Professional Documents

Culture Documents

Job Safety Analysis For Scaffolding 1

Uploaded by

nasar_mahsoodOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis For Scaffolding 1

Uploaded by

nasar_mahsoodCopyright:

Available Formats

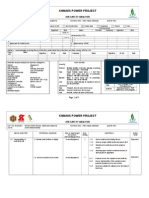

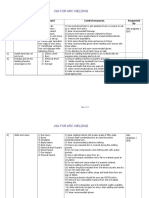

JOB SAFETY ANALYSIS (JSA) FORM

Job Location/Site: Task/Activity: ERECTION AND DISMANTLING OF SCAFFOLDING Work Area:

Emergency situation /Evacuation

SL. NO

JSA NO:11 PCR NO : PCR NO: Date:

Permit N0:

Gas Leak / Fire /Any Emergency: In case of emergency, all works must be stopped, equipment must be switched off

and left in safe condition. All personnel shall reach the nearest muster point considering the wind direction (upward or cross-ward) WHO IS AT RISK

ACTIVITY STEPS

HAZARDS INVOLVED

CONTROL MEASURES

Morning tool box Meeting And JHA Discussion

Work Permit

People Not Understanding What The Plan Or Hazards Are; People Afraid To Ask Questions Presence Of H2S gas and Toxic gas In Work Areas Presence of chemical or flammable items Unauthorized commencement of works May result in exposing people and/or potential to harm or danger.

People Equipment Facility Environment

Make Sure Everyone Is Involved With The JSA/JHA Discussion And Understands; Encourage Everyone To Ask Questions And Participate. Don't Make Anyone Feel For Speaking Up Or Questioning Try To Identify These Types Of things In Your Work Areas Before Starting the work; Clear Carefully Work Areas By gas testing and daily site inspection Authorized work permit holders shall ensure obtaining and maintaining valid work permits. The supervisor responsible for this activity has to check the PPE of his staff to ensure that all required items are available and properly used. Inform all people regarding permit conditions before work starts. Supervisors must conduct daily toolbox talk about nature of work and associated potential hazards and their essential precautionary measures. Carryout gas test by QP Authorized gas tester time to time. All groups working in different area inside station shall have H2S personal gas monitor(certified)

People Equipment Facility Environment

Gas test

May found toxic gas or H2S gas leak People or extreme oxygen limit in air Environment

PJ247/JSA-11-REV-0

ERECTION AND DISMANTLING OF SCAFFOLDING Page 1 of 3

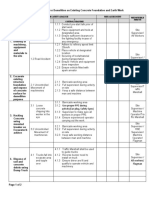

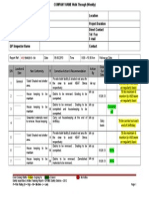

JOB SAFETY ANALYSIS (JSA) FORM

SL.NO ACTIVITY STEPS HAZARDS INVOLVED WHO IS AT RISK CONTROL MEASURES

4

Scaffolding Preparation of work/Hauling of materials

Mobility restriction, access obstruction, congestion in the work area if hauling/storing of material in not properly planned and coordinated. Nearby existing facilities if any subject to physical damage during material hauling

People Equipment Facility

Survey the area and confirm safe location of temporary of material prior to hauling. Provide temporary holding area at location that will not congest/obstruct plant access or restrict mobility of other activities. Obtain necessary permit Provide temporary holding area at location that will not congest/obstruct site access or restrict mobility of other activities. Scaffold rack is a must for holding scaffolding material. No pipes, couplers will be stored on the ground or anytime scattered on the ground. Observe extra caution in mobilizing material at site Take extreme care during erection and override it if needed.

Erection & of Scaffolding

Use Damage to onsite detectors People /switches / transmitters etc Facility Equipment Fall of objects / Tools. People Facility Equipment

Provide guardrail & toe board to prevent falling of tools /objects Dont keep the unnecessary materials on the scaffold platform Hand tools to be tied with permanent structure or person If required barricade the area during erection work.

7 8 9 10 11

Accidental Fall of Person Unstable Scaffold Weak Scaffold

People People Facility Equipment People Facility Equipment People Facility Equipment People Facility Equipment

The Scaffolder must use Safety Harness/full body harness to prevent accidental fall The scaffold must be inspected, certified & tagged bythe competent person confirming its suitability The scaffold tag must indicate the maximum load that itcan bear

Damaged Scaffold Modified Scaffold

The scaffolding is to be inspected at least weekly for any damage due to weather condition (rain, high windetc) or other unsafe conditions. In case of any modification, addition in the scaffold, ithas to be reinspected & certified Page 2 of 3

PJ247/JSA-11-REV-0

ERECTION AND DISMANTLING OF SCAFFOLDING

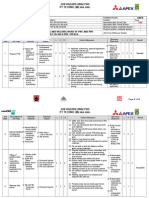

JOB SAFETY ANALYSIS (JSA) FORM

SL.NO ACTIVITY STEPS HAZARDS INVOLVED WHO IS AT RISK CONTROL MEASURES

12

Improperly Supported Scaffold

People Facility People Facility

Ensure Scaffold is securely supported on a rigid groundand not on process piping / vessel or equipment Do not use if green Tag is missing Do not use if red tag is available.

