Professional Documents

Culture Documents

Internship Report

Uploaded by

Umi IzharOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Internship Report

Uploaded by

Umi IzharCopyright:

Available Formats

.

Internship report on

Etihad Sugar Mills Limited Rahim Yar Khan

Submitted by: M. Asif Akram Submitted on: 9 Sept, 2011

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

Dedications

I dedicated this efforts to my Parents & Teachers Who guide & Encourage me during the Preparation of this report

And I want to say

My Parents & Teachers

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

Acknowledgement

All the thanks and praises for Allah who bestowed guidance and wisdom to mankind and enabled me to complete this work. I am very thankful to all my Superiors i.e. Mr. Muhammad Amjad Jam, Deputy Personnel Manager, Haji Shaukat Ali, Deputy Chief Accountant, Mian Farooq Masood, Accountant, who helped me a lot to produce this report. I am thankful to my department who accepted my request to do internship in Etihad Sugar Mills Limited, Rahim Yar Khan. I am also grateful to all employees of the Etihad Sugar Mills Limited who guide me during the course of internship. The behavior of all the department supervisors is very good to me because they gave me a lot of time to guide me the mechanism of all departments in which I worked. I am also thankful to the management of Etihad Sugar Mills Limited, Karamabad, Rahim Yar Khan, who gave me all the valuable support and opportunities to complete 06 weeks Internship programme and compile this report.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

Tables of Contents

Description Letter of undertaking Dedication Acknowledgement Introduction to the sugar and sugar industry Province-wise name of sugar mills in Pakistan Companys products Competitors Companys information Organizational chart for management Introduction to the higher management Introduction to organization

Page # 2 3 5 6 6 08 08 08 09 10 10 11 12 13 14 15 18 19 22 23 23 27 28 29 30 31 32 33 34 41

My Internship Programme Departments of the organization Accounts Department Organizational Chart of Accounts Department Administration Department Organizational Chart of Administration Department Cane Department Organizational Chart of Cane Department Chemical Department Processing of sugar cane in a sugar mill for manufacturing of white sugar. Organizational Chart of Chemical Department Electrical Department Organizational Chart of Electrical Department I.T. Department Organizational Chart of I.T. Department Laboratory Department Organizational Chart of Laboratory Department Mechanical Department Organizational Chart of Mechanical Department

SWOT Analysis Conclusion Recommendations for improvement References

68 70 71 72

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

Introduction to sugar and sugar industry

The word sugar originates from the Sanskrit word sharkara which means sugar. It may also be traced through all the Aryan languages, as schaker in Persian, sukkar in Arabic, sincer in Assyrian, zucchero in Italian, sucre in French, zucher in German, saccharum in Latin and ozucarin Spanish etc stand as Testimony for its origin from sharkara. Sugar is a major form of carbohydrates and is found probably in all green plants. It occurs in significant amounts in most fruits and vegetables. There are three main simple sugars Sucrose, Fructose and Glucose. Sucrose is in fact a combination of fructose and glucose and the body quickly breaks down into these separate substances. All energy stored in food is derived originally from the sun and it is made by green plant life. The sun's energy acts upon the green chemical "chlorophyll" in the leaves of plants to produce sugars and starches from the carbon-dioxide in the atmosphere and the water from the roots by a process known as Photosynthesis. These carbohydrates (starches and sugar) acts as a plants food and energy supply. The energy need of human body is largely dependent on the carbohydrates that are derived from plants. The sugar is one of the essential commodities of the life which plays very important role in the dietary of human beings as it quickly raises the level of glucose in the blood. The sugar can be produced by many of the sources, but two are the main sources for production of sugar in Pakistan i.e. Sugarcane and Sugar Beet. The other sources are Maple, Palm, Coconut and Apple, but these sources are costly and their production is in negligible quantities. But, the main crop which is being used for production of Sugar all over the world is Sugarcane. In a nut shell, the process for sugarcane refining is carried out in following steps

Pressing of sugarcane to extract the juice. Boiling the juice until it begins to thicken and sugar begins to crystallize. Spinning the crystals in a centrifuge to remove the syrup, producing raw sugar. Refining the raw sugar by washing and filtering to remove remaining non-sugar ingredients and color. Crystallizing, drying and packaging the refined sugar

Beet sugar processing is similar, but it is done in one continuous process without the raw sugar stage. The sugar beets are washed, sliced and soaked in hot water to separate the sugar-containing juice from the beet fiber. The sugar-laden juice is then purified, filtered, concentrated and dried in a series of steps similar to cane sugar processing.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

For the sugar industry, capacity utilization is conceptually different from that applicable to industries in general. It depends on three crucial factors the actual number of ton of sugarcane crushed in a day, the recovery rate which generally depends on the quality of the cane and actual length of the crushing season. In Pakistan, the sugar industry possesses the organized and unorganized players. The unorganized players mainly produce Gur and Shakkar, the less refined forms of sugar and the organized players are Sugar Mills owners. In the world, the Brazil is a country that is largest producer of sugarcane as well as Refined Sugar.

Province-wise name of Sugar Mills in Pakistan

According to Pakistan Sugar Mills Association (PSMA), there are 78 Sugar Mills in Pakistan (39 in Punjab, 32 in Sindh and 7 in NWFP). Province-wise sugar mills are listed below:- And in what ranking our organization is working now a day?

Punjab province

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. Abdullah Sugar Mills Limited Abdullah Sugar Mills Limited (Shahpur) Adam Sugar Mills Ashraf Sugar Mills Limited Baba Farid Sugar Mills Limited Brothers Sugar Mills Limited Chanar Sugar Mills Limited Chaudhry Sugar Mills Limited Colony Mills Limited Colony Sugar Mills Limited Cresent Sugar Mills Limited Etihad Sugar Mills Limited Fatima Sugar Mills Limited Fecto Sugar Mills Limited G. Samundri Sugar Mills Limited Hamza Sugar Mills Limited Haq Bahu Sugar Mills (Pvt) Limited Haseeb Waqas Sugar Mills Limited Huda Sugar Mills (Pvt) Limited Hunza Sugar Mills Limited Husein Sugar Mills Limited Indus Sugar Mills Limited Ittefaq Sugar Mills Limited JDW Sugar Mills Limited JDW Sugar Mills Limited (Unit II) Kamalia Sugar Mills Limited Kashmir Sugar Mills Limited

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39.

Kohinoor Sugar Mills Limited Layyah Sugar Mills Limited Madina Sugar & Chemicals (Pvt) Ltd. National Sugar Mills Limited Noon Sugar Mills Limited Pattoki Sugar Mills Limited Ramzan Sugar Mills Limited Safina Sugar Mills Limited Shahtaj Sugar Mills Limited Shakarganj Mills Limited Sheikhoo Sugar Mills Limited Tandlianwala Sugar Mills

Sindh province 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. Abdullah Shah Ghazi Sugar Mills Limited Al Abbas Sugar Mills Limited Al Noor Sugar Mills Limited Ansari Sugar Mills Limited Army Welfare Sugar Mills Limited Bachani Sugar Mills Limited Bawany Sugar Mills Limited Dadu Sugar Mills Limited Dewan Khoski Sugar Mills Limited Dewan Sugar Mills Limited Digri Sugar Mills Limited Faran Sugar Mills Limited Habib Sugar Mills Limited Khairpur Sugar Mills Limited Kiran Sugar Mills Limited Larr Sugar Mills Limited Matiari Sugar Mills Limited Mehran Sugar Mills Limited Mirpurkhas Sugar Mills Limited Mirza Sugar Mills Limited Najma Sugar Mills Limited Naudero Sugar Mills Limited Pangrio Sugar Mills Limited Ranipur Sugar Mills Limited Sakrand Sugar Mills Limited Sanghar Sugar Mills Limited Seri Sugar Mills Limited Shahmurad Sugar Mills Limited Sindh Abadgar Sugar Mills Limited T. M. K. Sugar Mills Tharparkar Sugar Mills Limited Thatta Sugar Mills Limited

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

NWFP Province 1. 2. 3. 4. 5. 6. 7.

