Professional Documents

Culture Documents

Mud Rheology Test

Uploaded by

Abhi SharmaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

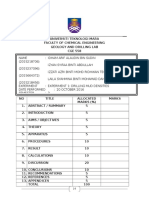

Mud Rheology Test

Uploaded by

Abhi SharmaCopyright:

Available Formats

Mud Rheology Test

Thu, 17 Feb 2011 22:02:53 | Drilling Engineering Related: diagnostic test Viscosity, Gel Strength and Yield Point Introduction Rheology refers to the deformation and flow behavior of all forms of matter. Certain rheologic measurements made on fluids, such as viscosity, gel strength, etc. help determine how this fluid will flow under a variety of different conditions. This information is important in the design of circulating systems required to accomplish certain desired objectives in drilling operations. (A) VISCOSITY: Theory Viscosity is defined as the resistance of a fluid to flow and is measured as the ratio of the shearing stress to the rate of shearing strain.

Two types of fluid characterizations are:

1. Newtonian (true fluids) where the ratio of shear stress to shear rate or viscosity is constant, e.g. water, light oils, etc. and 2. Non-Newtonian (plastic fluids) where the viscosity is not constant, e.g. drilling muds, colloids, etc.

300 RPM SETTING Figure 2.1: Flow Curves of Newtonian and non-Newtonian Fluids 300 RPM SETTING Figure 2.1: Flow Curves of Newtonian and non-Newtonian Fluids

Test Equipment The Baroid (Model 286) Rheometer is a coaxial cylindrical rotational viscometer, used to determine single or multi-point viscosities. It has fixed speeds of 3 (GEL), 100, 200, 300 and 600 RPM that are switch selectable with the RPM knob.

Figure 2.2: Variable Speed Rheometer Additionally, the same switch set to the VAR position enables speed selection of between 3 and 625 RPM, by manual adjustment of the variable knob.

VISCOSITY MEASUREMENT PROCEDURE

1. Place a recently agitated sample in the cup, tilt back the upper housing of the rheometer, locate the cup under the sleeve (the pins on the bottom of the cup fit into the holes in the base plate), and lower the upper housing to its normal position. 2. Turn the knurled knob between the rear support posts to raise or lower the rotor sleeve until it is immersed in the sample to the scribed line. 3. Stir the sample for about 5 seconds at 600 RPM, then select the RPM desired for the best. 4. Wait for the dial reading to stabilize (the time depends on the sample's characteristics). 5. Record the dial reading and RPM. RHEOLOGICAL CALCULATIONS 6. Plastic viscosity (in centipoise-up): Plastic Viscosity = j p = 600 RPM reading - 300 RPM Reading 2. Apparent Viscosity (in centipoise-cp): Apparent Viscosity = ja = 600 RPM Reading Yield Point = Y. P. = 300 RPM Reading - Plastic Viscosity (B) GEL STRENGTH: Theory

The Baroid Rheometer is also used to determine the Gel strength, in lb/100 sq. ft., of a mud. The Gel strength is a function of the inter-particle forces. An initial 10-second gel and a 10-minute gel strength measurement give an indication of the amount of gellation that will occur after circulation ceased and the mud remains static. The more the mud gels during shutdown periods, the more pump pressure will be required to initiate circulation again. Most drilling muds are either colloids or emulsions which behave as plastic or non-Newtonian fluids. The flow characteristics of these differ from those of Newtonian fluids (i.e. water, light oils, etc.) in that their viscosity is not constant but varied with the rate of shear, as shown in Figure 2.2. Therefore, the viscosity of plastic fluid will depend on the rate of shear at which the measurements were taken.

You might also like

- Mud Viscosity and RhelogyDocument8 pagesMud Viscosity and RhelogyHafizszul FeyzulNo ratings yet

- Mud Viscocities and Other Rheological PropertiesDocument23 pagesMud Viscocities and Other Rheological PropertiesMuhammad Naqiuddin Bin Zahid67% (3)

- Lab Manual For Drilling FluidDocument13 pagesLab Manual For Drilling FluidLemony Snickit100% (1)

- Mud Lab Manual - NewDocument32 pagesMud Lab Manual - Newfisco4ril67% (6)

- Drilling Lab 1 FullDocument14 pagesDrilling Lab 1 FullIdham Arif100% (1)

- Drilling Fluid Contamination TestDocument13 pagesDrilling Fluid Contamination TestHumaira Mirza0% (2)

- Final Drilling Fuild Lab ReportDocument19 pagesFinal Drilling Fuild Lab ReportTaufik Zainuddin100% (2)

- Petroleum Technology Drilling Fluid Lab Tests ProceduresDocument50 pagesPetroleum Technology Drilling Fluid Lab Tests ProceduresHomam MohammadNo ratings yet

