Professional Documents

Culture Documents

Jib Crane Example Problem

Uploaded by

earthboy2uOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jib Crane Example Problem

Uploaded by

earthboy2uCopyright:

Available Formats

12-631 Structural Design

Exam 1 Solution Sheet

S06

Jib Crane

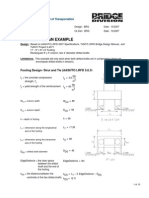

A steel jib crane is constructed of a Beam BC pinned at Joint B and supported by a tension Member AC at Joint C as shown on the following page. Beam BC is a double channel member made up of two C9x20 channels arranged back to back to make up the beam section. Tension member AC is a single 1/2" thick by 3" wide steel bar pinned at Joint A and bolted to the Beam BC at Joint C with two 3/4" Dia. A325-N bolts. Details of the bolted connection at Joint C are shown in the Elevation and Section Views of the Detail at Joint C. The steel bar and steel channels are made of A36 steel. The dimensions and properties of the double C9x20 channels are given in the tables below. The jib crane supports a vertical pick-up service live load, PL, which can act anywhere along Beam BC. Find the allowable magnitude for PL considering the tension strength of Member AC, the compression and bending strengths of Beam BC and the strength of the bolted connection at Joint C. In your analysis, the following assumptions can be made: 1. Only live loading occurs, that is, neglect the weight of the members and the dead load and impact load components of the pick-up load. 2. When the pick-up load is at Joint C, Beam BC is in "compression" only and the tension force in Member AC and compression force in BC are at their maximum values. 3. When the pick-up load is at some location between Joints B and C, the beam is in "bending" only. 4. The pinned connections at Joints A and B will not govern. 5. The compression flange of Beam BC is laterally stable. 6. Joints A, B & C are supported to prevent lateral displacement, i.e., these joints cannot move in a direction perpendicular to the Plane ABC. 7. Block shear and bending shear in the webs of the double channels will not govern.

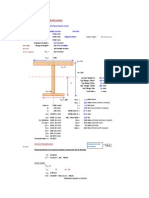

Dimensions of each C9x2 Channel: 0 d, in tw, in bf, in tf, in k, in 9.0 0.448 2.65 0.413 1.0 Properties of the Double C9x2 with a Separation 0 2 3 4 As, in Zx, in Ix, in Iy, in4 rx, in ry, in 11.74 33.8 121.8 13.0 3.22 1.05

t f

b f ( a v g . )

t w

1 / 2 "

Page 1 of 7

12-631 Structural Design

Exam 1 Solution Sheet

S06

1 0 ' 0 "

1 / 2 " x 3 " T e n s io n B a r

B PL 1 0 ' 0 "

3 "

T w o 3 / 4 " D ia . A 3 2 5 - N B o lt s 1 / 2 " 3 " 2 "

T w E

9 x 2 0

l e v a t i o n V i S we c t i o n a l V i e w e D E T A I L A T J O I N T C

kips := 1000lbf

Page 2 of 7

12-631 Structural Design

Exam 1 Solution Sheet

Fy := 36 ksi Lbc := 10 ft Fu := 58 ksi Fub := 120 ksi

S06

Material Properties: Length of Beam BC:

Es := 29000ksi

Tension Strength of Member AC

b := 3 in t := 1 2 in A g := b t s b := 3 in A g = 1.5in

2

Le := 2 in

d b :=

3 4

in

Tension Member Area:

Bolt Hole Dia.:

1 d h := d b + in 8

d h = 0.88in A n = 1.06in A e := U A n Tny = 48.6kips Tnf = 46.22kips A gt = 0.75in

2 2 2

Net Area: Effective Net Area: Yield Limit State:

A n := A g d h t

U := 1

A e = 1.06in

Tny := 0.9 Fy A g Tnf := 0.75Fu A n A gt := b 2 t

Fracture Limit State: Block Shear Limit State:

A nt := A gt 0.5 d h t A gv := s b + Le t A nv := A gv 1.5 d h t 0.6 Fu A nv = 64.16kips

A nt = 0.53in A gv = 2.5in

2

A nv = 1.84in

>

Fu A nt = 30.81kips

Therefore, shear fracture - tension yielding Tnbs := 0.75 0.6 Fu A nv + Fy A gt mode controls, and:

Tnbs = 68.37kips

Strength of Bolted Connection at C

Shear Strength of Bolts: Bolts in double shear, therefore, Bolt Area:

mb := 2

Rnv := 0.75 0.4 Fub mb A b

A b :=

db

A b = 0.44in

Since threads iNcluded in shear plane, the shear strength per bolt is:

Rnv = 31.81kips

Page 3 of 7

12-631 Structural Design

Exam 1 Solution Sheet

S06

Bearing Strength of Bolts on Tension Member AC:

s b = 3 in

>

3 d b = 2.25in

and

Le = 2 in

>

2.5 d b = 1.87in

Since the above spacing and end distances are met, then the bearing strength per bolts is:

Rnb := 0.75 2.4 Fu d b t

Rnb = 39.15kips

Bolt bearing in the channel sections will not govern since the bolt load transfered to each channel is one-half of the total bolt load, and the web thickness of the channels is more that one-half the thickness of the tension member.

Rnv = 31.81kips Rnb = 39.15kips

Minimum Strength of the Bolted Connection:

Tnb := 2 min Rnv , Rnb

Tnb = 63.62kips

Bolt shear controls connection strength. Min. Strength of Tension Member and Bolts:

Tu := min Tny , Tnf , Tnbs , Tnb

Tu = 46.22kips

Fracture Limit State controls strength of AC

Equilibium of Forces at Joint C

The maximum tension in AC and compression in BC will occur when the pick-up load is at Joint C. A free-body diagram of the forces at that joint is shown in the sketch below: Equilibrium of forces in the vertical direction gives: Tu sin 45o - Pu = 0 Equilibrium of forces in the horizontal direction gives: Cu - Tucos 45o = 0 Solving for Tu and Cu, we obtain: Tu = Pu/sin 45o = 1.414 Pu and Cu = Tu cos 45o = Pucos 45o/sin 45o = Pu

4 5

C u

Pu

Ultimate Pick-up Load Based on Tu:

Tu Put := 1.414

Put = 32.69kips

Page 4 of 7

12-631 Structural Design

Exam 1 Solution Sheet

S06

Compression Strength of Member BC

Required properties of the double C9x20 channels separated by 1/2" Properties of Both Channels:

A s := 11.74in Ix := 121.8in rx := 3.22in

4 2

Dimensions of Each Channel:

3

Zx := 33.8in Iy := 13.0in

d := 9 in b f := 2.65in k := 1 in

t w := 0.448in t f := 0.413in h := d 2 k

h = 7 in

ry := 1.05in bf tf = 6.42

Width to thickness ratios for each channel:

<

95 Fy ksi 253 Fy ksi

= 15.83

Therefore, the sections can yield before local buckling of the flange and web.

h tw

= 15.63 <

= 42.17

Unbraced Length:

Lbc = 10 ft

Kx := 1.0

Ky := 1.0

Since Kx = Ky = 1.0 and rx > ry, then buckling about the weak axis, y, will govern.

c := Ky Lbc ry Fy Es

2

c = 1.28

c < 1.5, therefore, inelastic buckling governs

2 0.658 c F Fcr := y

Fcr = 18.1ksi

Pnc = 180.62kips

Fcr := 0.85Fcr

Fcr = 15.39ksi

Pnc := 0.85Fcr A s

and the compression strength of the member becomes:

Cu := Pnc

Cu = 180.62kips

The maximum compression force in BC will occur when the pick-up load is at Joint C and from the above equilibrium equations, Pu = Cu. Ultimate Pick-up Load Based on Cu:

Puc := Cu

Puc = 180.62kips

Page 5 of 7

12-631 Structural Design

Exam 1 Solution Sheet

S06

Bending Strength of BC

Check if section is compact:

bf tf = 6.42

<

65 Fy ksi

= 10.83

h tw

= 15.63

<

640 Fy ksi

= 106.67

Also, it is assumed that the compression flanges of the channels are laterally stable. Therefore, the channels are compact and can develop the full plastic moment Moment Capacity of the Double C6x13 Section:

M n := 0.90Zx Fy M n = 91.26ft kips

M u := Mn

M u = 91.26ft kips

Pu B Pu

2 2

Pu L

2

Pu

2

L

M a x . M = P L / 4

As shown in the sketch above, the maximum moment in BC will occur when the pick-up load is at mid-span. In this case, the magnitude of the moment produced by the pick-up load will be: Mu = PumLbc/4 . Solving for Pum, we obtain: Ultimate Pick-up Load Based on Mu:

4 M u Pum := Lbc

Pum = 36.5kips

Page 6 of 7

12-631 Structural Design

Exam 1 Solution Sheet

S06

Minimum Value of Pu:

In summary, we have:

Put = 32.69kips Puc = 180.62kips Pum = 36.5kips

Therefore,

Pu := min Put , Puc , Pum

Pu = 32.69kips

Tension in AC governs.

