Professional Documents

Culture Documents

JSA G20 Scaffolding (Erection, Dismantling)

Uploaded by

Kanchalida ChampathongOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA G20 Scaffolding (Erection, Dismantling)

Uploaded by

Kanchalida ChampathongCopyright:

Available Formats

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

ACTIVITY OR TASK: Scaffolding (Erection and Dismantling)

JSA Preparation & task work team:

Competence = Relevant Training/Qualifications + Experience

Location / Project: Job Number: JSA Number: G20 Codes of Practice & Legislation that are applicable: JSA Revision:

Competence/ Qualificn reqd to complete work safely JSA approved by person responsible i.e.

Team Leader / Tradesman

Name:

Position / Competence/ License:

Date:

2. HAZARD IDENTIFICATION

compulsory

Identify hazards that may be present by ticking items on the list below.

3. PRECAUTIONS: hard hat, safety glasses, safety boots

ADDITIONAL PRECAUTIONS

Gloves: type . Goggles Full Face Shield High Visibility Vest Harness Fire Extinguishers Barricades Ventilation Lighting Erect Scaffolding to access Respirator or Dust mask Erect Warning signs Personal Locks or Tag system Group isolation Welding screen Fall Arrest systems Welding Face Shield

WORK LOCATION

Difficult Entry/Exit Oxygen Deficiency Oxygen Excess Engulfment (trench collapse) Poisonous Gas Present Temperature Extremes Defined Confined Space Explosive Gas Present

HAZARDOUS AREA

Hazardous Substances - attach MSDS to JSA Working at Heights Remote Area Motor Room Hazards Toxic Substances Potential for Difficult Rescue

HIGH RISK

Falling Objects Poor Lighting Slippery Surfaces Multiple Electrical Feeds Trip Hazards Electrical Hazards - LV Electrical Hazards - HV Manual Handling Sharp Materials Ladders used in the task Working at Heights Working near Crane & Crane Runways Rail Movement Pressurised Fluids Flamm. Materials Present

HIGH RISK

Suspended loads Poor Visibility Inhalable Dusts/Fibres High Noise Levels Use of Chemicals Elevated Work Platform Difficulty to Communicate amongst workers Moving Machinery Tools & Equipment Heat/ Sunlight/ Radiation Traffic Movement Working near Operation Processing Lines Live Rails Pneumatics

PERMITS

Hot Work Excavation Confined Space Hazardous Work Clearance Access to Area High Voltage Access Scaffolding Other?

HAZARDOUS SUBSTANCES in work area / to be used

-attach MSDS

Permit Number

4. ENVIRONMENTAL HAZARDS (IMPACTS) tick those identified

Air Pollution (dust, fumes) Noise (plant & equipment) Spills to drains/waterways Spills to ground Soil Erosion Hazard to Flora /Fauna

Other:

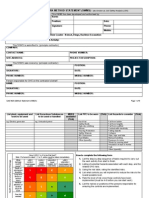

RISK RATING TABLE

This table is used to calculate whether the hazard you have identified is Extreme: 9-10 High: 7-8, Medium: 5-6 or Low: 3-4

The objective of rating the risk is to lower the risk by initiating risk control measures. The score is

Likelihood: How likely is it to be that bad? Almost Certain Expected to Occur

Consequences: how severe an injury? Death

Serious Injuries Medical Treatment Reqd 1st Aid reqd

10 9 8 7 6

9 8 7 6

8 7 6 5

7 6 5 4 3

5. EQUIPMENT REQUIRED: Static Plant & Equipment

Mobile Plant & Equipment

Likely could

happen sometime

Moderate could

happen but not likely

Unlikely could

happen but very rare

Revision Date: March 2005

. of ..

Rare - could happen

but probably never will

OHS-03-F01 5 4

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Safety / Emergency Equipt

noted in the JSA risk score column on the next page both before & after risk control measures have been nominated.

NAME OF TASK: Scaffolding (Erection and Dismantling)

JSA Number: Risk Rating

G20

Rev: Risk Rating

Of the risk following corrective action

Step No.

Logical sequence

Sequence of Basic Job Steps

Break down Job into steps. Each step should accomplish a major task and be logical. Environmental Aspects

Potential Safety & Environmental Hazards/Impacts

Recommended Corrective Action or Procedure

Determine what actions are necessary to eliminate or minimise all hazards that could lead to an accident, injury, illness or environmental incident. The risk must be reduced or controlled to a level that is acceptable before work commences. Indicate who is to perform the action where applicable against each action

Identify the hazards (health and safety or Use table on environmental) associated with each step, the previous examine each to find all possible risk factors page to score

risk

Site Inspection

Raise Permit

Transport scaffold equipment to site

Erect scaffolding

Injury as a result of exposure to substances released due to equipment failure Slips, Trips and Falls due to slippery surfaces, obstructions, restricted access. Injury due to equipment failure, moving equipment, activity Stress and frustration due to incorrect information misdirecting efforts Injury/damage related to vehicle operation and equipment handling Injury / damage due to collision / impact with other workgroups / equipment Injury / damage as a result of dropping tools and scaffold components Hot and cold burns as a result of contact with pipework Injury due to limited egress in emergency Injury / damage as a result of dropping tools and scaffold components

Be aware of and plan escape routes. Be aware of wind.

