Professional Documents

Culture Documents

Automatic temperature controlled fan circuit

Uploaded by

Jinil VsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic temperature controlled fan circuit

Uploaded by

Jinil VsCopyright:

Available Formats

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

INTRODUCTION

All fans which are used now a day are controlled manually by voltage regulators which have different stages of speed. This process is done manually which can be done automatically by the use of this circuit. Here we are introducing an efficient fan speed regulation circuit, by which the speed of a fan can be controlled depending up on the room temperature. The circuit is highly efficient since energy loss can be minimized by power saving as the circuit automatically adjusts the fans speed.

1

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

PRINCIPLE OF OPERATION

This circuit uses thermistor as the temperature sensor, i.e. one having a negative temperature coefficient. This circuit is designed in such a way that the speed of the fan increases/decreases with respect to the room temperature with a minimum parts counting and avoiding the use of special-purpose ICs, often difficult to obtain.

2

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

BLOCK DIAGRAM

TEMPERATURE SENSOR & WHEATSTONE BRIDGE TRIGGERING CIRCUIT SWITCHING CIRCUIT

LOAD

Figure 1. Block Diagram

3

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

COMPONENTS USED

NAME OF COMPONENT

SPECIFICATION 22K

QUANTITY 1

Linear Potentiometer-P1 Thermistor-R1 SCR-D2 Zener Diode-D1 Diodes-D3,D4,D5,D6 Transistors-Q1,Q2 Transistor-Q3 Polyester Capacitor-C1 Resistor-R2 Resistors-R3,R6 Resistors-R4,R5 Resistor-R7 Resistor-R8 Resistors-R9,R10 Female Mains socket -SK1 Male Mains plug-PL1

PCB Breadboard Connecting Wires

15K @ 20C n.t.c TYN612 BZX79C18 1N4007 1000V BC327 BC337 10nF 63V 100K 1/4W 10K 1/4W 22K 1/4W 100R 1/4W 470R 1/4W

68K 2W -

1 1

1 4 2

1 1 1

2

2 1 1

2 1 1 1 1 As required

Table No:1. Component List

4

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

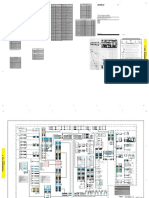

CIRCUIT DIAGRAM

Figure 2- Automatic Temperature Controlled Fan Circuit

5

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

WORKING

R3-R4 and P1-R1 are wired as a Wheatstone bridge in which R3-R4 generate a fixed two-thirds-supply "reference" voltage, P1-R1 generate a temperature-sensitive "variable" voltage, and Q1 is used as a bridge balance detector. P1 is adjusted so that the "reference" and "variable" voltages are equal at a temperature just below the required trigger value, and under this condition Q1 Base and Emitter are at equal voltages and Q1 is cut off. When the R1 temperature goes above this "balance" value the P1-R1 voltage falls below the "reference" value, so Q1 becomes forward biased, pulse-charging C1. This occurs because the whole circuit is supplied by a 100Hz half-wave voltage obtained from mains supply by means of D3-D6 Diode Bridge without a smoothing capacitor and fixed to 18V by R9 and Zener diode D1. Therefore the 18V supply of the circuit is not true DC but has a rather trapezoidal shape. C1 provides a variable phase-delay pulse-train related to temperature and synchronous with the mains supply "zero voltage" point of each half cycle, thus producing minimal switching RFI from the SCR. Q2 and Q3 form a trigger device, generating a short pulse suitable to drive the SCR.

6

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

COMPONENT DESCRIPTION

. SCR

Figure 3.. Symbol of SCR

Figure 4. Pictorial Representation of SCR

A thyristor, also known as a SCR (silicon controlled rectifier), is a special type of diode with four layers of alternating N and P-type material. They act as bistable switches, conducting when their gate receives a current pulse, and continue to conduct for as long as they are forward biased (that is, as long as the voltage across the device has not reversed). The thyristor is a four-layer, three terminal semiconducting devices, with each layer consisting of alternately N-type or P-type material, for example P-N-P-N. The main terminals, labelled anode and cathode, are across the full four layers, and the control terminal, called the gate, is attached to p-type material near to the cathode. (A variant called an SCSSilicon Controlled Switchbrings all four layers out to terminals.) The operation of a thyristor can be understood in terms of a pair of tightly coupled bipolar junction transistors, arranged to cause the self-latching action.

