Professional Documents

Culture Documents

01 Resistivity Theory

Uploaded by

dibakar_04Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 Resistivity Theory

Uploaded by

dibakar_04Copyright:

Available Formats

CHAPTER

RESISTIVITY THEORY

Introduction to Resistivity, Physics of the Measurement and Resistivity Tools

RESISTIVITY THEORY

TABLE OF CONTENTS

TABLE OF CONTENTS............................................................................................i,ii

PREFACE....................................................................................................................iii INTRODUCTION TO RESISTIVITY LOGGING.......................................................1 History Of Resistivity Logging...............................................................................1 Evaluation Of Hydrocarbons...................................................................................5 Invasion Profile........................................................................................................7 PHYSICS OF THE MEASUREMENT.........................................................................10 Absolute Potential.................................................................................................12 Potential Difference...............................................................................................13 Equipotential Surfaces...........................................................................................15 Current Density.....................................................................................................16 RESISTIVITIES FOR DIFFERENT CURRENT FLOW GEOMETRIES.............17 One Dimensional, Planar Flow - Mud Cup Analysis...........................................17 Spherical Current Flow -Unfocused Devices........................................................19 Cylindrical Current Flow - Guarded Devices........................................................22

TRAINING MANUAL

RESISTIVITY THEORY

ELECTRODE LOGGING DEVICES..........................................................................24 Defining the Tool - Resistivity vs Conductivity...................................................24 RESISTIVITY TOOLS..................................................................................................25 Unfocused Devices (ES Tools)..............................................................................25 Lateral Tool...........................................................................................................25 Normal Tool..........................................................................................................27 Problems Associated with the ES Tools...............................................................28 Focused Devices (Laterolog Tools)......................................................................29 DUAL LATEROLOG MEASUREMENTS.................................................................35 Dual Laterolog Tool Principles.............................................................................35 Depth Of Investigation..........................................................................................36 Radial Resistivity Profile......................................................................................37 SPHERICAL FOCUSING.............................................................................................42 Spherical Focused logging Tool (SFL).................................................................42 Micro-Spherical Focusing (MSFL Theory)..........................................................45 Microguard Tool (MG).........................................................................................48 Invasion Effects - The Butterfly Chart.................................................................49

ii

TRAINING MANUAL

Dual Laterolog Fingerprints..............................................................................51 The Microlog Tool................................................................................................52 REFERENCES............................................................................................................... 54

RESISTIVITY THEORY

PREFACE

In 1942 G. E. Archie of Shell developed the following equation that is known as ARCHIE EQUATION.

WATER SATURATION EQUATION

Sw = c

Rw / Rt /

Where c = 1.0 for carbonates and 0.90 for sands. This is the basic equation of log interpretation. The whole well-logging industry is built upon this equation. The equation shows that hydrocarbons in place can be evaluated if there are sufficient logs to give interstitial water resistivity ( R w ), formation resistivity ( R t ), and Porosity (). In practice Rw is obtained either from applying the equation in a nearby water sand ( S w = 1) or from the SP log or from catalogs or water sample measurements; and is obtained from porosity logs (Density, Neutron, or Sonic). R t is obtained from deep resistivity readings (Induction or Laterolog).

TRAINING MANUAL

iii

RESISTIVITY THEORY

INTRODUCTION TO RESISTIVITY LOGGING

History of Resistivity Logging

The history of resistivity logging is the history of electrical wireline logging. Wireline logging started with a resistivity device connected to a rubber insulated copper wire and suspended in a borehole drilled to 1,500 feet. The well, the Diefenback 2905 was owned by the Pechelbronn Company in Pechelbronn France. The date was September 5, 1927. Using the principle's first conceived and later put into practical use by Conrad Schlumberger for surface electrical prospecting. Henri Georges Doll designed the "sonde, and with the aid of two assistants produced the first electrical "log." At the time Doll, with a B.S. degree from the University of Lyon, France, was a research Engineer for the Schlumberger Company. The first sonde consisted of four electrodes wired into an insulating mandrel made of Bakelite. By weighting the sonde down with lead pellets, and descending to the bottom of the well and slowly pulling upward, a resistivity profile of the subsurface formations was obtained. This first operation was not a thing of beauty. In his own words, Doll explains some of the problems. We had no collector, instead, we had a plug, much like a common wall plug, at the side of the winch flange. When the winch had to be turned, the cable connection to the potentiometer was unplugged so the turn could be made. Then the cable was plugged back in so that we could make the reading. We began making our measurement. Someone had to unplug the connector, someone else turned the winch, someone had to run on the rig floor to look at the counter on the sheave...there was a lot of running back and forth. I wrote down the measurements on a pad, together with the depth reading. Then it was unplug, roll up one meter to the next station, and plug back in. Make the next reading, and so on, one meter at a time The primary aim of this first log was merely to define the geological (lithology) cross sections, not locate the hydrocarbon-bearing zones. The idea was to use this wireline tool as an "electrical coring device" to compensate for the shortcomings of mechanical (drill test) coring

TRAINING MANUAL

HISTORY OF RESISTIVITY LOGGING

INTRODUCTION

FIG: 1 The First Logging Operations (Pechelbronn 1927)

TRAINING MANUAL

RESISTIVITY THEORY LOGGING

HISTORY OF RESISTIVITY

After the initial operation, which was considered successful, Doll plotted his measurements on a strip of graph paper and drew the first of the typical diagrams that were to become familiar to the petroleum industry. This figure shows the first log." After logging a number of wells in the Pechelbronn field in the weeks to follow, positive conclusions were drawn. Hard formation layers appeared on the diagrams as peaks contrasting clearly with the soft and conductive marls (sands). When the log results were confirmed by actual physical core samples, electrical coring was firmly established as a valuable tool for geological surveys

FIG 2 The First Resistivity Log (Pechelbronn 1927)

TRAINING MANUAL

HISTORY OF RESISTIVITY LOGGING

RESISTIVITY THEORY

During the logging operations at Pechelbronn, Doll and his associates observed that even with no current emitted in the borehole by their tool, a potential difference was measured across a pair of monitor electrodes on the sonde. After integrating this self potential [called the Spontaneous Potential (SP)] over depth, one of the logs runs at Pechelbronn in 1931 was the first to demonstrate that the SP could clearly delineate shales from permeable formations. With the additional permeability and lithology information provided by the SP log, the basic electrical coring log in the mid 1930s provided enough resistivity, porosity, lithology and permeability information that (in most cases) hydrocarbon-bearing formations could be distinguished from hard, low permeability zones. Thus the initial electrical coring diagrams were subsequently replaced by the less restrictive "electric survey logs" that included the SP curve. Well logging, as we know it today, had begun.

FIG 3 Electric Coring Operations (California 1932)

TRAINING MANUAL

RESISTIVITY THEORY LOGGING

HISTORY OF RESISTIVITY

Evaluation of Hydrocarbons

The manner in which the presence of hydrocarbons in pore space is sensed is through the electrical resistance of the formation. The formation consists of rock matrix and pore space occupied by fluid. The resistivity of this combination of matrix and fluid is termed true resistivity," R t . For normal logging situations, the rock matrix is considered a perfect insulator; it conducts no electricity, therefore, the formations conductivity is only a function of the fluid in the pores. At depths below 2,000 feet, the water found in formation pores is generally saline, which makes it quite conductive. The conductive (resistive) property of water is a function of the salinity (number of ions' present) and temperature. The higher these two variables, the more conductive the water and the lower the resistivity of the formation that contains the water. The illustration on the next page shows the relationship between the fluid resistivity and salinity and temperature. Note that at constant temperature, the greater the salinity, the lower the resistivity. Also, at constant salinity, the greater the temperature the lower the resistivity. Remember that resistivity is the reciprocal of conductivity. The resistivity of the formation water is termed R w .

TRAINING MANUAL

HISTORY OF RESISTIVITY LOGGING

RESISTIVITY THEORY

FIG 4 Resistivity Salinity Temperature Of Aqueous NaCl Solutions

TRAINING MANUAL

RESISTIVITY THEORY LOGGING

HISTORY OF RESISTIVITY

What happens when some of the saline pore water is replaced by hydrocarbons? We have already mentioned that the rock matrix is an insulator. We should note, as can be seen from the table below, Hydrocarbons (oil or gas) are also insulators. Our resistivity measurement can not distinguish one insulator from another. Since these hydrocarbon fluids do not conduct electricity, their presence means there is less pore fluid available for conduction. We can say that the resisitivity of a sedimentary formation with hydrocarbons depends primarily on the resistivity of the water in the pores and the quantity of water present. This resistivity; to a lesser extent, will also depend on the formation texture (grain size, distribution of pores, etc.), clay content, and lithology.