Corrersponding Service Load:

The Live Load factor is 1.6 and the service pick-up load becomes:

Pu PL := 1.6 PL = 20.43kips

Therefore, this crane should be rated for a service load of 20 kips or 10 Tons.

Page 7 of 7

You might also like

- Jib Crane CalculationDocument2 pagesJib Crane Calculationpaiyyapan78% (9)

- Jib Foundation Sizing and Stability AnalysisDocument4 pagesJib Foundation Sizing and Stability AnalysisChiedu Okondu50% (2)

- AKUEB XI Physics Notes-1-1 PDFDocument162 pagesAKUEB XI Physics Notes-1-1 PDFM.BILAL MADNI91% (11)

- Design Concept For Jib CraneDocument12 pagesDesign Concept For Jib Cranevish5610100% (3)

- Manual Crane CalculationDocument98 pagesManual Crane CalculationLarry Bea67% (15)

- Lifitng Lug Design (BS5950)Document2 pagesLifitng Lug Design (BS5950)Aya MontesNo ratings yet

- Crane Design and CalculationDocument28 pagesCrane Design and Calculationodim7370% (23)

- Jib Crane Design SellDocument13 pagesJib Crane Design Selljafary100% (3)

- Jib Crane HandbookDocument10 pagesJib Crane Handbookprp_a100% (3)

- Crane BeamDocument8 pagesCrane BeamastorNo ratings yet

- EOT Crane Wheel Load CalculationDocument1 pageEOT Crane Wheel Load CalculationSantosh100% (2)

- Jib CranesDocument32 pagesJib CranesmaheshbandhamNo ratings yet

- Crane Gantry Girder (BS5950 - Part1 - 2000)Document6 pagesCrane Gantry Girder (BS5950 - Part1 - 2000)sayed100% (1)

- Monorail Beam DesignDocument6 pagesMonorail Beam DesignAnand.5No ratings yet

- Report of Lifting Beam DesignDocument5 pagesReport of Lifting Beam Designnarutothunderjet216100% (1)

- Design Gantry Girder Industrial Building CraneDocument28 pagesDesign Gantry Girder Industrial Building Cranes_bharathkumar75% (12)

- Workshop On EC4 - CompositeDocument53 pagesWorkshop On EC4 - CompositePeyman MznNo ratings yet

- Detailed connection design rules for cellular beamsDocument9 pagesDetailed connection design rules for cellular beamsMujjo SahbNo ratings yet

- Jib Cranr CalculationDocument2 pagesJib Cranr CalculationShishupal Choudhary50% (6)

- Crane Girder DesignDocument6 pagesCrane Girder Designarzu50% (2)

- Design of Gantry Girders 1Document10 pagesDesign of Gantry Girders 1Abhishek Agarwal100% (2)

- Design and Static Analysis of I Section Boom For Rotary Jib Crane IJERTV3IS080816Document4 pagesDesign and Static Analysis of I Section Boom For Rotary Jib Crane IJERTV3IS080816Evodius RweyemamuNo ratings yet

- Jibcrane 2Document14 pagesJibcrane 2exlexzonNo ratings yet

- CRANE BEAM DESIGN CHECKSDocument38 pagesCRANE BEAM DESIGN CHECKSyercNo ratings yet

- 5T X 25.5m DG CraneDocument10 pages5T X 25.5m DG CraneRv VaghasiaNo ratings yet

- Gantry GirderDocument5 pagesGantry GirderDas TadankiNo ratings yet

- Calculate Design Beam Jib CraneDocument25 pagesCalculate Design Beam Jib Cranejafary100% (14)

- Gantry Crane Design Calculations - Google SearchDocument2 pagesGantry Crane Design Calculations - Google SearchJebin Abraham100% (1)

- Design of Monorail BeamDocument6 pagesDesign of Monorail BeamMahata Priyabrata100% (2)

- ABUS 120.0t EOT Layout - 22.0m SpanDocument1 pageABUS 120.0t EOT Layout - 22.0m Spanfud3n100% (1)

- Most Applications, F.S. 5.0) : Calculation ReferenceDocument5 pagesMost Applications, F.S. 5.0) : Calculation ReferenceParthibanNo ratings yet

- Crane Beam DesignDocument7 pagesCrane Beam DesignTharanga Pradeep100% (2)

- Crane BeamDocument20 pagesCrane BeamPreyash Shah100% (1)