7

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

Figure 5 Transistor Equivalent Circuit of an SCR

Thyristors have three states: 1. Reverse blocking mode Voltage is applied in the direction that would be blocked by a diode 2. Forward blocking mode Voltage is applied in the direction that would cause a diode to conduct, but the thyristor has not yet been triggered into conduction 3. Forward conducting mode The thyristor has been triggered into conduction and will remain conducting until the forward current drops below a threshold value known as the "holding current"

8

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

The thyristor has three p-n junctions (serially named J1, J2, J3 from the anode).When the anode is at a positive potential VAK with respect to the cathode with no voltage applied at the gate, junctions J1 and J3 are forward biased, while junction J2 is reverse biased. As J2 is reverse biased, no conduction takes place (Off state). Now if VAK is increased beyond the breakdown voltage VBO of the thyristor, avalanche breakdown of

. Fig .6 Layer diagram of thyristor

J2 takes place and the thyristor starts conducting (On state).

If a positive potential VG is applied at the gate terminal with respect to the cathode, the breakdown of the junction J2 occurs at a lower value of VAK. By selecting an appropriate value of VG, the thyristor can be switched into the on state suddenly. It should be noted that once avalanche breakdown has occurred, the thyristor continues to conduct, irrespective of the gate voltage, until both: (a) the potential VG is removed and (b) the current through the device (anodecathode) is less than the holding current specified by the manufacturer. Hence VG can be a voltage pulse, such as the voltage output from a UJT relaxation oscillator. These gate pulses are characterized in terms of gate trigger voltage (VGT) and gate trigger current (IGT). Gate trigger current varies inversely with gate pulse width in such a way that it is evident that there is a minimum gate charge required to trigger the thyristor.

9

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

Figure 7 SCR Characteristic

In a conventional thyristor, once it has been switched on by the gate terminal, the device remains latched in the on-state (i.e. does not need a continuous supply of gate current to conduct), providing the anode current has exceeded the latching current (IL). As long as the anode remains positively biased, it cannot be switched off until the anode current falls below the holding current (IH).

A thyristor can be switched off if the external circuit causes the anode to become negatively biased. In some applications this is done by switching a second thyristor to discharge a capacitor into the cathode of the first thyristor. This method is called forced commutation.

10

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

SCR Phase Control In SCR Phase Control, the firing angle, or point during the half-cycle at which the SCR is triggered, determines the amount of current which flows through the device. It acts as a highspeed switch which is open for the first part of the cycle, and then closes to allow power flow after the trigger pulse is applied.

Figure .8 Output Wave form of SCR

Figure above shows an AC waveform being applied with a gating pulse at 45 degrees. There are 360 electrical degrees in a cycle; 180 degrees in a half-cycle. The number of degrees from the beginning of the cycle until the SCR is gated ON is referred to as the firing angle, and the number of degrees that the SCR remains conducting is known as the conduction angle. The earlier in the cycle the SCR is gated ON, the greater will be the voltage applied to the load.

11

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

Figure .9 Load voltage regulated by thyristor phase control.

For applications with frequencies higher than the domestic AC mains supply (e.g. 50 Hz or 60 Hz), thyristors with lower values of tQ are required. Such fast thyristors are made by diffusing into the silicon heavy metals ions such as gold or platinum which act as charge combination centers. Alternatively, fast thyristors may be made by neutron irradiation of the silicon.

