Professional Documents

Culture Documents

Nitrogen in Cast Iron

Uploaded by

Faizan TahirOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitrogen in Cast Iron

Uploaded by

Faizan TahirCopyright:

Available Formats

Nitrogen in cast iron

How much nitrogen

Source of nitroge n

compounds.

Nitrogen can enter the iron nitrogen content resins.

I

when the moulds and/or cores contain high

Metallurgical effects

These are seldom obvious except in very heavy sections.

ns by nitrogen contents increase in tensile strength ingot moulds as it lowers can result the increase in nitrogen Some of the advantages cast irons arise from this effect. and may lead to white iron carbide and pearlite from

Compacted graphite in 12 in dia. bar containing 0.015% nitrogen. Etched 4% picrai. x 60

high nitrogen content

Nitrogen

pinholes used by high-nitrogen resin-bonded cores. The defects occur where

the core forming the hub of the casting meets the greensand mould

Effect on soundness

Excessive nitrogen contents appear as blowholes and fissures In the castings. It is u~ommon for nitrogen blowholes to occur below about 0.013 per cent nitrogen in light section castings and 0.008 per cent in heavy castings. These defects most frequently arise In thick section castings made from cupola iron of low carbon equivalent prepared from high steel charges. Nitrogen fissure defects occur adjacent to cores bonded with high nitrogen content resins. These often appear as bubbles or fissures close to a re-entrant angle in a casting. Blowholes or fissures due to nitrogen may appear to have bright surfaces or contain a continuous layer of graphite. However, If the defects have been exposed to the air, or the casting has been heat treated, they may have dull oxidlsed surfaces.

How to avoid the effects of high nitrogen content

The effect of nitrogen can be neutralised by the addition of titanium to give a content of 0.02-0.03per cent in the iron before casting. Although additions of aluminium (to give a content in the iron of 0.02-0.04per cent) are used to neutrallse nitrogen in the production of large ingot moulds and heavy castings of similar application, aluminium should never be added to iron for light section and general engineering castings because it promotes hydrogen pinholes in such castings (see BCIRA Broadsheet 7). Carburiser materials having a high nitrogen content must be avoided. When defects are associated with moulds and cores bonded with high nitrogen content resins, a lower nitrogen content resin should be substituted. Resins having below 3 per cent nitrogen are unlikely to give trouble but sometimes it may be necessary to change to a nitrogen-free resin.

(--

Recommended further reading

DAWSON (J.V.), SMITH (LW.L.) and BACH (B.B.) Some effects of nitrogen in cast Iron. BCIRA Journal of Research and Development. 1953,v. 4, June, pp. 540-552. MOUNTFORD (F.A.) The Influence of nitrogen on the strength, soundness and structure of grey cast iron. British Foundryman,

1966. 59,April. pp. 141-151. v. External report 504.

Copies of any BCIRA

from British

Broadsheet can be obtained free Cast Iron Research Association, Alvechurch,

of charge by BCIRA members Birmingham B48 70B.

1976 British CastIron Research Association,A/vechurch,Birmingham,B48 70B.

Nitrogen in cast iron

How much nitrogen dissolves in cast iron?

Up to about 0-04 per cent nitrogen dissolves in cast iron, depending on the composition of the iron- A sharp drop in solubility occurs when the iron solidifies, accounting for the tendency of this element to causeblow-holes or fissures. In practice, the nitrogen content of castings cast in sand per cent, but castings are likely to be unsound with nitrogen contents above 0-010 per cent.

pl

.

~vJ-"

..)..y

mouldscan vary betweenabout 0 - 001 per cent and O.015

Sources of nitro~en Some nitrogen in cast iron is introduced by the charge materials,but morecommonlyit is absorbed the liquid into iron together with carbon from the coke in the cupola furnace.High nitrogen contentsare most likely to occur in cupola-meltedirons using high-steelcharges.When steel scrap charges are carburized in electric furnaces, high nitrogen contents can arise from the use of carburizing materialssuch as petroleumcoke.that contain nitrogenous compounds. Nitrogen can enter the iron during casting, when the moulds, cores or both are bonded with high-nitrogencontent resins.