Table 1 TYPICAL RESISTIVITY VALUES MATERIAL Marble Quartz Petroleum Distilled Water TYPICAL FORMATIONS Clay/Shale Salt-Water Sand Oil Sand Tight Limestone

2 10 0.5 10 5 10

10

3 3

RESISTIVITY (m)

5 x 10

12

10

10

3 x 10

14

14

2 x 10

5 x 10

TRAINING MANUAL

HISTORY OF RESISTIVITY LOGGING

RESISTIVITY THEORY

Invasion Profile

The formation resisitivity, R t , that we have been discussing is for the virginal zone. This is to say, R t is assumed to be the resistivity of the undisturbed reservoir beyond any invasion.

FIG: 5 Idealized Invasion Profile

TRAINING MANUAL

RESISTIVITY THEORY LOGGING

HISTORY OF RESISTIVITY

In the borehole you have the drilling mud of resistivity ( R m ). The effect of this drilling mud on permeable formations causes mudcake of resistivity ( R mc ) to build on the borehole wall and invasion of these formations by mud filtrate. There are two components of the invaded zone, one fully flushed by mud filtrate and the other a transition between fully flushed and uninvaded. The transition zone is neglected, and the diameter of invasion ( d i ) is measured to the edge of the flushed zone. The resistivity of the zone, whose pore space contains only mud filtrate of resistivity ( R mf ) and residual hydrocarbons if present in the formation, is denoted as ( R xo ). The associated water saturation is S xo . Beyond that zone is the undisturbed formation with resistivity ( R t ),interstitial water resistivity ( R w ), and water saturation ( S w ). The existence of invasion has forced the development of resistivity logging tools that make deep measurements in an effort to read R t uninfluenced by mud filtrate. However no tool has been developed that can read deeply enough under all circumstances and still maintain good vertical resolution. Consequently, the standard is to run three resistivity curves simultaneously with three difference depths of investigation: Deep resistivity curve. Medium resistivity curve. Shallow resistivity curve.

The reading of the deep investigation curve can be corrected for invasion effects to provide the R t value. The flushed zone resistivity and the diameter of invasion can also be estimated, using the three measurements in a set of simultaneous equations with three unknowns ( R t , R xo , and d i ).

TRAINING MANUAL

RESISTIVITY THEORY

PHYSICS OF THE MEASUREMENT

PHYSICS OF THE MEASUREMENT

As a starting point for resistivity theory considers the cylinder below. Suppose that a potential difference is established between the two ends of the conductor of length L and cross-sectional area A. For a given material, experiment shows that the resistance for this simple geometrical configuration is directly proportional to the length and inversely proportional to the cross sectional area.

FIG: 6 Resistivity Of A Cylindrical Conductor

Here

V = Voltage I = Current L = Length A = Cross Sectional Area

In an equation form, we can write the resistivity as:

1-1.

=R

L , = resistance A

TRAINING MANUAL

11

PHYSICS OF THE MEASUREMENT

RESISTIVITY THEORY

ere R is the resistivity. It is a property of the material of which the conductor is made, but does not depend on the conductor's physical shape. Resistivity has the units of ohmm2/m (or ohm-m) and is affected by temperature; exact resistivity values are always stated along with the corresponding value of temperature. The resisitivity values for two metal conductors are: copper = 1.7 x 10-8 ohm-m at 20 C nickel = 6.8 x 10-8 ohm-m at 20 C If we define: 1-2. then 1-3.

A/L = K

R = K

K can therefore be considered the constant of proportionality that converts resistance to resistivity. K has the units of length. From Ohm's law we know: 1-4.

V = I.

By combining equations 1-3 and 1-4 we obtain the general resistivity equation: 1-5.

R = K

V I

Resistivity can be computed if the voltage drop and current are known. The K constant is only a function of the geometry of current flow (which is controlled by the specific shape and arrangement of electrodes for a current emitting resistivity device in the wellbore). The geometry of current flow defines the shape of the equipotential surfaces associated with the flow. Since an understanding of the idea of equipotential surfaces is necessary for deriving the resistivity equations for more complicated flow patterns, we need to review some basic electromagnetic ideas.

12

TRAINING MANUAL

RESISTIVITY THEORY

PHYSICS OF THE MEASUREMENT

Absolute Potential

The absolute potential at a point in space is the work done against electrical forces in carrying a unit positive charge from infinity to that point. Hence for the geometry defined below, the absolute potential at "r" is the work done in bringing a unit positive charge from infinity () to r. The potential at is considered to be zero.

FIG: 7 The Position Vector

TRAINING MANUAL

13

PHYSICS OF THE MEASUREMENT

RESISTIVITY THEORY

tential Difference

The potential difference from point 2, to point 1, is the work done against electrical forces in carrying a unit positive charge from 2 to 1. See below.

FIG: 8 The Potential Difference Between Two Points

14

TRAINING MANUAL

RESISTIVITY THEORY

PHYSICS OF THE MEASUREMENT

The potential difference (V1 - V2) is therefore defined as a work/charge. This ratio has the specific units of Joule/coulomb and is called the volt. Potential Difference is defined by the line integral equation: 1-6.

V1 - V2 = -

r1 r2

E dr = -

r1

r2

dr Cos

In this case E is the electric field vector, and dr is an element of length along the current flow, and is the angle between E and dr. The minus sign arises because the potential is defined as the work done "against" the field E. For all practical cases, E and dr are parallel and Equation 6 reduces to the scalar form. 1-7.

V1 - V2 = -

r1

2

E dr

By definition you are able to choose V = 0 for an infinitely distant point (say, point 2), Equation 1-7 becomes:

1-8.

V = -

E dr

Where V is now the absolute potential at the point r.

TRAINING MANUAL

15

PHYSICS OF THE MEASUREMENT

RESISTIVITY THEORY

Equipotential Surfaces

Consider a simple case of a spherical current source electrode of radius ( r o ) in an infinite, homogenous, and isotropic medium centered at the origin (see below).

FIG: 9 Spherical Current Source

If the potential on the surface of the electrode is maintained constant with the current emanating from the electrode to infinity, then the electric field is radial and the potential at any point where r > ro will depends on the distance [V = V(r)]. Therefore, on a given radial distance of r, all points of the sphere of radius r will have the same potential. This therefore defines an equipotential surface. Indeed, we can imagine the electrode to be surrounded by an infinite number of concentric spherical surfaces, each point on a given sphere having the same potential, and each spherical equipotential surface differing from its neighboring surfaces in potential by a constant amount. The electric force lines, radially outward from the positive current source, are perpendicular to the equipotential surfaces. It should be understood that the electric force lines must be perpendicular to the equipotential surfaces. If this was otherwise, a component of the electric field (E) would be tangent (parallel) to the surface and current would be able to flow on the surface. If the current is flowing on the surface, the entire surface cannot be at the same potential (current flows from a higher to a lower potential). Therefore, if the surface is equipotential, only radial current flow is possible and the electric force lines must be perpendicular to the surface.

16

TRAINING MANUAL

RESISTIVITY THEORY

PHYSICS OF THE MEASUREMENT

Current Density

The magnitude of the current divided by the unit cross-sectional area of current flow (defined by the flow geometry) is called the current density. To take into account the direction of the flow, this current density must be a vector quantity. 1-9.

J=

I A

In this case n is a unit vector along the direction of current flow, I is the current and A is the cross sectional area. The magnitude of J is simply: 1-10.

I J= A

It has been found that throughout a wide range of conditions, in solids and liquids, the relationship between J and the electric field E is a linear one. 1-11.

E = RJ

Here R is the resistivity. Equation 1-11 is the microscopical equation of Ohm's law, and holds true for any point within a conductor of any shape. It should be obvious from Equation 1-10 that the exact expression for J is a function of the current flow pattern, which is dictated by the equipotential surfaces defined by the shape of the current source (and the spacing of the return electrode).

* NOTE: The current density J is not to be confused with the pseudo geometrical factor J in the of

Radial Resistivity Profile Section.