12

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

THERMISTOR

Figure .10 Pictorial Representation of Thermistor

Figure .11 Symbol of Thermistor

A thermistor is a type of resistor whose resistance varies with temperature. The word is a portmanteau of thermal and resistor. Thermistors are widely used as inrush current limiters, temperature sensors, self-resetting over current protectors, and self-regulating heating elements. The material used in a thermistor is generally a ceramic or polymer. The temperature responses of thermistor are typically achieve a higher precision within a limited temperature range [usually 90 C to 130 C].Assuming, as a first-order approximation, that the relationship between resistance and temperature is linear, then:

Where R = change in resistance T = change in temperature k = first-order temperature coefficient of resistance

13

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

Thermistors can be classified into two types, depending on the sign of k. If k is positive, the resistance increases with increasing temperature, and the device is called a positive temperature coefficient (PTC) thermistor, or posistor. If k is negative, the resistance decreases with increasing temperature, and the device is called a negative temperature coefficient (NTC) thermistor. Here we are using a thermistor with negative temperature coefficient Resistors that are not thermistors are designed to have a k as close to zero as possible(smallest possible k), so that their resistance remains nearly constant over a wide temperature range. Many NTC thermistors are made from a pressed disc or cast chip of

a semiconductor such as a sintered metal oxide. They work because raising the temperature of a semiconductor increases the number of electrons able to move about and carry charge - it promotes them into the conduction band. The more charge carriers that are available, the more current a material can conduct.

Most PTC thermistors are of the "switching" type, which means that their resistance rises suddenly at a certain critical temperature. The devices are made of doped

polycrystalline ceramic containing barium (BaTiO3) and other compounds. The dielectric constant of this ferroelectric material varies with temperature. Below the Curie point temperature, the high dielectric constant prevents the formation of potential barriers between the crystal grains, leading to a low resistance. In this region the device has a small negative temperature coefficient. At the Curie point temperature, the dielectric constant drops sufficiently to allow the formation of potential barriers at the grain boundaries, and the resistance increases sharply. At even higher temperatures, the material reverts to NTC behaviour.

14

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

Another type of PTC thermistor is the polymer PTC, which is sold under brand names such as "Polyswitch" "Semifuse", and "Multifuse". This consists of a slice of plastic with carbon grains embedded in it. When the plastic is cool, the carbon grains are all in contact with each other, forming a conductive path through the device. When the plastic heats up, it expands, forcing the carbon grains apart, and causing the resistance of the device to rise rapidly. This type of thermistors is used for switching, not for proportional temperature measurement.

Applications of Thermistor

PTC thermistors can be used as current-limiting devices for circuit protection, as replacements for fuses.

NTC thermistors are used as resistance thermometers in low-temperature measurements of the order of 10 K.

NTC thermistors can be used as inrush-current limiting devices in power supply circuits. They present a higher resistance initially which prevents large currents from flowing at turnon, and then heat up and become much lower resistance to allow higher current flow during normal operation.

NTC thermistors are regularly used in automotive applications. For example, they monitor things like coolant temperature and/or oil temperature inside the engine and provide data to the ECU and, indirectly, to the dashboard.

Thermistors are also commonly used in modern digital thermostats and to monitor the temperature of battery packs while charging.

15

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

ZENER DIODE

Figure.12 Zener Diode Symbol

A Zener diode is a type of diode that permits current not only in the forward direction like a normal diode, but also in the reverse direction if the voltage is larger than the breakdown voltage known as "Zener knee voltage" or "Zener voltage". A Zener diode exhibits almost the same properties of the conventional solid-state diode, except the device is specially designed so as to have a greatly reduced breakdown voltage, the so-called Zener voltage. By contrast with the conventional device, a reverse-biased Zener diode will exhibit a controlled breakdown and allow the current to keep the voltage across the Zener diode at the Zener voltage. For example, a diode with a Zener breakdown voltage of 3.2 V will exhibit a voltage drop of 3.2 V if reverse bias voltage applied across it is more than its Zener voltage. The Zener diode is therefore ideal for applications such as the generation of a reference voltage (e.g. for an amplifier stage), or as a voltage stabilizer for low-current applications. Zener diodes are widely used as voltage references and as shunt regulators to regulate the voltage across small circuits. When connected in parallel with a variable voltage source so that it is reverse biased, a Zener diode conducts when the voltage reaches the diode's reverse

