Professional Documents

Culture Documents

PQR-WPS-WPQR XXX Rev 0

Uploaded by

Brett GosselinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PQR-WPS-WPQR XXX Rev 0

Uploaded by

Brett GosselinCopyright:

Available Formats

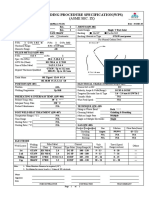

WELDING PROCEDURE QUALIFICATION RECORD

G.T.A.W- Without PWHT For Pressure Pipng & GTAW Applications: USE: Within the Limits of the relevant essential and sub essential variables and paramiters of the standard. To: ASME IX & AS/NZS 3992 WELDING PROCESS: G.T.A.W A1-P1 to A1-P1

009 REV: 0 19/02/2009 Test Date: 14/01/2009 WPS No: 001 REV: 0

PQR No: Date:

WELD JOINT AND PREPARATION

Page: 1 of 10 Welding Code: ASME IX 2010, AS/NZS 3992.1998 (Amdt 1) Construction Code: B31.3 2008 Others: JOINT TOLERENCE Included Angle : 60 Bevel Angle: 30 Position of groove: 3G Root Face (mm): 0 Root Gap (mm): 0--1mm Misalignment (mm): 1.6Max /1:4 Taper Backing: N/A Backing Type: N/A Prep Method: Grind / Machine Cleaning: Grind / Brush

CODE/ SPEC ASME 1X

Material 1 ASME P No: 1

BASE METAL QUALIFIED

GROUP No: 1 1 CE (%)

WELDED TO

CODE/ SPEC ASME 1X

ASME P No: 1

Material 2 GROUP No: 1 1

POSITION QUALIFIED

CE (%)

POSITION WELDING PROGRESSION

6G Notes:

Uphill Only Coupon 10mm Plate x 300mm

AS 3992 A1-A2 Batch Number: THICKNESS (mm) 10

AS 3992 A1-A2 Batch Number:

MATERIAL THICKNESS AND DIAMETER (mm) QUALIFIED OUTSIDE DIA (mm) INSIDE DIA (mm) FILLET SIZE (mm) N/A N/A N/A Consumable 1: Consumable 2:

ASME IX/AS/NZS3992 ASME IX/AS/NZS3992

OTHER INFORMATION: N/R = Not recorded. N/A = Not Applicable. SHEILDING AND BACKING GAS Comp.(%) Flow Rate(L/Min) ARGON Backing OTHER CONSUMABLE INFO Tungsten Size: 2.4 Tungsten Type: THOR 99.99 Gas Cup Size(ID): 16 CTWD(mm): 2.5 Consumable 1: Transfer Mode: Solid/Tubular: Solid Consumable 2: Transfer Mode: Solid/Tubular:

FILLER METALS Specification: Classification: Filler metal F No: Weld metal A No: Size of Filler Metal: Weld Metal Thickness: Trade Names: Wire Flux Designation: Flux Specification: Batch Number: Pipe/Clamp Details: alignment of joint. Tack Welds:

SFA 5.18 ER70S-6 6 1 2.4 N/R TALARC ST-50.6 N/A CMR No HJ2711331308 JOINT SUPPORT & TACKING N/A Lot No 6626309 Bend type: No of runs/side: No of Electrodes: Transfer mode: Other:

C

Type Shielding

Trailing

(QW 408) Other TECHNIQUE Weave all Passes 5 single N/A = Not Applicable. Uphill Progression all Passes

C

Bridge Tack and Remove as Required.

Oscillation: Back Gouging: Max. Run "t" Peening:

Inter-run Temp:

Wire Speed (mm/min)

6-14mm N/A <12mm N/A

131 C

PREHEAT & INTERRUN TEMPERATURES

Preheat: 40 C For Thickness 20mm For Thickness 20mm

Layer Run No: 1 3G 2 3G 3 3G 4 3G 5 3G 6 7 8 Other: PWHT (QW 407) NOTES: 1. Inter runs: 2. Weld Repairs :

WELDING DETAILS Position Process G.T.A.W G.T.A.W G.T.A.W G.T.A.W G.T.A.W

Classification

ASME SFA5.18ER70S-6 ASME SFA5.18ER70S-6 ASME SFA5.18ER70S-6 ASME SFA5.18ER70S-6 ASME SFA5.18ER70S-6

FILLER METAL: Trade name mm ST-50.6 2.4 ST-50.6 2.4 ST-50.6 2.4 ST-50.6 2.4 ST-50.6 2.4

Current (Amps) 100 156 158 155 156

Voltage VOLTS 10.5 13.5 12.5 12 11.8

ELECTRICAL CHARACTERISTICS INTER PASS POLARITY T/Speed Temp mm/min 52 40 DC83 62 DC57 65 DC56 86 DC40 131 DC-

WIRE Gas L/pm 12 12 12 12 12

Heat input

N/R N/R N/R N/R N/R

kj/mm 1.21 1.52 2.08 1.99 2.76

Temp:

N/A

Time(hrs):

N/A

Heating RateC/hr) N/A Cooling Rate(C/hr) Results: Report Number's Visual Radiographic Complies N.I & E.S Guide Bends Complies QRM09-0075-04 Other: Complies QRM09-0075D Tensile Complies QRM09-0075-04

N/A Macro Complies QRM09-0075-04 Face & Root Bends Complies QRM09-0075-04

Shall be free from any materials such as slag, scale etc which may impair the weld quality.

