Professional Documents

Culture Documents

Itsm Swps

Uploaded by

khashi_kh0 ratings0% found this document useful (0 votes)

17 views1 pageOriginal Title

itsm_swps

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pageItsm Swps

Uploaded by

khashi_khCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Labour and Immigration

Mechanical and Engineering

www.gov.mb.ca/labour/safety/mechanic

500 401 York Avenue

Winnipeg, MB R3C 0P8

PH: (204) 945-3373

Fax: (204) 948-2309

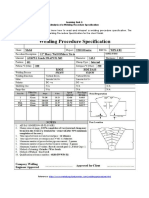

Demonstration of Standard Welding Procedure Specifications (SWPS)

(See Article V of ASME Code)

Identification of Standard Welding Procedure Specification Demonstrated: ________________________

Demonstration Welding Conditions

Specification, Type, and Grade of Base Metal(s): ____________________________________________

To Specification, Type and Grade of Base Metals(s):_______________________________________

Base Metal P- or S- Number _________to Base Metal P- or S- Number _________ Thickness________

Welding Process(es) Used: ___________________________________________________________

Plate

Pipe (enter diameter if pipe or tube):

____________________________________________

Groove Type (Single V, Double V, Single U, etc.): ____________________________________________

Initial Cleaning Method: ________________________________________________________________

Backing (Metal, Weld Metal, Backwelded, etc.): ______________________________________________

Filler metal (SFA) Specification: __________________________________________________________

Filler metal or Electrode Classification: _____________________________________________________

Filler Metal or Electrode Trade Name: _____________________________________________________

Tungsten Electrode Type and Size for GTAW: _______________________________________________

Consumable Insert Class and Size for GTAW or PAW: ________________________________________

Shielding Gas Composition and Flow Rate to GTAW, PAW, GMAW: _____________________________

Preheat Temperature (oF or oC) : _________________________________________________________

Position (1G, 2G, etc.) of Weld: __________________________________________________________

Progression (Uphill or Downhill): _________________________________________________________

Interpass Cleaning Method: _____________________________________________________________

Measured Interpass Temperature (oF or oC: ________________________________________________

Approximate Deposit Thickness for Each Filler Metal or Electrode Type (in.): ______________________

Current Type/Polarity (AC, DCEP, DECN): _________________________________________________

Postweld Heat Treatment Time and Temperature: ____________________________________________

Visual Examination of Completed Weld: _________________________ Date of Test: _______________

Bend Test

Type

Transverse Root and Face [QW-462.3 (a)]

Result

Type

Result

Type

Side [QW-462.2]

Result

Alternative Radiographic Examination Results: ______________________________________________

Specimens Evaluated By ____________________ Title: _________________ Company :____________

Welding Supervised By: _____________________ Title: ________________ Company ____________

Welders Name: _______________________________________

Stamp No: ________________

We certify that the statements in this record are correct and that the weld described above was prepared,

welded, and tested in accordance with the requirements of Section IX of the ASME Boiler and Pressure

Vessel Code.

Manufacturer or Contractor: ______________________________________

By: _______________________

Date: ___________________ Demonstration No: _______________

You might also like

- WPS TemplateDocument1 pageWPS TemplateMatt De Hoog100% (1)

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- AASHTO D1.5 welding procedure specificationDocument1 pageAASHTO D1.5 welding procedure specificationViswanath SreepadaNo ratings yet

- L2 WPSDocument1 pageL2 WPSBernardo LeorNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- WPS VarillaDocument2 pagesWPS Varillalabingles89No ratings yet

- AWS D1.1 WELDING PROCEDURE ANNEXDocument2 pagesAWS D1.1 WELDING PROCEDURE ANNEXsrinivasanNo ratings yet

- CS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Document2 pagesCS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Nazar Abdul KareemNo ratings yet

- WPS Format for Welding Procedure SpecificationDocument2 pagesWPS Format for Welding Procedure SpecificationKarthikNo ratings yet

- AWS B2.1/B2.1M:2014-AMD1 performance test recordDocument1 pageAWS B2.1/B2.1M:2014-AMD1 performance test recordNavanitheeshwaran SivasubramaniyamNo ratings yet

- Suggested Weldin Lr. VijDocument4 pagesSuggested Weldin Lr. Vijmallik017100% (2)

- WPS SampleDocument2 pagesWPS Sampleeetua100% (1)