16

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

breakdown voltage. From that point on, the relatively low impedance of the diode keeps the voltage across the diode at that value.A load may be placed across the diode in the circuit, and as long as the Zener stays in reverse breakdown, the diode will provide a stable voltage source to the load. A Zener diode used in this way is known as a shunt voltage regulator (shunt, in this context, meaning connected in parallel, and voltage regulator being a class of circuit that produces a stable voltage across any load). In a sense, a portion of the current through the resistor is shunted through the Zener diode, and the rest is through the load. Thus the voltage that the load sees is controlled by causing some fraction of the current from the power source to bypass ithence the name, by analogy with locomotive switching points.

17

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

DIODE

Figure .13 Symbol of Diode

A Diode is a two-terminal electronic component that conducts electric current in only one direction. The term usually refers to a semiconductor diode, the most common type today, which is a crystal of semiconductor connected to two electrical terminals. The most common function of a diode is to allow an electric current to flow through it in one direction (called the diode's forward direction) while blocking current in the opposite direction (the reverse direction). Thus, the diode can be thought of as an electronic version of a check valve. This unidirectional behavior is called rectification, and is used to convert alternating current to direct current, and extract modulation from radio signals in radio receivers. A modern semiconductor diode is made of a crystal of semiconductor like silicon that has impurities added to it to create a region on one side that contains negative charge carriers (electrons), called n-type semiconductor, and a region on the other side that contains positive charge carriers (holes), called p-type semiconductor. The diode's terminals are attached to each of these regions. The boundary within the crystal between these two regions, called a PN junction, is where the action of the diode takes place. The crystal conducts conventional current in a direction from the p-type side (called the anode) to the n-type side (called the cathode), but not in the opposite direction.

18

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

TRANSISTOR

Figure .14 Pictorial Representation and Symbol of Transistors

NPN

PNP

A transistor is a semiconductor device used to amplify and switch electronic signals. It is made of a solid piece of semiconductor material, with at least three terminals for connection to an external circuit. A voltage or current applied to one pair of the transistor's terminals changes the current flowing through another pair of terminals. A Bipolar transistor has terminals labelled base, collector, and emitter. A small current at the base terminal (that is, flowing from the base to

19

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

the emitter) can control or switch a much larger current between the collector and emitter terminals. Here we are using two types of transistors PNP and NPN.

NPN

NPN is one of the two types of bipolar transistors, in which the letters "N" and "P" refer to the majority charge carriers inside the different regions of the transistor. Most bipolar transistors used today are NPN, because electron mobility is higher than hole mobility in semiconductors, allowing greater currents and faster operation. NPN transistors consist of a layer of P-doped semiconductor (the "base") between two Ndoped layers. A small current entering the base in common-emitter mode is amplified in the collector output. In other terms, an NPN transistor is "on" when its base is pulled high relative to the emitter. The arrow in the NPN transistor symbol is on the emitter leg and points in the direction of the conventional current flow when the device is in forward active mode.

PNP

The other type of BJT is the PNP with the letters "P" and "N" referring to the majority charge carriers inside the different regions of the transistor. PNP transistors consist of a layer of N-doped semiconductor between two layers of Pdoped material. A small current leaving the base in common-emitter mode is amplified in the collector output. In other terms, a PNP transistor is "on" when its base is pulled low relative to the emitter. The arrow in the PNP transistor symbol is on the emitter leg and points in the direction of the conventional current flow when the device is in forward active mode.

20

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

ADVANTAGES

Circuit is simpler in design. The use of voltage regulators in fans can be avoided. Power saving. Temperature variations can be easily tracked down. Less maintenance. Easily repairable. Since there is no complex circuitry setup involved. Low installation cost.

