumen: No Isu./Tarikh Jum Mukasurat:

SB/MMSB3/T1/BMCS4353/4 1/15-2-2006 No Semakan/Tarikh 0

Figure 1: Cantilever schematic and notation

1/4

SB/MMSB1/T1/BMCS1323/4

If applying a moment about one of the principle axis then the beam will deflect in that direction only and the simple bending formula can predict the deflection. However, if the moment is at an angle to either of the axes then the beam will bend about both of the axes. The free end deflection will have two components - one in the direction of pull (U) and at right angles (V). If we were interested in predicting the magnitude of the deflections, we would need to resolve the moment into components acting about the principle axes. This leads to the following formulae (standard texts outline the derivation):

U =

1 1 FL3 1 1 + + cos 2 I 6 E I x I y y I x

(1)

V =

Where: L E U V Ix, Iy

1 1 FL3 sin 2 6E Ix Iy

(2)

= Effective length of the specimen (m) = Youngs modulus (GNm-2) = Deflection in the direction of pull (m) = Deflection at right angles to the pull (m) = Angle of pull () = Principle second moments of area (m4)

A good way of reading off the cantilever deflections for various angles is to construct a Mohr's Circle. The Mohr's Circle is an excellent graphical method, which you may have come across before in stress analysis. To construct a Mohr's Circle of deflections you would need to know at least the principle second moments of area (IX and Iy). In this experiment we will use the Mohr's Circle in reverse to establish values of the principle second moments of area from deflections measured off the equipment in each direction (U and V). We can then compare the principle second moments to theoretical values.

Figure 2: Mohrs circle of deflections to find the principle second moments of area

2/4

SB/MMSB1/T1/BMCS1323/4

EQUIPMENT 1. The unsymmetrical bending experiment in the structures frame is shown in Figure 3.

Figure 3: Unsymmetrical bending experiment in the structures frame

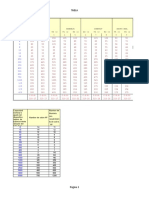

PROCEDURE 1. Loosen the two rearward facing thumbscrews on the indicator bosses, turn the indicators inward to contact the inner two datum pegs and lock off the thumbscrews. This sets the 90 angle between the two indicators. 2. Select one of the three specimens and fit it into the bottom chuck referring to Figure 5 for correct positions. 3. Fit the top of the specimen into the top chuck in the same relative position, ensure that the specimens are set squarely and all of the screws are tight. 4. Fit the extension piece to the bottom chuck, hook the cord onto the groove and pass it over sliding the pulley. 5. Undo the top chuck hand wheel and rotate the specimen so it is orientated as per Figure 5. When you feel the chuck 'click' into the correct position tighten the hand wheel. 3/4

SB/MMSB1/T1/BMCS1323/4

6. Ensure that the indicators have about 10-11 mm forward and 2 - 3 mm backward travel in this position; if not loosen the indicator top screw and slide the indicator to the correct position, retighten the screw. 7. Tap the frame sharply to reduce the effect of friction and zero the indicators. Apply loads in 100 g increments, up to a maximum of 500 g on the end of the cord. 8. Ensure the cord remains parallel to the lines on the plate below. 9. Tap the frame sharply after adding each load. Record the resulting deflections (left and right) in Table 1 under the 'Head angle: 0' title. 10. Undo the top chuck hand wheel, rotate the specimen clockwise 22.5 (i.e. to the next location) and tighten. 11. Adjust the indicators, if required, and then repeat the loading procedure, recording the results under 'Head angle: 22.5' in Table 1. 12. Continue taking results until the specimen has rotated 180. 13. Repeat step 2 12 for the other two specimens.

4/4

You might also like

- Lab Report On Waren GirderDocument12 pagesLab Report On Waren GirderSamuel Ogeda Otieno100% (2)

- SHEAR CENTRE Lab ReportDocument16 pagesSHEAR CENTRE Lab ReportAthirah Dinata100% (2)

- Lab REPORTTTDocument9 pagesLab REPORTTTepiXtremeNo ratings yet

- Forces in Redundant Truss and Forces in TrussDocument28 pagesForces in Redundant Truss and Forces in TrussNelda Geo0% (1)

- Reaction Beam LabDocument26 pagesReaction Beam LabAzhar Marzuki83% (6)

- Equilibrium of A BeamDocument5 pagesEquilibrium of A Beamawe_em50% (4)

- Central Deflection of A Simply Supported BeamDocument10 pagesCentral Deflection of A Simply Supported BeamwaqarNo ratings yet

- ) Lab InstructionsDocument10 pages) Lab Instructionswilson100% (1)

- Unsymmetrical Bending of a Cantilever BeamDocument6 pagesUnsymmetrical Bending of a Cantilever BeamWill Haynes0% (2)