3. Consumable handling: 4. Tack Welding: 5. Fabricator: VALIDITY: Name: Company: Sign: Date

As per the relevant code or standard and the consumable suppliers requirements and recommendations. 15mm Bridge tracks as required.

To prove ability to use this PQR, Visual inspection & report and NDT?Mechanical testing/reports as per Code/Standard requirements. This procedure is only valid when approved and endorsed by the fabricator, Client or Client representative.

Compiled by:

G.shields

National Inspection & Expediting Services Pty Ltd

Welded by:

Name: Company: Sign: Date Anthony J Brosnan ID: AB-01 Brosco Enterprises Pty Ltd

Approved by:

Name: Company: Sign: Date Brett Gosselin Brosco Enterprises Pty Ltd

1/20/2009

1/20/2009

1/20/2009

WPS No: Date:

008-1

REV: 1

Rev (1) 02/03/2012 Rev (0) 19/01/2009

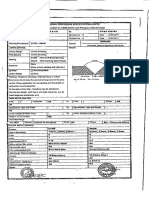

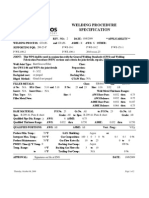

WELDING PROCEDURE SPECIFICATION

G.T.A.W- Without PWHT For Pressure Pipng & GTAW Applications: USE: Within the Limits of the relevant essential and sub essential variables and paramiters of the standard. To: ASME IX & AS 3992

Date:

Supporting PQR No: Page: WELDING PROCESS: G.T.A.W A1-P1 to A1-P1 Included Angle : Bevel Angle: Position of groove: Root Face (mm): Root Gap (mm): Misalignment (mm): Backing: Backing Type: Prep Method: Cleaning: Material 1 CODE/ SPEC ASME 1X AS 3992 ASME P No: 1 A1-A2 THICKNESS AND DIAMETER (mm) QUALIFIED THICKNESS (mm) 1.5 - 12.2 FILLER METALS Specification: Classification: Filler metal F No: Weld metal A No: Size of Filler Metal: Weld Metal Thickness: Trade Names: Wire Flux Designation: Flux Specification: JOINT SUPPORT & TACKING Pipe/Clamp Details: alignment of joint. Tack Welds: Use Mechanical Pipe Clamp to ensure Bend type: No of runs/side: No of Electrodes: Transfer mode: Other: Uphill Progression all Passes

For Thickness 20 C

1 of 1 AS/NZS 3992.1998 (Amdt 1)

Welding Code: ASME IX 2010, Construction Code: B31.3 2008 Others: ACTUAL JOINT TOLERENCE RECORD 60 30 45 Inclined 1 4 1.6Max /1:4 Taper N/A N/A Grind / Machine Grind / Brush

WELD JOINT AND PREPARATION

BASE METAL SPECS (QW 403)

GROUP No: 1 CE (%)

Material 2 CODE/ SPEC ASME 1X AS 3992 ASME P No: 1 A1-A2 N/R = Not recorded. N/A = Not Applicable. SHEILDING AND BACKING GAS Type Shielding Argon 99.90% 12--15 Comp.(%) Flow Rate(L/Min) GROUP No: 1 CE (%)

Material: 1

Material Grade QUALIFIED:

P1 G1 - P1 - G1 , P1 G1 - P1 G2 , P1 G2 - P1 G2 Material: 2 P1 G1 - P1 - G1 , P1 G1 - P1 G2 , P1 G2 - P1 G2 OTHER INFORMATION:

WELDED TO

OUTSIDE DIA (mm) ALL

INSIDE DIA (mm) ALL ASME IX SFA 5.18 ER70S-6 6 2.4

FILLET SIZE (mm)

ALL SIZES

AS/NZS3992 1167.2 R6 6 2.4

OTHER CONSUMABLE INFO Tungsten Size: Tungsten Type: Gas Cup Size(ID): CTWD(mm): 1.6-2.4 THOR 8--16 2.5

Backing

N/A Transfer Mode: Trailing N/A Flux Type: TECHNIQUE Root pass - Stringer Fill passes - Weave 3 single Oscillation: Back Gouging: Max. Run "t" Peening:

Inter-run Temp: C

No greater than 12mm Any Approved Supplier N/A N/A

N/A Solid N/A

Solid/Tubular:

12mm

Bridge tack or bullets Tack using same consumable as the root and remove as Required.