Due care and attention.

Liaise with permit authority / operations to minimize exposure to and creation of hazards. Ensure all information supplied is as accurate and understandable as possible. Use correct vehicle and handling procedures Plan route to avoid other personnel and equipment

Use appropriate barricades and bunting to protect personnel and equipment Adequate PPE with correct instruction and use. Ensure scaffold has adequate egress for any situation. Use appropriate barricades and bunting to protect personnel and equipment

Revision Date: March 2005

. of ..

OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Injury / damage due to scaffold collapse Injury / damage due to damaged components causing equipment failure Injury / damage caused by scaffold collapse due to excessive load on scaffold Injury / damage due to scaffolding erected by unauthorized personnel Injury / damage caused by scaffolding erected by persons with limited competency Injury / damage caused by personnel falling from scaffolding Injury / damage caused by persons falling whilst working outside scaffolding Injury as a result of incomplete scaffold, loose boards, kickplates, etc causing slips,trips and falls Excess scaffold components cause clutter. Injury results. Injury results from untidy worksite Injury / damage caused by falling objects Injury / damage caused by incorrect sequence of dismantling Erect and dismantle all scaffold to comply with all legal and site requirements. All components to be checked prior to installation

Check specified limits of scaffold before utilization

Scaffold must only be erected by trained personnel Licenced scaffolder to supervise apprentices at all times

Use appropriate barricades and bunting to protect personnel and equipment. Use IFAS harness. Use independent fall arrest system. 1.8m fall limit and standby person precautions Check scaffold properly before attaching scafftag. Tag must be signed by qualified person. Use scaffold checklist. Stack scaffold gear in stillage and remove from site. Keep site clean Keep worksite clean and tidy at all times to reduce hazards to a minimum Inspect scaffold to ensure it is clear of debris before turning boards and dismantling Correct procedure for dismantling of scaffold is adhered to.

Handover of scaffold

Dismantle scaffold

Revision Date: March 2005

. of ..

OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) CONSULTATION & SIGN-OFF RECORD

I confirm by my signature below, that I have attended a briefing on the requirements of the attached Job Safety & Environment Analysis and agree to perform the work in the manner detailed on it. I confirm that copies of the relevant Permits, MSDS's, Isolation Plans etc. have been reviewed.

JSA NAME JSA No:

Rev: DATE

NAME

(Please print)

SIGNATURE

THIS SAFE WORK BRIEFING / TRAINING WAS CARRIED OUT BY (responsible person at that location) : Name: Signature: Date: Client sign off (where applicable) Site / Project Manager sign off (document reviewed)

Revision Date: March 2005

OHS-03-F01

You might also like

- JSA - Cable Trench ExcavationDocument9 pagesJSA - Cable Trench Excavationfrancis_e_tan75% (4)

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- Electric Hand Drill Risk AssessmentDocument4 pagesElectric Hand Drill Risk AssessmentTariq AkhtarNo ratings yet

- Civil JSA Form Block WorkDocument3 pagesCivil JSA Form Block Workdrmuhsin86% (7)

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Job Safety Analysis For Scaffolding 1Document3 pagesJob Safety Analysis For Scaffolding 1nasar_mahsood71% (34)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- Jsa For Lifting (Crane) 016Document6 pagesJsa For Lifting (Crane) 016aliraza572270% (27)

- Erect Steel Structures SafelyDocument9 pagesErect Steel Structures SafelyLuqman Osman77% (13)

- JSA Steel Erection ManliftsDocument1 pageJSA Steel Erection Manliftsrudygoot100% (1)

- JSA WeldingDocument2 pagesJSA WeldingSigint Sides0% (3)

- Job Safety Analysis for Concrete WorksDocument8 pagesJob Safety Analysis for Concrete Worksfrancis_e_tan93% (27)

- Column Erection JSA AnalysisDocument6 pagesColumn Erection JSA AnalysisRaghava Richhu100% (2)

- 7 - Civil WorkDocument12 pages7 - Civil WorkPerwez21100% (1)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 pagesJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Jsa CraneDocument3 pagesJsa Cranenattwa201075% (24)

- JSA Jackhammer RemovalDocument3 pagesJSA Jackhammer Removalbashirdarak80% (5)