- Shear Centre of C-Channel SectionDocument12 pagesShear Centre of C-Channel SectionAshrafur Rahman100% (1)

- Bending Moment in A BeamDocument8 pagesBending Moment in A BeamLim Ksoon100% (1)

- Torsion Lab Report PDFDocument9 pagesTorsion Lab Report PDFHans100% (1)

- s2 Bending MomentDocument22 pagess2 Bending MomentismailNo ratings yet

- Experiment Shearing ForcesDocument17 pagesExperiment Shearing ForcesAnushaBheenuck73% (11)

- Shear Force in A Beam (Edited) 1Document20 pagesShear Force in A Beam (Edited) 1Ana Jannah80% (5)

- Structure CableDocument7 pagesStructure CableEriey ZuhairiNo ratings yet

- Experiment 4 - Structural Analysis 1 Lab ReportDocument24 pagesExperiment 4 - Structural Analysis 1 Lab Reportfatinkeon77% (48)

- Buckling of Struts: Effects of Length and End ConditionsDocument12 pagesBuckling of Struts: Effects of Length and End ConditionsJoshua ReynoldsNo ratings yet

- 1.bending Moment in A BeamDocument7 pages1.bending Moment in A BeamNur Syahirah Mohd NoorNo ratings yet

- Structural Mechanics Lab ReportDocument31 pagesStructural Mechanics Lab Reportmalicat alwroodNo ratings yet

- JNTU Hall Ticket Marks SheetDocument20 pagesJNTU Hall Ticket Marks SheetbhargavNo ratings yet

- Documents - MX - Ps Work BooksolutionDocument39 pagesDocuments - MX - Ps Work BooksolutionHaziq MansorNo ratings yet

- Computational Physics - Fortran Version - Koonin PDFDocument660 pagesComputational Physics - Fortran Version - Koonin PDFJosé Roberto LessaNo ratings yet

- EXPERIMENTAL BEAMSDocument10 pagesEXPERIMENTAL BEAMSNurul NadhirahNo ratings yet

- Measure bending moment with loadsDocument9 pagesMeasure bending moment with loadsOmar Arabi0% (1)

- Bending Moment Beam LabDocument14 pagesBending Moment Beam LabMorapedi D. KealebogaNo ratings yet

- Bending Moment in A Beam Lab Report - Green MechanicDocument9 pagesBending Moment in A Beam Lab Report - Green Mechanicmohdiqbal93No ratings yet

- Experiment 2 - Shear Force in BeamsDocument8 pagesExperiment 2 - Shear Force in BeamsSubuk T. Rathod100% (1)

- S3-Deflection in Beam and CantileverDocument97 pagesS3-Deflection in Beam and CantileverBruh100% (1)

- Bending Beam LabDocument17 pagesBending Beam Labdoremon50% (2)

- Truss ReportDocument20 pagesTruss ReportSyuhaidah Zul Hadi100% (2)

- Deflection of Simply Supported and Cantilever BeamsDocument7 pagesDeflection of Simply Supported and Cantilever BeamsZol Has100% (1)

- MARA University of Technology Faculty of Mechanical EngineeringDocument12 pagesMARA University of Technology Faculty of Mechanical EngineeringAdiela Syuhada Roslan100% (1)

- Shear ForceDocument22 pagesShear ForceGregory MillerNo ratings yet

- Torsion of Cylindrical RodsDocument16 pagesTorsion of Cylindrical RodsStephen Mirdo83% (18)

- Discussion For Shear Centre LabDocument2 pagesDiscussion For Shear Centre Labkevinblache67% (3)

- Bending Moment Lab Sheet Proposal BendingDocument3 pagesBending Moment Lab Sheet Proposal BendingKim Won ShikNo ratings yet

- Deflection of Curved BarsDocument11 pagesDeflection of Curved Bars伟伦100% (1)

- Structure Lab-Three Hinge Arc (Example Lab Report)Document13 pagesStructure Lab-Three Hinge Arc (Example Lab Report)NabilZaed0% (2)

- Bending MomentDocument30 pagesBending MomentMuhammad ImranNo ratings yet

- CVE 230. Lab Report 4 (Torsion Testing) .Document4 pagesCVE 230. Lab Report 4 (Torsion Testing) .Juan Villa100% (1)

- Buckling of Struts Lab Report AnalysisDocument29 pagesBuckling of Struts Lab Report AnalysisAzfar Azpo100% (1)

- Lab8-Shear Force (New)Document15 pagesLab8-Shear Force (New)Nur Syamiza Zamri100% (1)

- Truss Lab ActivityDocument15 pagesTruss Lab Activitysaifudin.itsNo ratings yet

- Shear Force Experiment - 2Document6 pagesShear Force Experiment - 2Mohamad Afiq Afandi100% (1)