TRAINING MANUAL 17

RESISTIVITY THEORY

PHYSICS OF THE MEASUREMENT

RESISTIVITIES FOR DIFFERENT CURRENT FLOW GEOMETRIES

One Dimensional, Planar Flow - Mud Cup Analysis

Referring to figure 6 , we can apply Equation 1-6 and the microscopical form of Ohm's law (Equation 1-11) to obtain the expression for the resistivity of the cylinder. We may assume that the configuration obeys the coordinates as shown below:

FIG: 10 One Dimensional Planar Flow

Since the equipotential surfaces are circular planes, the area and current density are given by:

1-12.

A = lo2 = constant,

J = Io /lo2

The vectors J and E are parallel. And an element of current flow length dr is parallel to E and J.

TRAINING MANUAL

18

RESISTIVITY THEORY GEOMETRYS

RESISTIVITIES FOR DIFFERENT CURRENT FLOW

From Equations 1-6 and 1-11: 1-13.

V0 - VL = -

0 L

E dr = -

0 L

RJ dr

Since J and dr are parallel, the dot product J dr becomes just the scalar product Jdr and Equation 13 reduces to:

V0 - VL = - R

0 L

Jdr = - R

0 L

I0 2 0

dr

V0 - VL =

I0 R l2 0

dr =

I0 R L l2 0

defining Vo - VL as V:

V =

I0R L l 2 0

or in terms of the resistivity

R = K

V I0

, K =

l2 0 L

A L

these are just equations 1-5 and 1-2 respectively.

TRAINING MANUAL

19

RESISTIVITIES FOR DIFFERENT CURRENT FLOW GEOMETRYS

RESISTIVITY THEORY

A practical use of the previous Equations is made by the measurement of resistivity in the "mud tester" on the logging truck. This tester is a cylindrical shaped hollow container in which fluid is drawn. A d.c. potential is maintained across the ends of the tester and current flows through the fluid within. Resistivity is computed from Equations 5 and 2. As an example, suppose a mud tester with a cylinder of 0.5 inches and a length of 4 inches is filled with mud filtrate. The voltage across the sample is 10 volts with the current equal to 0.5 Amps. The resistivity of the fluid is easily computed as follows:

A K= L V R =K I =

lo2 = L

(3.14) (0.00635)2 m2 = 0.00127 m 0.10 m 10V = 0.0253 ohm-m 0.5A

= (0.00127 m)

20

TRAINING MANUAL

RESISTIVITY THEORY GEOMETRYS

RESISTIVITIES FOR DIFFERENT CURRENT FLOW

NOTE: The dimensions in inches had to be converted into meters in the above equations to keep K and

R in the correct units.

Spherical Current Flow - Unfocused Devices

The downhole formation resistivities are not so easily computed as the direct measurements made by a mud tester. Still the approach to obtaining apparent resistivities of the formation again uses equation 1-5. The earliest popular resistivity devices (by their unfocused nature) approximated the case of a spherical electrode emitting constant current I o radially in an infinite, isotropic and homogenous medium. For the spherical current flow shown below, we want to obtain an expression for the resistivity between two concentric equipotential surfaces whose radii are greater than the source electrode radius ( r o ).

FIG: 11 Two Concentric Equipotential Spheres

The radius of the inner surface is AM, and that of the other surface is AN. Here A is the origin. From our definition of the potential difference, the potential difference between the two equipotential surfaces is just the work done in moving a positive charge from the surface N (the outer surface) to the surface M (the inner surface)

TRAINING MANUAL

21

RESISTIVITIES FOR DIFFERENT CURRENT FLOW GEOMETRYS

RESISTIVITY THEORY

1-14.

- VN = -

AM AN

E dr

For the spherical geometry, the surface area and current density are given by:

1-15.

A = 4r2,

J = Io / 4r2

As before, J and dr are parallel and our dot product with E = RJ becomes a scalar product.

VM - VN = - R AN J dr = - R AN J dr = - R AN

AM AM

AM

I 0 dr 4r 2

VM

I R - VN = - 0 4

AM AN

I R dr = - 0 r2 4 1 r

AM AN

1 - r

AM AN

1-16.

VMN = VM - VN = +

I0R 4

I R 1 1 = 0 4 AM AN

In terms of R,

1-17.

K (VM - VN) R= I0

Where K is given by

4

1-18

K= (

1 AM -

1 AN )

We see that if the potential at the two equipotential surfaces can be measured, and the distances AM and AN is known along with the constant current output Io, R can be calculated from Equations 1-17 and 1-18. The "Lateral" and "Normal" unfocused resistivity

22 TRAINING MANUAL

RESISTIVITY THEORY GEOMETRYS

RESISTIVITIES FOR DIFFERENT CURRENT FLOW

devices with approximate spherical current patterns obey this equation. They will be discussed in a later section.

Cylindrical Current Flow - Guarded Devices

If a resistivity device is designed to maintain lateral current flow around a cylindrical source electrode emitting a constant current Io, cylindrical equipotential surfaces exist in the ideal case of a homogenous and isotropic medium. See Figure 12 below.

FIG: 12 Cylindrical Current Flow

For this geometry the surface area and current density are:

A = 2rh ,

J = Io /2rh

TRAINING MANUAL

23

RESISTIVITIES FOR DIFFERENT CURRENT FLOW GEOMETRYS

RESISTIVITY THEORY

We want to find the resistivity between the source surface of radius ro and some equipotential surface a distant L from the center. The absolute potential at the surface of the source electrode is VO and the absolute potential at our reference surface is VL. As before, E, J, and dr are parallel and we use Equation 6.

V0 - VL = -

ro

L

E dr E dr = - R

V0 - VL = -

ro

L

ro

L

J dr = - R

ro

L

I 0 dr 2rh

V0 - VL = -

2h

dr = - 0 1nr r 2h

ro L

2h

1nr

1-19

V0 - VL = -

I 0R 1n ( L / r0 ) 2 h

In terms of R, 1-20.

Vo - VL R=K Io

Where K is now given by 1-21.

2h K = ln L/ro

If L is chosen at a sufficiently large distance (not ) the potential at L is negligible (VL 0). In this case: 1-22.

K Vo R = Io

24

TRAINING MANUAL

RESISTIVITY THEORY GEOMETRYS

RESISTIVITIES FOR DIFFERENT CURRENT FLOW

We see that for this type of device, R can be computed from the tool current flow pattern, the current, and the absolute potential at the source electrode (i.e., the potential difference between a surface ground and the source electrode).

ELECTRODE LOGGING DEVICES

Defining the Tool - Resistivity vs Conductivity

Equation 1-5 holds for all types of electrode tool systems in which current is emitted from the tool into the borehole. Obviously, electrode tools do not work in non-conductive borehole fluids such as oil base muds, or air-filled boreholes. The definitions of these tools as either resistivity or conductivity is determined by the measured parameter. If the measured parameter is voltage, with the current held constant, Equation 1-5 can be written:

Vm R = K Io

Here Vm is the measured voltage. It is directly proportional to R, (resistivity). This type of device is designated as a resistivity tool. If the measured parameter is the current with voltage being constant, then Equation 5 can be written:

1

1-23.

= =K

Im Vo

-1

Here Im is the measured current. It is inversely proportional to R and therefore directly proportional to , (conductivity). This type of device is designated as a conductivity tool. If there is variation in current and voltage, then Equation 1-5 can be written:

Vm

1-24.

R=K Im

= K ratm

This type of device is referred to as a resistivity tool; the more correct term might be resistivity/conductivity tool or simply ratio tool

TRAINING MANUAL

25

RESISTIVITY THEORY

RESISTIVITY TOOLS

RESISTIVITY TOOLS

Unfocused Devices (ES Tools) Lateral Tool

The early unfocused resistivity devices, called ES (Electrical Survey) tools, actually incorporated a four electrode system. The tools were not actually placed in an infinite, homogenous, and isotropic medium because (1) a borehole is required and (2) no formation is infinite, homogenous, or isotropic. Of the four electrodes, two were used as current electrodes (one transmitted current and the other received the current), and the other two were used as monitor electrodes (they measured the potential at different locations). The illustration below is one ES type tool. It is called a Lateral Tool.

FIG: 13 Lateral Tool

TRAINING MANUAL

31

RESISTIVITY TOOLS

RESISTIVITY THEORY

Current is emitted from the source electrode A to the return electrode B (on the surface). The potential difference between M and N is measured. The distance between M and N is small compared to the spacing between A and the midpoint of M and N (the point O in the illustration). Originally, the distance MN was 32 inches and the spacing AO was 18 feet and 8 inches. The spacing AO defines the investigational region. With this large spacing, the lateral tool could record the resistivity of the uninvaded (virginal) zone. Because of its unfocused nature, the current flow pattern exhibits approximately spherical symmetry and therefore the equipotential surfaces are somewhat spherical in shape. We can use Equations 1-17 and 1-18.