- 003 JSA All Civil WorksDocument5 pages003 JSA All Civil WorksMohammed Minhaj100% (11)

- Jsa ExcavationDocument33 pagesJsa Excavationlal5012002390782% (17)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- JHA - Survey WorksDocument3 pagesJHA - Survey WorksNazirul Syazwan100% (3)

- JSA-Manual Lifting of MaterialsDocument3 pagesJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- Tie in Hot Work JHADocument4 pagesTie in Hot Work JHAmalik jahan100% (2)

- JSA For Cutting, Grinding and WeldingDocument4 pagesJSA For Cutting, Grinding and Weldingyc safety100% (3)

- Job Steps, Hazards and ControlsDocument4 pagesJob Steps, Hazards and ControlsCristina Rican100% (1)

- JSA's ModelsDocument56 pagesJSA's ModelsSaberDjet80% (5)

- Job Safety Analysis: Required References Jsa ReviewDocument4 pagesJob Safety Analysis: Required References Jsa ReviewMoaatazz Nouisri100% (4)

- JSA To Perform Greasing of Motor BearingDocument9 pagesJSA To Perform Greasing of Motor BearingChung Trịnh100% (1)

- JSA for Erection and Removal of ScaffoldingDocument5 pagesJSA for Erection and Removal of ScaffoldingPanchdev KumarNo ratings yet

- JSA For False CeilingDocument4 pagesJSA For False CeilingJaved100% (3)

- JSA For HDPE Liner Fusion Welding2Document6 pagesJSA For HDPE Liner Fusion Welding2Mohammed Minhaj100% (8)

- Assess and Manage Construction RisksDocument1 pageAssess and Manage Construction RisksAnonymous goXrLOI33% (3)

- JSA For Demobilization WorksDocument2 pagesJSA For Demobilization WorksIanne Dee85% (13)

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- JSA ScaffoldingDocument2 pagesJSA ScaffoldingHrishikesh UnnikrishnanNo ratings yet

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Raman SawNo ratings yet

- JSA - SK-erection & DismantlingDocument1 pageJSA - SK-erection & DismantlingEngr Tahir UL Haq100% (3)

- Part-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykeDocument4 pagesPart-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykevivekaramanaNo ratings yet

- JHA 15-Work at Height Using ScaffoldingDocument3 pagesJHA 15-Work at Height Using ScaffoldingWte SB100% (7)

- Excavation and Back Filling Works JsaDocument3 pagesExcavation and Back Filling Works JsaNazir Hussain67% (12)

- Jsa For Scaffolding Erection & DismentlingDocument7 pagesJsa For Scaffolding Erection & Dismentlingsanath adhikary100% (5)

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- JHA Scaffolding ErectionDocument12 pagesJHA Scaffolding ErectionChayank TiwariNo ratings yet

- Job Safety Analysis (Jsa)Document11 pagesJob Safety Analysis (Jsa)Noraini Binti Osman50% (2)

- Cable Laying Safety AnalysisDocument6 pagesCable Laying Safety AnalysisLuqman Osman100% (6)

- JSA for Scaffolding Erection, Dismantling and Other Construction WorksDocument9 pagesJSA for Scaffolding Erection, Dismantling and Other Construction Worksuttam mishra100% (1)

- 1 - Scaffolding WorkDocument16 pages1 - Scaffolding WorkPerwez21100% (14)

- Excavations: Job Safety AnalysisDocument5 pagesExcavations: Job Safety AnalysisJICKNo ratings yet

- EPC-3 Gasoline package Assembly & Erection JSADocument3 pagesEPC-3 Gasoline package Assembly & Erection JSAFrancis Vinoj100% (1)

- Typical JHA FormDocument5 pagesTypical JHA FormNasrullah Jan100% (4)

- JHA Civil WorksDocument2 pagesJHA Civil Worksethelchudi100% (11)

- JSA M36 Hydro Testing Spool Pieces & PipeworkDocument4 pagesJSA M36 Hydro Testing Spool Pieces & PipeworkMianNo ratings yet

- SAFE LIFTING WITH SCISSOR LIFTDocument6 pagesSAFE LIFTING WITH SCISSOR LIFTjokerseri100% (3)

- ROBOT - Manufacture, Assembly, Test & OperationDocument33 pagesROBOT - Manufacture, Assembly, Test & Operationharikiran3285No ratings yet

- OHS SWMS Form 005 ExcavationDocument8 pagesOHS SWMS Form 005 Excavationazlinaz100% (2)

- JSA FormDocument6 pagesJSA FormAjeesh CochinNo ratings yet

- QHSE Risk Register for ONGC Drilling Rig in MumbaiDocument24 pagesQHSE Risk Register for ONGC Drilling Rig in Mumbaivikrant911100% (2)

- Crane Mobile SpecificationDocument13 pagesCrane Mobile Specificationsancakemre100% (2)