- BPQ SampleDocument1 pageBPQ Samplesudeep_singh1No ratings yet

- PQRDocument2 pagesPQRRavi KumaranNo ratings yet

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Document2 pagesSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- Welding Procedure Specification (WPS) : BackingDocument1 pageWelding Procedure Specification (WPS) : BackingtimkemperNo ratings yet

- Sample Format: Sensitivity: LNT Construction Internal UseDocument2 pagesSample Format: Sensitivity: LNT Construction Internal UseKarthikNo ratings yet

- M/S SPML Infra LTDDocument6 pagesM/S SPML Infra LTDyouuuuyNo ratings yet

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- Welding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) YesDocument4 pagesWelding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) Yesvarun100% (1)

- WPS - Sample - Form D17.1 D17.1M 2010Document1 pageWPS - Sample - Form D17.1 D17.1M 2010Mohammed AzizNo ratings yet

- FM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)Document2 pagesFM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)tayyabNo ratings yet

- Nuclear Power Corporation of India Litd.: Quality Assurance GroupDocument4 pagesNuclear Power Corporation of India Litd.: Quality Assurance GroupviswamanojNo ratings yet

- Wps Borang AdiDocument2 pagesWps Borang AdixernozaqilNo ratings yet

- QW-482 WPS BlankDocument2 pagesQW-482 WPS Blankj29mahonNo ratings yet

- Joint (QW-402)Document3 pagesJoint (QW-402)MuhammadNajibNo ratings yet

- Brazing Procedure SpecificationsDocument5 pagesBrazing Procedure Specificationssajay2010100% (1)

- Form L-4-Procedure Qualification Record (PQR) WorksheetDocument1 pageForm L-4-Procedure Qualification Record (PQR) WorksheetCemal NergizNo ratings yet

- F4-WPS PQR Stud WeldingDocument1 pageF4-WPS PQR Stud WeldingBernardo LeorNo ratings yet

- WPS - Pre-Insulated PipesDocument4 pagesWPS - Pre-Insulated Pipesharis bhuttoNo ratings yet

- Annex Form J3 D1.1 D1.1M 2020Document1 pageAnnex Form J3 D1.1 D1.1M 2020Donaldo CausilNo ratings yet

- AWS D1.5 PQR TitleDocument1 pageAWS D1.5 PQR TitleNavanitheeshwaran SivasubramaniyamNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNavanitheeshwaran SivasubramaniyamNo ratings yet

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocument1 pageAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajNo ratings yet

- B2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFDocument2 pagesB2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFNavanitheeshwaran SivasubramaniyamNo ratings yet

- Form N 3 Sample Procedure Qualification RecordDocument1 pageForm N 3 Sample Procedure Qualification RecordViswanath SreepadaNo ratings yet

- M 3 D1.1 2015 FormDocument1 pageM 3 D1.1 2015 FormĐỗ Văn ChinhNo ratings yet

- QIR 121 Bolts Torque ReportDocument1 pageQIR 121 Bolts Torque ReportSamer BayatiNo ratings yet

- Form N3 PDFDocument1 pageForm N3 PDFTavo RojasNo ratings yet

- B2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormDocument1 pageB2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormtuanNo ratings yet

- L3 PQRforQualificationDocument1 pageL3 PQRforQualificationBernardo LeorNo ratings yet

- WELDING PROCEDURE QUALIFICATION TRAVELERDocument8 pagesWELDING PROCEDURE QUALIFICATION TRAVELERHoangNo ratings yet

- Start-Up Sheet For CompressorsDocument1 pageStart-Up Sheet For CompressorsGreg LundyNo ratings yet

- Sample PQRDocument2 pagesSample PQRudaysrp33% (3)

- Boiler inspection checklist guideDocument2 pagesBoiler inspection checklist guideSadiq KhattakNo ratings yet

- Form O-4-Procedure Qualification Record (PQR) WorksheetDocument1 pageForm O-4-Procedure Qualification Record (PQR) WorksheetNavanitheeshwaran SivasubramaniyamNo ratings yet

- SMAW 9 Week 4 Learning Task 5 AnalysisDocument2 pagesSMAW 9 Week 4 Learning Task 5 AnalysisCrauxz de TraxNo ratings yet