21

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

APPLICATIONS This circuit can be employed in places such as railway stations and such public places where people use to gather and they dont care about the working of these fans. In such places these circuits can be employed so the voltage regulators need not be operated manually. Installing these circuits in such places leads to power saving as the circuit automatically adjusts the fans speed. Another application of these circuit is that this can be used in houses which uses air conditioners for power saving.

22

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

RESULT

Automatic temperature controlled fan circuit was setup and connected to 230V mains supply and obtained the required output according to different temperature conditions. The circuit was found to be working as the temperature increased, speed of the fan increased and vice versa.

23

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

SCOPE FOR FUTURE WORK

The circuit can be expanded by incorporating a passive infrared sensor along with the temperature sensor. The passive infrared sensor can include a fresnel lens for sensing a 360 circumference beneath the fan so that the fan can be turned on and off based on motion of persons approaching and leaving a selected area .

24

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

CONCLUSION

This circuit is found to be more reliable than a regulator circuit since this seems to be more efficient than conventional regulator circuits. Since power consumption can be minimised to a greater extent. Even though it is simple this has a significant role to play in the development of technology. Every small step is significant in the path of success. Our project though simple is significant in the current status of our country facing energy crisis.

25

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

REFERENCES

http://www.redcircuits.com/ http://en.wikipedia.org/ http://www.allaboutcircuits.com/ http://www.pc-control.co.uk/ http://www.howstuffworks.com/

26

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

APPENDIX

27

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

DATA SHEET

28

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

29

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

30

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

31

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

32

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

33

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

34

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

35

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

36

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

37

DEPARTMENT OF EEE,VAST

AUTOMATIC TEMPERATURE CONTROLLED FAN

MINI PROJECT11

38

DEPARTMENT OF EEE,VAST

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Everything You Need to Know About DC DrivesDocument10 pagesEverything You Need to Know About DC DrivesSuyog ShingareNo ratings yet

- Camshaft CatalogDocument6 pagesCamshaft CatalogAhmedNo ratings yet

- AKG1212 CNC RouterDocument9 pagesAKG1212 CNC RouterVictor BravoNo ratings yet

- Pajero Sports Workshop-Service Manual 1999Document934 pagesPajero Sports Workshop-Service Manual 1999kiran_rm200693% (15)

- 8085 VerilogDocument21 pages8085 VerilogvatsalyatNo ratings yet

- Automatic Head Lamp Alignment SystemDocument48 pagesAutomatic Head Lamp Alignment SystemAakash Dindigul100% (1)

- Design and Construction of Earth Fault Relay For Single Phase SystemDocument3 pagesDesign and Construction of Earth Fault Relay For Single Phase SystemGururaj BandaNo ratings yet

- Air Cadet Pumps ManualDocument12 pagesAir Cadet Pumps ManualEdgar Campusano SanchezNo ratings yet

- Construction of 4-Lane Flyover at Amberpet Mini Project PresentationDocument9 pagesConstruction of 4-Lane Flyover at Amberpet Mini Project PresentationVujjini RaghuNo ratings yet

- Interacoustics As216 Screening AudiometerDocument34 pagesInteracoustics As216 Screening Audiometerjuvillegas0% (1)

- Manual Book Dryer PDFDocument64 pagesManual Book Dryer PDFrochmad eko suyudiNo ratings yet

- Fabrication of Chain Link Wire Mesh Making MachineDocument36 pagesFabrication of Chain Link Wire Mesh Making MachineHari ArtsNo ratings yet

- Gogte Institute of Technology: Dr.V.N.SatwikDocument16 pagesGogte Institute of Technology: Dr.V.N.Satwikaditya thakkarNo ratings yet

- Coin Based Water Controlling SystemDocument34 pagesCoin Based Water Controlling SystemSanthosh Guduru75% (4)

- On "Footstep Power Generation System Using Microconroller" Submitted in Partial Fulfillment For The Award of The Degree of in Submitted by Iiibtech1 SEM (17701A0215)Document26 pagesOn "Footstep Power Generation System Using Microconroller" Submitted in Partial Fulfillment For The Award of The Degree of in Submitted by Iiibtech1 SEM (17701A0215)geetha lakshmiNo ratings yet

