Professional Documents

Culture Documents

Abstract

Uploaded by

Ary RachmanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abstract

Uploaded by

Ary RachmanCopyright:

Available Formats

ABSTRACT

Plans of mud drilling methods used in a drilling largely determines the success or failure. Along with the rapid development of mud drilling technology, currently found mud types is characteristically very different from one another as a result of the added additives that is used to maintain the stability of mud on each depth. The drilling mud is also known for the use of polymer mud that essentially included in the mud system with the basic ingridients of salt water. The goal of adding weighting material Barite is to increase the density of drilling mud. At normal pressure, water and solids in the drilling is able to withstand the pressure of the formation. For pressures lower than normal (subnormal) density of the mud should be minimized so loss of circulation does not occur. In contrary, if the pressures are greater than normal then the addition of barite as a weight is necessary. On the other hand the main function of XCD polymer is as the main thickener in the sea water mud. It also served as a barrier to the weighting material. XCD begins to degrade at 350F and generally have less ability to control the filtration rate with the discovery of this polymer mud, a cost effective solution of the drilling operations has also been founded.

ii

You might also like

- Mud Weight VS TemperaturDocument45 pagesMud Weight VS TemperaturAry RachmanNo ratings yet

- Laporan LAb Fixed (Version 1)Document4 pagesLaporan LAb Fixed (Version 1)Ary RachmanNo ratings yet

- Tabel 1Document37 pagesTabel 1Ary RachmanNo ratings yet

- Water Well Drilling MethodsDocument21 pagesWater Well Drilling MethodsAry Rachman100% (3)

- Wellbore Strengthening Without Propping FracturesDocument1 pageWellbore Strengthening Without Propping FracturesAry RachmanNo ratings yet

- YYY YYY YYY YYY YYY Yyyyy Yyy YDocument9 pagesYYY YYY YYY YYY YYY Yyyyy Yyy YAry RachmanNo ratings yet

- Daftar Pustaka Tugas Akhir RahmanDocument1 pageDaftar Pustaka Tugas Akhir RahmanAry RachmanNo ratings yet

- Well Intervention and ControlDocument10 pagesWell Intervention and ControlAry RachmanNo ratings yet

- Risk Assessment and Evaluation of The Conductor Pipe Setting DepthDocument85 pagesRisk Assessment and Evaluation of The Conductor Pipe Setting DepthAry RachmanNo ratings yet

- Successful Application of Synthetic Graphite To Overcome Severe Lost CirculationDocument12 pagesSuccessful Application of Synthetic Graphite To Overcome Severe Lost CirculationAry RachmanNo ratings yet

- Syn 98347Document2 pagesSyn 98347Ary RachmanNo ratings yet

- SPE ConferenceDocument2 pagesSPE ConferenceAry RachmanNo ratings yet

- Preventing Differential Sticking and Mud Losses in Highly Depleted SandsDocument10 pagesPreventing Differential Sticking and Mud Losses in Highly Depleted SandsAry RachmanNo ratings yet

- UBD Reservoir DesignDocument22 pagesUBD Reservoir DesignAli MuseNo ratings yet

- Successfully Replacing Oil-Based Drilling Fluids With Water-Based Drilling Fluids CaseDocument16 pagesSuccessfully Replacing Oil-Based Drilling Fluids With Water-Based Drilling Fluids CaseAry RachmanNo ratings yet

- Lost Circulation Solutions For Severe Sub-Salt Thief ZonesDocument7 pagesLost Circulation Solutions For Severe Sub-Salt Thief ZonesAry Rachman100% (1)

- Associative Polymers For Invasion Control in Water - and Oil-Based MudsDocument15 pagesAssociative Polymers For Invasion Control in Water - and Oil-Based MudsAry RachmanNo ratings yet

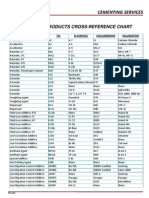

- Tabel Kimia Additiv SementDocument1 pageTabel Kimia Additiv SementAry RachmanNo ratings yet

- Inter Facial Phenomena in Dispersed SystemDocument27 pagesInter Facial Phenomena in Dispersed SystemAry RachmanNo ratings yet

- Deepwater Drilling FluidsDocument6 pagesDeepwater Drilling FluidsAry RachmanNo ratings yet

- Richards Micro Pile Construction Methods and MaterialsDocument29 pagesRichards Micro Pile Construction Methods and MaterialsAry RachmanNo ratings yet

- Chapter 62C-27 Conservation of Oil and Gas: DrillingDocument4 pagesChapter 62C-27 Conservation of Oil and Gas: DrillingAry RachmanNo ratings yet

- Drilling Fluids Engineering: CatalogDocument14 pagesDrilling Fluids Engineering: CatalogAry RachmanNo ratings yet

- Legends of DrillingDocument17 pagesLegends of DrillingAry Rachman100% (2)

- Controlled Pressure DrillingDocument22 pagesControlled Pressure DrillingAry Rachman100% (1)

- Canadian Driller DSIDocument2 pagesCanadian Driller DSIAry RachmanNo ratings yet

- Rumus Compressive StrengthDocument16 pagesRumus Compressive StrengthAry RachmanNo ratings yet

- Cement: - Wellbore Cementing ModelDocument21 pagesCement: - Wellbore Cementing ModelAry RachmanNo ratings yet

- Teknika CementDocument6 pagesTeknika CementAry RachmanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ellingham Diagram UsesDocument4 pagesEllingham Diagram Usesnanda rizkyNo ratings yet

- Astm B 138 - B 138M - 06Document4 pagesAstm B 138 - B 138M - 06Ramsi AnkziNo ratings yet

- BS en 196-5-2005-02Document13 pagesBS en 196-5-2005-02Abey VettoorNo ratings yet

- Unit 2 SpecificationsDocument11 pagesUnit 2 SpecificationsNidhi MehtaNo ratings yet

- Piers PDFDocument3 pagesPiers PDFmahmoud elkhedrNo ratings yet

- E80dc1b2 01e9 4aee b425 C074a3d3649c Bukango Seed School Mid Term ExamsDocument38 pagesE80dc1b2 01e9 4aee b425 C074a3d3649c Bukango Seed School Mid Term ExamsDaniel MarkNo ratings yet

- Drug Delivery Lab - Effervescent Powder FormulationDocument3 pagesDrug Delivery Lab - Effervescent Powder FormulationAntonio CharismaNo ratings yet

- Novel Technologies For Wear Protection and Monitoring in DredgingDocument23 pagesNovel Technologies For Wear Protection and Monitoring in DredgingRASHEED YUSUFNo ratings yet

- 2011 04 11 Biomass GasificationDocument48 pages2011 04 11 Biomass GasificationHotib PerwiraNo ratings yet

- Material Approximate Cost EstimateDocument1 pageMaterial Approximate Cost EstimateKurt Laurhon CabahugNo ratings yet

- Earth Work RatesDocument92 pagesEarth Work RatesNiteshNo ratings yet

- Training Activity Matrix SMAW NC I-COREDocument52 pagesTraining Activity Matrix SMAW NC I-COREEugenio Mates Jr.No ratings yet

- Aromatic HydrocarbonsDocument3 pagesAromatic Hydrocarbonsmihai_bors_01No ratings yet

- Glass: A Versatile MaterialDocument34 pagesGlass: A Versatile MaterialRUSHALI SRIVASTAVANo ratings yet

- Annexure-A Technical Specifications For Heat Shrinkable Cable Terminations and Joints For 6.6kV, XLPE CablesDocument4 pagesAnnexure-A Technical Specifications For Heat Shrinkable Cable Terminations and Joints For 6.6kV, XLPE CablesHossam AlzubairyNo ratings yet

- Sika Concrete HandbookDocument151 pagesSika Concrete HandbookFatjon ShahaNo ratings yet

- 2016CompositeList Web 65Document1 page2016CompositeList Web 65AnuranjanNo ratings yet

- Review of Techniques The Sodium-Fusion: in LassaigneDocument2 pagesReview of Techniques The Sodium-Fusion: in LassaigneKthryn93No ratings yet

- Shibori Examples 1yzh7laDocument2 pagesShibori Examples 1yzh7laFathi Mustafa100% (1)

- Alkanes, Alkenes and AlcoholsDocument149 pagesAlkanes, Alkenes and AlcoholsFaria TahsinNo ratings yet

- Bphe Danfoss CataloqDocument4 pagesBphe Danfoss CataloqRidwan PramudyaNo ratings yet

- PT - trasTI SUPPLIER (Pumps For Industry, Mining, Oil and Gas)Document19 pagesPT - trasTI SUPPLIER (Pumps For Industry, Mining, Oil and Gas)Faturachman Reza100% (1)

- Instrumentation 02-2011 PDFDocument40 pagesInstrumentation 02-2011 PDFGina Moron MoronNo ratings yet

- Applications of Coordination CompoundsDocument6 pagesApplications of Coordination CompoundsFizsNo ratings yet

- Salscent (SST) : A Self-Encapsulation Fragrance TechnologyDocument2 pagesSalscent (SST) : A Self-Encapsulation Fragrance TechnologyRaisha RamadantiNo ratings yet

- Pentagon Filmtek Suppliers & Installers of Solar Gard Antimicrobial Films Dubai, UAEDocument4 pagesPentagon Filmtek Suppliers & Installers of Solar Gard Antimicrobial Films Dubai, UAEPentagon FilmtekNo ratings yet

- CP 653 BA Technical-information-ASSET-DOC-LOC-1540979Document1 pageCP 653 BA Technical-information-ASSET-DOC-LOC-1540979AdityaNo ratings yet

- Pressure Molding & Vacuum Forming Processes ExplainedDocument22 pagesPressure Molding & Vacuum Forming Processes ExplainedRik PtlNo ratings yet

- Main Stages Construction Projects Explained in 40 CharactersDocument7 pagesMain Stages Construction Projects Explained in 40 CharactersAsanterabi LaizerNo ratings yet

- Gulf Harmony AW 46 Data SheetDocument1 pageGulf Harmony AW 46 Data SheetRezaNo ratings yet