.

Almoiz Industries Limited Bannu Sugar Mills Limited Chashma Sugar Mills Limited Frontier Sugar Mills Limited Khazana Sugar Mills Limited Premier Sugar Mills Limited Saleem Sugar Mills Limited

Introduction to Organization

Etihad Sugar Mills Limited, Karamabad, Rahim Yar Khan was established on 1st June, 2006 as a Private Limited Company and is listed at Lahore Stock Exchange of Pakistan. The company is engaged in the manufacturing and sale of sugar. The companys site is situated at Mouza Karamabad Abad, Tehsil & District Rahim Yar Khan. Its head office is situated at Lahore. Total number of employees during off-season are 620 and during season it raises to 1140 excluding contractors labour. The mills covered total 100 Acres out of which 74 acres is for Mills plant, yard and offices, rest of the 26 acres are for colony, quarters, grounds, hostels and Masjid.

Organizations Products The companys main product is White Refined Sugar, however it has also following by products:1. 2. 3. Bagasse Molasses Press Mud

Competitors Although, 78 sugar mills are installed in Pakistan, out of these 77 are the competitors for Etihad Sugar Mills Limited, but the most competition is lying in following nearest sugar mills:1. 2. JDW Sugar Mills Limited, Sadiqabad JDW Sugar Mills Limited (Unit-II), Sadiqabad

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

3. 4. 5. 6. 7.

RYK Mills Limited, Liaqatpur Hamza Sugar Mills Limited, Khanpur Ghotki Sugar Mills Limited, Ghotki SGM Sugar Mills Limited, Ghotki Ashraf Sugar Mills Limited, Bahawalpur

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

10

Companys information Board of Directors Ch. Muhammad Shakeel Chief Executive Officer Makhdum Omar Shehryar Ch. Muhammad Shabbir -doCh. Adil Shabbir Ch. Tahir Jamil Haji Muhammad Ibrahim -doCh. Riaz Ahmad Abid Mr. Rashid M. Chaudhry -doCompany Secretary Mr. Zafar Iqbal, General Manager (Finance & Accounts) Head Office 3-Bawa Park, Upper Mall, Lahore Tel: 042-35751865-6, 042-35758724-7 Fax: 042-35751867 Site (Operations) Mouza Karamabad, Tehsil & District Rahim Yar Khan. Tel: 068-5678531-2, 5678534-6 Fax: 068-5678533 Internal Auditors Mr. Aziz Khan Lodhi, Chie Auditor (at head office) Mr. Muhammad Usman Zakki, Senior Internal Auditor (at site) Mr. Zahid Mehmood Iqbal, Internal Auditor (at site) -do-do-doDirector

Banks National Bank of Pakistan Muslim Commercial Bank Bank Al-falah Faysal Bank

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

11

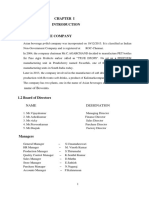

Organization Chart for Management

Introduction to the higher management

Chief Executive Officer (Ch. Muhammad Shakeel) The CEO has his office at Head Office, Lahore and also visit Site once quarterly. He is answerable to Chairman. Director (Ch. Muhammad Shabbir) The Director has its office at Site and he look-after over all working of Site and answerable to CEO. At Site, he has full powers. At Site, he takes final decisions. General Manager (Ch. Nasir Ahmad) His office is at Site. He is overall General Manager of the Site. He is technical man and just qualified upto DAE (Mechanical) but he has about 40 Years of service tenure in different Sugar Mills of the Pakistan. He is answerable to the Director as well as CEO. At Site, he takes technically final decisions related to Mechanical, Laboratory, Electrical and Chemical Departments only. He also participate the other meetings related to Administration, Cane and Finance Departments. But the most of the hold on these three departments is of Director.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

12

General Manager Finance & Accounts (Mr. Zafar Iqbal) He sits at head office. Being the head of the Finance & Accounts Department, he directs the head office & site finance & accounts department. He often comes at site and check the procedures and to observe the working of his department.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

13

My Internship Programme Change all the dates according to internship letter and also paste a scan copy of the letter? By the grace of Almighty ALLAH, I did my internship in Etihad Sugar Mills Limited for the period of 06 weeks starting from 24th May, 2010 upto 3rd July, 2010. The department wise duration is as under:Administration Cane Chemical / Production Electrical Information Technical Laboratory Mechanical Finance 24-05-201 29-05-2010 01-06-2010 05-06-2010 07-06-2010 07-06-2010 08-06-2010 14-06-2010 28-05-2010 31-05-2010 04-06-2010 12-06-2010 03-07-2010

During my internship programme, my supervisor Mr. Muhammad Amjad Jam had deputed me to observe the working of all sections / department but not to interfere in any activity. So he directed me to follow the above schedule and he informed the concerned heads of the departments as well, regarding my internship programme. I attended all departments and observed its working, which surely extended my knowledge and after conducting my internship programme, I am feeling that I can start my professional career in a good manner. My observation during internship programme is hereunder please:

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

14

Departments of the Organization The Etihad Sugar Mills Limited has its following departments to functioning well:1. 2. 3. 4. 5. 6. 7. 8. Accounts Administration Cane Chemical / Production Electrical Information Technology Laboratory Mechanical

Accounts Department Mian Muneer Ahmad Ch., DGM (Finance) is head of the department and he is supervising all the departmental matters. He is directly report to the General Manager (Finance) at Head Office as well as General Manager (Site). The main function of finance and accounts department to look after all the related matters and keep the record of all accounts and finance activities. The department is using computerized software for all kind of transactions. The formats being used by the Mills for cash receipt voucher, bank / cash payment voucher and sample of computerized voucher are hereunder:This department has three sections in it:1. 2. 3. 4. 5. Accounts Finance Cane Accounts Main Store Store Account

Accounts Section The sectional incharge is Haji Shaukat Ali Deputy Chief Accountant, he deals all payments for local purchases, other purchases, salaries etc. He is doing all jobs with the help of the staff under his command i.e. Accountants, Assistant Accountants, Accounts Clerks and Accounts Assistants. All the salaries and other accounts transactions are carried out on computerized software. Finance Section In this era of information technology, Etihad Sugar Mills Limited is also fully computer technology in almost all of its sections. The finance section of this department keeps the record of all receipts and also arranges the funds in coordination with the head office.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

15

The cheques are also prepared in this section. As the department is computerized, therefore, the manual record keeping is not undertaken. Cane Account Mian Khalid Shaheen, Senior Accounts Officer (cane) is sectional incharge and deals with all cash payment of sugarcane and loan cheques. He himself and his team comprising of Accountant, Accounts Assistant and Accounts Clerks are enough to deal the growers. The growers approach him to know the actual status of loan, payment, deduction, etc. He also uses computerized software for this purpose. The cash payment of sugarcane is made after seeing the original CPR (Cane Payment Receipt) Procedure of payment of sugarcane to the grower The cane reaching the mill is weighted and voucher is prepared in quadruplicate. The voucher shows the net weight of cane and its payment. The first copy of voucher is given to the grower and second copy is sent to the cane department. The third copy is sent to the cane account section and the last copy is sent to the carriage contactor. If the grower has taken loan from the Mills, the software automatically deducts amount of first supply and adjusts the growers account. If the grower did not taken loan from Mills, he can take cash from the Cash Counter. In case of loanees supply of sugarcane, he would not be able to get cash of sugarcane supplied by his, until the loan is recovered by the Mills. He is in an emergency, he will submit a written request to the DGM (Cane) to allow him to get cash from the cash counter. If the DGM (Cane) allowed, he can collect cash even he had taken loan, otherwise, the loan account will be adjusted against supply of sugarcane. Store Account Mr. Abdul Waheed Khalid, Accounts Officer (Store) handling this section. This section maintains the record of machinery and different parts used in the project .The purchases and consumption of different parts is adjusted monthly and annually. The main account section pays all the suppliers bills. When some items are purchased and received in the store, the store in charge prepare the Goods Receiving Note (GRN) showing the amount and quantity of items received. The receiving report is sent to the main account section. This section then makes arrangement for payment to the supplier.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