- Test Slender Column Strength & Buckling LoadsDocument6 pagesTest Slender Column Strength & Buckling LoadsAsad UzzamanNo ratings yet

- ME 457 Experimental Solid Mechanics (Lab) Torsion Test: Solid and Hollow ShaftsDocument5 pagesME 457 Experimental Solid Mechanics (Lab) Torsion Test: Solid and Hollow Shaftsanon-735529100% (2)

- Mechanics of Materials - Principal Stresses and StrainsDocument14 pagesMechanics of Materials - Principal Stresses and StrainsDavid Clark100% (5)

- Deflection of A Simply Supported BeamDocument15 pagesDeflection of A Simply Supported Beamshuqing heongNo ratings yet

- Bending Moment in A BeamDocument12 pagesBending Moment in A BeamOdarie HunterNo ratings yet

- Deflection of Beam PDFDocument8 pagesDeflection of Beam PDFSalam Albaradie100% (1)

- Experiment 3 (Bending Moments in Beam)Document13 pagesExperiment 3 (Bending Moments in Beam)Shafiq MahadiNo ratings yet

- Bending Moment Lab (CES511)Document8 pagesBending Moment Lab (CES511)Alif AkhmizanNo ratings yet

- Bending in Beam: Lab ReportDocument30 pagesBending in Beam: Lab ReportLa'ibah KamalNo ratings yet

- THEORY AM2.2 Unsymmetrical Bending Jan 2019Document12 pagesTHEORY AM2.2 Unsymmetrical Bending Jan 2019uzayr shahzadNo ratings yet

- AS2 Ex. No. 1Document11 pagesAS2 Ex. No. 1sarathkumar sebastinNo ratings yet

- Rolled Steel JoistsDocument20 pagesRolled Steel Joistsmanish dhariwalNo ratings yet

- Unsymmetrical Bending Intro+ ProcedureDocument2 pagesUnsymmetrical Bending Intro+ ProcedureJeffery WilliamsNo ratings yet

- Report Buckling of StructsDocument7 pagesReport Buckling of StructsAnonymous 59kjvq4OLBNo ratings yet

- Principle of StructureDocument3 pagesPrinciple of StructureDhananjay KumarNo ratings yet

- Fatigue Testing: Experiment 2Document5 pagesFatigue Testing: Experiment 2Mohd RozairieNo ratings yet

- UTHM Mechanical Engineering document on rotor balancingDocument46 pagesUTHM Mechanical Engineering document on rotor balancinghamryNo ratings yet

- Stress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandStress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (4)

- LRFD Implementation of Shallow FootingsDocument8 pagesLRFD Implementation of Shallow Footingsrodolfoordiguez_70No ratings yet

- DIALux Direct3D InformationDocument2 pagesDIALux Direct3D Informationrodolfoordiguez_70No ratings yet

- High Voltage SystemDocument7 pagesHigh Voltage Systemamrit403No ratings yet

- Siemes Ais DesignsDocument6 pagesSiemes Ais DesignsRajesh Sirigirisetty SNo ratings yet

- 6312 1-5Document5 pages6312 1-5rodolfoordiguez_70No ratings yet

- Read Me AlwaysDocument23 pagesRead Me AlwaysRodrigo MenegonNo ratings yet

- High Voltage SystemDocument7 pagesHigh Voltage Systemamrit403No ratings yet

- DIALux DXF InformationDocument2 pagesDIALux DXF Informationrodolfoordiguez_70No ratings yet

- Your Profile PDFDocument4 pagesYour Profile PDFrodolfoordiguez_70No ratings yet

- Lista de Equipos de Subesatcion PDFDocument6 pagesLista de Equipos de Subesatcion PDFrodolfoordiguez_70No ratings yet

- Different Types of BusDocument2 pagesDifferent Types of Busrodolfoordiguez_70No ratings yet

- Different Types of BusDocument2 pagesDifferent Types of Busrodolfoordiguez_70No ratings yet

- TECHFDocument19 pagesTECHFrodolfoordiguez_70No ratings yet

- PDFDocument4 pagesPDFrodolfoordiguez_70No ratings yet

- Your Profile PDFDocument4 pagesYour Profile PDFrodolfoordiguez_70No ratings yet

- Extractor EsDocument1 pageExtractor Esrodolfoordiguez_70No ratings yet

- Extractor EsDocument1 pageExtractor Esrodolfoordiguez_70No ratings yet

- PEVADocument5 pagesPEVArodolfoordiguez_70No ratings yet

- 19-10-2017Document2 pages19-10-2017rodolfoordiguez_70No ratings yet

- Your ProfileDocument4 pagesYour Profilerodolfoordiguez_70No ratings yet

- SignifDocument415 pagesSignifrodolfoordiguez_70No ratings yet

- ReadmeDocument8 pagesReadmerodolfoordiguez_70No ratings yet

- Survey Specifications for Transmission Line RouteDocument7 pagesSurvey Specifications for Transmission Line Routeahmadove1No ratings yet