PREHEAT & INTERRUN TEMPERATURES

Preheat: 35 For Thickness 20mm C

Layer Run No: Root H/Pass CAP

WELDING DETAILS Process G.T.A.W G.T.A.W G.T.A.W

FILLER METAL: Classification ER70-4 / ER70-6 ER70-4 / ER70-6 ER70-4 / ER70-6 Trade name ST-50.6 ST-50.6 ST-50.6 mm 2.4 2.4 2.4 Current (Amps) 116-140 116-140 116-140 Voltage VOLTS 10--12 10--12 10--12

ELECTRICAL CHARACTERISTICS T/Speed mm/min 54--78 54--78 54--78

INTER PASS Temp

WIRE

Wire Speed (mm/min)

POLARITY DCDCDC-

Gas L/pm 12 12 12

Heat input

kj/mm

35 35 35

N/R N/R N/R

Other: PWHT NOTES: 1. Inter runs: 2. Weld Repairs : 3. Consumable handling: 4. Tack Welding: 5. Fabricator: VALIDITY: Name: Company: Sign: Date 1/20/2009 Shall be free from any materials such as slag, scale etc which may impair the weld quality. This procedure also covers weld repairs and weld build up. As per the relevant code or standard and the consumable suppliers requirements and recommendations. Welders shall be qualified to and work within the essential variables and parameters of this WPS To prove ability to use this WPS by documented evidence of a supporting PQR, Visual inspection & report and NDT/Mechanical testing/reports as per Code/Standard requirements. (QW 407) Temp: N/A C Time(hrs): N/A Heating RateC/hr) N/A Cooling Rate(C/hr) N/A

This procedure is only valid when approved and endorsed by the fabricator, Client or Client representative.

Compiled by:

G.shields

National Inspection & Expediting Services Pty Ltd

Approved By:

Name: Company: Sign: Date 1/20/2009 Brett Gosselin Brosco Enterprises Pty Ltd

Client Approval by:

Name: Company: Sign: Date

PQR No:

008 Date Tested:

REV:

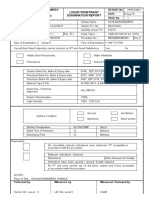

WELDER QUALIFICATION RECORD

WPS No: G.T.A.W- Without PWHT For Pressure Pipng & GTAW Applications: USE: Within the Limits of the relevant essential and sub essential variables and paramiters of the standard. To: ASME 1X & AS WELDING PROCESS:

008-1

REV:

WELD JOINT AND PREPARATION

Page: 1 of 10 Welding Code: ASME IX 2010, AS/NZS 3992.1998 (Amdt 1) G.T.A.W Construction Code: B31.3 2008 A1-P1 to A1-P1 Others: QCLNG-BX00-PIP-SPE-300041 JOINT TOLERENCE ACTUAL Included Angle : 60-70 Bevel Angle: 30-35 Position of groove: 45 Inclined Root Face (mm): 0-2 Root Gap (mm): 3--4mm Misalignment (mm): 1.6Max /1:4 Taper Backing: N/A Backing Type: N/A Prep Method: Grind / Machine Cleaning: Grind / Brush Material 2

Material 1 CODE/ SPEC ASME 1X AS 3992 ASME P No: 1 A1-A2 GROUP No: 1 CE (%)

BASE METAL QUALIFIED

POSITION QUALIFIED

CE (%) Notes:

POSITION WELDING PROGRESSION

WELDED TO

CODE/ SPEC ASME 1X AS 3992 FILLET SIZE (mm) AS/NZS3992 1167.2 R6 6 1 2.4 N/R

ASME P No: 1 A1-A2

GROUP No: 1 1

THICKNESS (mm) FILLER METALS Specification: Classification: Filler metal F No: Weld metal A No: Size of Filler Metal: Weld Metal Thickness: Trade Names: Wire Flux Designation: Flux Specification: Batch Number: Pipe/Clamp Details: alignment of joint. Tack Welds:

1 MATERIAL THICKNESS AND DIAMETER (mm) QUALIFIED OUTSIDE DIA (mm) INSIDE DIA (mm) ASME IX SFA 5.18 ER70S-6 6 1 2.4 N/R INE N/A N/A E00410103 JOINT SUPPORT & TACKING Use Mechanical Pipe Clamp to ensure

OTHER INFORMATION: N/R = Not recorded. N/A = Not Applicable. SHEILDING AND BACKING GAS OTHER CONSUMABLE INFO Type Comp.(%) Flow Rate(L/Min) Tungsten Size: Shielding Tungsten Type: Argon 99.99% 11 Gas Cup Size(ID): CTWD(mm): Backing Transfer Mode: Solid/Tubular: Flux Type:

2.4 THOR 10 2.5

Trailing (QW 408) Other TECHNIQUE Root-Stringer / Fill & Cap weaved 3 single Uphill Progression all Passes

C

N/A Solid N/A

Bridge Tack and Remove as Required.

Bend type: No of runs/side: No of Electrodes: Transfer mode: Other:

Oscillation: Back Gouging: Max. Run "t" Peening:

Inter-run Temp:

Wire Speed (mm/min)

N/A N/A Root-3mm

PREHEAT & INTERRUN TEMPERATURES

Preheat: For Thickness 20mm C For Thickness 20 C

Layer Run No: Root Fill/ Cap

WELDING DETAILS Position Process 6G 6G G.T.A.W G.T.A.W

Classification

ER70-6 ER70-6

FILLER METAL: Trade name mm INE 2.4 INE 2.4

Current (Amps) 115 130

Voltage VOLTS 9.9 11.8

ELECTRICAL CHARACTERISTICS INTER PASS POLARITY T/Speed Temp mm/min 90 40 DC66 60 DC-

WIRE Gas L/pm 15 15

Heat input

N/R N/R

kj/mm 0.76 1.39

Other: PWHT (QW 407) Temp: N/A C Time(hrs): N/A Heating RateC/hr) N/A Cooling Rate(C/hr) N/A NOTES: Results: Report Number's Visual Radiographic Macro 1. Inter runs: Shall be free from any materials such as slag, scale etc which may impair the weld quality. Complies Complies 2. Weld Repairs : N/A Brett Gosselin Guide Bends Face & Root Bends Tensile 3. Consumable handling: As per the relevant code or standard and the consumable suppliers requirements and recommendations. 4. Tack Welding: 15mm Bridge tracks as required. Other: Purchase order 4469 ALS Labaratory 5. Fabricator: VALIDITY: Name: Company: Sign: Date To prove ability to use this PQR, Visual inspection & report and NDT? Mechanical testing/reports as per Code/Standard requirements. This procedure is only valid when approved and endorsed by the fabricator, Client or Client representative.

Compiled by:

Brett Gosselin Brosco Enterprises Pty Ltd

Welded by:

Name: Company: Sign: Date ID No: Brosco Enterprises Pty Ltd

Approved by:

Name: Company: Sign: Date Brett Gosselin Brosco Enterprises Pty Ltd

PQR No:

008 Date Tested:

REV:

1/20/2009

WELDER QUALIFICATION RECORD

WPS No: G.T.A.W- Without PWHT For Pressure Pipng & GTAW Applications: USE: Within the Limits of the relevant essential and sub essential variables and paramiters of the standard. To: ASME 1X & AS WELDING PROCESS:

008-1

REV:

WELD JOINT AND PREPARATION

Page: 1 of 1 Welding Code: ASME IX 2010, AS/NZS 3992.1998 (Amdt 1) G.T.A.W Construction Code: B31.3 2008 A1-P1 to A1-P1 Others: QCLNG-BX00-PIP-SPE-300041 JOINT TOLERENCE ACTUAL Included Angle : 60-70 70 Bevel Angle: 30-35 35 Position of groove: 45 Inclined 6G/45 Root Face (mm): 0-2 0 Root Gap (mm): 3--4mm 4 Misalignment (mm): 1.6Max /1:4 Taper 0 Backing: N/A N/A Backing Type: N/A N/A Prep Method: Grind / Machine Grind / Machine Cleaning: Grind / Brush Grind / Machine Material 2

Material 1 CODE/ SPEC ASME 1X ASME P No: 1 GROUP No: 1 1 CE (%)

BASE METAL QUALIFIED

POSITION QUALIFIED

CE (%)

POSITION WELDING PROGRESSION

WELDED TO

CODE/ SPEC ASME 1X

ASME P No: 1

GROUP No: 1

6/G Notes:

Uphill only ASTM A106 Grade B SCH 40

AS 3992 A1-A2 1 801157 Batch Number: 801157 MATERIAL THICKNESS AND DIAMETER (mm) QUALIFIED OTHER INFORMATION: THICKNESS (mm) OUTSIDE DIA (mm) INSIDE DIA (mm) FILLET SIZE (mm) N/R = Not recorded. 6.02 114.3 102.26 N/A N/A = Not Applicable. FILLER METALS ASME IX AS/NZS3992 SHEILDING AND BACKING GAS OTHER CONSUMABLE INFO Specification: SFA 5.18 1167.2 Type Comp.(%) Flow Rate(L/Min) Tungsten Size: Classification: ER70S-6 R6 Shielding Tungsten Type: Filler metal F No: 6 6 Argon 99.99% 11 Gas Cup Size(ID): Weld metal A No: 1 1 CTWD(mm): Size of Filler Metal: 2.4 2.4 Backing Weld Metal Thickness: N/R N/R Trade Names: Talarc ST-50.6 Transfer Mode: Wire Flux Designation: N/A Trailing Solid/Tubular: Flux Specification: N/A Batch Number: CMR No HJ2711331308 Lot No 6626309 (QW 408) Other Flux Type: JOINT SUPPORT & TACKING TECHNIQUE Pipe/Clamp Details: Use Mechanical Pipe Clamp to ensure Bend type: Root-Stringer / Fill & Cap weaved alignment of joint. No of runs/side: 3 Oscillation: N/A Tack Welds: Bridge Tack and Remove as Required. No of Electrodes: single Back Gouging: N/A Transfer mode: Max. Run "t" Root-3mm Other: Uphill Progression all Passes Peening:

AS 3992 A1-A2 Batch Number:

2.4 THOR 10 2.5

N/A Solid N/A

PREHEAT & INTERRUN TEMPERATURES

Preheat: 35 C For Thickness 20mm C For Thickness 20 C Inter-run Temp:

Wire Speed (mm/min)

127(max) C

Layer Run No: Root 2 3

WELDING DETAILS Position Process 6G 6G 6G G.T.A.W G.T.A.W G.T.A.W

Classification

ER70-6 ER70-6 ER70-6

FILLER METAL: Trade name mm INE INE INE

2.4 2.4 2.4

Current (Amps) 115 140 130

Voltage VOLTS 10 12 11.7

ELECTRICAL CHARACTERISTICS INTER PASS POLARITY T/Speed Temp mm/min 90 40 DC66 60 DC78 127 DC-

WIRE Gas L/pm 15 15 15

Heat input

N/R N/R N/R

kj/mm 0.77 1.53 1.17

Other: PWHT (QW 407) Temp: N/A C Time(hrs): N/A Heating RateC/hr) N/A NOTES: Results: Report Number's Visual 1. Inter runs: Shall be free from any materials such as slag, scale etc which may impair the weld quality. Complies 2. Weld Repairs : N/A N.I & E.S Guide Bends 3. Consumable handling: As per the relevant code or standard and the consumable suppliers requirements Complies and recommendations. QRM09-0075-07 4. Tack Welding: 15mm Bridge tracks as required. Other: 5. Fabricator: VALIDITY: Name: Company: Sign: Date To prove ability to use this PQR, Visual inspection & report and NDT? Mechanical testing/reports as per Code/Standard requirements. This procedure is only valid when approved and endorsed by the fabricator, Client or Client representative.

Cooling Rate(C/hr)

N/A

Radiographic Macro Complies Complies QRM09-0075-J QRM09-0075-07 Face & Root Bends Tensile Complies QRM09-0075-07 Purchase order 01719 ALS Labaratory

Compiled by:

Brett Gosselin Brosco Enterprises Pty Ltd

Welded by:

Name: Company: Sign: Date Anthony Brosnan ID No: Brosco Enterprises Pty Ltd AB-01

Approved by:

Name: Company: Sign: Date Brett Gosselin Brosco Enterprises Pty Ltd

1/20/2009

1/20/2009

1/20/2009

PQR No:

008

REV:

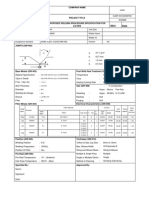

WELDER QUALIFICATION RECORD

WPS No: G.T.A.W- Without PWHT For Pressure Pipng & GTAW Applications: USE: Within the Limits of the relevant essential and sub essential variables and paramiters of the standard. To: ASME 1X & AS WELDING PROCESS:

Date Tested: 2/10/2012 008-1 REV: 1

WELD JOINT AND PREPARATION

Page: 1 of 2 Welding Code: ASME IX 2010, AS/NZS 3992.1998 (Amdt 1) G.T.A.W Construction Code: B31.3 2008 A1-P1 to A1-P1 Others: QCLNG-BX00-PIP-SPE-300041 JOINT TOLERENCE ACTUAL Included Angle : 60-70 70 Bevel Angle: 30-35 35 Position of groove: 45 Inclined 6G / 45 Root Face (mm): 0-2 0 Root Gap (mm): 3--4mm 3 Misalignment (mm): 1.6Max /1:4 Taper 0 Backing: N/A N/A Backing Type: N/A N/A Prep Method: Grind / Machine Machined Cleaning: Grind / Brush Grind/Brush Material 2

Material 1 CODE/ SPEC ASME 1X AS 3992 ASME P No: 1 A1-A2 GROUP No: 1 CE (%)

BASE METAL QUALIFIED

POSITION QUALIFIED

CE (%)

POSITION WELDING PROGRESSION

WELDED TO

CODE/ SPEC ASME 1X

ASME P No: 1 A1-A2

GROUP No: 1 1

6G Notes:

Uphill

1 AS 3992 MATERIAL THICKNESS AND DIAMETER (mm) QUALIFIED THICKNESS (mm) OUTSIDE DIA (mm) INSIDE DIA (mm) FILLET SIZE (mm) N/A 4.55 33.4 24.3 FILLER METALS ASME IX AS/NZS3992 Specification: SFA 5.18 1167.2 Classification: ER70S-6 R6 Filler metal F No: 6 6 Weld metal A No: 1 1 Size of Filler Metal: 2.4 2.4 Weld Metal Thickness: N/R N/R Trade Names: INE Wire Flux Designation: N/A Flux Specification: N/A Batch Number: E00410103 JOINT SUPPORT & TACKING Pipe/Clamp Details: Use Mechanical Pipe Clamp to ensure Bend type: alignment of joint. No of runs/side: Bridge Tack and Remove as Required. Tack Welds: No of Electrodes: Transfer mode: Other:

Preheat: 25 C For Thickness 20mm C

OTHER INFORMATION: N/R = Not recorded. N/A = Not Applicable. SHEILDING AND BACKING GAS OTHER CONSUMABLE INFO Type Comp.(%) Flow Rate(L/Min) Tungsten Size: 2.4 Shielding Tungsten Type: THOR Argon 99.99% 11 Gas Cup Size(ID): 10 CTWD(mm): 2.5 Backing Transfer Mode: Solid/Tubular: Flux Type: N/A Solid N/A

Trailing (QW 408) Other TECHNIQUE Root-Stringer / Fill & Cap weaved 2 single Uphill Progression all Passes

C

Oscillation: Back Gouging: Max. Run "t" Peening:

Inter-run Temp:

Wire Speed (mm/min)

N/A N/A Root-3mm

PREHEAT & INTERRUN TEMPERATURES

For Thickness 20 127(Max) C

Layer Run No: Root Fill/ Cap

WELDING DETAILS Position Process 6G 6G G.T.A.W G.T.A.W

Classification

ER70-6 ER70-6

FILLER METAL: Trade name mm INE 2.4 INE 2.4

Current (Amps) 115 130

Voltage VOLTS 9.9 11.8

ELECTRICAL CHARACTERISTICS INTER PASS POLARITY T/Speed Temp mm/min 90 40 DC66 60 DC-

WIRE Gas L/pm 15 15

Heat input

N/R N/R

kj/mm 0.76 1.39

Other: PWHT (QW 407) Temp: N/A C Time(hrs): N/A Heating RateC/hr) N/A Cooling Rate(C/hr) N/A NOTES: Results: Report Number's Visual Radiographic Macro 1. Inter runs: Shall be free from any materials such as slag, scale etc which may impair the weld quality. Complies Complies 2. Weld Repairs : N/A Brett Gosselin 44120232-02 Guide Bends Face & Root Bends Tensile 3. Consumable handling: As per the relevant code or standard and the consumable suppliers requirements and recommendations. 4. Tack Welding: 15mm Bridge tracks as required. Other: PO 4469 ALS Labaratory Report: 44120232-02 (06/03/2012) 5. Fabricator: To prove ability to use this PQR, Visual inspection & report and NDT? Mechanical testing/reports as per Code/Standard requirements. VALIDITY: This procedure is only valid when approved and endorsed by the fabricator, Client or Client representative.

Compiled by:

Name: Company: Sign: Date Brett Gosselin Brosco Enterprises Pty Ltd

Welded by:

Name: Company: Sign: Date Neil Wildgoose ID No: Brosco Enterprises Pty Ltd NW-54

Approved by:

Name: Company: Sign: Date Brett Gosselin Brosco Enterprises Pty Ltd

2/10/2012

2/10/2012

2/25/2012

PQR No:

008 Date Tested:

REV:

2/25/2012

WELDER QUALIFICATION RECORD

WPS No: G.T.A.W- Without PWHT For Pressure Pipng & GTAW Applications: USE: Within the Limits of the relevant essential and sub essential variables and paramiters of the standard. To: ASME 1X & AS WELDING PROCESS:

008-1

REV:

WELD JOINT AND PREPARATION

Page: 1 of 10 Welding Code: ASME IX 2010, AS/NZS 3992.1998 (Amdt 1) G.T.A.W Construction Code: B31.3 2008 A1-P1 to A1-P1 Others: QCLNG-BX00-PIP-SPE-300041 JOINT TOLERENCE ACTUAL Included Angle : 60-70 70 Bevel Angle: 30-35 35 Position of groove: 45 Inclined 6G / 45 Root Face (mm): 0-2 0 Root Gap (mm): 3--4mm 3 Misalignment (mm): 1.6Max /1:4 Taper 0 Backing: N/A N/A Backing Type: N/A N/A Prep Method: Grind / Machine Machined Cleaning: Grind / Brush Grind/Brush Material 2

Material 1 CODE/ SPEC ASME 1X AS 3992 ASME P No: 1 A1-A2 GROUP No: 1 CE (%)

BASE METAL QUALIFIED

POSITION QUALIFIED

CE (%)

POSITION WELDING PROGRESSION

WELDED TO

CODE/ SPEC ASME 1X AS 3992 FILLET SIZE (mm) AS/NZS3992 1167.2 R6 6 1 2.4 N/R

ASME P No: 1 A1-A2

GROUP No: 1 1

6G Notes:

Uphill

THICKNESS (mm) FILLER METALS Specification: Classification: Filler metal F No: Weld metal A No: Size of Filler Metal: Weld Metal Thickness: Trade Names: Wire Flux Designation: Flux Specification: Batch Number: Pipe/Clamp Details: alignment of joint. Tack Welds:

1 MATERIAL THICKNESS AND DIAMETER (mm) QUALIFIED OUTSIDE DIA (mm) INSIDE DIA (mm) ASME IX SFA 5.18 ER70S-6 6 1 2.4 N/R INE N/A N/A E00410103 JOINT SUPPORT & TACKING Use Mechanical Pipe Clamp to ensure

OTHER INFORMATION: N/R = Not recorded. N/A = Not Applicable. SHEILDING AND BACKING GAS OTHER CONSUMABLE INFO Type Comp.(%) Flow Rate(L/Min) Tungsten Size: Shielding Tungsten Type: Argon 99.99% 11 Gas Cup Size(ID): CTWD(mm): Backing Transfer Mode: Solid/Tubular: Flux Type:

2.4 THOR 10 2.5

Trailing (QW 408) Other TECHNIQUE Root-Stringer / Fill & Cap weaved 3 single Uphill Progression all Passes

C

N/A Solid N/A

Bridge Tack and Remove as Required.