- Remote & Temperature Controlled Fan CircuitDocument8 pagesRemote & Temperature Controlled Fan Circuitchipku23No ratings yet

- Foot Step Power GenerationDocument5 pagesFoot Step Power GenerationAbhishek Kumar0% (2)

- Boost DC voltage with a simple DC-DC converter circuitDocument3 pagesBoost DC voltage with a simple DC-DC converter circuitFawwaaz HoseinNo ratings yet

- 267 Button Operated Electromagenetic Gear Changer For Two Wheeler (Report)Document46 pages267 Button Operated Electromagenetic Gear Changer For Two Wheeler (Report)tariq76100% (5)

- Panou Solar MPPT in Punct de UmbraDocument50 pagesPanou Solar MPPT in Punct de UmbraAndrei CocorNo ratings yet

- Eco Friendly POWER Generation Through Speed Breakers: Presented By-Biswajeet Pradhan 1301104035 Electrical Engg. (7 Sem)Document28 pagesEco Friendly POWER Generation Through Speed Breakers: Presented By-Biswajeet Pradhan 1301104035 Electrical Engg. (7 Sem)Subhashree Rout100% (1)

- 1 PDFDocument8 pages1 PDFB.Kailash Krishna PrasadNo ratings yet

- 1.protection of Busbar Distribution From Over LoadDocument4 pages1.protection of Busbar Distribution From Over LoadPooja BanNo ratings yet

- Speed Control of A DC Motor Using Hand GestureDocument4 pagesSpeed Control of A DC Motor Using Hand GestureArka Prava LahiriNo ratings yet

- Short ReportDocument2 pagesShort ReportRaj MandloiNo ratings yet

- Matlab-Simulink Controller DesignDocument4 pagesMatlab-Simulink Controller DesignMohamed SomaiNo ratings yet

- 5 Ddcet Syllabus Engineering1702910382 - 231218 - 203535Document9 pages5 Ddcet Syllabus Engineering1702910382 - 231218 - 203535alonewarrior2004No ratings yet

- DC Motor Speed Control Using PWMDocument14 pagesDC Motor Speed Control Using PWMVincent KorieNo ratings yet

- Design and Construction of A 2000W Inverter: Lawal Sodiq Olamilekan 03191100Document20 pagesDesign and Construction of A 2000W Inverter: Lawal Sodiq Olamilekan 03191100Da Saint100% (1)

- PPTDocument25 pagesPPTSaranya GuttulaNo ratings yet

- Thesis - Design, Control and Simulation of PMSG Based Stand-AloneDocument68 pagesThesis - Design, Control and Simulation of PMSG Based Stand-AloneMAZHAR ALAM MALLICKNo ratings yet

- Thermal Analysis of Fins: Effects of Shape on Heat TransferDocument31 pagesThermal Analysis of Fins: Effects of Shape on Heat TransferJalagam Ravinder RaoNo ratings yet

- Iot Based Geyser Controller: A Project ReportDocument40 pagesIot Based Geyser Controller: A Project ReportNexus vijayawadaNo ratings yet

- SRMDocument60 pagesSRMKrupa KaranNo ratings yet

- Aqua Drone Ieee PaperDocument3 pagesAqua Drone Ieee PaperAkash ShahuNo ratings yet

- Microcontroller Protection of Induction MotorsDocument45 pagesMicrocontroller Protection of Induction MotorsabellNo ratings yet

- Literature Survey On Variable Frequency Drive: Anuradha Tomar Devesh SinghDocument8 pagesLiterature Survey On Variable Frequency Drive: Anuradha Tomar Devesh SinghAjay DSElectrical100% (1)

- PLC Based Home Automation PDFDocument95 pagesPLC Based Home Automation PDFRameshwar TalwarNo ratings yet

- Speed Control of DC Motor Using PWM TechniqueDocument76 pagesSpeed Control of DC Motor Using PWM TechniquekishoreNo ratings yet