- Design Analysis-Jib CraneDocument22 pagesDesign Analysis-Jib Cranesainal100% (3)

- Double Girder Box Type Eot Crane Design v2.0Document64 pagesDouble Girder Box Type Eot Crane Design v2.0deua2004100% (1)

- Crane Buffer ForcesDocument243 pagesCrane Buffer ForcesFourHorsemenNo ratings yet

- Jib CraneDocument16 pagesJib Cranesuperman3k100% (2)

- Lifting Beam DesignDocument4 pagesLifting Beam DesignX100% (1)

- 11 Crane Frame StructuresDocument6 pages11 Crane Frame StructuresYonas YGNo ratings yet

- 16 Jib Crane ANA5201Document5 pages16 Jib Crane ANA5201vodugu123100% (1)

- Ancient cranes lifted constructionDocument25 pagesAncient cranes lifted constructionIshaan00748850% (2)

- CraneBeam v1 1Document44 pagesCraneBeam v1 1harry_1981No ratings yet

- Shaft Footing ExampleDocument10 pagesShaft Footing Exampleอภิรักษ์ มานะกิจศิริสุทธิNo ratings yet

- Joist SlabDocument13 pagesJoist SlabAhmed Nabil80% (5)

- RC Beam Torsion DesignDocument33 pagesRC Beam Torsion Design2011kumarNo ratings yet

- ONE-WAY SLABS DESIGNDocument26 pagesONE-WAY SLABS DESIGNJohn Mejia50% (4)

- CE Weekend Knockout Quiz With Answer Key PDFDocument19 pagesCE Weekend Knockout Quiz With Answer Key PDFppppp100% (1)

- Tutorials 1 5Document7 pagesTutorials 1 5faizankhan260690No ratings yet

- RCD - Interaction Diagram & Long Column: ExampleDocument8 pagesRCD - Interaction Diagram & Long Column: ExampleAurora VillalunaNo ratings yet

- PEC ERyRM I PDFDocument11 pagesPEC ERyRM I PDFAlejandro serrano pozoNo ratings yet

- Beam-Column Self Study Report by Othman and HaniDocument29 pagesBeam-Column Self Study Report by Othman and Haniozzieastro100% (2)

- HES2340 Fluid Mechanics 1, Semester 1, 2012, Assignment 2Document13 pagesHES2340 Fluid Mechanics 1, Semester 1, 2012, Assignment 2StephenPYBongNo ratings yet

- HW#8 8 - 20 SolDocument13 pagesHW#8 8 - 20 Solderp2ooNo ratings yet

- Axially Loaded RC Column DesignDocument17 pagesAxially Loaded RC Column DesignBert EngNo ratings yet

- Interaction Formula:: 1.0 resistance effects load ΣDocument20 pagesInteraction Formula:: 1.0 resistance effects load ΣwilliamzitoNo ratings yet

- Mechanics of Materials Chap 10-03Document16 pagesMechanics of Materials Chap 10-03Suraj Kumar SNo ratings yet

- MPPSC Previous Year Paper 2017 CE Paper - IIDocument24 pagesMPPSC Previous Year Paper 2017 CE Paper - IIMy TubeNo ratings yet

- Strut and tie modeling, yield line analysis, and plastic analysis of concrete and steel structuresDocument9 pagesStrut and tie modeling, yield line analysis, and plastic analysis of concrete and steel structuresmalumius100% (2)

- Electrical Power Systems: Mohamed Taha MouwafiDocument18 pagesElectrical Power Systems: Mohamed Taha MouwafiAHMED BAKRNo ratings yet

- Stresses in Wing Ribs A21.4 Rib For Single Cell 2-Flange BeamDocument23 pagesStresses in Wing Ribs A21.4 Rib For Single Cell 2-Flange BeamAnonymous LMfIjpENo ratings yet

- Chapter 6 Plate GirderDocument23 pagesChapter 6 Plate GirderolomuNo ratings yet

- Cold Steel Designers ManualDocument73 pagesCold Steel Designers Manualearthboy2uNo ratings yet

- COVERBAKDocument1 pageCOVERBAKearthboy2uNo ratings yet

- Thumb Rules For Steel DesignDocument3 pagesThumb Rules For Steel Designpranit_rai100% (1)

- Strawbalehomebasics 2008Document7 pagesStrawbalehomebasics 2008earthboy2uNo ratings yet

- Waves Transfer EnergyDocument40 pagesWaves Transfer EnergyGellirose S. Bantayan100% (1)