K (VM - VN) R= I0 K= ( 1

4 ) AN 1

AM

32

TRAINING MANUAL

RESISTIVITY THEORY

RESISTIVITY TOOLS

Normal Tool

Another unfocused ES is a Normal Tool. Constant current is passed between the source electrode A and returns electrode B (at the surface). The measured voltage (potential difference) appears between electrodes M and N.

FIG: 14 Normal Tool

From the illustration we see that the N electrode is sufficiently far from the source electrode A (i.e. AN ) that VN is negligible (i.e. VN 0). Equations 1-17 and 1-18 are applicable for these types of devices (producing approximately Spherically symmetric current patterns) and for a normal tool configured as in the above Figure, the equations reduce to: 1-25.

K VM R= I0 , K = 4AM

The remaining distance AM is called the spacing, and determines the depth of investigation. Originally for the Short Normal device a shallow investigation was achieved by having AM = 16". The Long Normal investigated deeper and had AM = 64". For both lateral and normal tools, R as computed from equation 1-17 and 1-18 is reasonably accurate provided the formation is sufficiently thick and homogenous and borehole effects are negligible.

TRAINING MANUAL

33

RESISTIVITY TOOLS

RESISTIVITY THEORY

Problems Associated With The ES Tools

Prior to 1950, resistivity logging consisted of running simultaneously a Short Normal, a Long Normal, and a Lateral tool. With this combination, three different depths of investigation were possible, with the deepest being provided by the lateral tool. Although used very extensively for a number of years (approximately 20 years) the ES tools produced logs that were difficult, sometimes almost impossible to interpret. Extensive charts were required to correct for borehole, bed thickness, and adjacent-bed resistivity effects. It was found that the curves were relatively useless for bed thickness less than 1.5 times the spacing, i.e. 28 ft. for the Lateral and 8 ft. for the Long Normal. The Short Normal curve was the most usable, but it was severely affected by invasion. The basic problem with the ES logs was that the direction of the survey current was not controlled. This current took the path of least resistance, favoring conductive mud and conductive shoulder beds over resistive beds at the level of the tool.

FIG: 15 Unfocussed Tool - Possible Current Path

As a result of all the problems, the Normal and Lateral curves was replaced in the 1950s by focused logs in which the path of the survey current was controlled. The focusing minimized borehole and adjacent bed effects and provided good bed resolution. Two types of focused tools were introduced. One was the Induction tool that works by inducing (not injecting) a current flow of closed loops concentric with the tool axis in the formation. This tool works best in non-conductive or low conductivity borehole environments (oil based muds, air filled boreholes or fresh mud systems). The other tool was the laterolog device. This is an electrode type "Guard" tool that works well in very conductive boreholes (i.e. salt mud systems). The Induction tool is fully discussed in the Induction Training Notes.

34

TRAINING MANUAL

RESISTIVITY THEORY

RESISTIVITY TOOLS

Focused Devices (Laterolog Tools)

Laterolog systems utilize a multiple electrode array to force survey current to travel laterally across the mud and into the adjacent formation. The advantages of this technique are the ability to operate in very salty mud, while providing excellent bed definition, independent of neighboring bed resistivities. There are two basic types of focused-electrode laterolog arrays. One is the 3-electrode system commonly called guard log or LL3 and the other is the 7 to 13 electrode system, with designation LL7, LL8, and dual laterolog (with 9 to 13 electrodes). Both systems operate on much the same principle, as illustrated below showing the LL7 and LL3.

FIG: 16 Laterolog 3 (LL3)

FIG: 17 Laterolog 7 (LL7)

TRAINING MANUAL

35

RESISTIVITY TOOLS

RESISTIVITY THEORY

For an understanding of the focusing feature we will take an in-depth look at the laterolog 7 devices. These types of logging tools are designed in such a way that the source current is kept from flowing up and down in the drilling fluid. This is accomplished by placing focusing electrodes on both sides of a centrally located source electrode as seen in the LL7 representation. All of the electrodes are maintained (essentially) at the same potential and send currents out in the same sense (i.e. all currents have the same phase). Since like charges repel and unlike charges attract, the current flowing out of the upper and lower guard electrodes (A1U and A1L) tends to repel the current flowing out of the center electrode (AO). The center current pattern (i.e. the survey current) is therefore kept from flowing upward toward A1U or down toward A1L. The survey current Io is forced to flow in a horizontal layer at right angles to the borehole before it begins to flow toward the return electrode. To keep the Ao, A1U and A1L electrodes at approximately the same potential, (which keeps Io focused) as the tool moves upward through the successive formation beds during logging, two sets of monitor electrodes are used. If a potential difference is sensed across a set of monitor electrodes (either across M1U and M2U or across M1L and M2L), indicating that the survey current lateral pattern is not being maintained, the potential of the guard electrodes (A1U and A1L) is increased or decreased to maintain the focused cylindrical (disc shape) path of survey current Io into the formation. Increasing the potential of the guard electrodes tends to "push" the survey pattern away from the electrodes. Decreasing the potential of the guard electrodes tends to "pull" the survey pattern toward the electrodes. This push or pull feature is essential in maintaining the correct vertical resolution. As an example, a very thin resistive bed across from Ao surrounded by conductive beds would require the system to "push" the survey current into the resistive bed since the current would separate and migrate above and below the bed. A very conductive bed whose thickness is less than the required disc thickness (usually 2 feet) surrounded by resistive beds will require the electrodes to "pull" the survey current pattern toward the electrodes, thus increasing the disc height. This is illustrated below.

FIG: 18 Thin Bed Effect

36

TRAINING MANUAL

RESISTIVITY THEORY

RESISTIVITY TOOLS

The resistivity of the formation is computed from the physics of the measurement assuming cylindrical equipotential surfaces. If we assume that the monitor electrodes are maintaining lateral survey flow, the current distribution pattern (ideally) is a uniform cylindrical disc as shown below.

FIG: 19 Ideal Current Pattern For Laterolog Tools

The resistivity is computed from Equations 21 and 22 respectfully:

V0 R=K I0 2h K = ln L/r0

Here h is the thickness of the cylindrical disc, L is the length and is dependent on the radial distance this disc shape is maintained, and r0 is the radius of the cylindrical source electrode. Equations 1-21 and 1-22 are applicable for all laterolog (guard) tools.

TRAINING MANUAL

37

RESISTIVITY TOOLS

RESISTIVITY THEORY

* NOTE: The above equation only provides an approximated K value for laterolog tools. A more

correct expression is obtained by computer, mathematical modeling with real borehole formation effects considered

The original laterolog-7 (LL7) differed from the original laterolog-3 (LL3), in that it used small guard electrodes, while the LL3 used long guard electrodes (5-6 feet) and the LL7 used monitor electrodes to ensure lateral flow. At present, a shortened guard version of the LL3 (less than 18") is used for a shallow Rxo (invaded zone resistivity). The length of a guard defines, to a great extent, the depth of investigation (we must also consider the return path). The Dual Laterolog Tool system was introduced in the 1970s. The system provided simultaneous deep and medium curves produced from a dual focusing electrode array of up to 13 electrodes. The focusing feature produces two cylindrical current discs of different radial lengths (L) but with the same thickness (h). The resistivity for both the shallow and medium system is again computed from Equations 1-21 and 1-22 with the appropriate input constants and measured parameters.

38

TRAINING MANUAL

RESISTIVITY THEORY

DUAL LATEROLOG MEASUREMENTS

DUAL LATEROLOG MEASUREMENTS

Dual Laterolog Tool Principles

The dual laterolog system uses both small and large guard electrodes. The operational aspect of this tool is the same as the LL7, except now we have both a deep and shallow system working simultaneously. This is the dual aspect of that tool. For both systems, horizontal cylindrical discs are maintained by the action of the guard and monitor electrodes. The systems, using the same electrodes, operate at different frequencies and have different depths of investigation. Both systems maintain the same vertical resolution of 2 feet (disc thickness). The deep tool needs long guards and remote current return, while for the shallow it is necessary for the guards to be short and the return relatively near (on the tool). Figures 20 and 21 shows the electrode arrangement and current patterns.