Metallurgical effects

These are seldom obvious except in very heavy sections. A compacted form of graphite is produced in heavy sections by nitrogen contents aboveabout 0.008 per cent. Compacted

graphite causesan increasein tensile strength but this graphite structure is undesirablein somedesignsof ingot moulds as it lowers the thermal shockresistance. An increase tensilestrengthof 30- 45 N/mm2 can result in from the increase nitrogencontentarisingfrom the useof in high-steelchargesin the cupola. Someof the advantages claimedfor the useof high-steelcharges high-duty cast for irons arise from this effect. High nitrogencontentspromotepearliteformationandmay lead to white-iron structures. In malleableirons, high nitrogen contentsstabilizecarbide and pearliteand hinder annealing, problemsof this type but are uncommon. Nitrogen hasno significant effect in ductile irons.

Effect on soundness Excessive nitrogen contents result in blow-holes and fissures in the castings. It is uncommon for nitrogen blowholes to occur below about 0.013 per cent nitrogen in lightsection castings and O. 008 per cent in heavy castings. These defects most frequently arise in thick-section castings made from cupola iron of low carbon equivalent prepared from high steel charges, or electric-melted irons carburized with materials such as petroleum coke.

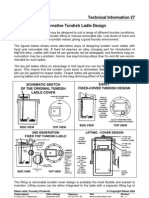

Fig. 1 Compacted graphite in 30 cm bar 0.015% nitrogen. Etched in 4% picral.

containing x60

Fig. 3 Nitrogen pinholes caused by high-nitrogen resin-bonded cores. The defects occur where the core forming the hub of the casting meets the greensand mould.

Nitrogen fissure defectsoccur next to coresbonded with high-nitrogen-content resins.Theseoften appearasbubbles or fissurescloseto a re-entrantanglein a casting. Blow-holesor fissures due to nitrogen may have bright surfaces or contain a discontinuous layer of graphite. However,if the defectshavebeenexposed the air, or the to castinghasbeenheat treated,they may havedull oxidized surfaces.

RECOMMENDED FURTHER READING BClRA Broadsheet Pinholesformed by hydrogengasduring 7*: solidification of iron castings. BClRA Broadsheet 49*: Holes in castingscaused high-nitroby gen-content resin-bindersystems. BClRA Broadsheet 165: Changes the nitrogen content of cast in iron during melting and holding in a coreless induction furnace. BClRA Broadsheet 218: The determination of nitrogen in chemicallybondedsands. BClRA Broadsheet 294: in ctst irons. DAWSON,J. V., SMITH, W L. &; BACH,B. B. Someeffectsof nitrogen in cast iron. BCIRA 355.

MOUNTFORD, F. A. The influence of nitrogen on the strength, soundness and structure of grey cast iron. British Foundrymsn, April 1966, Vol. 59, 141-151. SIMMONS, W. Experiments into the complementary effects of hydrogen and nitrogen in the fonnation of gas holes in iron castings. BCIRA Repon 1122.t SMITH, L. W. L. Detennination of the nitrogen content of carbon materials. BCIRA Repon 1177.t GREENHILL, J. M. & REYNOLDS,N. M. Nitrogen defects in iron castings. BCIRA Repon 1189.t

EVANs, E. R. Nitrogen in cast irons-and its neutralization by aluminium. BCIRA Repon 1260.t The effects of alloying elements in cast iron-5: nitrogen. BCIRA Repon 1299.t

How

to avoid

the

effects

of high

nitrogen content The effect of nitrogen can be neutralized by the addition of enough titanium to give a content of 0.02-0.03 per cent in the iron before casting. Although additions of aluminium (to give a content in the iron of 0.02-0.04 per cent) are used to neutralize nitrogen in the production of large ingot moulds and heavy castings for similar applications, aluminium should never be addedto iron for light-section and general engineering castings because it promotes hydrogen pinholes in such castings (seeBCIRA Broadsheet 7*). Large amounts of carburizer materials having a high nitrogen content must be avoided. When defects are associatedwith moulds and cores bonded with high-nitrogen-content resins, a resin with less nitrogen should be substituted. Resins with less than 3 per cent nitrogen are unlikely to give trouble, but sometimes it may be necessaryto change to a nitrogen-free resin.