13

Incomplete Scaffold

14 15

Old Scaffolding Housekeeping Clean up worksite

Doubtful Integrity

Do not use if it does not have valid inspection tag attached Remove tools equipment and rubbish from worksite and maintain a clean work environment. Arrange housekeeping on daily and every shift bases Supervisor shall conduct tool box meeting in this regards

Slips trips and falls due to poor housekeeping

People Environment Facility Equipment

Project Engineer PREPARED BY:

HSE/QA/QC Manager REVIEWED BY:

Project Manager APPROVED BY:

Page 3 of 3 PJ247/JSA-11-REV-0 ERECTION AND DISMANTLING OF SCAFFOLDING

You might also like

- JSA Concrete WorksDocument8 pagesJSA Concrete Worksfrancis_e_tan93% (27)

- JSA G20 Scaffolding (Erection, Dismantling)Document4 pagesJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- Job Safety Analysis (14) For Cable Laying and PullingDocument4 pagesJob Safety Analysis (14) For Cable Laying and Pullingnasar_mahsood79% (34)

- Column Lifting & Erection JSADocument7 pagesColumn Lifting & Erection JSAAli Mohsin100% (3)

- Aboveground Piping Installation Works 2016Document7 pagesAboveground Piping Installation Works 2016Aldrin75% (4)

- JSA-Working at HeightDocument2 pagesJSA-Working at Heightsubhanmusadiq83% (109)

- BYDP-JHA-05 Erection of ScaffoldingDocument4 pagesBYDP-JHA-05 Erection of ScaffoldingAhmad Shauqi100% (6)

- Jsa For Scaffolding Erection & DismentlingDocument7 pagesJsa For Scaffolding Erection & Dismentlingsanath adhikary100% (5)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRana Waseem Khan82% (79)

- JSA CarpentryDocument2 pagesJSA Carpentrysubhanmusadiq91% (11)

- Jsa For Road WorksDocument11 pagesJsa For Road Worksyc safety75% (12)

- JHA 15-Work at Height Using ScaffoldingDocument3 pagesJHA 15-Work at Height Using ScaffoldingWte SB100% (7)

- Job Safety Analysis (Jsa)Document11 pagesJob Safety Analysis (Jsa)Noraini Binti Osman50% (2)

- JSA For Cement Plaster at Office ExtensionDocument4 pagesJSA For Cement Plaster at Office ExtensionMohammed Minhaj50% (2)

- Jsa For Lifting (Crane) 016Document6 pagesJsa For Lifting (Crane) 016aliraza572270% (27)

- Jsa For Drilling.Document3 pagesJsa For Drilling.Belsyah Nofriyan75% (4)

- JSA-Manual Lifting of MaterialsDocument3 pagesJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- JSA WeldingDocument2 pagesJSA WeldingSigint Sides0% (3)

- Civil JSA Form Block WorkDocument3 pagesCivil JSA Form Block Workdrmuhsin86% (7)

- JSA PaintingDocument1 pageJSA Paintingsubhanmusadiq63% (16)

- Jsa ExcavationDocument33 pagesJsa Excavationlal5012002390782% (17)

- JSA PlumbingDocument2 pagesJSA Plumbingsubhanmusadiq71% (7)

- Copy (2) of JSA For Removal of MS Sheet For E&P ShedDocument12 pagesCopy (2) of JSA For Removal of MS Sheet For E&P Shedmidozoty50% (2)

- JSA of Pipe Unloading.Document2 pagesJSA of Pipe Unloading.vijay kumar singh100% (1)

- JSA Erection of Steel StructureDocument9 pagesJSA Erection of Steel StructureLuqman Osman77% (13)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- JSA MasnoryDocument4 pagesJSA Masnorysubhanmusadiq100% (1)

- JSA For Demobilization WorksDocument2 pagesJSA For Demobilization WorksIanne Dee85% (13)

- JSA Working at HeightDocument2 pagesJSA Working at HeightFadzira Syahira Fadzaleh100% (7)