TRAINING MANUAL

39

DUAL LATEROLOG MEASUREMENTS

RESISTIVITY THEORY

The shallow (LLS) current layer (disc) starts to spread after a short distance into the formation. The reason is the focusing currents are emitted from electrodes A1U and A1L and the returns are the nearby A2U and A2L electrodes. To keep the survey current focused, the shallow system monitors the values of the Electrodes M1 and M2 upper and lower. From these measurements, the system will control the upper and lower focusing routine, with each one (upper or lower) being controlled independently. The designations of the electrodes used here are for illustrative purposed and are different from those in the DLLT Manual.

FIG: 20 Dual Laterolog Tool Shallow Current Pattern

40

TRAINING MANUAL

RESISTIVITY THEORY

DUAL LATEROLOG MEASUREMENTS

The deep laterolog measurement requires a long guard system. The focusing above A0 is accomplished by combining the outputs from the A1U and A2U electrodes. Below A0, the outputs from the A1L and A2L electrodes are combined. The return for the deep pattern is an electrode approximately 75 feet away from A0. The combination of long guards and the remote return, causes the layer of logging current to hold its horizontal thickness far into the formation. To keep this deep system focused, monitor electrodes M1, M3, and M4 (upper and lower are utilized).

FIG: 21

TRAINING MANUAL

41

DUAL LATEROLOG MEASUREMENTS

RESISTIVITY THEORY

Different frequencies are used by the different systems. For the shallow measurement a frequency of 1050 Hz is used; whereas for the deep (which requires a lower frequency), 131 Hz is used. Because each system is sensitive to its own frequency, continuous recording of data is attained. The tool measure's values of v o and I o and using Equations 1-21 and 1-22, two resistivity values are determined. Two different K values are required for the resistivity computations, due to the different radial investigations (this changes the value of L in equation 1-21).

Depth of Investigation And Vertical Resolution

For any specific arrangement of electrodes, the distance into the formation for which the current maintains its lateral (disc shaped) pattern is the depth of investigation associated with that specific arrangement (see below). This is true because as the current lines begin to spread, the cross sectional area of the current path increases, which effectively makes the resistance associated with that region of space negligible. The vertical resolution is approximately the height of the disc. Figure 22 depicts this, and shows that for the Dual Laterolog, the deep measures approximately 5-7 ft. into the formation; whereas, the shallow is 2-3 ft. The vertical resolution is approximately 2 ft. for both.

Deep 5 - 7 ft Shallow 2 - 3 ft

Deep 5 - 7 ft

Shallow I I 2 - 3 ft

I I

2 ft

I I I

FIG: 22 DLLT Depth Of Investigation And Vertical Resolution

42

TRAINING MANUAL

RESISTIVITY THEORY

DUAL LATEROLOG MEASUREMENTS

Radial Resistivity Profile

When using a dual laterolog, under normal ideal conditions, the radial profile of resistivities is as shown below (i.e. Rm < Rxo < Rt). Between the invaded (flushed) zone and the undisturbed formation, there is a transition zone that has a resistivity value between the values of Rt and Rxo. Figure (24) is a diagram showing a plane view of a horizontal slice made through the tool and the formation that surrounds it. This figure shows current flowing radially outward from the tool and passing through the mud, the invaded zone, and the undisturbed formation before arriving at the return electrode.

FIG: 23 Radial Distribution Of Resistivities

TRAINING MANUAL

43

DUAL LATEROLOG MEASUREMENTS

RESISTIVITY THEORY

FIG: 24 Laterolog Current Paths

If held constant, the current will then develop a series of voltage drops across each zone encountered. The relationship between these voltages can be simplistically written as: 1-26.

Vtotal = Vmud + Vinvaded + Vundisturbed

Each voltage drop is proportional to the product of the current, the resistivity of the zone, and some relative weight function, Ji, that gives the percentage that zone contributes to the total signal.

44

TRAINING MANUAL

RESISTIVITY THEORY

DUAL LATEROLOG MEASUREMENTS

1-27.

Vtotal = Jm (IRm) + Jxo (IRxo) + Jt (IRt)

Here

Vmud = Jm (IRm), Vinvaded = Jxo (IRxo), Vundisturbed = Jt (IRt)

Vtotal is related to the measured current I and the resistivity (RLL) measured by the tool

by:

Vtotal = IRLL

Thus, the equation for resistivity measured by the laterolog (RLL) can be written as: 1-28.

RLL = Jm Rm + Jxo Rxo + Jt Rt

Logically, Jm will depend on the hole size, while Jxo and Jt will depend on the invasion diameter (di) and on the contrast between Rt and Rxo. The sum Ji must be one by definition. An equivalent electrical circuit for a laterolog measurement is shown below.

FIG: 25 Equivalent Electrical Circuit For Laterolog Measurement

We see that in the laterolog tool the zones add in series. The tool therefore responds primarily to the most resistive zone. This is in contrast to an induction tool that sees zones surrounding the tool (including the shoulder bed) as adding in parallel and thus responds to the most conductive zone (conductivity device).

TRAINING MANUAL

45

DUAL LATEROLOG MEASUREMENTS

RESISTIVITY THEORY

Referring to Equation 1-28, usually the mud column contributes a small signal and in most cases can be ignored (Jm 0). The usual exception is in large boreholes, in which case borehole correction charts are available to correct for this effect. Figure 26 shows the correction charts used for the laterolog deep reading. Therefore, after correcting for the mud effect, the laterolog response in an invaded formation is described by the pseudo geometrical factors, Jxo and Jt. The term "pseudo" refers to the fact that, as previously mentioned, Jxo and Jt are not only a function of the invasion diameter, but they also depend on the contrast between Rt and Rxo. From Equation 28 we now write: 1-29.

RLL = Jxo Rxo + Jt Rt Since i Ji = 1, Jxo + Jt = 1 RLL = Jxo Rxo + (1 - Jxo) Rt

Dropping the subscript on Jxo, J is called the pseudo radial geometrical factor, and Equation 29 takes the final form: 1-30.

RLL = JRxo + (1 - J) Rt

J is a variable with a value between 0 and 1; at di = 0, J = 0; at di = , J = 1. Each of the two laterolog measurements (deep and shallow) has its own J-di relationship as shown in figure 27.

46

TRAINING MANUAL

RESISTIVITY THEORY

DUAL LATEROLOG MEASUREMENTS

*NOTE: In practice, along with the borehole correction, a bed thickness correction is also applied to

the log before invasion corrections are applied.

FIG: 26 Deep Laterolog Borehole Correction

TRAINING MANUAL

47

DUAL LATEROLOG MEASUREMENTS

RESISTIVITY THEORY

FIG: 27 Pseudo Geometrical Factor

SPHERICAL FOCUSING

Spherically Focused Logging Tool (SFL)

We have already discussed the problems associated with the early electric survey tools. The main problem being that the direction of the survey current was not controlled but took the more conductive (less resistive) path (see Figure 15). The laterolog devices improved the situation by forcing the survey currents to flow in a lateral, disc shaped pattern by introducing guard electrodes above and below the center current emitting electrodes (see Figure 17). Another focusing method was introduced by Schlumberger (as a replacement for the short normal) that forces the survey current to produce a spherical flow pattern into the formation. The tool was called an SFL (Spherically Focused Log), and was designed to make a shallow measurement (primarily influenced by R xo ). If a tool system is maintaining a truly spherical current flow pattern in the formation, equipotential surfaces are spheres. For this case, the geometry associated with the flow will be that of Figure 11, and the associated equation for the potential difference (voltage) between two equipotential surfaces M and N is given by the lateral equation.

FIG: 28 Two Concentric Equipotential Spheres

48

TRAINING MANUAL

RESISTIVITY THEORY

SPHERICAL FOCUSING

1-31.

VM VN =

I0 R 1 1 4 AM AN

{same as Equation 16}

Which as before reduces to: 1-32.

R =

K ( VM VN ) I0

{same as Equation 17}

or in terms of conductivity 1-33.

K -1 I 0 ( VM VN )

TRAINING MANUAL

49

SPHERICAL FOCUSING

RESISTIVITY THEORY

The SFL was designed to measure the conductivity of a region of formation just outside the borehole and extending vertically a short distance either side of the A o electrode. The actual electrode placement on the sonde along with the ideal current distribution pattern is shown below.

Figure 29 Current Pattern

To achieve the pattern above, two current systems are required. The bucking current I b leaves the A o electrode and returns to A 1 and A 1 by traveling through the borehole. The survey current I o leaves A o and is returned to the remote electrodes (Cable Armor and lower tool body). The combined effect is that I o is forced into the formation since I b creates a barrier in the borehole (i.e. I o cannot cross I b ).

50

TRAINING MANUAL

RESISTIVITY THEORY

SPHERICAL FOCUSING

Micro-Spherical Focusing (MSFL Theory)

Even though the results with the SFL tool were far better than the short normal, the spherical focusing deteriorates under very high R t R m contrast because very large bucking currents are required to flow in the mud since I b is responsible for the maintenance of the equipotential shells inside the borehole. The next logical step was to produce a pad-type miniature version of the SFL, to eliminate borehole effects and achieves superior shallow investigation. The result was the MicroSpherically Focused Tool (MSFL). The MSFL is the state-of-the-art in R xo (flushed zone resistivity) measurements. It provides good results under a wide range of invasion and mudcake thickness. The MSFL electrode arrangement is shown in figure 30. Notice the number and geometrical distribution of electrodes, as well as the resulting current flow patterns, is the same as the SFL.

FIG: 30 MSFL Pad And Current Patterns

The actual physical description of the pad face is shown in the lower left corner. The electrodes are rectangular, metal strips concentrically molded into the rubber pad body. The electrodes are recessed in the rubber surface.

TRAINING MANUAL

51

SPHERICAL FOCUSING

RESISTIVITY THEORY

In a manner "identical" to the SFL, the MSFL provides spherical focusing and a value for the flushed zone conductivity. In describing the specifics of the tool operation, we can first start by simply explaining the functions of the two current loops produced from the two separate, but interacting, current feedback systems. I b (the bucking current) is responsible for (1) preventing I o from flowing through the mudcake, and (2) establishing and maintaining (by interacting with I o ) the constant potential difference across the spherical shell. I o is responsible for (1) preventing I b from flowing across the monitor electrode pair, M 1 - M 2 (this keeps I b essentially traveling vertically through the mudcake to A 1 and A 1 ), and (2) providing the measurement proportional to flushed zone resistivity. Now we can provide a little more detail. The current leaving the central electrode A o is I T . I T consist of the two components: bucking current and the two components surveys (measure) current. Here I b and I o represent both the upper and lower components, (it would probably be more correct to refer to the bucking and survey currents as 2 I b and 2 I o , respectively). The bucking currents return to symmetrical electrodes A 1 and A 1 . I b , which is restrained to essentially flow in the mudcake due to the very small spacing of the electrodes and its interaction with I o , establishes a current barrier for I o . I o is forced to flow deeper into the formation by the "bucking action" of the I b current lines (i.e. like currents repel). I o is returned to a remote electrode that is the mandrel body The resulting equipotential surfaces due to the combined current paths are approximately concentric spheres (or to be more exact, hemi-spheres) as shown by the dashed lines in Figure 30. The I o current system is driven by the potential difference between the M 1 - M 2 electrode pair. The I o current is adjusted continuously and automatically to make this difference zero (i.e. v M1 - v M2 = 0). The effect of this is to create an equipotential barrier between M 1 - M 2 which further confines I b in the vertical direction. The potential difference being zero insures the bucking current will not flow across the pair (current flows only across a potential difference). The MSFL resistivity is computed across the spherical shell of thickness M o M 1 (to be exact the shell thickness is between the M electrode and the M 1 M 2 center tap) using Equation (17). Halliburton has two versions of the MSFL. The G-series tool maintains the potential across the shell at a constant reference value, v R . This makes this a conductivity tool. On the other hand, the W-series (DITS) allows both the current and voltage to vary, measuring both. This is a ratio tool.

52

TRAINING MANUAL

RESISTIVITY THEORY

SPHERICAL FOCUSING

The actual pad size and electrode spacing determine where in space the spherical shell is located (i.e. the investigational region). The pad dimensions are such that this shell is deep enough to avoid the mudcake, but not too deep as to be significantly influenced by the uninvaded zone. The MSFL external pad system is shown in figure 31.

FIG: 31 MSFL Sonde

TRAINING MANUAL

53

SPHERICAL FOCUSING

RESISTIVITY THEORY

Microguard Tool (MG)

The W-series Dual Laterolog Tool (depending on the version) can be run with the MSFL or another type microresistivity device called the Microguard or (MG). This tool is also sometimes referred to as the FORXO (as in for R xo ). To make its measurement, the Microguard uses a pad that contains a central button electrode that is encircled by a guard ring electrode. The current from the guard ring provides the focusing feature. Figure 32 below shows the features of the Microguards and current flow patterns. Notice that a side view of the current flow pattern shows the Microguard to be like a pad type LL3.

FIG: 32 Microguard Current Flow

Operationally, current from the guard ring focuses the survey current, the current from the central electrode, by forcing this current to only flow radially away from the tool. This current flows into the first few inches of the formation (the flushed zone) and returns to the Microguard Mandrel housing.

54 TRAINING MANUAL

RESISTIVITY THEORY

SPHERICAL FOCUSING

Invasion Effects - The Butterfly Chart

Since the dual laterolog provides two resistivity values at different radial depths, Equation 1-30 can be broken into the deep and shallow components (after borehole corrections). 1-34. 1-35.

RLLD = JD Rxo + (1 - JD ) Rt RLLS = JS Rxo + (1 - JS) Rt Where JD = JD (di), JS = JS (di)

The dual laterolog is usually combined with some kind of very shallow investigation device. This is usually one of the pad micro-resistivity system such as the MSFL (or MG) which allows us to determine a value for Rxo. When this resistivity is also borehole corrected, we obtain two equations and two unknowns. With the borehole corrected MSFL resistivity assumed equal to Rxo, (as a first approximation) Equation 1-34 and 1-35 shows the unknowns is Rt and di. Note that JD and JS are a function of the same diameter of invasion. The Butterfly Chart (figure 31) is used for invasion effects. It graphically solves our two equations. The chart plots RLLD/Rxo vs RLLD/RLLS. From the chart, correct values for Rt and di are obtained, as well as a more correct value for Rxo.

TRAINING MANUAL

55

SPHERICAL FOCUSING

RESISTIVITY THEORY

FIG: 33 Laterolog Invasion Correction Chart

56

TRAINING MANUAL

RESISTIVITY THEORY

SPHERICAL FOCUSING

Dual Laterolog Fingerprints

The behavior of the dual laterolog-MSFL (or the Dual Laterolog-MG) in zones with movable hydrocarbons permits simple quick-look interpretation. One good rule-of-thumb is the hydrocarbons are indicated where R LLD > R LLS > R MSFL . Conversely, the pattern R MSFL > R LLS > R LLD is a good indication that the zone is wet (100% water saturation). The log example of figure (34) demonstrates these features.

FIG: 34 Finger Print Log

TRAINING MANUAL

57

SPHERICAL FOCUSING

RESISTIVITY THEORY

The Microlog Tool

The Microlog tool is a simple three-electrode, non-focused electrical logging device. It was originally used to indicate porosity. When that use was supplanted by modern porosity devices such as the density, neutron, and sonic logs, use of the microlog fell off dramatically. It has seen increasing use, however, since the mid-1980s. The tool is valuable because it offers a superb means to identify mud cake and, therefore, permeable zones. The Microlog is normally run as a separate tool, but Halliburton has also combined this resistivity measurement with the density tool by placing a Microlog pad on the density caliper arm. This combination, of course, has the added advantage of indicating mud cake (and therefore confirming the Microlog measurement) when the caliper reads less than drill bit size. The electrode configuration on the pad is shown below.

FIG: 35 Electrode Configuration

58

TRAINING MANUAL

RESISTIVITY THEORY

SPHERICAL FOCUSING

Operationally, a constant survey current is emitted from the lower button. This current flows through the mud cake, formation, and borehole before returning to the tool case. A Micronormal resistivity curve is recorded by measuring the potential between the upper or middle button and tool case. Similarly a Microlateral (also called a microinverse) is recorded by measuring the potential between the middle and upper buttons. For this tool, the depth of investigation of the Micronormal is approximately twice the spacing between A o and the other button that is used. For the upper button, this gives a depth of investigation of 4 inches. Using the measurement from the middle button we obtain a 2 inch depth of investigation. For the Microlateral, the depth of investigation is approximately equal to the spacing between A o and the measure point (the mid point of the upper and middle electrodes). This gives a value of 1.5 inch.

TRAINING MANUAL

59

SPHERICAL FOCUSING

RESISTIVITY THEORY

ing the 2 inch Micronormal (with 4 inch depth of investigation) and the Microlateral, when no mud cake is present, as in impermeable zones, both curves should read the same value (i.e., they overlay). Thus the curves overlay in shales or in impermeable sands or carbonates if resistivity is not too high. The presence of mud cake will cause the curves to separate. The mud cake generally has lower resistivity than the flushed zone. Since the Microlateral measurement has the shallowest depth of investigation, it should respond primarily to the mud cake, and read a lower resistivity than the Micronormal. The presence of mud cake (permeability) is indicated by a positive separation between the Micronormal and Microlateral curves (Micronormal > Microlateral) and the Microlateral reads close to R mc . The Log example below shows this effect.

FIG: 36 PERMEABILITY INDICATOR LOG

60

TRAINING MANUAL

RESISTIVITY THEORY

SPHERICAL FOCUSING

REFERENCES

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Bateman, Richard M., Open-Hole Log Analysis and Formation Evaluation, IHROL, Boston, 1985 Dewan, John T., Essentials of Modern Open-Hole Log Interpretation, Penn Well Publishing Company, Tulsa, Oklahoma, 1983 Study Guide-Dual Laterolog, Gearhart Publications Formation Evaluation Chart Book, Gearhart Publications Pirson, Sylvain, Handbook of Well Log Analysis, Prentice-Hall, Inc, Englewood Cliffs, N.J., 1963 Houston Chapter-SPWLA, The Art of Ancient Log Analysis, Houston, Texas, 1979 Martin, Maurice H., and Louis A. Allaud, Schlumberger, The History of a Technique, John Wiley and Sons, New York, 1977 Bueche, Fredrick J., College Physics, Schaum's Outline Series, McGraw-Hill Book Company, New York, 1979 Sears, Francis W. and Mark W. Zemansky, University Physics, Addison-Wesley Publishing Company, Reading, Mass., 1977 Stratton, Julius Adams, Electromagnetic Theory, McGraw-Hill Book Company, New York, 1941 Thomas, George B., Calculus and Analytic Geometry, Addison-Wesley Publishing Company, Reading, Mass., 1969 Weidner, Richard T., and Robert Sells, Elementary Classical Physics, Allyn and Bacon, Inc., Boston, 1965 Study Guide-Micro Resistivity, Gearhart Publications

TRAINING MANUAL

61

You might also like

- Silicon Integrated Circuits: Advances in Materials and Device ResearchFrom EverandSilicon Integrated Circuits: Advances in Materials and Device ResearchDawon KahngNo ratings yet

- Well LoggingDocument25 pagesWell LoggingMohd Wirawan PutraNo ratings yet

- Chapter1 PDFDocument7 pagesChapter1 PDFhafedhNo ratings yet

- An Overview of LoggingDocument43 pagesAn Overview of LoggingVaibhav BhardwajNo ratings yet

- PetEvalCh1 PDFDocument16 pagesPetEvalCh1 PDFIbtihaj AtiqNo ratings yet

- WIRELINE LOGGING MANUAL V1 Ch2 Tool Descriptions: October 1986Document29 pagesWIRELINE LOGGING MANUAL V1 Ch2 Tool Descriptions: October 1986Min Thant MaungNo ratings yet

- Well Logging in Oil & Gas Industry - WikipediaDocument7 pagesWell Logging in Oil & Gas Industry - WikipediaFaiz Ahmad100% (1)

- Induced Polarization: A R3Ethou OF Geophysical ProspectingDocument26 pagesInduced Polarization: A R3Ethou OF Geophysical ProspectingjoseNo ratings yet

- Introduction To Well Logging: 1.1 Oil and Gas ExplorationDocument16 pagesIntroduction To Well Logging: 1.1 Oil and Gas ExplorationAMAR DWI PURNOMONo ratings yet

- The Effects of Hydrostatic Pressure On The Properties 111-V SemiconductorsDocument16 pagesThe Effects of Hydrostatic Pressure On The Properties 111-V SemiconductorsJose Leon GonzalezNo ratings yet

- Understanding Piezoelectric Quartz CrystalsDocument5 pagesUnderstanding Piezoelectric Quartz CrystalsfabirznNo ratings yet

- Ultrasonics PhysicsDocument14 pagesUltrasonics PhysicsafifezzatNo ratings yet

- Well Logging History PDFDocument9 pagesWell Logging History PDFClaudia MontañoNo ratings yet

- Physical Treatise 01 Go Rdu of TDocument436 pagesPhysical Treatise 01 Go Rdu of TEttel YuangNo ratings yet

- Kuenstliche WasseradernkreuzungDocument26 pagesKuenstliche WasseradernkreuzungSven PetkovNo ratings yet

- Piezoelectric History: Discovery and InsightsDocument5 pagesPiezoelectric History: Discovery and InsightsBülentAlkanNo ratings yet

- 49 - Electrical LoggingDocument42 pages49 - Electrical Loggingrizal tri susilo100% (1)

- Cern 94 01 V1Document523 pagesCern 94 01 V1Diego Antonio Rodriguez CoronadoNo ratings yet

- History of SemiconductorsDocument14 pagesHistory of SemiconductorsSergio Andres Fajardo SaldarriagaNo ratings yet

- Peter Graneau's Paper On Over-Unity Power From Arcs in FogDocument3 pagesPeter Graneau's Paper On Over-Unity Power From Arcs in Fogjrod100% (1)

- Douglas G. Tasker, Richard J. Lee and Paul K. Gustavson-The Measurement of Electrical Conductivity in Detonatiing Condensed ExplosivesDocument59 pagesDouglas G. Tasker, Richard J. Lee and Paul K. Gustavson-The Measurement of Electrical Conductivity in Detonatiing Condensed ExplosivesGhoree23456No ratings yet

- History of LoggingDocument5 pagesHistory of LoggingMudLogggerAUSNo ratings yet

- One Degree of Freedom Resonance Wave Energy ConvertorDocument11 pagesOne Degree of Freedom Resonance Wave Energy ConvertorMr PolashNo ratings yet

- CGE 674 CGE 674 CGE 674 CGE 674 Formation Evaluation Formation Evaluation Formation Evaluation Formation EvaluationDocument65 pagesCGE 674 CGE 674 CGE 674 CGE 674 Formation Evaluation Formation Evaluation Formation Evaluation Formation EvaluationNamwangala Rashid NatinduNo ratings yet

- Alberto A. Martinez - Replication of Coulombs Torsion Balance ExperimentDocument47 pagesAlberto A. Martinez - Replication of Coulombs Torsion Balance ExperimentAleph CardeckNo ratings yet

- DIPESH PHY PROJECT (Super Conductors)Document23 pagesDIPESH PHY PROJECT (Super Conductors)Dipesh GuptaNo ratings yet

- Ion Gauge TheoryDocument14 pagesIon Gauge TheoryDan Ste MarieNo ratings yet

- Gravity Nullified Antigravity Free EnergyDocument9 pagesGravity Nullified Antigravity Free EnergyMariusNo ratings yet

- Archaeology TechniquesDocument7 pagesArchaeology TechniquesvanpatoNo ratings yet

- Electrochimica Acta: Claude GabrielliDocument20 pagesElectrochimica Acta: Claude GabrielligabrielliNo ratings yet

- Electrochimica Acta: Claude GabrielliDocument20 pagesElectrochimica Acta: Claude GabrielligabrielliNo ratings yet

- The Evolution of Log Analysis MethodsDocument3 pagesThe Evolution of Log Analysis Methodsvelkus2013No ratings yet

- Shell Buckling LinearDocument17 pagesShell Buckling LineargiuseppeNo ratings yet

- Biefeld Brown Effect - Cetin BAL - GSM - +90 05366063183 - Turkiye - DenizliDocument13 pagesBiefeld Brown Effect - Cetin BAL - GSM - +90 05366063183 - Turkiye - DenizliBarry Wood100% (2)

- 10 3997@1873-0604 2017063 PDFDocument16 pages10 3997@1873-0604 2017063 PDFmahmood jassimNo ratings yet

- Chapter 3: Reservoir CharacterizationDocument23 pagesChapter 3: Reservoir CharacterizationKarlina DewiNo ratings yet

- Efficiency and AuthorityDocument28 pagesEfficiency and Authority홍성욱No ratings yet

- The Variation With Temperature of The Dynamic Properties of Rubber and Sythetic RubberDocument7 pagesThe Variation With Temperature of The Dynamic Properties of Rubber and Sythetic RubberHue Trang Nguyen ThiNo ratings yet

- Historical Background: Resistivities Ohms MZ/MDocument3 pagesHistorical Background: Resistivities Ohms MZ/MAnonymous gJ0dR3No ratings yet

- Well LogsDocument3 pagesWell LogsRizwan FaridNo ratings yet

- Logging History Rich With Innovation: Subsurface Data IntegrationDocument4 pagesLogging History Rich With Innovation: Subsurface Data IntegrationAsahel NuñezNo ratings yet

- Nutionai Geophysical Research Institute, Hyderabad (India)Document10 pagesNutionai Geophysical Research Institute, Hyderabad (India)Raul Marihuan GonzálezNo ratings yet

- 0404005Document8 pages0404005Alfonso Bustamante100% (1)

- LCR CircuitDocument24 pagesLCR CircuitZinan KakkodanNo ratings yet

- Adsorption: Solid ElectrodesDocument84 pagesAdsorption: Solid ElectrodesNemo NeroNo ratings yet

- Fundamentals of Electrical Logging: Ified Jorm AlDocument8 pagesFundamentals of Electrical Logging: Ified Jorm AlAnonymous gJ0dR3No ratings yet

- PhysicsDocument73 pagesPhysicsCarmen DraghiaNo ratings yet

- Flow Measurement ABBDocument21 pagesFlow Measurement ABBAndy FloresNo ratings yet

- Radio Mobile4Document28 pagesRadio Mobile4Topcom Toki-VokiNo ratings yet

- Superconductivity: LntroductionDocument1 pageSuperconductivity: LntroductionNurul Fahmi AriefNo ratings yet

- Creeping-Wave Analysis of Acoustic Scattering by Elastic Cylindrical ShellsDocument121 pagesCreeping-Wave Analysis of Acoustic Scattering by Elastic Cylindrical ShellsMohamad HojjatiNo ratings yet

- Super Con Uc Tivity 2Document11 pagesSuper Con Uc Tivity 2surbhiNo ratings yet

- Progress in Electrogravitics and Electrokinetics FDocument11 pagesProgress in Electrogravitics and Electrokinetics FGary McKinnonNo ratings yet

- Well LoggingDocument80 pagesWell LoggingNagalakshmi ThirunavukkarasuNo ratings yet

- Characteristics of The Metal-Oxide-semiconductor Transistors 60sDocument22 pagesCharacteristics of The Metal-Oxide-semiconductor Transistors 60sMarcoNo ratings yet

- 05 Triaxial InductionDocument21 pages05 Triaxial InductioncarlosNo ratings yet

- BartonN 2022 Keynotelecture LARMS2022Document27 pagesBartonN 2022 Keynotelecture LARMS2022Sajjad AnwarNo ratings yet

- Ranajn Seminar Project F Report - DocinalDocument19 pagesRanajn Seminar Project F Report - Docinalrks02No ratings yet

- Well Logs: Prof. Dr. Hassan Z. HarrazDocument80 pagesWell Logs: Prof. Dr. Hassan Z. HarrazEzzadin BabanNo ratings yet

- Book ReviewDocument3 pagesBook Reviewdibakar_04No ratings yet

- United NationsDocument2 pagesUnited Nationsdibakar_04No ratings yet

- Trigonometric RelationsDocument1 pageTrigonometric RelationsDiego PonceNo ratings yet

- Its MagicDocument16 pagesIts MagicRaju100% (15)

- Yuzik Jesse 202001 MSCDocument130 pagesYuzik Jesse 202001 MSCLong An ĐỗNo ratings yet

- Dentistry Journal: Adhesion of Two New Glass Fiber Post Systems Cemented With Self-Adhesive Resin CementsDocument8 pagesDentistry Journal: Adhesion of Two New Glass Fiber Post Systems Cemented With Self-Adhesive Resin CementsDeisy Angarita FlorezNo ratings yet

- Centrifuge Modeling of The Cyclic Lateral Behavior of Large-Diameter Monopiles in Soft Clay Effects of Episodic Cycling and ReconsolidationDocument17 pagesCentrifuge Modeling of The Cyclic Lateral Behavior of Large-Diameter Monopiles in Soft Clay Effects of Episodic Cycling and ReconsolidationSunil Ranjan MohapatraNo ratings yet

- Manual 2WBDocument4 pagesManual 2WBAlfredo Zambra Alarcón Alias MorroNo ratings yet

- T BeamDocument17 pagesT BeamManojNo ratings yet

- Friction Coefficient Hdpe Slip MembraneDocument4 pagesFriction Coefficient Hdpe Slip MembraneBogdanBNo ratings yet

- Internal Arc Testing of MV Switchgear-Experience With IEC 62271-200Document5 pagesInternal Arc Testing of MV Switchgear-Experience With IEC 62271-200Zineddine BENOUADAHNo ratings yet

- Fator - Torque ValueDocument2 pagesFator - Torque Valuemahmoud fawzyNo ratings yet

- Fundamentals of Cavity PreprationDocument70 pagesFundamentals of Cavity PreprationSATNAMNo ratings yet

- MidMeki Manual DSY10003ADocument17 pagesMidMeki Manual DSY10003AMarivee DollosaNo ratings yet

- Smooth Spectra of Horizontal and Vertical Ground MDocument14 pagesSmooth Spectra of Horizontal and Vertical Ground MRamanathan GnanasambandamNo ratings yet

- Aerial Infrared Thermography For Low-Cost and Fast Fault Detection in Utility-Scale PV Power PlantsDocument14 pagesAerial Infrared Thermography For Low-Cost and Fast Fault Detection in Utility-Scale PV Power PlantsJoão TeixeiraNo ratings yet

- Etasr 4935Document9 pagesEtasr 4935Maulik ShahNo ratings yet

- Ece Correl 1 Quiz 2Document6 pagesEce Correl 1 Quiz 2pclr07No ratings yet

- B737-Flight Controls Systems SummaryDocument24 pagesB737-Flight Controls Systems SummaryTrailblazer487100% (1)

- Boga Ard 1985Document11 pagesBoga Ard 1985曾帅No ratings yet

- DA2103 - Structural SystemsDocument22 pagesDA2103 - Structural SystemsZULKEFLE ISMAILNo ratings yet

- PhysicsDocument19 pagesPhysicsapi-254985234No ratings yet

- Chem Notes (Yr11)Document46 pagesChem Notes (Yr11)nguyenbohaeNo ratings yet

- Properties of NR EPDM Blends With or Without Methyl Methac...Document12 pagesProperties of NR EPDM Blends With or Without Methyl Methac...CY KuoNo ratings yet

- Tie-In List (Epcc-09) : DOC. NO.: IBCE-6373-471-PRS-IFD-000-0001Document3 pagesTie-In List (Epcc-09) : DOC. NO.: IBCE-6373-471-PRS-IFD-000-0001srini100% (1)

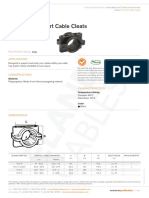

- Two Part Cable CleatsDocument1 pageTwo Part Cable Cleatssaghaee.rezaNo ratings yet

- NetCol5000-A In-Row Air Cooled Cooling Product DatasheetDocument2 pagesNetCol5000-A In-Row Air Cooled Cooling Product DatasheetalfredoculajayNo ratings yet

- Carnot's Theorem PDFDocument17 pagesCarnot's Theorem PDFAsif Mahmoud100% (1)

- Travelling Wave TubeDocument24 pagesTravelling Wave TubeEden DonatoNo ratings yet

- Case Study TrianglesDocument3 pagesCase Study TrianglesSifatNo ratings yet

- BOTIL Product CatalogueDocument176 pagesBOTIL Product CataloguenappyNo ratings yet

- Eckel Hydraulic Power Tong Model 20 PDFDocument31 pagesEckel Hydraulic Power Tong Model 20 PDFanon_74908267% (3)

- Electrical Standards SLD Symbols Legend PDFDocument13 pagesElectrical Standards SLD Symbols Legend PDFBuyankhishig MonkhbaatarNo ratings yet

- K Iev58 Ink 1Document5 pagesK Iev58 Ink 1Leandro Belardinucci LimaNo ratings yet