16

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

17

Administration Department Lt. Col. (R) Muhammad Riaz, DGM (HR & A) being the head of the department supervising administration department. He act as Liaison Officer for the Mills and responsible for all kinds of administrative works. The administration department has following sections in it:i. Security & Safety Section Maj. (R) Zia Ahmad Khan, Chief Security Officer is incharge of Security and safety section. The main responsibility of this section is to provide the security to the Mills assets and safety guidelines to the Mills employees. He had arranged Rescue 1122 Training Programme on Safety Measures to educate the Mills employees. He also acts as number two of DGM (HR & A). In the absence of DGM (HR & A), Chief Security Office officiates as head of the department. He is reported to DGM (HR & A) ii. Civil Works Section Syed Munir Hussain Shah, Civil Works Supervisor is responsible for all kind of civil works directed to him by the DGM (HR & A). He himself alongwith his team comprising of Clerk, Masons & Labourers complete all civil jobs assigned to them. He is direct report to DGM (HR & A) iii. Establishment Section Mr. Muhammad Amjad Jam, Deputy Personnel Manager is incharge of this section and he is responsible for keeping personal files record of the employees, all other record like PESSI (Pakistan Employees Social Security Institution) record, EOBI (Employees Old-age Benefit Institution) record, Labor Department record and all other kind of office record. He is direct reported to DGM (HR & A). iv. Transport Section Syed Niaz Hussain Shah, Transport Incharge is handling all the matters related to Transport. He also supervises the auto workshops staff. He maintained all vehicles record. Presently, the company own Seven Tractors, One Bus, Two Toyota Hiaces, One Pajero, Three Corolla Cars, Two Honda City, Ten Suzuki Cultus Cars, Two Shahzor Mini Truck, Sixty Yamaha Motorcycles, etc. v. Masjid There is very beautiful Masjid constructed by the Company which is enough for 1000 persons. The staff for Masjid is one Khateeb / Imam Masjid, one Moazzan, One Khadim Masjid and one Helper Masjid.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

18

vi.

Horticulture Mr. Muhammad Hanif Ramey, Incharge Horticulture is supervising the section and he also working for the landscaping in the Mills. He and his team comprising of ten Baildars and Malis is doing look-after of the plants of the Mills.

vii.

House Keeping (Hostels) As this project is newly established, its colony is under approval session from the Chairman, and there is only three hostels according to the status of the officers (i) HODs Hostel, (ii) Officers Hostel (iii) Labour Hostel. The hostels are being handled by Mr. Muhammad Asif Saftain, Incharge General Administration, who is directly reported to DGM (HR & A) The HODs hostel (luxury type) consisting of 25 Rooms, AC fitted, Single Beds with Mattresses and Bed Sheets, attached bath. The Mess for HODs is in the hostel. There are 05 Guest Rooms also for the guests to stay at night, who visit the Mills. The officers hostel is the hostel, where Foremens and Officers level employees are residing. In the officers hostel, there are 32 rooms. These rooms are also of high standard, but less than the HODs. Two Mess containing two dining hall, kitchens are included in this hostel. The Labour Hostel is like a simple hostel, where total number of rooms is 16. These are big rooms and about 30-35 employees are residing in a room. Their standard like a army barrack, where 30 iron cots are laid down.

viii.

Time Office Time office is a section, where attendance of all mills employees are maintained and keep it recorded on daily basis. Mr. Shahid Pervez, Incharge Time Office is doing supervision and the time office is functioning with 03 time keepers and 03 time office clerks. The time office inchagre is answerable to DGM (HR &A) in coordination with Deputy Personnel Manager.

ix.

Telephone Exchange Mr. Muhammad Abdul Jabbar, Senior Telephone Operator is supervisor of telephone exchange. Total 4 personnel are deputed in telephone exchange round the clock shift-wise (03 operators and 01 lineman). He is also answerable to DGM (HR & A)

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

19

x.

General Administration Mr. Muhammad Asif Saftain, Incharge General Administration is directly reported to DGM (HR & A). In the general administration, he looks after cleanliness of the Mills, and perform routine general duties. All the sweepers and their supervisor are under is command. He is responsible for all general administrative issues.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

20

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

21

Cane Department

Ch. Abdul Rauf Gujjar, DGM (Cane) being the head of the department leading the Mills toward the progress. The main purpose of Cane Department is to provide the maximum services (required by the growers) i.e. loan, guidelines regarding crop, etc. at the door step of the grower. In this regard, the Cane Department has opened Circle Office at every famous place / station. Presently, Etihad Sugar Mills Limited has their 25 circle offices on the following stations. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. Iqbalabad Fateh pur Punjabian Chowk Bahadarpur Rahim Yar Khan Kotsmaba Tranda Sway Khan Khanpur Sadiqabad Rukan Pur Sardargarh Sheikh Wahan Rajanpur Zahir Pir Sehja Feroza Shah Pur Abad Pur Jajjab Abbasian Head Haji Pur Garhi Ikhtiar Khan Kotla Pathan Bhondi Shahbaz Pur Machi Goth Chowk Swetra

Every circle office possesses one Field Officer, one Cane Supervisor and one Fieldsman. The cane department has the following section in it:i. Cane Section The cane office is the location, where the DGM (Cane) and ancillary staff is present for the convenience of the growers.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

22

ii.

Programme Section The programme office is a technical office of cane department, where the programme is maintained that how many units will be allowed to come in mills per day, how much sugarcane will we have, etc. This office is being handled by the Programme Officer, Programme Assistant and Programme Clerks.

iii.

Loan Section The Loan office provides the requisite guidelines to the growers. This section keeps the record of loanee growers and also provide the information to the field staff at the time of loan recovery. This section is handled by Loan Officer and Loan Assistant.

iv.

Yard Section During the season, the main function of cane department at site is performs by the yard staff. Yard is the heart of the mills, at which, every one has vigilant eyes. The mechanical department also observes how many units are available in the yard for crushing at the time. They rotate the mills speed on the arrival of sugarcane at said date / time. When the trolley / truck (or any unit) enters in the premises of the Mills, firstly he attends the token post, from where he gets the token, then he reaches to the yard and then it unloads the sugarcane after fulfillment of codal formalities i.e. clearance of documents and weightment etc.