- PETE 203 Drilling Engineering Lab ManualDocument98 pagesPETE 203 Drilling Engineering Lab ManualMarshal betaNo ratings yet

- Drilling Fluids Lab ManualDocument32 pagesDrilling Fluids Lab ManualDhiraj Y100% (1)

- Drilling Fluids Lab FinalDocument24 pagesDrilling Fluids Lab FinalHameed Bin AhmadNo ratings yet

- Reservoir Lab SheetDocument36 pagesReservoir Lab SheetSteve Lian Kuling100% (1)

- PET 310E Experiment #1 Page 1 of 10 Drilling and Completion Fluids LaboratoryDocument10 pagesPET 310E Experiment #1 Page 1 of 10 Drilling and Completion Fluids LaboratoryEmin KaragözNo ratings yet

- Drilling Fluid ExperimentsDocument48 pagesDrilling Fluid ExperimentsSamwel MmariNo ratings yet

- Part III Mud TestingDocument117 pagesPart III Mud TestingSlim.BNo ratings yet

- Lab Mud Solid Content DeterminationDocument10 pagesLab Mud Solid Content DeterminationIngenieur Khairuddin Ngah33% (3)

- Lab 9-Measurement of Filtrate Loss and Mud Cake Thickness of Drilling Mud Sample Using Dead Weight Hydraulic Filter Press Considering API Standard.Document17 pagesLab 9-Measurement of Filtrate Loss and Mud Cake Thickness of Drilling Mud Sample Using Dead Weight Hydraulic Filter Press Considering API Standard.Sunny BbaNo ratings yet

- Mud Filtraion 1Document5 pagesMud Filtraion 1ايمن القنونيNo ratings yet

- Lab 3Document13 pagesLab 3ismael hashiNo ratings yet

- Mud Filtration: University of Zawia Faculty of Oil & Gas Engineering Drilling Fluid Lab ExperimentDocument5 pagesMud Filtration: University of Zawia Faculty of Oil & Gas Engineering Drilling Fluid Lab Experimentايمن القنونيNo ratings yet

- Several Tests For Drilling Fluid in FieldDocument9 pagesSeveral Tests For Drilling Fluid in FieldMufti Ghazali100% (1)

- Lab Report Drilling Fluids LabDocument10 pagesLab Report Drilling Fluids LabLaura Demarch100% (1)

- Sand Content: University of Zawia Faculty of Oil & Gas Engineering Drilling Fluid Lab ExperimentDocument6 pagesSand Content: University of Zawia Faculty of Oil & Gas Engineering Drilling Fluid Lab Experimentايمن القنونيNo ratings yet

- Filtration ControlDocument8 pagesFiltration ControlapsekarNo ratings yet

- Drilling Fluid IntroductionDocument11 pagesDrilling Fluid IntroductiongasmigasmiNo ratings yet

- Measuring Clay YieldDocument7 pagesMeasuring Clay YieldMohammed Ali AlnooriNo ratings yet

- Drilling Fluids W181Document70 pagesDrilling Fluids W181Shamia Essam100% (1)

- BP Lost Circulation TechniquesDocument6 pagesBP Lost Circulation TechniquesInderjeet HoodaNo ratings yet

- Rule of Thumbs For MudDocument2 pagesRule of Thumbs For MudUsama Bin Sabir67% (3)

- Drilling Fluid 2 (C5)Document44 pagesDrilling Fluid 2 (C5)jibriilmustafa5No ratings yet

- Flat Rheology Drilling Fluid BenefitsDocument8 pagesFlat Rheology Drilling Fluid Benefitsمحمد سعيدNo ratings yet

- Properties of drilling fluidsDocument3 pagesProperties of drilling fluidsAnsell EwemeNo ratings yet

- Mud TestingDocument62 pagesMud TestingChukwuma LystanNo ratings yet

- Advances in Chromatographic Analysis of Hydrocarbon Gases in Drilling Fluids - The Application of Semi-Permeable Membrane Technology To High Speed TCD Gas ChromatographyDocument9 pagesAdvances in Chromatographic Analysis of Hydrocarbon Gases in Drilling Fluids - The Application of Semi-Permeable Membrane Technology To High Speed TCD Gas ChromatographyNA NANo ratings yet

- Casing Design1.9 Burst, Collapse, TensionDocument19 pagesCasing Design1.9 Burst, Collapse, Tensionjuanca_eduNo ratings yet

- Iraqi Oil Ministry Drilling Mud TrainingDocument48 pagesIraqi Oil Ministry Drilling Mud TrainingAminNo ratings yet

- Experiment On Sand ContentDocument15 pagesExperiment On Sand ContentAnsell EwemeNo ratings yet