- MaximaDocument3 pagesMaximarodolfoordiguez_70No ratings yet

- 5B Settle PDFDocument53 pages5B Settle PDFArif HDNo ratings yet

- Assignment 1Document2 pagesAssignment 1Tu Tu DarNo ratings yet

- Gis Building: Costa Rica Common PracticeDocument11 pagesGis Building: Costa Rica Common Practicerodolfoordiguez_70No ratings yet

- Cond AluminioDocument40 pagesCond Aluminiorodolfoordiguez_70No ratings yet

- Site Investigation: Assist. Prof. Berrak TEYMURDocument13 pagesSite Investigation: Assist. Prof. Berrak TEYMURsujan_duttaNo ratings yet

- Civil Engineering Practical Notes A-ZDocument142 pagesCivil Engineering Practical Notes A-Zhossainsultan100% (5)

- Bearing Design Method BDocument3 pagesBearing Design Method BDhurai KesavanNo ratings yet

- 02page SageDocument140 pages02page SageSergio MontesNo ratings yet

- Mohr's Theorem and Corollaries PDFDocument8 pagesMohr's Theorem and Corollaries PDFEvaNo ratings yet

- 5 2 A A Geometric Constraints 1Document3 pages5 2 A A Geometric Constraints 1api-248595624No ratings yet

- Acceleration and DecelerationDocument28 pagesAcceleration and DecelerationCt RahayuNo ratings yet

- Unpacking PDFDocument15 pagesUnpacking PDFNicole HernandezNo ratings yet

- Thesis - Robust Control of Power Electronic ConvertersDocument172 pagesThesis - Robust Control of Power Electronic ConvertersDhananjayNo ratings yet

- Module 3: Mass Transfer Coefficients: Lecture No. 1Document4 pagesModule 3: Mass Transfer Coefficients: Lecture No. 1walisyhNo ratings yet

- Anel Peralta Participation Activity 2Document7 pagesAnel Peralta Participation Activity 2Indira AlfonsoNo ratings yet

- Gaining Confidence With GD T - Part 3Document20 pagesGaining Confidence With GD T - Part 3Abraham ThomasNo ratings yet

- 1 Nature of MathematicsDocument15 pages1 Nature of MathematicsAngelica GeronNo ratings yet

- Yasmin Schulberg Mid Year TranscriptDocument1 pageYasmin Schulberg Mid Year Transcriptapi-405077147No ratings yet

- Assignments-Assignment 4 PDFDocument4 pagesAssignments-Assignment 4 PDFniki098No ratings yet

- Lesson Plan Template 20170831 Mathematical InductionDocument2 pagesLesson Plan Template 20170831 Mathematical Inductionapi-367457807100% (1)

- Flat and Elongated Particles TestDocument4 pagesFlat and Elongated Particles Testmido_20067581No ratings yet

- Guide to Time Series DecompositionDocument66 pagesGuide to Time Series DecompositionRuth CapchaNo ratings yet

- Bartok's Music For Strings, Percussion and CelesteDocument16 pagesBartok's Music For Strings, Percussion and CelesteWolfgang SalazarNo ratings yet

- Cooling Tower Thermal DesignDocument106 pagesCooling Tower Thermal Designxuense100% (4)

- DNR II de HARELDocument15 pagesDNR II de HARELhenry palmaNo ratings yet

- Comparitive Study of Various Watermarking TechniquesDocument7 pagesComparitive Study of Various Watermarking TechniquesHitanshi SachdevaNo ratings yet

- Numerical Modeling of The Dynamic Behavior of A Wind Turbine TowerDocument21 pagesNumerical Modeling of The Dynamic Behavior of A Wind Turbine TowerHenrique Castro FilhoNo ratings yet

- Geo 5 User Guide enDocument1,431 pagesGeo 5 User Guide enShahab KhaledNo ratings yet

- CK 12 Basic Algebra Concepts B v16 Jli s1Document780 pagesCK 12 Basic Algebra Concepts B v16 Jli s1Phil Beckett100% (1)

- Alfa Laval Flow Transmitter Product LeafletDocument4 pagesAlfa Laval Flow Transmitter Product LeafletsanjeevNo ratings yet

- DTE MCQ QUESTION BANK ON DIGITAL ELECTRONICS GATESDocument29 pagesDTE MCQ QUESTION BANK ON DIGITAL ELECTRONICS GATESAmal NairNo ratings yet

- Programming For Problem Solving Set 3Document8 pagesProgramming For Problem Solving Set 3Md. Al MamunNo ratings yet

- Automatic Parallel Parking System ReportDocument23 pagesAutomatic Parallel Parking System ReportFrances Ekenedilichukwu Awachie50% (2)