The process of cane department regarding handling of growers starts from here. After exhaust of crushing season, the cane department immediately meets the grower to convince them for sowing of sugarcane crop. This process takes about one month and after this, the staff of cane department holds the survey work. In the sugar industry, the word survey mean the how much sugarcane is sowed by the growers in the respective. The survey is collected department wise and summarized at the programme office of cane department. All the relation / correspondence of Mills and growers took place through field staff. All announcements are also brought to the notice of growers through field staff. The grower contacts the filed staff at the respective circle office regarding any matter. During the loan documents submission, the growers contact circle officer and get the file completed for loan, after completion of process, the grower is informed to collect the cheque for loan amount from accounts department of Mills after provision of requisite documents i.e. original CNIC. The loan may be in shape of cash, pesticides, seeds, diesel, implements, fertilizers etc.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

23

At the start of crushing season, the field staff contact the growers and advised them to remain ready for supply of sugarcane. They try their best to make available the continuous supply of sugarcane to the Mills to avoid any stoppage of crushing. Because, due to shortage of sugarcane, the seasons, nowadays of 90-100 days which was previously of 150-200 days and every second is very precious for the sugar mills during the season. The management is also dislikes the stoppage in crushing during season. The field staff emphasize the growers to repay the loan as soon as possible, because, this is the only way (supply of sugarcane by grower) to recover the loan from growers.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

24

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

25

Chemical Department

Engr. Muhammad Rahat Saeed, DGM (Production) is head of the department and he is responsible for all boiling / chemical procedures apply on the sugarcane juice. The chemical department is totally responsible for production of sugar from juice. They apply methods, heat and some chemicals to transform the sugar from sugarcane. The complete process of production of sugar is as under:-

Processing of sugar cane in a sugar mill for manufacturing of white sugar:.

CANE TIPPERS Loaded cane trolleys are tilted by hydraulic jacks into feeding tables. Feeding tables transfer cane into carrier # 01. CANE CUTTER # 01 Motor 1000KW, Knives 40 Nos. It is driven by electric motor. It performs the duty of cane chopping and leveling. Its clearance is about 2 Ft. CANE CUTTER # 02 Motor 850KW, Knives 40 Nos. It cuts the cane into small pieces, its clearance is about 10 CANE CUTTER # 03 Motor 1000KW, Knives 80 Nos. It completely cuts the cane into small pieces at minimum clearance of 2. SHREDDER Steam Turbine 3000KW, Swinging Hammers 88 Nos. It shreds the cane and raptures all the sugar cane cells to open position. MILLS TENDEM Mills tendem consists of 05 Mills driven by steam turbines having power 850KW each. Shredded cane is passed through series of 05 mills for extraction of juice. Imbibition water is sprayed on last mills for maximum extraction of juice. This extracted mixed juice is filtered through rotary screens. Screened juice is sent to Boiling House for processing and bagasse from last mills is sent to boilers as fuel. BOILERS 03 NOS. (CAPACITY 80TON/HOUR EACH) Main object of boiler is to produce steam at pressure 23Kg/cm 2 and temperature of 350C. Bagasse is fed to boilers, furnaces where it is burnt and produces steam at the rate of 80 Ton/hour each. Surplus bagasse is sent to bagasse yard, which is sold out. In case of shortage of bagasse, furnace oil is burnt as standby fuel.

POWER HOUSE

Steam Turbine Generators 02 Nos., Capacity 5MW each. Steam produced by

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

26

boilers is used for the operation of steam turbine generators. 10MW power is used for the operation of all electric motors installed in Mills. JUICE HEATERS 1. Condensate & Primary Juice Heaters (04 Nos.) (H.S. 350m2 each) Screened juice is passed through juice heaters in series and temperature is raised upto 65C by using steam / vapours. 2. Defecations Tanks Here milk of lime (M.O.L.) is added in heated juice and after some retention time, juice is passed through secondary juice heaters. 3. Secondary Juice Heaters (03 Nos.) (H.S. 350m2 each) Limed mixed juice is passed through secondary juice heaters and temperature is raised upto 105C for further treatment in juice clarifiers. 4. Juice Clarifier (03 Nos.) (Capacity 170m3 each) After secondary heating poly electrolyte is used before entering of juice in clarifiers it stays there for 1 to 1:30 hours to complete the reaction between M.O.L. and impurities of the juice. The impurities settle down in the clarifier. Settling is speedy by addition of poly electrolyte. The clear juice from clarifier is decanted and passed through rotary screens. This filtered juice is sent to series of evaporators. Settled impurities (Muddy Juice) is taken out from the bottom of the clarifiers and is sent to vacuum filters for filteration. VACUUM FILTERS (04 NOS.) FILTERING AREA (58M2 EACH) Muddy juice taken from clarifiers is mixed with Bagacillo in Mud Mixer and sent to the troughs of vacuum filters. Vacuum filter drum rotates and mud climbs over the drum. Hot water is sprayed by Nozzles on the drum. Remaining juice and washing water is sucked through tubes by vacuum. Sucked filtered juice is returned to defecation tank and mud is sent out by scrapping the mud from drums of vacuum filters. It is manure for cane growers.

EVAPORATORS (07 NOS.) Decanted juice from juice clarifier called clear juice is taken into series of evaporators. It is boiled with help of exhaust steam (obtained from turbines of mills and power house). The thick juice obtained from evaporators called syrup is fed to pans. VACUUM PANS (RAW SIDE) FOR A, B & C MASSECUITES. Batch Pan (04Nos.) Conti Pan (02 Nos.) Capacity 70Ton each. Capacity 68m3 each.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

27

Conti Pan (02 Nos.)

Capacity 102m3 each.

The syrup is fed into pans where it is again boiled to produce mixture of crystals and molasses called A Massecuite. Prepared massecuite is dropped into crystallizers. MASSECUITE CRYSTALLIZERS (13 NOS.) (RAW SIDE) Prepared massecuite from pans is sent into crystallizers for further crystallization by motion of massecuite by scrolls driven by gear and motor. The massecuite is transferred to centrifugal station by massecuites pumps. Centrifugal K-1100 (25 Nos.) (Raw Side) Massecuite is passed through centrifugals which separates crystals of sugar and molasses. First separate molasses, A Heavy is again boiled in B-Pans for B-Massecuite. B-Massecuite is again passed through centrifugals for separation of sugar crystals and molasses. This obtained molasses called BHeavy is again boiled in C-Pans for C-Massecuite. C-Massecuite is again passed through centrifugals for separation of sugar crystals and final molasses. This final molasses is sent out in molasses ponds for sale as a raw material for distilleries and sugar crystals separated from B & C Massecuite are used as seed in pans and sugar crystals obtained from A-Massecuite are taken into sugar remelter. SUGAR REMELTER (CAPACITY 30TON/HR.) Here sugar is remelted by using hot water and steam with 02 Nos. stirrers. This remelt is called raw liquor. This raw liquor is sent to Talo station. TALO CLARIFIER Raw liquor before taking into clarifier is treated with phosphoric acid, colour quest, lime sucrate and talo float. These chemicals are used to remove remaining impurities in sugar. In talo clarifier with some retention time these impurities float up in clarfier and clear liquor is taken out from bottom side. Floated impurities called scum is removed from clarifier by scraper driven by gear and motor. The clear (fine) liquor is sent to pan station. The removed serum is sent back to defecation tank. REFINE PANS (05 NOS.) (CAPACITY 70 TON EACH) Fine liquor is taken into pan. It is boiled for some time to get required brix for crystallization. Very small fine crystals seed (obtained from the sugar grader not bagable) is fed into it. Required crystal size is obtained by further boiling called the refine massecuite. Prepared massecuite is dropped into crystallizers. From which it is pumped to refine centrifugals for separation of crystals and molasses. REFINE CENTRIFUGALS TSK (03 NOS.) Refine centrifugals are automatic batch type centrifugals which separates fine sugar crystals and molasses. This molasses is reused for making more refine

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

28

massecuites. Fine crystals (Sugar) is dropped into hopper which shift it to sugar dryers. SUGAR DRYER (02 NOS.) While sugar passes through these dryers, remaining moisture is removed by blowing hot air through them. Hot air is passed by fans called blowers fitted for this purpose. SUGAR ELEVATORS. (02 NOS.) Elevators lift the dried sugar through buckets at some height and feed to sugar grader for its size wise separation. SUGAR GRADERS (02 NOS.) Here, sugar travels over graders moving to and for. At sugar grader frames of screens of different mesh are fitted. Through which fine, very small crystals (seed) and extra large size crystals are separated and sugar crystals of required size drop into sugar bins. SUGAR BINS (03 NOS.) Sugar bins are used for holding bag able sugar. AUTOMATIC WEIGHING MACHINE (02 NOS.) Automatic weighing machines are installed under sugar bins, machine drops sugar after 50Kgs accurate weight into poly propylene bag attached under it manually. The weight of these bags is re-checked by electronic weighing scales kept under. After that the bags sewing is done by sewing machines (02 Nos.) fitted over wooden conveyors. These sewed bags are sent to sugar godown where it is stacked upto the height of 50 layers by sugar stacker.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