- Inverse Power Method with Shift for Eigenvalue CalculationDocument9 pagesInverse Power Method with Shift for Eigenvalue CalculationSerkan SancakNo ratings yet

- Chapter 4 PDFDocument47 pagesChapter 4 PDFAdolfo ElizondoNo ratings yet

- BE 8256 - Basic Mechanical Engineering / U – II / Compiled by R.Arul KamalakumarDocument24 pagesBE 8256 - Basic Mechanical Engineering / U – II / Compiled by R.Arul KamalakumararulrakkNo ratings yet

- Radiation Protection and Dosimetry Assessment 2Document2 pagesRadiation Protection and Dosimetry Assessment 2George ChahniNo ratings yet

- Physics of The Impossible: A Scientific Exploration Into The World of Phasers, Force Fields, Teleportation, and Time Travel by Michio KakuDocument2 pagesPhysics of The Impossible: A Scientific Exploration Into The World of Phasers, Force Fields, Teleportation, and Time Travel by Michio KakuHomeroom TabNo ratings yet

- 1Q - Week 1 Physical ScienceDocument23 pages1Q - Week 1 Physical ScienceJEBONIE TUBICENo ratings yet

- Phy 104 Modern Physics Assignment 2Document24 pagesPhy 104 Modern Physics Assignment 2Ahmed AliNo ratings yet

- JEE (MAIN+ADVANCED) NURTURE LIVE PHASE-I (TARGET 2025) ENGLISH HINDI SYLLABUSDocument1 pageJEE (MAIN+ADVANCED) NURTURE LIVE PHASE-I (TARGET 2025) ENGLISH HINDI SYLLABUSTechnology LifeNo ratings yet

- Master Resource Book in Physics @unacademyplusdiscounts For JEE-pages-734,738Document2 pagesMaster Resource Book in Physics @unacademyplusdiscounts For JEE-pages-734,738rishithhr rajeevNo ratings yet

- Wood 1902Document9 pagesWood 1902Lucho GonzalezNo ratings yet

- Https Courses Lumenlearning Com Precalctwo Chapter Testing-polar-equations-For-symmetryDocument6 pagesHttps Courses Lumenlearning Com Precalctwo Chapter Testing-polar-equations-For-symmetryAkash TutiNo ratings yet

- Physical Science Prelim - FinalDocument10 pagesPhysical Science Prelim - FinalrichardsamranoNo ratings yet

- Uit RGPV First Year SyllabusDocument19 pagesUit RGPV First Year SyllabusYasir MujtabaNo ratings yet

- Intensity of Optical Absorption by Excitons (Elliott 1957) PDFDocument6 pagesIntensity of Optical Absorption by Excitons (Elliott 1957) PDFDavid ParfittNo ratings yet

- Fa 2 Brood 3Document8 pagesFa 2 Brood 3LanceDavidNo ratings yet

- Numerical Modeling of Physical Process of Far Field Underwater ExplosionsDocument11 pagesNumerical Modeling of Physical Process of Far Field Underwater ExplosionsKristjan TabriNo ratings yet

- Conduct FAILURE ANAYLSISDocument10 pagesConduct FAILURE ANAYLSISMohamad Nadzri YahayaNo ratings yet

- CV 2017Document9 pagesCV 2017AviJainNo ratings yet

- Skema Fizik SPM Trial Perak 2009Document16 pagesSkema Fizik SPM Trial Perak 2009fizmie100% (2)

- 1st Year Important Questions 2019 - 2020Document3 pages1st Year Important Questions 2019 - 2020Lohith CharyNo ratings yet

- Flow Velocities: Line Printed Heading CommentsDocument4 pagesFlow Velocities: Line Printed Heading Commentssj_scribdNo ratings yet

- Heat Balance GCLDocument6 pagesHeat Balance GCLIrshad HussainNo ratings yet

- Applied Thermal Engineering: SciencedirectDocument15 pagesApplied Thermal Engineering: SciencedirectSadegh AhmadiNo ratings yet

- Units & Dimensions 43 Yrs IITJEEDocument21 pagesUnits & Dimensions 43 Yrs IITJEEHarshitNo ratings yet

- Experiment No: Objective: ApparatusDocument3 pagesExperiment No: Objective: ApparatusAfzaal FiazNo ratings yet

- FC Sem 3 NATURE AND DEVELOPMENT OF SCIENCEDocument11 pagesFC Sem 3 NATURE AND DEVELOPMENT OF SCIENCEPravin RnsNo ratings yet

- CFTSDocument4 pagesCFTSStefan NaricNo ratings yet