FALLON, M. J. Nitrogen pinhole defects in manensitic white iron castings. BCIRA Repon 1635.t DAWSON,J. V. The influence of nitrogen on the tensile properties of blackhean malleable cast irons. BCIRA Repon 1674.t DAWSON,J. V. The properties ofwhitehc tAvailable only to BCIRA Members. litrogen on the structure and iron. BCIRA Repon 1709.t

Memberscan obtain free copies of any BCIRA Broadsheet from BCIRA, Alvechurch, Birmingham B48 7aB

@ 1989BCIRA

You might also like

- Back to BASICS: Nitrogen fissures defects in iron castingsDocument2 pagesBack to BASICS: Nitrogen fissures defects in iron castingsJustin DixonNo ratings yet

- Selection of NodularizersDocument2 pagesSelection of Nodularizersarnaldorcr8646100% (2)

- Nitrogen FissuresDocument1 pageNitrogen Fissuresarnaldorcr8646100% (1)

- Magnesium Slag Defects in Ductile IronDocument1 pageMagnesium Slag Defects in Ductile Ironarnaldorcr8646100% (1)

- Slag Defects in Grey IronDocument1 pageSlag Defects in Grey Ironarnaldorcr8646100% (1)

- Inoculation of Heavy Section CastingsDocument2 pagesInoculation of Heavy Section Castingsarnaldorcr8646100% (1)

- Selection of Inoculants For Ductile Cast IronDocument1 pageSelection of Inoculants For Ductile Cast Ironarnaldorcr8646100% (1)

- Common Metallurgical Defects in Grey Iron: Hydrogen Blowhole Nitrogen Fissure Compaction of Graphite Flakes ShrinkageDocument1 pageCommon Metallurgical Defects in Grey Iron: Hydrogen Blowhole Nitrogen Fissure Compaction of Graphite Flakes ShrinkageJoao LuisNo ratings yet

- Effects of Alloying Elements On The Micro Structures and Mechanical On Ductile Cast IronsDocument5 pagesEffects of Alloying Elements On The Micro Structures and Mechanical On Ductile Cast IronsCharlie Chong100% (6)

- Poor Nodularity in Ductile IronDocument2 pagesPoor Nodularity in Ductile Ironarnaldorcr864675% (4)

- Effects of Minor and Trace Elements in Cast IronDocument2 pagesEffects of Minor and Trace Elements in Cast Ironarnaldorcr864667% (3)

- Carbon Monoxide Blowholes in Grey IronDocument1 pageCarbon Monoxide Blowholes in Grey Ironarnaldorcr8646No ratings yet

- Technical InformationDocument78 pagesTechnical InformationCarlos Barrachina Martínez100% (2)

- Composition of Grey Cast IronDocument2 pagesComposition of Grey Cast IronPranil GhatageNo ratings yet

- Fading of Nodularity in Ductile IronDocument2 pagesFading of Nodularity in Ductile Ironarnaldorcr8646100% (4)

- SG Iron ProductionDocument20 pagesSG Iron ProductionShreyashri Nayak100% (1)

- Mechanism and Conditions for Obtaining Different Graphite Structures in Gray Cast IronDocument21 pagesMechanism and Conditions for Obtaining Different Graphite Structures in Gray Cast IronArjyajyoti Goswami100% (1)

- Common Metallurgical Defects in Ductile IronDocument1 pageCommon Metallurgical Defects in Ductile IronMehdi Koneshlou100% (1)

- Shrinkage in Ductile IronDocument5 pagesShrinkage in Ductile Ironkarthikkanda100% (1)

- Analyzing Casting Defects in Foundry TechnologyDocument12 pagesAnalyzing Casting Defects in Foundry TechnologyVirendra Gupta100% (1)

- Magnesium Contents in Ductile IronDocument2 pagesMagnesium Contents in Ductile Ironarnaldorcr8646No ratings yet

- Effect of Minor and Trace Elements in Cast IronDocument2 pagesEffect of Minor and Trace Elements in Cast IronsachinguptachdNo ratings yet

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFDocument23 pages1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- S.G IronDocument6 pagesS.G IronQasim BarkatNo ratings yet

- Recovery of Magnesium in A Ductile Iron Process.: AbstractDocument8 pagesRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazNo ratings yet

- Cerium in Ductile IronDocument2 pagesCerium in Ductile Ironvivek1312100% (2)