29

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

30

Electrical Department

Engr. Nadeem Ghafoor, DGM (Electrical) is head of the department and he is responsible for all electrical and instrumental jobs of the Mills. The electrical department have two section in it:1. 2. Electrical Section Instrument Section

Mills have 02 Steam Turbo Generators and 02 Diesel Generators for standby supply of electricity at Power House Section. 02 Steam Turbo Generators having capacity of 5 MW each provides the electricity during the season to the Mills. Various electrical panels are installed at Power House and all electricity matters are controlled from Power House. At the time of start up, the electrical department do not depend on WAPDA, therefore electrical department takes the start up of Mills on Generators supply. They just start the boilers motors on Generator and when the boiler gets start, it supply the steam to the steam turbo generators, which runs and provides the electricity to all Mills, then the power supply of boilers taken on Steam Turbines and the Diesel Generators kept powered off. The instrument section is responsible for the repair and maintenance of all instruments available in the Mills.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

31

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

32

Information Technology Department

Mr. Omair Ahmad, Manager (I.T.) is head of the department and doing maximum efforts to introduce advanced technology in the best interest of the Mills. To avoid any inconvenience during the crushing season, he introduced Wireless networking of work stations and fiber-optic cable networking as alternative to that. The job is under process and will be completed within couple of days. The I.T. Department is also looking-after the database and keeps its record daily on DVD, which sent to the head office for record on daily basis. In addition to this, the repair and maintenance of I.T. equipment is also its responsibility. He and Mr. Umer Sharif, Deputy Manager (I.T.) very enthusiastically changing the previous (non-developed) pattern. Before their joining, there was simple networking, which becomes out of order off & on and the management faces trouble as a result thereof. During the season, single second is very precious and cannot be wasted. Therefore, they convinced the management to lay down the fiber-optic cable and WAN to get rid of this problem. The management understand the issue and approved the case as it was proposed.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

33

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

34

Laboratory

Mr. Muhammad Amjad Khan, Manager (Lab.) is head of the Laboratory department. In the laboratory, different type of laboratory tests related to water, sugarcane, juice, bagasse, molasses, etc. are conducted. He is directly responsible to the General Manager, but as per nature of his duty, he should have to report the Directors and CEO at any time regarding production, recovery of sugarcane etc. These lab. Tests helps the management in decision making.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

35

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

36

Mechanical Department

Engr. Muhammad Nawaz Sandhu, DGM (Technical) is head of the Mechanical Department. In view of the employees, this department is one of the biggest department of the Etihad Sugar Mills Limited. The Mechanical Department has following sections in it:i. ii. iii. iv. v. vi. vii. Mill House Boiling House Boiler House Workshop Steam Turbine Welding Section Fabrication Section

Mill House This section contains 05 Mills alongwith steam turbines. In the Mill House, juice from the bagasse extracted and bagasse sent to the boilers and juice sent to the boiling house for further process. In this section, heavy machinery is installed. machinery is installed at Mill House. Boiling House In the boiling house section, chemicals, heat and other processes are applied at juice for transformation into sugar. Most of the machinery is installed in this section and this section is biggest mechanically as compared to the other mechanical sections. The following machinery is installed in Boiling House:Boiler House This section of mechanical department has 03 boiler of 80 Ton / hr capacity. Each boiler generates 80 Ton steam in single hour, which become 240 Tons per hour from all three boilers. In the boilers, water is boiled and steam generated as a result thereof. Workshop In the workshop, the Mills have its machinery for repair / maintenance of plant. There are many Molder machines, Laithe Machine, Binding Machine etc. All the mechanical jobs are completed here. Steam Turbine Section The section is responsible for repair & maintenance of all the steam turbines installed in the Mills at Power House, Mills House and Boiling House. Welding Section The following

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

37

All the welding jobs are carried out by this section. This section has various mobile welding plants for completion of jobs at the plant. Fabrication Section In the sugar mill, there are various mechanical tricks, to implement these tricks, fabrication section offers its services.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

38

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

39

ETIHAD SUGAR MILL, RAHIM YAR KHAN Consolidated Income Statement For the years ended 30-09-(8-) 2010 Net Sales Cost of Sales Gross Profit Administrative Expenses Distribution & Marketing Expenses Other operating expenses Other operating income Workers' profit particiation fund Workers' welfare fund Operating Profit Finance cost Share of loss of associated company Profit before taxation Taxation Net Profit 9,901,225,775 (7,515,692,484 ) 2,385,533,291 (219,495,198) (20,014,879) (115,552,852) 24,438,859 (330,624,070) 2,054,909,221 (1,127,467,695 ) (405,913) 927,035,613 (339,381,836) 587,653,777 2009 10,801,461,407 (8,818,583,211 ) 1,982,878,196 (215,740,080) (135,778,796) (91,141,209) 70,322,340 (372,337,745) 1,610,540,451 (816,217,951) 794,322,500 (309,869,960) 484,452,540 2008 5,344,240,796 (4,527,891,865) 816,348,931 (140,329,553) (7,624,033) (4,272,079) 102,200,217 (7,152,207) (2,713,414) (59,891,069) 756,457,862 (697,959,899) 58,497,963 (35,310,805) 23,187,158

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

40

ETIHAD SUGAR MILL, RAHIM YAR KHAN Consolidated Balance Sheet As on 30-09-2010 2010 2009 2008 315,361,900 718,536,715 (6,345,583) 1,027,553,032 260,900,000 3,017,702,890 328,038,520 387,284,676 12,132,409 4,006,058,495 2,316,752,803 447,164,952 551,987,795 172,013,779 39,000,000 3,526,919,329 8,560,530,856 SHARE CAPITAL & RESERVES Share Capital 442,840,570 381,254,260 Reserves 1,548,014,772 1,129,798,008 Minority interest Total Share Capital & Reserves 1,990,855,342 1,511,052,268 NON-CURRENT LIABILITIES Subordinated loan from Director 260,900,000 260,900,000 Long term loans 3,375,777,778 3,600,000,000 Liabilities against assets subject to finance lease 329,960,452 353,881,872 Deferred liabilities 878,242,713 585,574,775 Deferred Income 3,945,104 7,890,204 Total Non-current Liabilities 4,848,826,047 4,808,246,851 CURRENT LIABILITIES Short term borrowings 3,765,402,741 1,970,380,636 Current portion of non-current liabilities 693,564,179 154,934,612 Trade and other payables 803,490,123 1,726,633,296 Interest and mark-up accrued 180,218,438 101,105,342 Provision for taxation 49,990,394 54,087,075 Total Current Liabilities 5,492,665,875 4,007,140,961 Total Liabilities 12,332,347,264 10,326,440,080 NON-CURRENT ASSETS Property, plant and equipment Operating fixed assets 6,829,407,871 6,049,189,068 Capital work in progress 25,573,823 256,839,123 Store & spares held for capital expenditure 12,296,025 6,854,981,694 6,318,324,216 Investment property 350,753,636 212,290,716 Investments 394,847,861 375,000 Goodwill 608,310,693 581,931,578 Long term depsoits 48,877,275 37,731,155 Total Non-current Assets 8,257,771,159 7,150,652,665 CURRENT ASSETS Stores, spares and loose tools 424,291,134 371,253,099 Stock in trade - finished goods 1,436,296,905 876,391,873 Trade debts 36,588,056 222,970,512 Advances, deposits, prepayments and other receiveables 2,169,390,789 1,681,912,007 Tax refunds from government 1,431,700 1,431,700 Cash and bank balances 6,577,521 21,828,224 Total Current Assets 4,074,576,105 3,175,787,415 Total Assets 12,332,347,264 10,326,440,080

