Professional Documents

Culture Documents

Thickness Calculation

Uploaded by

Akash MehrotraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thickness Calculation

Uploaded by

Akash MehrotraCopyright:

Available Formats

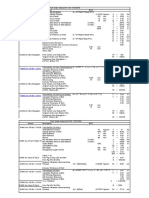

F-40 THICKNESS CALCULATION

t=PD

+c

2(SE+PY)

P

DESIGN PRESSURE

D

S

E

Y

OD OF PIPE

ALLOWABLE STRESS

(TAB )

QUALITY FACTOR

(TAB A-1A OR A-1B)

CO-EFF FROM TABLE

FROM TABLE 304.1.1

DESIGN CONDITIONS:

DESIGN PRES.(P)

TEMPERATURE

=

PIPING MATERIAL

:

ALLOWABLE STRESS

C.A

MILL TOLERENCE

48

KG/CM2 (g)

350

662

ASTM-A358 304 EFW

13652

960.056259

12.5 MM

t = minimum calculated thickness, t1= Actual thickness

NPS

(INCH)

O.D.

D.P.

MILL

MM

KG/CM2(g)

KG/CM2(g)

(D)

(P)

(f)

t=PD

t1=

+c

Tolerence

t/(1-m)

2(SE+PY)

m=12.5%

or t/0.875

(MM)

(MM)

ADOPTED

THICKNESS

(MM)

REMARKS

SCH

0.5

21.34

48

960

0.52

0.125

0.60

3/4

26.67

48

960

0.65

0.125

0.75

33.40

48

960

0.82

0.125

0.94

1 1/2

48.30

48

960

1.18

0.125

1.35

60.30

48

960

1.48

0.125

1.69

2.5

73.05

48

960

1.79

0.125

2.05

88.90

48

960

2.18

0.125

2.49

THICKNESS

114.30

48

960

2.80

0.125

3.20

ADOPTED

168.30

48

960

4.12

0.125

4.71

IS

219.08

48

960

5.37

0.125

6.14

SAFE

10

273.00

48

960

6.69

0.125

7.65

12

323.90

48

960

7.94

0.125

9.07

14

355.60

48

960

8.72

0.125

9.96

16

406.40

48

960

9.96

0.125

11.38

18

457.00

48

960

11.20

0.125

12.80

20

508.00

48

960

12.45

0.125

14.23

TEST

PRESS.=

72

KG/CM2(g) (TEST PRESSURE ARE CALCULATED AS PER CLAUSE NO.374 OF IBR 1992 EDITION &

CLAUSE No.137.4.5 of ANSI B31.1 1989 EDITION

You might also like

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Document6 pagesCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNo ratings yet

- 8KL FERMENTER DESIGN CALCULATIONSDocument3 pages8KL FERMENTER DESIGN CALCULATIONSkirandas_mullasseryNo ratings yet

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Mathcad - ASME I I VIII I Thickness Cylindrical ShellDocument3 pagesMathcad - ASME I I VIII I Thickness Cylindrical ShellkurcekNo ratings yet

- Base Plate and Anchor Bolt DesignDocument9 pagesBase Plate and Anchor Bolt DesignShaikh Muhammad Ateeq100% (2)

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Thickness Calculation of Pressure Vessel ShellDocument22 pagesThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- Rumus Internal External PressureDocument6 pagesRumus Internal External PressureDidi SudiprayitnaNo ratings yet

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Thickness Calculation of Pressure Vessel ShellDocument17 pagesThickness Calculation of Pressure Vessel ShellVishnuGK100% (1)

- API Calcs Rev1 Version 2Document107 pagesAPI Calcs Rev1 Version 2JithuJohnNo ratings yet

- Wall THK Calculation Asme b31.4Document7 pagesWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- API Calcs Rev1 (Version 2)Document112 pagesAPI Calcs Rev1 (Version 2)Jake Sparrow100% (1)