- Seminar S.G IronDocument32 pagesSeminar S.G Ironravikataria02No ratings yet

- Inoculation of Grey and Ductile Iron A Comparison of Nucleation Sites and Some Practical AdvisesDocument12 pagesInoculation of Grey and Ductile Iron A Comparison of Nucleation Sites and Some Practical AdvisesZody YtuNo ratings yet

- Selection of Inoculants For Grey Cast IronDocument2 pagesSelection of Inoculants For Grey Cast Ironarnaldorcr8646No ratings yet

- ELMAGDocument2 pagesELMAGthomazfabricioNo ratings yet

- Fading of InoculationDocument2 pagesFading of Inoculationarnaldorcr8646No ratings yet

- O HC HCDocument101 pagesO HC HCIndustrial Infra Jobs100% (1)

- Elkem 07 Magnesiun Contents in Ductile IronDocument2 pagesElkem 07 Magnesiun Contents in Ductile Ironmarcotulio123No ratings yet

- Contineous CastingDocument3 pagesContineous CastingMuhammad ImranNo ratings yet

- Common Metallurgical Defects in Grey Cast Irons 2Document1 pageCommon Metallurgical Defects in Grey Cast Irons 2Rasool MohammadiNo ratings yet

- Alternative Tundish Ladle DesignDocument2 pagesAlternative Tundish Ladle Designarnaldorcr8646No ratings yet

- S.G. Iron : MouldingDocument11 pagesS.G. Iron : MouldingsureshbabuamalaNo ratings yet

- Ductile Dross Formation MonitoringDocument27 pagesDuctile Dross Formation MonitoringsachinguptachdNo ratings yet

- Chunky GraphiteDocument16 pagesChunky GraphitesachinguptachdNo ratings yet

- Carbon Dioxide Moulding ProcessDocument17 pagesCarbon Dioxide Moulding ProcessqwertyuioNo ratings yet

- Mapa MetalograficoDocument1 pageMapa MetalograficoBreno DellaNo ratings yet

- Offsetting Macro-Shrinkage in Ductile IronDocument13 pagesOffsetting Macro-Shrinkage in Ductile IronmetkarthikNo ratings yet

- Shrinkage in Iron CastingsDocument10 pagesShrinkage in Iron CastingskarthikkandaNo ratings yet

- Late Metal Stream InoculationDocument2 pagesLate Metal Stream Inoculationarnaldorcr8646No ratings yet

- Effect of Minor and Trace Elements in Cast IronDocument2 pagesEffect of Minor and Trace Elements in Cast IronsachinguptachdNo ratings yet

- Sampling of Liquid Cast IronDocument2 pagesSampling of Liquid Cast Ironarnaldorcr8646No ratings yet

- Feeding Steel and Ductile Iron CastingDocument22 pagesFeeding Steel and Ductile Iron Castingjosemiguelzu100% (1)

- Manganese, Sulfur and Manganese-Sulfur Ratio Effects in Gray Cast IronDocument30 pagesManganese, Sulfur and Manganese-Sulfur Ratio Effects in Gray Cast IronNetoNo ratings yet

- Grains Structure of IngotsDocument6 pagesGrains Structure of Ingotshayder1920No ratings yet

- Elkem 13 Compacted Graphite IronDocument2 pagesElkem 13 Compacted Graphite Ironmarcotulio123No ratings yet

- 09 Cast IronDocument34 pages09 Cast IronyogeshmangulkarNo ratings yet

- Tramp Elements and Billet CarckingDocument7 pagesTramp Elements and Billet CarckingOmar TahaNo ratings yet

- Recommended Target Analysis For Ductile IronDocument2 pagesRecommended Target Analysis For Ductile Ironarnaldorcr8646100% (2)

- Engineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeFrom EverandEngineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeNo ratings yet

- EeoDocument14 pagesEeoFaizan TahirNo ratings yet

- Bricks Calculation of Ladels Side Walls Layer # Height (H) P (H) Tan (Theta) 2 (3.142) (R+P)Document4 pagesBricks Calculation of Ladels Side Walls Layer # Height (H) P (H) Tan (Theta) 2 (3.142) (R+P)Faizan TahirNo ratings yet

- Routine Test Procedures On Standard Test Pieces Moulding: Sand-Preparation ofDocument2 pagesRoutine Test Procedures On Standard Test Pieces Moulding: Sand-Preparation ofFaizan Tahir100% (2)