4,507,512,438 1,244,965,955 131,086,097 5,883,564,490 566,283,676 375,000 34,673,790 6,484,896,956 224,711,294 914,974,191 186,199,993 654,057,273 95,691,149 2,075,633,900 8,560,530,856

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

41

ETIHAD SUGAR MILL, RAHIM YAR KHAN Comparative Horizontal Common Size Income Statement For the years ended on 30-09-2010

Net Sales Cost of Sales Gross Profit Administrative Expenses Distribution & Marketing Expenses Other operating expenses Other operating income

185% 166% 292% 156% 263% 817% 24% 552%

202% 195% 243% 154% 1,781% 645% 69% 622% 213% 117%

100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100%

Operating Profit Finance cost Share of loss of associated company Profit before taxation Taxation Net Profit

272% 162%

1,585% 961% 2,534%

1,358% 878% 2,089%

100% 100% 100%

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

42

SHARE CAPITAL & RESERVES Share Capital Reserves Miniority interest Total Share Capital & Reserves NON-CURRENT LIABILITIES Subordinated loan from Director Long term loans Liabilities against assets subject to finance lease Deferred liabilities Deferred Income Total Non-current Liabilities CURRENT LIABILITIES Short term borrowings Current portion of non-current liabilities Trade and other payables Interest and mark-up accrued Provision for taxation Total Current Liabilities Total Liabilities NON-CURRENT ASSETS Property, plant and equipment Operating fixed assets Capital work in progress Store & spares held for capital expenditure Investment property Investments Goodwill Long term depsoits Total Non-current Assets CURRENT ASSETS Stores, spares and loose tools Stock in trade - finished goods Trade debts Advances, deposits, prepayments and other receiveables Tax refunds from government Cash and bank balances Total Current Assets Total Assets

140% 215% 194% 100% 112% 101% 227% 33% 121% 163% 155% 146% 105% 128% 156% 144%

121% 157% 147% 100% 119% 108% 151% 65% 120% 85% 35% 313% 59% 139% 114% 121%

100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100%

152% 2% 117% 105,293 % 107% 141% 233% 189% 157% 20% 345% 6% 7% 196% 144%

134% 21% 9% 107% 100% 103% 109% 138% 165% 96% 120% 268% 6% 23% 153% 121%

100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100% 100%

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

43

ETIHAD SUGAR MILL, RAHIM YAR KHAN Consolidated Income Statement For the years ended 30-09-(2010) 2010 Net Sales Cost of Sales Gross Profit Administrative Expen0ses Distribution & Marketing Expenses Other operating expenses Other operating income Operating Profit Finance cost Share of loss of associated company Profit before taxation Taxation Profit after taxation 39.31% 3.43% 42.74% 100.00% 75.91% 24.09% 2.22% 0.20% 1.17% 0.25% 27.93% 11.39% 2009 100.00% 81.64% 18.36% 2.00% 1.26% 0.84% 0.65% 23.11% 7.56% 0.00% 30.66% 2.87% 33.53% 2008 100.00% 84.72% 15.28% 2.63% 0.14% 0.26% 1.91% 20.22% 13.06% 0.00% 33.28% 0.66% 33.94%

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

44

ETIHAD SUGAR MILL, RAHIM YAR KHAN Consolidated Balance Sheet As on 30-09-(2010)

2010 SHARE CAPITAL & RESERVES Share Capital Reserves Miniority interest Total Share Capital & Reserves NON-CURRENT LIABILITIES Subordinated loan from Director Long term loans Liabilities against assets subject to finance lease Deferred liabilities Deferred Income Total Non-current Liabilities CURRENT LIABILITIES Short term borrowings Current portion of non-current liabilities Trade and other payables Interest and mark-up accrued Provision for taxation Total Current Liabilities Total Liabilities NON-CURRENT ASSETS Property, plant and equipment Operating fixed assets Capital work in progress Store & spares held for capital expenditure Investment property Investments Goodwill Long term depsoits Total Non-current Assets CURRENT ASSETS Stores, spares and loose tools Stock in trade - finished goods Trade debts Advances, deposits, prepayments and other receiveables Tax refunds from government Cash and bank balances Total Current Assets Total Assets 4% 13% 16% 2% 27% 3% 7% 0.03% 39% 31% 6% 7% 1% 0% 45% 100% 55% 0.21% 56% 3% 3% 5% 0.40% 11% 3% 12% 0.30% 18% 0.01% 0.05% 33% 100%

2009 4% 11% 15% 3% 35% 3% 6% 0.08% 47% 19% 2% 17% 1% 1% 39% 100% 59% 2% 0.12% 61% 2% 0% 6% 0.37% 8% 4% 8% 2% 16% 0.01% 0.21% 31% 100%

2008 4% 8% 0% 12% 3% 35% 4% 5% 0.14% 47% 27% 5% 6% 2% 0% 41% 100% 53% 15% 2% 69% 0.004% 7% 0.41% 7% 3% 11% 2% 7% 0.30% 1% 24% 100%

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

45

Future prospects of the organization Etihad Sugar Mills Limited focuses on the future growth of sugar mills in sugar industry, for which they are planning to start corporate farming at about 1000 acres initially. Vision To be the lead in sugar industry by building the companys image through quality improvement, competitive prices and meeting social obligations. Mission 1. To endeavour to be the market leader by offer high quality sugar to our valuable customers at competitive prices. 2. To continue improving operating performance and profitability thereby ensuring growth for the company.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

46

SWOT Analysis Following are some points of strengths and weaknesses for internal environment and opportunities and threats for external environment of the bank respectively. Strengths Problem solving and understand management attitude. Lecture programme on fire fighting and safety measures is delivered to the employees to avoid any disaster situation. Strong and healthy working relationship with growers. Nearest growers are like to supply their sugarcane to Etihad Sugar Mills Limited and they avoid to go other sugar mills having long distance as compared to Etihad Sugar Mills Ltd. Due to provision of loans to the growers, the growers are bound to their sugarcane to Etihad Sugar Mills Limited. Due to payment at the spot, the growers supply their sugarcane to Etihad Sugar Mills Limited, because they want payment for the urgencies. Provision of guidelines to the growers to have better yield per acre. Due to nearest sugar mills of rahim yar khan city, it just takes 25 minutes to travel to Mills or to the city. However, other competitors are away and minimum travel required is one hour. Weaknesses Limited number of circle offices at nearest main stations only Due to price war in sugar mills, the benefits goes toe the grower and the sugra mills management had to pay extra money to the grower. Salary package of lower staff is low as compared to other sugar mills. Mills colony yet not been constructed and employees forcefully residing in city away from mills about 30 KM and travel on daily basis who residing in city area. No school for employees children is present there.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

47

Opportunities Expansion of circle offices in outer stations, where circle office not exists. Outreach to growers especially far flung areas. The land of the vicinity is very fruitful for the sugar Mills. The area at Etihad Sugar Mills Limited is shining area of the Punjab for production of sugarcane. Threats Changes in policies suffer the growers as well as employees. Most of the staff is illiterate but is experienced. Lack of non-technical knowledge. No electronically connection with circle offices except mobile phone. Non provision of proper transport to the field staff.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

48

Conclusion To summarize the things I would like to say that in a short span of time Etihad Sugar Mills Limited, Rahim Yar Khan has developed itself maximum, but still some development is required and is under process. Although, it is achieving a land mark amongst all the competitors of the area. Its first operation was started on 28th December, 2006. Due to installation of Etihad Sugar Mills Limited, the nearest famous station is Iqbalabad, which has developed rapidly, before installation of this Mills, it was just like a small town (non-developed) now due to installation of this Mills, there is a Bank recently opened with the name of DAWOOD Islamic Bank and many other developments taken place. Since, this mills is newly installed and yet not completed its construction, installation and other jobs, therefore, have some loss and some profits in the season. Insha ALLAH, this mill will recover all previous losses within 2-3 crushing seasons only. This sugar mills is situated at KLP road and this facility has own only by Hamza Sugar Mills Limited and RYK Mills Limited, both the JDW units are away from KLP and Ghotki Sugar Mills is also away from KLP, this help the easy transportation of machinery etc. So in the end I just want to say that Etihad Sugar Mills Limited is a good place a Sugar Mill and to excel in the sugar industry with its promising location and products. In the future, this Mills will be a market leader sugar mill of the area.

