Professional Documents

Culture Documents

PB Cloudifier

Uploaded by

Yusry SuryawiraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PB Cloudifier

Uploaded by

Yusry SuryawiraCopyright:

Available Formats

Niro Soavi S.p.A.

Via Mario Da Erba Edoari 29/A 43100 PARMA - ITALY tel: +39 0521 965411 fax: +39 0521 242819 e-mail: niro-soavi@niro-soavi.it http:\\www.niro-soavi.it

Document Ref.:

PROCESS BULLETIN

Subject:

PB/2-8/002

Issued by: Date:

SG

06/10/03

Emulsion high pressure homogenisation: Couldifiers

TEST REPORT

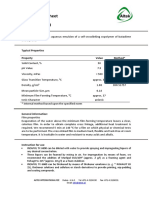

Product description: The product is a cloudifier based on water, vegetable oil and stabilizer. The cloudifier is a beverage emulsion and it is the most innovative solution to obtain exceptionally high cloud in the beverage industry using only natural ingredients. The product consists of fruit water extract ( f.i. orange or lemon) and vegetable oil. This means that the label declaration is clean, free from any chemical additives. Test purposes: The target is to stabilize the emulsion reducing the average particle size below 1 m.

Product composition: starch, oil, water, sodium benzoate and citrus acid. Product preparation: the components have been mixed at 30C. A good pre-mix can be

prepared using a ultra high shear mixer (eg. Ultra Turrax IKA or Silverson); this is a very important step for producing a stable emulsion characterized by a closed particle size distribution ( Average particle size diameter below 10m).

Afterwards the pre-emulsion has been homogenised at 500 bar and at 800 bar at room temperature using the second stage (50 bar) for multiple passes (one, two or three passages). Homogenisation conditions:

Homogeniser: PANDA2K NS1001L; capacity 10l/h max pressure 1500 bar. Homogenising valve: type PS Homogenisation conditions: the inlet temperature was 26C; product has been

homogenized at 500/50 bar x1, 500/50 bar x2 passes and at 800/50 bar, 800/50 bar x2, 800/50 bar x3 passes.

___________________________________________________________________________________ file: C:\silvia\new process bulletin\2) Food\8-Ingredients\pb_cloudifier_eng.doc page 1/4 The information contained in this document is property of Niro Soavi S.p.A.

You might also like

- Novozymes LiquefactionApplicationSheetDocument5 pagesNovozymes LiquefactionApplicationSheetI. Murali KrishnaNo ratings yet

- Novozymes Innovation Citrus 1212Document21 pagesNovozymes Innovation Citrus 1212Santiago Campillo50% (2)

- Production Process of JamsDocument3 pagesProduction Process of JamsElkhatibi Fatima-Ezzahra100% (1)

- Z&S PES-elsDocument5 pagesZ&S PES-elsguven44No ratings yet

- Clariant Blue MagicDocument9 pagesClariant Blue MagicHrishikesh DhawadshikarNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationRating: 3 out of 5 stars3/5 (1)

- Fixapret F ECODocument4 pagesFixapret F ECOSajida Hafeez0% (1)

- Solvalitt TDSDocument4 pagesSolvalitt TDSphillipskincaidNo ratings yet

- User Manual: FOR Soniclean Digital Benchtop Ultrasonic CleanersDocument12 pagesUser Manual: FOR Soniclean Digital Benchtop Ultrasonic Cleanersغزوان عماد الدين الحسينيNo ratings yet

- R1603 QUICK Histamin 08-02.20Document14 pagesR1603 QUICK Histamin 08-02.20Geraldine Pardo MariluzNo ratings yet

- Project PPT 1Document22 pagesProject PPT 1Swarnalatha Katta0% (1)

- Lnci Technical Information: Altranol-NoviDocument4 pagesLnci Technical Information: Altranol-Novithe griffendorsNo ratings yet

- Evolution Fuel Economy 5W30: DescriptionDocument2 pagesEvolution Fuel Economy 5W30: DescriptionGiga KekaNo ratings yet

- Mango ProcessingDocument8 pagesMango ProcessingelgibinNo ratings yet

- Rohapect 10 L: ® Description and Specification 2009-12-08Document2 pagesRohapect 10 L: ® Description and Specification 2009-12-08Germán R ZapsanNo ratings yet

- Elastocool MH1040Document4 pagesElastocool MH1040TajmirMahmudNo ratings yet

- R.O Chemical Cleaning ProcedureDocument4 pagesR.O Chemical Cleaning ProcedureAbu Bakar Hamada100% (2)

- Samara UnverstyDocument12 pagesSamara UnverstyMekoninn HylemariamNo ratings yet

- Pds Hempadur Multi-Strength GF 35870 En-GbDocument3 pagesPds Hempadur Multi-Strength GF 35870 En-GbThines KumarNo ratings yet

- MS GF 35870 en-GBDocument2 pagesMS GF 35870 en-GBLinnie McleodNo ratings yet

- User Manual For Soniclean Digital Benchtop Ultrasonic Cleaners 191013 PDFDocument12 pagesUser Manual For Soniclean Digital Benchtop Ultrasonic Cleaners 191013 PDFRafael GonzalezNo ratings yet