- BS156 1Document8 pagesBS156 1Faizan TahirNo ratings yet

- A Study On Thermal Cracking of Cast IronDocument10 pagesA Study On Thermal Cracking of Cast IronthuronNo ratings yet

- Physicochemical Analysis of Cocoa Pod PDFDocument5 pagesPhysicochemical Analysis of Cocoa Pod PDFPatrick Ehi ImoisiliNo ratings yet

- Waste Management: Chea Chandara, Khairun Azizi Mohd Azizli, Zainal Arifin Ahmad, Etsuo SakaiDocument5 pagesWaste Management: Chea Chandara, Khairun Azizi Mohd Azizli, Zainal Arifin Ahmad, Etsuo SakaiTrí Thông PhạmNo ratings yet

- Concrete Materials, Properties, Uses and Production GuideDocument6 pagesConcrete Materials, Properties, Uses and Production GuideShah KhanNo ratings yet

- 2013 03 Interturbine Product CatalogueDocument80 pages2013 03 Interturbine Product Cataloguejydix100% (1)

- CMP Product Manual Version 4Document151 pagesCMP Product Manual Version 4Jean Valjean100% (1)

- Determination of Fineness of Hydraulic Cement by The No. 200 SieveDocument3 pagesDetermination of Fineness of Hydraulic Cement by The No. 200 SieveCamille Andrea SequitinNo ratings yet

- Executive Summary: 0.1 GeneralDocument20 pagesExecutive Summary: 0.1 Generaler_br_choudahryNo ratings yet

- Orthodontic WiresDocument4 pagesOrthodontic Wiresizcooi100% (1)

- PatentsDocument2 pagesPatentssuchthatNo ratings yet

- PP AFC Honeywell Spectra Fiber 1000 Product Information SheetDocument2 pagesPP AFC Honeywell Spectra Fiber 1000 Product Information Sheetcrestind100% (1)

- RCC91 One-Way Solid Slabs (Tables)Document7 pagesRCC91 One-Way Solid Slabs (Tables)Sachin RajaleNo ratings yet

- F 1068 - 90 R98 - Rjewnjgtotbsothfmq - PDFDocument4 pagesF 1068 - 90 R98 - Rjewnjgtotbsothfmq - PDFRománBarciaVazquezNo ratings yet

- Internal Linings: NIOEC-SP-80-05Document11 pagesInternal Linings: NIOEC-SP-80-05aminNo ratings yet

- Guidelines For Reviewing Concrete Mix DesignsDocument60 pagesGuidelines For Reviewing Concrete Mix DesignsruwanpuraNo ratings yet

- Durock Cement Board System Guide en SA932Document12 pagesDurock Cement Board System Guide en SA932Ko PhyoNo ratings yet

- Six-Year Evaluation of ThermalSprayed Coating of ZnAlDocument11 pagesSix-Year Evaluation of ThermalSprayed Coating of ZnAlPinto DamianNo ratings yet

- Design of Cantilever Retaining WallDocument2 pagesDesign of Cantilever Retaining WallRamilArtatesNo ratings yet

- MM 003Document7 pagesMM 003mcgNo ratings yet

- PavementDocument13 pagesPavementmohanganeNo ratings yet

- Khadi Extended DocumentationDocument14 pagesKhadi Extended DocumentationarchaggNo ratings yet

- Concrete BlocksDocument16 pagesConcrete BlocksRohita DasguptaNo ratings yet

- Rapid CastingDocument23 pagesRapid CastingquarkenNo ratings yet

- Sca-Pca RCC Design SeminarDocument40 pagesSca-Pca RCC Design Seminarintimate4lifeNo ratings yet

- Sika PDS E Sika CrackstopDocument2 pagesSika PDS E Sika Crackstoplwin_oo2435No ratings yet

- Tur BDocument148 pagesTur Bel_morshedyNo ratings yet

- DAR Vol 2Document1,371 pagesDAR Vol 2gyan_th9229No ratings yet

- Arkema PDFDocument38 pagesArkema PDFDo Hyung KimNo ratings yet

- 7465 - Sigmacover 435Document0 pages7465 - Sigmacover 435eraswastaNo ratings yet

- Design Application & Installation Information: Service ConditionsDocument10 pagesDesign Application & Installation Information: Service ConditionsjoechengshNo ratings yet