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

49

Recommendations for Improvement 1. Mark-up free loan to the growers may be given to bring improvements in sugar industry as well as in Rahim Yar Khan District. 2. Maximum sowing of sugarcane may be ensured to avoid stoppages due to nocane during the seasons. 3. I.T. section of Etihad Sugar Mills Limited, required to taken on line the circle office for instant updation of growers record. 4. Gifts may be given to the trolley / truck drivers, this will help to increase in supply of sugarcane by the growers. 5. The salary of lower staff may be improved so that they can perform duty without any tension. 6. Mechanical staff may be directed to remain vigilant to avoid any mechanical stoppage, which will discourage the growers and they shall supply their sugarcane to another sugar mills. 7. Increase in the number of circle offices to cater the needs of ever increasing no of potential growers. References Used Nawaz, Muhammad. (n.d.) Mills employees. Retrieved from Saeed, Rahat. (n.d.) Mills employees. Retrieved from Khan, Zia Ahmad. (n.d.) Mills employees. Retrieved from Amjad, Muhammad. (n.d.) Mills employees. Retrieved from Ali, Shaukat. (n.d.) Mills employees. Retrieved from Masood, Farooq. (n.d.). Mills employees. Retrieved from Qasim, Muhammad. (n.d.) Mills employees. Retrieved from Rehman, Naveed. (n.d.) Mills employees. Retrieved from

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

50

Internship report on Etihad Sugar Mills Limited, Rahim Yar Khan

51

You might also like

- Summer Report On Customer Awareness and Perception Towards Multigrain Food Pvt. Ltd. (ATUL Bakery), Surat.Document110 pagesSummer Report On Customer Awareness and Perception Towards Multigrain Food Pvt. Ltd. (ATUL Bakery), Surat.HirenGandhi33% (3)

- MGTi620 - Internship Report - Virtual University of PakistanDocument11 pagesMGTi620 - Internship Report - Virtual University of PakistanSammz Hills100% (1)

- Human Resources Management (Orient)Document56 pagesHuman Resources Management (Orient)Muhammad TariqNo ratings yet

- Internship Report Bawany Sugar Mills LTDDocument41 pagesInternship Report Bawany Sugar Mills LTDHyder Khan100% (1)

- Summer Training Report (Pranjal)Document40 pagesSummer Training Report (Pranjal)Aman agrawalNo ratings yet

- Internship ReportDocument18 pagesInternship Reportaamirqaisar10No ratings yet

- Comparison of Performance Appraisal of Different Companies Under FMCG Sector in IndiaDocument6 pagesComparison of Performance Appraisal of Different Companies Under FMCG Sector in Indiaridhima100% (1)

- Internship Report FinalDocument69 pagesInternship Report FinalSyed Usman NisarNo ratings yet

- Final Copy, Management and Leadership at Coca-ColaDocument27 pagesFinal Copy, Management and Leadership at Coca-ColaБлагица МилановаNo ratings yet

- Project Report On Sales Improv. of CCD-1Document81 pagesProject Report On Sales Improv. of CCD-1Ashish Yaduvanshi67% (3)

- Mother Dairy - TanviDocument52 pagesMother Dairy - TanviTanvi Nahar60% (5)

- BIR Focuses On Taxpayer's Lifestyles PDFDocument62 pagesBIR Focuses On Taxpayer's Lifestyles PDFMark Lord Morales BumagatNo ratings yet

- Internship Report, Etihad Sugar Mills Limted, RYKDocument13 pagesInternship Report, Etihad Sugar Mills Limted, RYKMohammad Usman HabibNo ratings yet

- Internship Report On Shakarganj Sugar Mill by SYED AHMAD MUSTAFADocument21 pagesInternship Report On Shakarganj Sugar Mill by SYED AHMAD MUSTAFAAhmad Mustafa100% (2)

- Internship ReportDocument59 pagesInternship ReportYasir Khosa0% (1)

- Shakarganj Mills LTD - Allah Dita Hassan - 2Document44 pagesShakarganj Mills LTD - Allah Dita Hassan - 2Muhammad Asif Noor100% (1)

- Swot Analysis of Askari Commercial BankDocument4 pagesSwot Analysis of Askari Commercial BankAhsan IjazNo ratings yet

- A Project Report On Budgetary ControlDocument28 pagesA Project Report On Budgetary ControlPranit Anil Chavan100% (2)

- Project Report On Ask Automotive in Customer Satisfaction and BrandlolityDocument77 pagesProject Report On Ask Automotive in Customer Satisfaction and Brandlolitydebprit100% (2)

- Project Report of VasudharaDocument36 pagesProject Report of VasudharaAppa Kamble100% (2)

- Project Report HR PoliciesDocument94 pagesProject Report HR Policiessantoshkohli100% (1)

- Final DKSSKDocument79 pagesFinal DKSSKSarita Latthe100% (2)

- A Project Report On Recruitment and SeleDocument79 pagesA Project Report On Recruitment and SeleAshi KaurNo ratings yet

- Report On Working Capital ManagementDocument53 pagesReport On Working Capital ManagementRaman Kumar0% (1)

- Summer Internship On Amul Butter MilkDocument65 pagesSummer Internship On Amul Butter Milkshahzanladiwala100% (1)

- MCQ-on-FM WITH SOLDocument28 pagesMCQ-on-FM WITH SOLarmansafi761100% (1)

- Varun Beverage LimitedDocument4 pagesVarun Beverage LimitedIshan YashviNo ratings yet

- FinalDocument103 pagesFinalazzurocstarNo ratings yet

- PPT. Slides of Internship Report NBPDocument51 pagesPPT. Slides of Internship Report NBPrabirabi86% (37)

- FULL ProjectDocument63 pagesFULL ProjectSrk Siva Iyer50% (2)

- Afrin Akthari GS Coolege SynpsisDocument31 pagesAfrin Akthari GS Coolege Synpsisshubham moonNo ratings yet

- Final Project On Parag Dairy IndustryDocument68 pagesFinal Project On Parag Dairy IndustrySNEHAM29100% (2)

- AMULDocument19 pagesAMULKaty JohnsonNo ratings yet

- Askari Bank LTD - Management Information SystemDocument18 pagesAskari Bank LTD - Management Information Systemsara24391No ratings yet

- Davangere SugarDocument65 pagesDavangere SugarAnjan Bathi100% (1)

- Mitchell's Fruit Farms Pvt. Ltd. Virtual University of Pakistan Internship ReportDocument43 pagesMitchell's Fruit Farms Pvt. Ltd. Virtual University of Pakistan Internship ReportMirza Rashid Mehmood78% (9)

- Sugar Factory ProjectDocument75 pagesSugar Factory Projectkalaivani100% (1)