- JSA-Loading UnloadingDocument2 pagesJSA-Loading Unloadingsubhanmusadiq82% (55)

- Job Hazard Analysis For Crane DismantlingDocument2 pagesJob Hazard Analysis For Crane DismantlingVaisham92% (24)

- JSA ElectricalDocument2 pagesJSA Electricalsubhanmusadiq100% (6)

- Jsa CraneDocument3 pagesJsa Cranenattwa201075% (24)

- JHA 08 On Erection of Roofing SheetsDocument3 pagesJHA 08 On Erection of Roofing SheetsAkhilesh KumarNo ratings yet

- 003 JSA All Civil WorksDocument5 pages003 JSA All Civil WorksMohammed Minhaj100% (11)

- Jsa For TELESCOPING BOOM AERIAL LIFTDocument2 pagesJsa For TELESCOPING BOOM AERIAL LIFTVipul Shankar100% (1)

- JSA For Concrete, Brecking, ExavationDocument6 pagesJSA For Concrete, Brecking, ExavationBinay0% (1)

- JSA - SK-erection & DismantlingDocument1 pageJSA - SK-erection & DismantlingEngr Tahir UL Haq100% (3)

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- JHA Chain HoistDocument1 pageJHA Chain HoistKrishna Patil100% (2)

- Scaffolding JSA (General)Document5 pagesScaffolding JSA (General)Panchdev KumarNo ratings yet

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- JSA Lifting OperationsDocument4 pagesJSA Lifting OperationsCristina Rican100% (1)

- Backfilling Compaction JSADocument2 pagesBackfilling Compaction JSArashid zaman84% (25)

- JSA Installation of PumpsDocument6 pagesJSA Installation of Pumpsyc safety100% (2)

- JSA For Working at HeightDocument1 pageJSA For Working at HeightSafety& Security Supervisor100% (1)

- Job Safety Analysis Sheet: Electrical IsolationDocument1 pageJob Safety Analysis Sheet: Electrical IsolationLal Dhwoj100% (2)

- JSA To Perform Greasing of Motor BearingDocument9 pagesJSA To Perform Greasing of Motor BearingChung Trịnh100% (1)

- Jsa For Arc WeldingDocument3 pagesJsa For Arc Weldingtnssbhaskar100% (5)

- Hira - Insulation & Cladding WorkDocument9 pagesHira - Insulation & Cladding WorkAbzad HussainNo ratings yet

- Jha New Format Painting Revision PDFDocument8 pagesJha New Format Painting Revision PDFNakkolopNo ratings yet

- Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job DetailsDocument4 pagesJob Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Detailsnasar_mahsood100% (2)

- Job Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Document20 pagesJob Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Barkat Ullah50% (2)

- JHA Manual Excavation For Cable TrenchDocument5 pagesJHA Manual Excavation For Cable TrenchNasrullah Jan100% (4)

- Job Safety Analysis WorksheetDocument3 pagesJob Safety Analysis WorksheetPaul Sodipo100% (1)

- Crane JHA OKDocument4 pagesCrane JHA OKAbu Maaz100% (1)

- Job Safety Analysis For Scaffolding 1Document3 pagesJob Safety Analysis For Scaffolding 1Arshad Khan100% (5)

- Safe Work Method Statement: Fixed ScaffoldDocument11 pagesSafe Work Method Statement: Fixed ScaffoldJoe Waller100% (1)

- Safety Analysis Lifting of Plat For Tank WeldingDocument2 pagesSafety Analysis Lifting of Plat For Tank Weldingnasar_mahsood100% (2)

- Monthly Hse Logistics StatisticsDocument3 pagesMonthly Hse Logistics Statisticsnasar_mahsoodNo ratings yet

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood50% (2)

- Monthly Hse Logistics StatisticsDocument3 pagesMonthly Hse Logistics Statisticsnasar_mahsoodNo ratings yet

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood50% (2)

- Monthly Hse Logistics StatisticsDocument3 pagesMonthly Hse Logistics Statisticsnasar_mahsoodNo ratings yet

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood50% (2)

- Jsa Radiography ActivitiesDocument4 pagesJsa Radiography Activitiesnasar_mahsood80% (15)

- Hand Tool's For Mechanical WorkDocument1 pageHand Tool's For Mechanical Worknasar_mahsoodNo ratings yet

- Safety WalkthroughDocument1 pageSafety Walkthroughnasar_mahsood100% (1)

- Toolbox Talk Grinding and CuttingDocument1 pageToolbox Talk Grinding and Cuttingnasar_mahsoodNo ratings yet

- Toolbox Talk About PpeDocument3 pagesToolbox Talk About Ppenasar_mahsoodNo ratings yet

- Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job DetailsDocument4 pagesJob Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Detailsnasar_mahsood100% (2)

- Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job DetailsDocument4 pagesJob Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Detailsnasar_mahsood100% (1)

- Project - Dreambox Remote Video StreamingDocument5 pagesProject - Dreambox Remote Video StreamingIonut CristianNo ratings yet

- Contemporary Architecture Is The Architecture of The 21st Century. No Single Style Is DominantDocument2 pagesContemporary Architecture Is The Architecture of The 21st Century. No Single Style Is DominantShubham DuaNo ratings yet

- Hssive-Xi-Chem-4. Chemical Bonding and Molecular Structure Q & ADocument11 pagesHssive-Xi-Chem-4. Chemical Bonding and Molecular Structure Q & AArties MNo ratings yet

- Army Public School No.1 Jabalpur Practical List - Computer Science Class - XIIDocument4 pagesArmy Public School No.1 Jabalpur Practical List - Computer Science Class - XIIAdityaNo ratings yet

- Dental Clinic - Floor Plan R3-2Document1 pageDental Clinic - Floor Plan R3-2kanagarajodisha100% (1)

- Inglês - Advérbios - Adverbs.Document18 pagesInglês - Advérbios - Adverbs.KhyashiNo ratings yet

- Origins - and Dynamics of Culture, Society and Political IdentitiesDocument4 pagesOrigins - and Dynamics of Culture, Society and Political IdentitiesJep Jep Panghulan100% (1)

- Principles of Volumetric AnalysisDocument5 pagesPrinciples of Volumetric AnalysisMax TennerNo ratings yet

- Poster PresentationDocument3 pagesPoster PresentationNipun RavalNo ratings yet

- KKS Equipment Matrik No PM Description PM StartDocument3 pagesKKS Equipment Matrik No PM Description PM StartGHAZY TUBeNo ratings yet

- A Quick Guide To Artificial IntelligenceDocument41 pagesA Quick Guide To Artificial IntelligenceFrancis Violet Raymond100% (2)

- Viking 062293Document8 pagesViking 062293Lukman ZakariyahNo ratings yet

- JurnalDocument12 pagesJurnalSandy Ronny PurbaNo ratings yet

- TVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsDocument9 pagesTVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsNelPalalonNo ratings yet

- American University of Beirut PSPA 210: Intro. To Political ThoughtDocument4 pagesAmerican University of Beirut PSPA 210: Intro. To Political Thoughtcharles murrNo ratings yet

- Weather Prediction Using Machine Learning TechniquessDocument53 pagesWeather Prediction Using Machine Learning Techniquessbakiz89No ratings yet

- Sullivan's Interpersonal TheoryDocument27 pagesSullivan's Interpersonal TheoryJezalen GonestoNo ratings yet

- Claudia Maienborn, Semantics, 381Document34 pagesClaudia Maienborn, Semantics, 381robert guimaraesNo ratings yet

- ESG Conundrum PDFDocument30 pagesESG Conundrum PDFVijay Kumar SwamiNo ratings yet

- LG) Pc-Ii Formulation of Waste Management PlansDocument25 pagesLG) Pc-Ii Formulation of Waste Management PlansAhmed ButtNo ratings yet

- Project 2 Analysis of Florida WaterDocument8 pagesProject 2 Analysis of Florida WaterBeau Beauchamp100% (1)

- Sailpoint Topic Wise SyllabusDocument2 pagesSailpoint Topic Wise SyllabusKishore KodaliNo ratings yet

- Maharashtra State Board of Technical Education. Academic Monitoring Department ProfileDocument14 pagesMaharashtra State Board of Technical Education. Academic Monitoring Department Profilevspd2010No ratings yet

- Job Stress InterventionsDocument5 pagesJob Stress InterventionscocaralucamihaelaNo ratings yet

- Quiz EditedDocument6 pagesQuiz EditedAbigail LeronNo ratings yet

- Dial 1298 For Ambulance - HSBCDocument22 pagesDial 1298 For Ambulance - HSBCDial1298forAmbulanceNo ratings yet

- ActivityDocument2 pagesActivityShaira May SalvadorNo ratings yet

- 3.1.1 - Nirmaan Annual Report 2018 19Document66 pages3.1.1 - Nirmaan Annual Report 2018 19Nikhil GampaNo ratings yet

- Microcontrollers DSPs S10Document16 pagesMicrocontrollers DSPs S10Suom YnonaNo ratings yet

- Character Paragraph Analysis RubricDocument2 pagesCharacter Paragraph Analysis RubricDiana PerrottaNo ratings yet