- Full Lab 1Document18 pagesFull Lab 1Zafirah ZaidiNo ratings yet

- Mud TestingDocument62 pagesMud TestingTuan Nguyen HuuNo ratings yet

- Oil Based Mud Properties and UsesDocument7 pagesOil Based Mud Properties and Usesmmohsinaliawan100% (1)

- Mud TestingDocument35 pagesMud TestingHarits Pamitran100% (1)

- Cement Consistometer TestsDocument10 pagesCement Consistometer TestsAlimahmood BahraniNo ratings yet

- Lecture 2 - Drilling Fluids - Lab and MeasurementsDocument41 pagesLecture 2 - Drilling Fluids - Lab and MeasurementsJacob TuminskiNo ratings yet

- Core Cleaning Lab ReportDocument19 pagesCore Cleaning Lab ReportJombaca Berubah0% (2)

- Determining Fluid Saturation in Core SamplesDocument6 pagesDetermining Fluid Saturation in Core SamplesMohammef MohammedNo ratings yet

- Mud Densities Exp NewDocument8 pagesMud Densities Exp NewHafizszul FeyzulNo ratings yet

- Solids Control1Document83 pagesSolids Control1Yusian KasiwalliNo ratings yet

- Walid Questions, 2020Document69 pagesWalid Questions, 2020MoNo ratings yet

- Flat RheologyDocument16 pagesFlat RheologyAnonymous JMuM0E5YONo ratings yet

- Mud NotesDocument56 pagesMud Notesrainaldy sebastianNo ratings yet

- All About Mud PDFDocument91 pagesAll About Mud PDFMASAGUS MANGKU GAMANo ratings yet

- PETE 203 Drilling Engineering Laboratory Manual ExperimentsDocument98 pagesPETE 203 Drilling Engineering Laboratory Manual ExperimentsFima Molly100% (1)

- Experiment-No 2 PDFDocument7 pagesExperiment-No 2 PDFix JanNo ratings yet

- Drilling LabDocument7 pagesDrilling Labahmed abdul razaqNo ratings yet

- Covenant University Canaanland, OtaDocument14 pagesCovenant University Canaanland, OtaOluwadare FolarinNo ratings yet

- Rheological Properties of Drilling Fluids Prac 3Document23 pagesRheological Properties of Drilling Fluids Prac 3Las TresNo ratings yet

- Fundamental of Drilling Engineering: Prepared By: Amir Sabah KhalidDocument15 pagesFundamental of Drilling Engineering: Prepared By: Amir Sabah KhalidMohammed MohammedNo ratings yet

- Drilling Lab. Report: Mud Rheological Properties TestDocument9 pagesDrilling Lab. Report: Mud Rheological Properties Testعلي خالد ALINo ratings yet

- 30 Day Ab Challenge For Those Who Need Some Motivation Like MeKLDocument3 pages30 Day Ab Challenge For Those Who Need Some Motivation Like MeKLAbhi SharmaNo ratings yet

- Tears HJKKDocument1 pageTears HJKKAbhi SharmaNo ratings yet

- Tinsukia Dist TETDocument4 pagesTinsukia Dist TETAbhi SharmaNo ratings yet

- ClayDocument2 pagesClayAbhi SharmaNo ratings yet

- Hydraulics AnalyzedDocument1 pageHydraulics AnalyzedDrumil BaruahNo ratings yet

- Guar Gum UsesDocument10 pagesGuar Gum UsesAbhi SharmaNo ratings yet

- All You Wanted To Know About Pension Plans!: Share ThisDocument10 pagesAll You Wanted To Know About Pension Plans!: Share ThisAbhi SharmaNo ratings yet

- Ecd SPP Hole CleaningDocument1 pageEcd SPP Hole CleaningAbhi SharmaNo ratings yet

- How Wait and Weight Method Controls Bottom Hole PressureDocument3 pagesHow Wait and Weight Method Controls Bottom Hole PressureAbhi SharmaNo ratings yet

- Pretreatment in Reverse Osmosis Seawater DesalinatDocument9 pagesPretreatment in Reverse Osmosis Seawater DesalinataquaNo ratings yet

- NJ DEP Guidance on Process Hazard Analysis and Risk AssessmentDocument17 pagesNJ DEP Guidance on Process Hazard Analysis and Risk AssessmentaakashtrivediNo ratings yet

- Vision IAS Prelims 2020 Test 18 SDocument34 pagesVision IAS Prelims 2020 Test 18 StriloksinghmeenaNo ratings yet

- Rev.2 / DEC.2021Document6 pagesRev.2 / DEC.2021Linh PhạmNo ratings yet

- Manual Trane Chiller RTAFDocument122 pagesManual Trane Chiller RTAFFred GarciaNo ratings yet