- NEW Organizational Climate Dhanalakshmi Sugar MillDocument86 pagesNEW Organizational Climate Dhanalakshmi Sugar MillKrithi SelvaNo ratings yet

- Product Launching TractorDocument29 pagesProduct Launching TractorMahesh GowdaNo ratings yet

- Acc CementDocument33 pagesAcc Cementanon_7046386650% (1)

- Project Guidelines 3rd Sem MBADocument11 pagesProject Guidelines 3rd Sem MBAsushank jaiswalNo ratings yet

- Asian Beverages Report DoneDocument35 pagesAsian Beverages Report Doneakshaya100% (2)

- Cost Analysis of Shahabad Co-Op Sugar Mills LTDDocument78 pagesCost Analysis of Shahabad Co-Op Sugar Mills LTDVinay ManchandaNo ratings yet

- Training & Development VerkaDocument95 pagesTraining & Development Verkasachin11haha67% (3)

- Abin Intership repoRT EDITED NEW PDFDocument74 pagesAbin Intership repoRT EDITED NEW PDFparvathy Shanmughan100% (1)

- GokulDocument13 pagesGokulSamrat Patil50% (2)

- Internship Report On Performance Management System, GreameenphoneDocument57 pagesInternship Report On Performance Management System, GreameenphoneAbul Hasnat87% (15)

- Inplant Training ReportDocument70 pagesInplant Training ReportPurushottam71% (7)

- A Project Report On Leverage Analysis at Satish Sugar LTDDocument62 pagesA Project Report On Leverage Analysis at Satish Sugar LTDBabasab Patil (Karrisatte)No ratings yet

- Summer Internship Report - PepsiDocument80 pagesSummer Internship Report - PepsiMegha SharmaNo ratings yet

- AmulDocument8 pagesAmulgaurangi24267% (3)

- Final Lijjat PapadDocument22 pagesFinal Lijjat Papadniteshm4u100% (1)

- Final Project of N.S.LDocument58 pagesFinal Project of N.S.LZiyaulla ZiyaNo ratings yet

- MBA ReportDocument100 pagesMBA ReportAkshay JiremaliNo ratings yet

- Group-2 Amit KR Singh Harleen Singh Prakash Priyank Tyagi Vinod KumarDocument19 pagesGroup-2 Amit KR Singh Harleen Singh Prakash Priyank Tyagi Vinod KumarRandie Deos0% (2)

- Organisation Study of KAMCODocument62 pagesOrganisation Study of KAMCORobin Thomas100% (11)

- 16 Chapter5 PDFDocument76 pages16 Chapter5 PDFSwapnija MaliNo ratings yet

- Arihant Sugar FactoryDocument9 pagesArihant Sugar FactoryNikhil HallurNo ratings yet

- Summer Internship Report-Final Sakthi SugarsDocument12 pagesSummer Internship Report-Final Sakthi SugarsSangeetha Prabha80% (5)

- SL NO Topics Page No Part-A Introduction To The ConceptDocument101 pagesSL NO Topics Page No Part-A Introduction To The ConceptsaheeshnairNo ratings yet

- Shree Chalthan Vibhag Khand Udyog Sahakari Mandli LTD - Viral ShahDocument66 pagesShree Chalthan Vibhag Khand Udyog Sahakari Mandli LTD - Viral Shahviral shah100% (4)

- Advance Series PTR NovDocument20 pagesAdvance Series PTR NovVeena AndeliNo ratings yet

- Notes On Corporate Tax PlanningDocument198 pagesNotes On Corporate Tax PlanningShainaNo ratings yet

- Penman 5ed Chap012Document28 pagesPenman 5ed Chap012Hirastikanah HKNo ratings yet

- HUL Directors Report Ar 2013 14Document24 pagesHUL Directors Report Ar 2013 14Lakshmi MNo ratings yet

- Fiserv November SalaryDocument1 pageFiserv November SalarySiddharthNo ratings yet

- T778 Child Care Expenses DeductionDocument4 pagesT778 Child Care Expenses DeductionbatmanbittuNo ratings yet

- Untitled 1Document6 pagesUntitled 1hagos dargoNo ratings yet

- Gap Between Irrigation Service Price PDFDocument370 pagesGap Between Irrigation Service Price PDFNguyen Van KienNo ratings yet

- Add01 New-1Document52 pagesAdd01 New-1Do Tuan Anh (K16HL)No ratings yet

- Business and Other Transfer Taxes - PrelimDocument47 pagesBusiness and Other Transfer Taxes - PrelimYoseph WooNo ratings yet

- Herarc Realty Corporation vs. The Provincial Treasurer of Batangas DigestDocument2 pagesHerarc Realty Corporation vs. The Provincial Treasurer of Batangas DigestEmir MendozaNo ratings yet

- Declaration 3830366377261Document4 pagesDeclaration 3830366377261Sammar Aziz KhanNo ratings yet

- Import InvoiceDocument1 pageImport InvoiceSultan Gamer 18No ratings yet

- Full Download Test Bank For Health Economics and Policy 5th Edition James W Henderson Download PDF Full ChapterDocument36 pagesFull Download Test Bank For Health Economics and Policy 5th Edition James W Henderson Download PDF Full Chapterjakraging7odbt100% (19)

- Praahar3.0 Indian Economy SummaryDocument62 pagesPraahar3.0 Indian Economy Summaryjeshwanth2305No ratings yet

- Introduction of Tourism Business DIstrictDocument12 pagesIntroduction of Tourism Business DIstrictShizuka DaihyoogaNo ratings yet

- From: Melquiades A. Cancela, CPADocument6 pagesFrom: Melquiades A. Cancela, CPAFaith BariasNo ratings yet

- Bachelor of Administration (Hons) in Islamic Finance: Waqf EBB30503Document15 pagesBachelor of Administration (Hons) in Islamic Finance: Waqf EBB30503irfan sururiNo ratings yet

- Shell Vs Central BankDocument3 pagesShell Vs Central BankJohn UndaNo ratings yet

- (No. 6584. October 16, 1911.) INCHAUSTI & Co., Plaintiff and Appellant, vs. ELLIS CROMWELL, Collector of Internal Revenue, Defendant and AppelleeDocument11 pages(No. 6584. October 16, 1911.) INCHAUSTI & Co., Plaintiff and Appellant, vs. ELLIS CROMWELL, Collector of Internal Revenue, Defendant and AppelleeJohn Rey CodillaNo ratings yet

- A System Dynamics Model of Capital StrucDocument14 pagesA System Dynamics Model of Capital StrucAbhishek ModakNo ratings yet

- Cir Vs Castaneda Terminal Leave Exempt From TaxDocument1 pageCir Vs Castaneda Terminal Leave Exempt From Taxfrancis_asd2003No ratings yet

- Answer Key Module 5Document3 pagesAnswer Key Module 5Clara NathaniaNo ratings yet

- 1 Given The Information Provided Use Worksheet 5 2 To EvaluateDocument1 page1 Given The Information Provided Use Worksheet 5 2 To Evaluatetrilocksp SinghNo ratings yet

- Group Activity Mina HanDocument4 pagesGroup Activity Mina HanLevi's DishwasherNo ratings yet

- Responsible Leadership: Tax-Free Savings AccountDocument2 pagesResponsible Leadership: Tax-Free Savings AccountbaxterNo ratings yet

- Municipality of Tumauini: (Based On 1991 LGC Rate of Disposition)Document4 pagesMunicipality of Tumauini: (Based On 1991 LGC Rate of Disposition)Genesis MaggayNo ratings yet

- General Manager Construction CFO COO in Scranton PA Resume Edward ConwayDocument3 pagesGeneral Manager Construction CFO COO in Scranton PA Resume Edward ConwayEdwardConwayNo ratings yet