- Physico-Chemical Properties of Dehydrated GuavaDocument7 pagesPhysico-Chemical Properties of Dehydrated Guavanishi@sainiNo ratings yet

- Da 640Document8 pagesDa 640Alek KrótkiNo ratings yet

- Alpha-Sulfonated Methyl Ester As An Active Ingredient in Palm-Based Powder DetergentsDocument7 pagesAlpha-Sulfonated Methyl Ester As An Active Ingredient in Palm-Based Powder DetergentsPermata AdindaNo ratings yet

- Pds Hempadur 15570 En-GbDocument3 pagesPds Hempadur 15570 En-GbdcsamaraweeraNo ratings yet

- Inzapol TX 6600Document2 pagesInzapol TX 6600New EmailNo ratings yet

- Hempadur Multi-Strength GF 35870 PDFDocument3 pagesHempadur Multi-Strength GF 35870 PDFAnuar SalehNo ratings yet

- Product Data: HEMPADUR 45143Document2 pagesProduct Data: HEMPADUR 45143JoaoNo ratings yet

- UltrafloDocument7 pagesUltrafloLong ThuậnNo ratings yet

- MA 3000 NIC 600 2233 01 Simplified Operation ManualDocument10 pagesMA 3000 NIC 600 2233 01 Simplified Operation ManualPaul PlimNo ratings yet

- SeaQuantum Classic - English (Uk) - Issued.06.12.2007Document3 pagesSeaQuantum Classic - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Probase Cold: Complies With / Entspricht: Iso 20795-1 en Iso 20795-1 For Dental Use Only. RX OnlyDocument28 pagesProbase Cold: Complies With / Entspricht: Iso 20795-1 en Iso 20795-1 For Dental Use Only. RX OnlyrikaNo ratings yet

- Repsol Carrera 5W50: DescriptionDocument2 pagesRepsol Carrera 5W50: DescriptionGiga KekaNo ratings yet

- PDS Hempadur Multi-Strength 45753 en-GBDocument2 pagesPDS Hempadur Multi-Strength 45753 en-GBJosip LasanNo ratings yet

- Rahul - Industrial Visit ReportDocument5 pagesRahul - Industrial Visit ReportPrashant KumarNo ratings yet

- Emulsion Breaker 210 Product SheetDocument7 pagesEmulsion Breaker 210 Product SheetBen WigginsNo ratings yet

- International Olive CouncilDocument19 pagesInternational Olive CouncilSYAMSUL BACHRIENo ratings yet

- Ethanol: Assay ProcedureDocument16 pagesEthanol: Assay ProcedureCatalin OpreaNo ratings yet

- Superclear X-TRADocument4 pagesSuperclear X-TRAMuhammad Aasim HassanNo ratings yet

- Pds Envacol 206 v.13002Document1 pagePds Envacol 206 v.13002MelvinDapitanonNo ratings yet

- Esters Plant: 24,000 MTPYDocument11 pagesEsters Plant: 24,000 MTPYsatish kumarNo ratings yet

- Ultra Tex 4pdsDocument5 pagesUltra Tex 4pdscan.seNo ratings yet

- Basosoft EUK Conc. PDSDocument4 pagesBasosoft EUK Conc. PDSazambhabibNo ratings yet

- Chemflake Special - English (Uk) - Issued.08.01.2010Document5 pagesChemflake Special - English (Uk) - Issued.08.01.2010Mohamed FaragNo ratings yet

- Hempathane HS 55610Document2 pagesHempathane HS 55610prabha221No ratings yet

- QS Rovabio® Advance L2 - APAC ONLY (En)Document3 pagesQS Rovabio® Advance L2 - APAC ONLY (En)embahNo ratings yet

- DNA From Animal StoolDocument3 pagesDNA From Animal StoolCosmin ValentinNo ratings yet

- Rotary Evaporators EYELA JapanDocument12 pagesRotary Evaporators EYELA Japanard_caballeroNo ratings yet

- Gluco AmylaseDocument1 pageGluco AmylasePhong LyNo ratings yet

- Specification Eudragit L 30 D 55Document6 pagesSpecification Eudragit L 30 D 55Jivan Battu100% (1)

- Fixapret F-ECO TIDocument5 pagesFixapret F-ECO TISajida HafeezNo ratings yet

- Microlab: High Pressure HomogenizersDocument2 pagesMicrolab: High Pressure HomogenizersMohamed EshawiNo ratings yet

- Materials and Methods (For Fruit)Document2 pagesMaterials and Methods (For Fruit)Marie Joy EngayNo ratings yet

- KVASOVKE Premium Fructo 2 - 0 En1Document2 pagesKVASOVKE Premium Fructo 2 - 0 En1At YugovicNo ratings yet

- TDS - Tankguard HB - English (Uk) - Issued.06.12.2007Document3 pagesTDS - Tankguard HB - English (Uk) - Issued.06.12.2007AckmonNo ratings yet

- HiLoad Superdex 200 PrepGradeDocument6 pagesHiLoad Superdex 200 PrepGradeRubén Zapata PérezNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet