Professional Documents

Culture Documents

Technical Bulletins Hydrostatic Pressure & Flow Test Results Rev3

Uploaded by

api-3752216Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Bulletins Hydrostatic Pressure & Flow Test Results Rev3

Uploaded by

api-3752216Copyright:

Available Formats

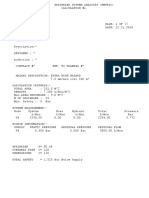

HYDROSTATIC PRESSURE & FLOWRATE TEST RESULTS

Revision 3 - 2001

OIL &

****** ******** COOLANT FILL ******** ******

& EVACUATION

MODEL PART No SWP ( kPa/psi) BP ( kPa/psi) MF (LPM/GPM)

Crankcase AUS27W Receiver 10,000 / 1,450 >40,000 / >5,800

AUS29W Nozzle 3,000 / 435 12,000 / 1,740 - ISO 46 Oil -

Coupled 4,750 / 690 19,000 / 2,756 100 (26.4)

Hydraulic AUS34A Nozzle 10,000 / 1,450 >40,000 / >5,800

AUS41A Receiver 10,000 / 1,450 >40,000 / >5,800 - ISO 46 Oil -

Coupled 4,000 / 580 16,000 / 2,320 100 (26.4)

Transmission AUS32W Nozzle 4,250 / 615 17,000 / 2,465

AUS33W Receiver 10,000 / 1,450 >40,000 / 5,800 - ISO 46 Oil -

Coupled 11,500 / 1,668 46,000 / 6,671 30 (7.9)

Coolant AUS36A Nozzle 10,000 / 1,450 >40,000 / >5,800 - Water -

AUS37W Receiver 10,000 / 1,450 >40,000 / >5,800 40 (10.6)

Coupled 7,500 / 1090 30,000 / 4,350 (estimated)

Push-To- AUS38W Receiver 10,000 / 1,450 >40,000 / >5,800

Connect AUS39W Nozzle 1,000 / 145 4,000 / 580 - ISO 46 Oil -

Coupled 10,000 / 1,450 >40,000 / >5,800 100 (26.4)

High Flow Oil AUS80 Receiver 6,000 / 870 24,000 / 3,481

(1”) AUS81 Nozzle 2,500 / 365 10,000 / 1,450 - ISO 46 Oil -

Coupled 2,500 / 365 10,000 / 1,450 180 (47.6)

Grease AUSGR Receiver 10,000 / 1,450 >40,000 / >5,800

Fittings AUSGN Nozzle not applicable not applicable not applicable

Coupled 9,000 / 1,305 >35,000 / >5,076

REFUELLING

****** ******** EQUIPMENT ******** ******

Bulk Transfer AUSS5 Nozzle 4,000 / 580 24,000 / 3,481

(0-800LPM) S5 and AUS23 7,500 / 1,088 30,000 / 4,350 800/211

S5 and ZN2A 5,000 / 725 20,000 / 2,900

Break-Away AUS4W-50 (2”) 2,000 / 290 8,000 / 1,160 800 / 211

Valve AUS4W-75 (3”) 1,250 / 181 5,000 / 725 1050 / 277

Diesel B800 Series 2,500 / 363 10,000 / 1,450

Refuelling B800 and AUS23 4,500 / 653 18,000 / 2,610 800 / 211

Nozzle B800 and ZN2A 4,000 / 580 16,000 / 2,320

B1000 Series

B1000 and AUS43 1000 / 264

LEGEND: 1. Safe Working Pressure (SWP): maximum recommended working pressure

2. Minimum Burst Pressure (BP): minimum pressure at which fitting will suffer fail

3. Maximum Flowrate (MF): maximum recommended liquid flowrate through coupled

fittings – observe fluid used in points 6 & 7

4. All results refer to hydrostatic hydraulic pressure applied within fitting(s)

5. “Coupled” results refer to test conducted with nozzle and receiver engaged

6. All flow test results for Oil & Coolant Fill & Evacuation fittings obtained using test fluid

as shown in table (ISO 46 Hydraulic Oil (SG 0.89) or water)

7. All flow test results for Refuelling Equipment obtained using diesoline fuel

(SG 0.84, 6.5cSt)

8. Data for the AUSGN Grease Nozzle applies only to items sold after September 2001,

and does NOT apply to earlier parts where the face plate was welded to the nozzle body

Confidential Information – Property of Banlaw Pipeline Pty Ltd ©2001

You might also like

- PhoneList (FirstName)Document35 pagesPhoneList (FirstName)api-3752216100% (3)