- Calculation of Minimum Pipe ThicknessDocument1 pageCalculation of Minimum Pipe ThicknessSanda PribicNo ratings yet

- Lug Support DesignDocument3 pagesLug Support DesignSajal KulshresthaNo ratings yet

- ASME B31.3 - 2008 PipeCalculationDocument6 pagesASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Asme Viii CalcsDocument20 pagesAsme Viii CalcsSriram VjNo ratings yet

- ASME Design of Buoy For FRP Pipe TestingDocument5 pagesASME Design of Buoy For FRP Pipe TestingarkadjyothiprakashNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Asme Sec 1 (Boiler)Document15 pagesAsme Sec 1 (Boiler)Arie MahendraNo ratings yet

- Design 1Document29 pagesDesign 1Nikki RobertsNo ratings yet

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínNo ratings yet

- Design of Hinged Base r3 22, Mar. 2011Document10 pagesDesign of Hinged Base r3 22, Mar. 2011sitehabNo ratings yet

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- Weight CalculatorDocument12 pagesWeight CalculatorShafqat AfridiNo ratings yet

- Isolated Sloped FootingDocument9 pagesIsolated Sloped Footingarif_rubinNo ratings yet

- Design Calc Sheet - Septic Tank Rev1 15-03-09 - 200Document12 pagesDesign Calc Sheet - Septic Tank Rev1 15-03-09 - 200Bok MortegaNo ratings yet

- Pipe Thickness Design Calculation 1500 MMDocument1 pagePipe Thickness Design Calculation 1500 MMSatish Kumar MauryaNo ratings yet

- Engineering Example CalculationDocument78 pagesEngineering Example Calculationkae kaeNo ratings yet

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- ASME B31.3 wall thickness calcDocument11 pagesASME B31.3 wall thickness calcAnonymous wIPMQ5rhNo ratings yet

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuNo ratings yet

- Code Sec.: PD C Se P Y C D Set Xcrxyrs C DDocument1 pageCode Sec.: PD C Se P Y C D Set Xcrxyrs C DsubhaNo ratings yet

- Lifting Lug Analysis DesignDocument5 pagesLifting Lug Analysis DesignAlessio BarboneNo ratings yet

- PV Elite 2008 Licensee: Zishan Engineers (PVT.) Ltd. Filename: Tach - Internal Pressure Calculations Step: 3 9:38A May 4,2013Document11 pagesPV Elite 2008 Licensee: Zishan Engineers (PVT.) Ltd. Filename: Tach - Internal Pressure Calculations Step: 3 9:38A May 4,2013Nassima ChaoukiNo ratings yet

- Super CalculationsDocument12 pagesSuper CalculationsCarlos Tijerina0% (1)

- Anchor Bolt Chairs - CalculationDocument8 pagesAnchor Bolt Chairs - Calculationchicaiza123No ratings yet

- Reinforcement CheckDocument2 pagesReinforcement Checkviv0102No ratings yet

- Isolated Footing UniaxialDocument8 pagesIsolated Footing Uniaxialrvshankar143No ratings yet

- Pipe Wall Thickness CalculationDocument8 pagesPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- Bracket - 4 DesignDocument1 pageBracket - 4 Designbjreddy100% (2)

- Calculation of PipeReinforcement ASMEB31.1Document3 pagesCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- Mud Gas Separator CalculationDocument16 pagesMud Gas Separator CalculationErwin Gomop-asNo ratings yet

- Stress NomographDocument1 pageStress NomographAkash MehrotraNo ratings yet

- 10131948Document66 pages10131948Akash MehrotraNo ratings yet

- Steam Source Book 2Document108 pagesSteam Source Book 2joe_pulaskiNo ratings yet

- Dat P Gas PipingDocument1 pageDat P Gas PipingAkash MehrotraNo ratings yet

- Material Data Sheets For Piping M-630Document85 pagesMaterial Data Sheets For Piping M-630Akash MehrotraNo ratings yet