Bend type: No of runs/side: No of Electrodes: Transfer mode: Other:

Oscillation: Back Gouging: Max. Run "t" Peening:

Inter-run Temp:

Wire Speed (mm/min)

N/A N/A Root-3mm

PREHEAT & INTERRUN TEMPERATURES

Preheat: 35 C For Thickness 20mm C For Thickness 20 124 C

Layer Run No: Root 2 3

WELDING DETAILS Position Process 6G 6G 6G G.T.A.W G.T.A.W G.T.A.W

Classification

ER70-6 ER70-6 ER70-6

FILLER METAL: Trade name mm INE INE INE

2.4 2.4 2.4

Current (Amps) 115 130 130

Voltage VOLTS 9.9 11.8 11.8

ELECTRICAL CHARACTERISTICS INTER PASS POLARITY T/Speed Temp mm/min 83 40 DC77 60 DC58 124 DC-

WIRE Gas L/pm 15 15 15

Heat input

N/R N/R N/R

kj/mm 0.82 1.20 1.59

Other: PWHT (QW 407) Temp: N/A C Time(hrs): N/A Heating RateC/hr) N/A Cooling Rate(C/hr) N/A NOTES: Results: Report Number's Visual Radiographic Macro 1. Inter runs: Shall be free from any materials such as slag, scale etc which may impair the weld quality. Complies Complies 2. Weld Repairs : N/A Brett Gosselin Guide Bends Face & Root Bends Tensile 3. Consumable handling: As per the relevant code or standard and the consumable suppliers requirements and recommendations. 4. Tack Welding: 15mm Bridge tracks as required. Other: Purchase order 4471 ALS Labaratory Report: 5. Fabricator: To prove ability to use this PQR, Visual inspection & report and NDT? Mechanical testing/reports as per Code/Standard requirements. VALIDITY: This procedure is only valid when approved and endorsed by the fabricator, Client or Client representative.

Compiled by:

Name: Company: Sign: Date Brett Gosselin Brosco Enterprises Pty Ltd

Welded by:

Name: Company: Sign: Date Larry Nevaro ID No: Brosco Enterprises Pty Ltd LN-56

Approved by:

Name: Company: Sign: Date Brett Gosselin Brosco Enterprises Pty Ltd

2/25/2012

2/25/2012

2/25/2012

You might also like

- WPSDocument2 pagesWPSJuli Agus50% (2)

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- Asme PQRDocument4 pagesAsme PQRHong Dae Yoon100% (2)

- Wps A53 SMAW+GTAW R00Document3 pagesWps A53 SMAW+GTAW R00Richard Periyanayagam50% (2)

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (1)

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlDocument1 pageIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayNo ratings yet

- PT. VISTA BANGUN UTAMA Welder QualificationDocument1 pagePT. VISTA BANGUN UTAMA Welder QualificationHaryanto RNo ratings yet

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 pageWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNo ratings yet

- Inspection Plan - NDTDocument4 pagesInspection Plan - NDTgymadniNo ratings yet

- WPS Asme IxDocument4 pagesWPS Asme Ixjcarlosherrerac7100% (1)

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiNo ratings yet

- Welder Performance Qualification Record (WPQ) : Testing Condition and Qualification LimitsDocument9 pagesWelder Performance Qualification Record (WPQ) : Testing Condition and Qualification Limitsahmed mohamedNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS MCC 001 PDFDocument1 pageWPS MCC 001 PDFNuwan RanaweeraNo ratings yet

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiNo ratings yet

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Atf Wpqr-Blank v1Document1 pageAtf Wpqr-Blank v1lth770310No ratings yet

- Welder Visual Inspection ReportsDocument24 pagesWelder Visual Inspection ReportsKyNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111Document15 pagesWELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111surya1960No ratings yet

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- L.P.T Reports.Document12 pagesL.P.T Reports.Shaikh AdilNo ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- Stainless steel welding procedure qualification recordDocument1 pageStainless steel welding procedure qualification recordchandraNo ratings yet

- WELDER QUALIFICATION REPORTDocument2 pagesWELDER QUALIFICATION REPORTAkash Singh TomarNo ratings yet

- Differences between Welding Procedure Specification and Welder Performance QualificationDocument1 pageDifferences between Welding Procedure Specification and Welder Performance QualificationFazeel Rick MohammedNo ratings yet

- REGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRDocument2 pagesREGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRAnonymous Xa5rkMZm9ZNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- Dep 30.10.60.32 - Welding of Metals, Based On Iso StandardsDocument76 pagesDep 30.10.60.32 - Welding of Metals, Based On Iso StandardsPablo PazNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Welding Defects: Ganesan V Assistant Manager-TSD D&H Secheron Electrodes PVT - LTDDocument49 pagesWelding Defects: Ganesan V Assistant Manager-TSD D&H Secheron Electrodes PVT - LTDPrakash RajNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- WPS PQR-08Document8 pagesWPS PQR-08Ranjan KumarNo ratings yet

- PQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0Document12 pagesPQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0rodwellbNo ratings yet

- WPS FormatDocument1 pageWPS FormatAbdullah AnsariNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Aluminim WPSDocument2 pagesAluminim WPSKarthikeyan ShanmugavelNo ratings yet

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Document24 pagesPrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- p22MNVMB MN Gtaw+Smaw (Pipe)Document2 pagesp22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1No ratings yet

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Document2 pagesPreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremNo ratings yet

- Kaushik Shah Date: 2011 Form 001 - Format CDocument6 pagesKaushik Shah Date: 2011 Form 001 - Format CsriramNo ratings yet

- Chempump 430 SeriesDocument20 pagesChempump 430 SeriesDieguin SuárezNo ratings yet

- 1729Document52 pages1729praj24083302No ratings yet

- Material Science Cheatsheet For Midterm NewDocument1 pageMaterial Science Cheatsheet For Midterm NewDill0% (1)

- Rolling Mill AGMA STD DevelopmentDocument2 pagesRolling Mill AGMA STD DevelopmentR BhattacharyaNo ratings yet

- Asme Section II A Sa-403 Sa-403mDocument12 pagesAsme Section II A Sa-403 Sa-403mAnonymous GhPzn1x100% (1)

- RT Finalpresenatation08 161118104713Document56 pagesRT Finalpresenatation08 161118104713sajay2010No ratings yet

- Indian Standard: Cement Paint - Specification (Document18 pagesIndian Standard: Cement Paint - Specification (Frank StephensNo ratings yet

- 1.2.2 Isoline ZN RibbonDocument2 pages1.2.2 Isoline ZN Ribbongharsallah mounaNo ratings yet

- ROV Tooling 3Document41 pagesROV Tooling 3siswout100% (1)

- Asme Specifications SA36 ToSA423Document4 pagesAsme Specifications SA36 ToSA423Venkat Dora100% (1)

- 13 - Q+T Steels & Welding Q+T SteelsDocument22 pages13 - Q+T Steels & Welding Q+T SteelsbbqarNo ratings yet

- A 216Document3 pagesA 216Carlos AméricoNo ratings yet

- Five Steps To Improving Die PerformanceDocument5 pagesFive Steps To Improving Die Performanceromanhawranek100% (1)

- Dual Plate 800 NB-ModelDocument1 pageDual Plate 800 NB-ModelTanmoy DuttaNo ratings yet

- Properties and uses of wrought ironDocument4 pagesProperties and uses of wrought ironAbdul HameedNo ratings yet

- AFL Substation Bus ConductorsDocument24 pagesAFL Substation Bus ConductorsMaman86No ratings yet

- Power PlantDocument17 pagesPower PlantVasu RajaNo ratings yet

- IMOA-Imgrund Molybdenum and Stainless SteelDocument40 pagesIMOA-Imgrund Molybdenum and Stainless SteelYohanes KurniawanNo ratings yet

- Dredge Yard Gate Valve BrochureDocument5 pagesDredge Yard Gate Valve BrochureFederico BabichNo ratings yet

- Aluminium Packaging ApplicationsDocument8 pagesAluminium Packaging ApplicationsedelapolloNo ratings yet

- HiPosPlus BOMT09 INNO - 8-2008NEU PDFDocument2 pagesHiPosPlus BOMT09 INNO - 8-2008NEU PDFDado OgameNo ratings yet

- Factors Influencing The Recovery and Addition of MagnesiumDocument4 pagesFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646No ratings yet

- Casing and TubingDocument6 pagesCasing and TubingWulandari Tri Maharani100% (1)

- ASTM F 467m-03aDocument9 pagesASTM F 467m-03aJORGE ARTURO TORIBIO HUERTANo ratings yet

- A250 8Document28 pagesA250 8saravanan_c1No ratings yet

- 9 FtestDocument4 pages9 Ftest박찬우100% (2)

- Are View of The Rhomboid It y Problem in Billet CastingDocument11 pagesAre View of The Rhomboid It y Problem in Billet CastingSuhaib AshrafNo ratings yet

- SheaveDocument1 pageSheaveDavicho Cisterna AguayoNo ratings yet

- A Casa SaddleDocument2 pagesA Casa SaddlesalamrefighNo ratings yet

- Painting ScheduleDocument3 pagesPainting SchedulewaqasNo ratings yet