- Wiggins Vents Info Wiggins VentsDocument2 pagesWiggins Vents Info Wiggins Ventsapi-3752216No ratings yet

- Technical Bulletins TB - Quick-Fill Tank VentsDocument13 pagesTechnical Bulletins TB - Quick-Fill Tank Ventsapi-3752216No ratings yet

- Technical Bulletins TB - 800LPM Installation AdviceDocument4 pagesTechnical Bulletins TB - 800LPM Installation Adviceapi-3752216No ratings yet

- Bam 800 T004 - Nozzle Flow Testing GuidelinesDocument11 pagesBam 800 T004 - Nozzle Flow Testing Guidelinesapi-3752216100% (1)

- Technical Bulletins TB - Quick-Fill Tank VentsDocument13 pagesTechnical Bulletins TB - Quick-Fill Tank Ventsapi-3752216No ratings yet

- Technical Bulletins TB - Nozzle Shut-Off MechanismDocument4 pagesTechnical Bulletins TB - Nozzle Shut-Off Mechanismapi-3752216No ratings yet

- Technical Bulletins TB - Dual Tanks 0300Document4 pagesTechnical Bulletins TB - Dual Tanks 0300api-3752216No ratings yet

- Technical Bulletins TB - Multi Compartment Tanks 0300Document4 pagesTechnical Bulletins TB - Multi Compartment Tanks 0300api-3752216No ratings yet

- Technical Bulletins TB - Fluid Theory 0400Document8 pagesTechnical Bulletins TB - Fluid Theory 0400api-3752216No ratings yet

- Technical Bulletins TB - 1000LPM Installation Advice 0601 - 1Document5 pagesTechnical Bulletins TB - 1000LPM Installation Advice 0601 - 1api-3752216No ratings yet

- Technical Bulletins TB - 800LPM Installation Advice 0601Document5 pagesTechnical Bulletins TB - 800LPM Installation Advice 0601api-3752216No ratings yet

- Installation Guidelines Installation and Inspection Guidlines For The AUS 25A Quick Fill VentsDocument1 pageInstallation Guidelines Installation and Inspection Guidlines For The AUS 25A Quick Fill Ventsapi-3752216No ratings yet

- Risk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3Document39 pagesRisk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3api-3752216100% (1)

- Bam 800 T001 - Air TestDocument2 pagesBam 800 T001 - Air Testapi-3752216No ratings yet

- Fast Fill Couplers LubeCentralhfcouplingsDocument2 pagesFast Fill Couplers LubeCentralhfcouplingsapi-3752216No ratings yet

- Scully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection SystemDocument3 pagesScully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection Systemapi-3752216100% (1)

- Oil Sampling Valve Oil Sampling Valve0001Document1 pageOil Sampling Valve Oil Sampling Valve0001api-3752216No ratings yet

- Scully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection SystemDocument3 pagesScully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection Systemapi-3752216100% (1)

- Fuel Trial Results Fuel TrialsDocument2 pagesFuel Trial Results Fuel Trialsapi-3752216No ratings yet

- Filtered Vents FilteredVentDocument2 pagesFiltered Vents FilteredVentapi-3752216No ratings yet

- Installation Guidelines Installation Guidlines On The Installation of 800LPM Refueling SystemDocument1 pageInstallation Guidelines Installation Guidlines On The Installation of 800LPM Refueling Systemapi-3752216No ratings yet

- Banlaw Sales Brochures Filtered VentDocument2 pagesBanlaw Sales Brochures Filtered Ventapi-3752216No ratings yet

- Fast Fill Couplers NEW FJ Broch PG 12Document1 pageFast Fill Couplers NEW FJ Broch PG 12api-3752216No ratings yet

- Fill Safe General Operating Instructions 08-05Document1 pageFill Safe General Operating Instructions 08-05api-3752216No ratings yet

- Fast Fill Couplers LC Hi-Flow FlyerDocument3 pagesFast Fill Couplers LC Hi-Flow Flyerapi-3752216No ratings yet

- Banlaw Sales Brochures FillSafeDocument2 pagesBanlaw Sales Brochures FillSafeapi-3752216No ratings yet

- Fast Fill Couplers Flush Face Flyer - PDDocument2 pagesFast Fill Couplers Flush Face Flyer - PDapi-3752216No ratings yet

- Fast Fill Couplers FF Coupling Price List-06Document1 pageFast Fill Couplers FF Coupling Price List-06api-3752216No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fluids Jee-Main-Oline 2021 Without AnswersDocument2 pagesFluids Jee-Main-Oline 2021 Without AnswersHarsh SinghNo ratings yet

- Turbomachinery AerodynamicsDocument21 pagesTurbomachinery AerodynamicsbunnykfaNo ratings yet