- Numerical Analysis of Temperature Separation in a Vortex TubeDocument47 pagesNumerical Analysis of Temperature Separation in a Vortex TubeKristoff CongoNo ratings yet

- A Study of Feasibility of Atmospheric Water Generator: Chhattisgarh Swami Vivekanand Technical University, Bhilai (INDIA)Document41 pagesA Study of Feasibility of Atmospheric Water Generator: Chhattisgarh Swami Vivekanand Technical University, Bhilai (INDIA)Shriya100% (1)

- SRCEM Three level H-bridge inverter reportDocument7 pagesSRCEM Three level H-bridge inverter reportAnil ShahNo ratings yet

- Design and Fabrication of Mechanical Footstep Power GeneratorDocument19 pagesDesign and Fabrication of Mechanical Footstep Power GeneratorMonika kakadeNo ratings yet

- Smart Home Energy Management SystemDocument4 pagesSmart Home Energy Management SystemDikimbie GatpuNo ratings yet

- DS 2 Group No - 30 (682,683,689,691) Solar Power Auto Irrigation SystemDocument19 pagesDS 2 Group No - 30 (682,683,689,691) Solar Power Auto Irrigation SystemChirag RathvaNo ratings yet

- AMEE310 Lab5Document12 pagesAMEE310 Lab5tsunaseetNo ratings yet

- Automatic Door Open @close Report FinalDocument36 pagesAutomatic Door Open @close Report FinalFelixJosephNo ratings yet

- Over Speed Fuel CutoffDocument3 pagesOver Speed Fuel Cutoffselvaganapathy1992No ratings yet

- Delta Dvp-Se I Mul 20130208Document20 pagesDelta Dvp-Se I Mul 20130208daocongdablNo ratings yet

- Buck Converter Full ProjectDocument38 pagesBuck Converter Full Project2k18-EE-243 Vethushan VinnayagamoorththiNo ratings yet

- Foldable Bicycle AnalysisDocument49 pagesFoldable Bicycle AnalysisNistha RavalNo ratings yet

- 80-Watt Piezoelectric Crosswalk Energy Harvesting System: Technological Institute of The Philippines Manila CampusDocument22 pages80-Watt Piezoelectric Crosswalk Energy Harvesting System: Technological Institute of The Philippines Manila CampusJan Vher ampeloquioNo ratings yet

- ENERGY HARVESTING FOOTSTEPS PIEZOELECTRICDocument2 pagesENERGY HARVESTING FOOTSTEPS PIEZOELECTRICcamila0% (1)

- Solenoid Valve - How They Work: Normally Open Normally ClosedDocument7 pagesSolenoid Valve - How They Work: Normally Open Normally Closedmuhammad aliNo ratings yet

- Major DocumentDocument61 pagesMajor DocumentLE-224 MeghanaReddyNo ratings yet

- Atmospheric Water Generator - ReportDocument38 pagesAtmospheric Water Generator - ReportArif AliNo ratings yet

- Variable Frequency DrivesDocument17 pagesVariable Frequency DrivesAshok SutharNo ratings yet

- Heat & Mass Transfer Lab: Shell and Tube Heat Exchanger AnalysisDocument9 pagesHeat & Mass Transfer Lab: Shell and Tube Heat Exchanger AnalysisMuhammad TanveerNo ratings yet

- Accident Alert in Modern Traffic System With CameraDocument12 pagesAccident Alert in Modern Traffic System With CameraLeander Lawrence100% (1)

- Design and Fabrication of Power Generation Shock AbsorberDocument1 pageDesign and Fabrication of Power Generation Shock AbsorberVijay GanapathyNo ratings yet

- A Novel Dynamic Voltage Restorer Based On Matrix ConvertersDocument17 pagesA Novel Dynamic Voltage Restorer Based On Matrix ConvertersJexux010% (1)

- Foot Step Based Power GeneratorDocument15 pagesFoot Step Based Power Generatorchanda SindhuraNo ratings yet