- Tata Consulting Engineers Limited: P Q T R (PQR)Document2 pagesTata Consulting Engineers Limited: P Q T R (PQR)Rajat KoleyNo ratings yet

- WELDER PERFORMANCE QUALIFICATION TEST REPORTDocument1 pageWELDER PERFORMANCE QUALIFICATION TEST REPORTKentDemeterioNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- PT/MT/VT Examination RecordDocument1 pagePT/MT/VT Examination RecordCarlos Nombela PalaciosNo ratings yet

- Welding News 1 - 2012: Super Duplex Miscellanea New ColleaguesDocument10 pagesWelding News 1 - 2012: Super Duplex Miscellanea New ColleaguesCarlos Nombela PalaciosNo ratings yet

- SteelSpec Sep 2015Document2 pagesSteelSpec Sep 2015Carlos Nombela PalaciosNo ratings yet

- Me Car 015Document1 pageMe Car 015Carlos Nombela PalaciosNo ratings yet

- Boehler Dcms Ti-Fd Fde en 1Document1 pageBoehler Dcms Ti-Fd Fde en 1Carlos Nombela PalaciosNo ratings yet

- Certificado 6222 Mo FCMDocument1 pageCertificado 6222 Mo FCMCarlos Nombela PalaciosNo ratings yet

- RM10 A CHNDocument3 pagesRM10 A CHNDino OiiNo ratings yet

- Feritscope FMP30 Measurement of The Ferrite Content in Austenitic and Duplex SteelDocument8 pagesFeritscope FMP30 Measurement of The Ferrite Content in Austenitic and Duplex SteelBiju_PottayilNo ratings yet

- Plate 'N' Sheet Professional 3Document71 pagesPlate 'N' Sheet Professional 3Roger NicholsNo ratings yet

- Manufacturing Quality Control BrochureDocument6 pagesManufacturing Quality Control BrochureCarlos Nombela PalaciosNo ratings yet

- FP7079Document10 pagesFP7079Carlos Nombela PalaciosNo ratings yet

- Alform 700 MCDocument9 pagesAlform 700 MCCarlos Nombela PalaciosNo ratings yet

- RM09 A BulDocument3 pagesRM09 A BultendeanNo ratings yet

- ISO & ASME welding positions guideDocument1 pageISO & ASME welding positions guideMehmet Soysal100% (1)

- ISO & ASME welding positions guideDocument1 pageISO & ASME welding positions guideMehmet Soysal100% (1)

- Quality Control SystemsDocument8 pagesQuality Control SystemsCarlos Nombela PalaciosNo ratings yet

- WPS Asme IxDocument4 pagesWPS Asme Ixjcarlosherrerac7100% (1)

- Manufacturing Quality Control BrochureDocument6 pagesManufacturing Quality Control BrochureCarlos Nombela PalaciosNo ratings yet

- Suscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, AquíDocument2 pagesSuscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, AquíCarlos Nombela PalaciosNo ratings yet

- Suscribete GRATIS a la revista SOLDADURA LATINOAMERICADocument1 pageSuscribete GRATIS a la revista SOLDADURA LATINOAMERICACarlos Nombela PalaciosNo ratings yet

- European Welding New-StandardsDocument39 pagesEuropean Welding New-StandardsJOECOOL67100% (3)

- Fontargen Sales ProgramDocument20 pagesFontargen Sales ProgramCarlos Nombela PalaciosNo ratings yet

- AWS - Welding SymbolsDocument1 pageAWS - Welding SymbolsAli Saifullizan IsmailNo ratings yet

- PQR Asme Ix - CompletedDocument3 pagesPQR Asme Ix - CompletedCarlos Nombela Palacios100% (1)

- 112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Document33 pages112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Carlos Nombela PalaciosNo ratings yet

- Confronto en 10297Document1 pageConfronto en 10297Carlos Nombela PalaciosNo ratings yet

- Comparing Isodis 90012014 and Isodis 140012014 at PDFDocument26 pagesComparing Isodis 90012014 and Isodis 140012014 at PDFjohnoo7No ratings yet

- ASME Pressure VesselDocument13 pagesASME Pressure Vesselamechmar5935No ratings yet

- C1e 010Document9 pagesC1e 010Carlos Nombela PalaciosNo ratings yet

- Asmeqcrev 2Document70 pagesAsmeqcrev 2Carlos Nombela PalaciosNo ratings yet