- Crystal Appearance/Characteristics Clinical SignificanceDocument4 pagesCrystal Appearance/Characteristics Clinical SignificanceAngela LaglivaNo ratings yet

- To Study The Quantity of Casein Present in Different Samples of MilkDocument12 pagesTo Study The Quantity of Casein Present in Different Samples of MilkVartika MehrotraNo ratings yet

- CPCB SOPs Utilization Spent Alkali Bromide Manufacturing Recovery BromineDocument11 pagesCPCB SOPs Utilization Spent Alkali Bromide Manufacturing Recovery Brominekrunal soniNo ratings yet

- Diffuser AugmentedDocument8 pagesDiffuser Augmentedanthony100% (1)

- (Faringita Streptococica:copii: 250 MG de 2-3 Ori Pe Zi Adolescenţi Şi Adulţi: 250 MG de 4 Ori Pe Zi Sau 500 MG de 2 Ori Pe Zi Timp de 10 ZileDocument5 pages(Faringita Streptococica:copii: 250 MG de 2-3 Ori Pe Zi Adolescenţi Şi Adulţi: 250 MG de 4 Ori Pe Zi Sau 500 MG de 2 Ori Pe Zi Timp de 10 ZileAlina C100% (1)

- Criteria air pollutants: Sources, health effects and control of particulate matterDocument8 pagesCriteria air pollutants: Sources, health effects and control of particulate matterSumaiya ImamNo ratings yet

- ChemistryDocument188 pagesChemistrySamveg ClassesNo ratings yet

- 41 42Document4 pages41 42alfa alfaNo ratings yet

- Air Sampling and Industrial HygieneDocument276 pagesAir Sampling and Industrial HygieneGenilson Almeida100% (1)

- Investigating Oxygen and Carbon Dioxide Levels in Inhaled and Exhaled AirDocument2 pagesInvestigating Oxygen and Carbon Dioxide Levels in Inhaled and Exhaled AirAdy Phanterz100% (1)

- Iccesd 2020 PDFDocument12 pagesIccesd 2020 PDFzeekoNo ratings yet

- Materials Finer Than 75 - : Standard Test Method For M (No. 200) Sieve in Mineral Aggregates by WashingDocument3 pagesMaterials Finer Than 75 - : Standard Test Method For M (No. 200) Sieve in Mineral Aggregates by WashingLuis Alejandro Sánchez LópezNo ratings yet

- Importance of Analytical Instrumentation. Concepts To RememberDocument4 pagesImportance of Analytical Instrumentation. Concepts To RememberPrimer AsaltoNo ratings yet

- MPI/Injection-Compression Training Manual: For WindowsDocument37 pagesMPI/Injection-Compression Training Manual: For WindowsMaria NicolaescuNo ratings yet

- Extract Human DNA from Cheek Cells in 40 StepsDocument1 pageExtract Human DNA from Cheek Cells in 40 StepsJosaphat M. AnteNo ratings yet

- Hypoeutectiod Steel Alloys - SteelDocument52 pagesHypoeutectiod Steel Alloys - SteelnotsofarNo ratings yet

- Topic: Concrete Paver Block Reinforced With Mature Coconut Fiber As An AdditiveDocument10 pagesTopic: Concrete Paver Block Reinforced With Mature Coconut Fiber As An AdditiveXcyl Myrrh PreciosoNo ratings yet

- A Barcode KonversiDocument97 pagesA Barcode KonversiFerri JiNo ratings yet

- Organoboranes in Organic Syntheses Including Suzuki Coupling ReactionDocument29 pagesOrganoboranes in Organic Syntheses Including Suzuki Coupling Reactionratul mahataNo ratings yet

- Fundamentals of AerodynamicsDocument25 pagesFundamentals of AerodynamicsPaul Timothy Hao100% (3)

- CKRD-MS-03 (2020)Document51 pagesCKRD-MS-03 (2020)Shakoor MalikNo ratings yet

- Cursor Tier 3 Series I PDFDocument216 pagesCursor Tier 3 Series I PDFDenis Hernandez100% (1)

- Determination of Tissue Equivalent Materials of A Physical 8-Year-Old Phantom For Use in Computed TomographyDocument8 pagesDetermination of Tissue Equivalent Materials of A Physical 8-Year-Old Phantom For Use in Computed TomographyInas Fathinah SaepudinNo ratings yet

- Ecoliser-100Kg: Features Specifications CustomizationDocument1 pageEcoliser-100Kg: Features Specifications CustomizationjohnNo ratings yet

- SVR Engineering College Document on Effects of Moisture Change in Expansive SoilsDocument27 pagesSVR Engineering College Document on Effects of Moisture Change in Expansive SoilsAnika dixitNo ratings yet