- TEE3211 DrivesDocument126 pagesTEE3211 DrivesWebster Fungirai100% (1)

- Hardware Implementation: 3.1 Block Diagram & Components DescriptionDocument10 pagesHardware Implementation: 3.1 Block Diagram & Components DescriptionRajaiah JagariNo ratings yet

- ThyristorDocument46 pagesThyristorvivekkuru100% (1)

- ThyristerDocument5 pagesThyristerapi-3753995100% (2)

- 3.1 Block Diagram & Components Description:: Fig: 3.1 Block Diagram of Cyclo-Converter Using MicrocontrollerDocument10 pages3.1 Block Diagram & Components Description:: Fig: 3.1 Block Diagram of Cyclo-Converter Using MicrocontrollerSwamyNo ratings yet

- Hydrostatic Pump (Manual Controls, AHC & ACS) (Right Half) - S300Document4 pagesHydrostatic Pump (Manual Controls, AHC & ACS) (Right Half) - S300Alfredo GuzmánNo ratings yet

- Smart TrolleyDocument24 pagesSmart TrolleyAbdul Razzak100% (1)

- Fosmon 4-In-1 Charging Dock For Nintendo Switch Joy-Con Controller With LED IndicatorDocument2 pagesFosmon 4-In-1 Charging Dock For Nintendo Switch Joy-Con Controller With LED Indicatorhenry sarmientoNo ratings yet

- PrintDocument9 pagesPrintJob MandezNo ratings yet

- Writing BDR (JULIANA)Document2 pagesWriting BDR (JULIANA)jodie comerNo ratings yet

- Evolution of Intel Microprocessors PDFDocument2 pagesEvolution of Intel Microprocessors PDFErikaNo ratings yet

- Fundamentals of Computers: Reema TharejaDocument39 pagesFundamentals of Computers: Reema TharejaYash SharmaNo ratings yet

- LS01 ServiceDocument53 pagesLS01 ServicehutandreiNo ratings yet

- Horizontal Multi-Stage Pumps: Component MaterialDocument2 pagesHorizontal Multi-Stage Pumps: Component MaterialBrayan CJNo ratings yet

- MSA M1 SCBA LeafletDocument5 pagesMSA M1 SCBA LeafletForum PompieriiNo ratings yet

- Unisource Series 2612 HoseDocument1 pageUnisource Series 2612 HosejoeNo ratings yet

- Mcmurdo Smartfind Nav-7 Navtex User ManualDocument52 pagesMcmurdo Smartfind Nav-7 Navtex User ManualtariktunadNo ratings yet

- M 325 D (1) ElectDocument4 pagesM 325 D (1) ElectJesus CortesNo ratings yet

- Selected Objective Question On Introduction To Computers With Answer Set 5Document27 pagesSelected Objective Question On Introduction To Computers With Answer Set 5Ankit JainNo ratings yet

- Yamaha RX V365 Owners ManualDocument1 pageYamaha RX V365 Owners ManualandreiNo ratings yet

- Teste de Isolação e Megagem de GeradorDocument5 pagesTeste de Isolação e Megagem de Geradorwagner_guimarães_1No ratings yet

- Valvulas Introduccion (Ingles)Document21 pagesValvulas Introduccion (Ingles)Luis VilcañaupaNo ratings yet

- BY320P 150wDocument2 pagesBY320P 150wIngeniería y Proyectos IG-PROJETNo ratings yet

- 502 Series DC Power System: Netsure™Document8 pages502 Series DC Power System: Netsure™Sahand ArasNo ratings yet

- Kil Gu-Un Series UnionsDocument2 pagesKil Gu-Un Series UnionsNoe AlvarezNo ratings yet

- BCS WS CS BZ 250Document3 pagesBCS WS CS BZ 250GabrielGrecoNo ratings yet

- Bennic (Bi-Polar Radial-Axial) B03 SeriesDocument3 pagesBennic (Bi-Polar Radial-Axial) B03 Seriesester853No ratings yet