- Fluids 1 Toricelli ExperimentDocument7 pagesFluids 1 Toricelli ExperimentKiasha ChettyNo ratings yet

- PRV Sizing - XLSMDocument11 pagesPRV Sizing - XLSMDesiree MolinaNo ratings yet

- 10 21 0030 - MPFDocument20 pages10 21 0030 - MPFdavid leeNo ratings yet

- Steel PipeDocument133 pagesSteel PipePlavec IloNo ratings yet

- DF5 - Modelling Inflow PerformanceDocument6 pagesDF5 - Modelling Inflow Performanceadnan0307No ratings yet

- Hydrodynamics of Packed ColomnDocument6 pagesHydrodynamics of Packed ColomnDhananjay KadamNo ratings yet

- EIL-ALLOWABLE NOZZLE LOADSDocument5 pagesEIL-ALLOWABLE NOZZLE LOADSdarshanNo ratings yet

- Tutorial Problems on Integral Momentum Balance and Bernoulli EquationDocument2 pagesTutorial Problems on Integral Momentum Balance and Bernoulli EquationelizaroyNo ratings yet

- Vol. 13 No. 3 - March (2021) - CFD LettersDocument5 pagesVol. 13 No. 3 - March (2021) - CFD LettersSinggihDwiPrasetyoNo ratings yet

- Basics-Of-Hydraulics 8159920 PowerpointDocument26 pagesBasics-Of-Hydraulics 8159920 PowerpointbeselamuNo ratings yet

- AOT305 - Ktu Qbank PDFDocument7 pagesAOT305 - Ktu Qbank PDFUmarul MushtaqNo ratings yet

- Cavitation Apparatus FM 1849 21Document15 pagesCavitation Apparatus FM 1849 21Alyan YousafNo ratings yet

- QUIZ 3 OF LP3 (Fluid Kinematics) OF MC PHYSICS 1 (FLUID MECHANICS)Document3 pagesQUIZ 3 OF LP3 (Fluid Kinematics) OF MC PHYSICS 1 (FLUID MECHANICS)fj damayoNo ratings yet

- Conversion of Standard Volumetric Flow Rates of Gas - NeutriumDocument4 pagesConversion of Standard Volumetric Flow Rates of Gas - NeutriumfarhanNo ratings yet

- Fluid Mechanics Problem Solving on Navier-Stokes (39Document3 pagesFluid Mechanics Problem Solving on Navier-Stokes (39vinay kumarNo ratings yet

- NEE 4101 - Bautista Activity No. 1Document5 pagesNEE 4101 - Bautista Activity No. 1JETTDOMINIC BAUTISTANo ratings yet

- A Conceptual Study of Finger-Type Slug Catcher For Heavy-Oil FieldsDocument8 pagesA Conceptual Study of Finger-Type Slug Catcher For Heavy-Oil FieldsfanziskusNo ratings yet

- Optimize Vertical Lift PerformanceDocument27 pagesOptimize Vertical Lift PerformanceMira MirzabaevaNo ratings yet

- Energy & Hydraulic Grade LinesDocument11 pagesEnergy & Hydraulic Grade LinesKd CaisedoNo ratings yet

- Reservoir Unit MDDF TVDDF Tvdss Gradient Pressure: InternalDocument27 pagesReservoir Unit MDDF TVDDF Tvdss Gradient Pressure: InternalYber LexNo ratings yet

- Wall treatments and functions in CFD simulationsDocument15 pagesWall treatments and functions in CFD simulationssantiagoNo ratings yet

- Vortex Induced VibrationDocument55 pagesVortex Induced Vibrationstructural vinay100% (5)

- Self-Priming Centrifugal Pumps What You Need To Know PDFDocument2 pagesSelf-Priming Centrifugal Pumps What You Need To Know PDFhumshkhNo ratings yet

- A Single Formmula For Law of The WallDocument4 pagesA Single Formmula For Law of The Wallitssid19No ratings yet

- Che 321 Centrifugation 2Document33 pagesChe 321 Centrifugation 2Glory UsoroNo ratings yet

- Extra High Hazard Sample Hydraulic CalculationsDocument15 pagesExtra High Hazard Sample Hydraulic CalculationszaszaNo ratings yet

- PIP PCEFL001 Flow Measurement GuidelinesDocument28 pagesPIP PCEFL001 Flow Measurement GuidelinesMax AdamsonNo ratings yet

- ORIFICE DISCHARGE EXPERIMENTDocument12 pagesORIFICE DISCHARGE EXPERIMENTgongweejieNo ratings yet