- Disciplinary Policy AAADocument3 pagesDisciplinary Policy AAAKanchalida ChampathongNo ratings yet

- Disciplinary Policy AAADocument3 pagesDisciplinary Policy AAAKanchalida ChampathongNo ratings yet

- EP-23 Emergency Preparedness & Response Procedure V4-EngDocument5 pagesEP-23 Emergency Preparedness & Response Procedure V4-EngKanchalida ChampathongNo ratings yet

- Method For Tie-InDocument2 pagesMethod For Tie-InKanchalida ChampathongNo ratings yet

- Emergency Plan 2Document58 pagesEmergency Plan 2Kanchalida ChampathongNo ratings yet

- 360 PathwaysDocument4 pages360 PathwaysAlberto StrusbergNo ratings yet

- Rock ClimbingDocument11 pagesRock ClimbingDaria TurdalievaNo ratings yet

- Amity Online Exam OdlDocument14 pagesAmity Online Exam OdlAbdullah Holif0% (1)

- All Types of Switch CommandsDocument11 pagesAll Types of Switch CommandsKunal SahooNo ratings yet

- Classification of MatterDocument2 pagesClassification of Matterapi-280247238No ratings yet

- Benedict - Ethnic Stereotypes and Colonized Peoples at World's Fairs - Fair RepresentationsDocument16 pagesBenedict - Ethnic Stereotypes and Colonized Peoples at World's Fairs - Fair RepresentationsVeronica UribeNo ratings yet

- Article 106899Document6 pagesArticle 106899Abhinave SNo ratings yet

- Case Study On Maruti 800Document4 pagesCase Study On Maruti 800Nizar MesaniNo ratings yet

- ccpc15 Supportive and Preventive WorkbookDocument30 pagesccpc15 Supportive and Preventive WorkbookJeremy HamptonNo ratings yet

- RFID Receiver Antenna Project For 13.56 MHZ BandDocument5 pagesRFID Receiver Antenna Project For 13.56 MHZ BandJay KhandharNo ratings yet

- 3 - 6consctructing Probability Distributions CG A - 4 - 6 Lesson 2Document24 pages3 - 6consctructing Probability Distributions CG A - 4 - 6 Lesson 2CHARLYN JOY SUMALINOGNo ratings yet

- DelhiDocument40 pagesDelhiRahul DharNo ratings yet

- Karate Writing AssessmentDocument2 pagesKarate Writing AssessmentLeeann RandallNo ratings yet

- 1 API 653 Exam Mar 2015 MemoryDocument12 pages1 API 653 Exam Mar 2015 MemorymajidNo ratings yet

- Assessing Khazaria-Serpent PeopleDocument1 pageAssessing Khazaria-Serpent PeopleJoao JoseNo ratings yet

- Book 2 - Test 1Document2 pagesBook 2 - Test 1Đức LongNo ratings yet

- Westford University College readies flagship campus with new programsDocument20 pagesWestford University College readies flagship campus with new programsSaju JanardhananNo ratings yet

- Chapter 1 Critical Thin...Document7 pagesChapter 1 Critical Thin...sameh06No ratings yet

- Title Page Title: Carbamazepine Versus Levetiracetam in Epilepsy Due To Neurocysticercosis Authors: Akhil P SanthoshDocument16 pagesTitle Page Title: Carbamazepine Versus Levetiracetam in Epilepsy Due To Neurocysticercosis Authors: Akhil P SanthoshPrateek Kumar PandaNo ratings yet

- Ubc 2015 May Sharpe JillianDocument65 pagesUbc 2015 May Sharpe JillianherzogNo ratings yet

- CPS Layoffs BreakdownDocument21 pagesCPS Layoffs BreakdownjroneillNo ratings yet

- Chapter 1 - The Empirical Beginnings and Basic Contents of Educational PsychologyDocument9 pagesChapter 1 - The Empirical Beginnings and Basic Contents of Educational PsychologyJoshua Almuete71% (7)

- JKR Specs L-S1 Addendum No 1 LED Luminaires - May 2011Document3 pagesJKR Specs L-S1 Addendum No 1 LED Luminaires - May 2011Leong KmNo ratings yet

- Educational Leadership Platform PaperDocument4 pagesEducational Leadership Platform Paperapi-273087939No ratings yet

- IntegrityDocument5 pagesIntegrityPritam Kumar100% (1)

- Pengkondisian Kesiapan Belajar Untuk Pencapaian Hasil Belajar Dengan Gerakan Senam OtakDocument9 pagesPengkondisian Kesiapan Belajar Untuk Pencapaian Hasil Belajar Dengan Gerakan Senam OtakSaadah HasbyNo ratings yet

- Exploratory Data Analysis: M. SrinathDocument19 pagesExploratory Data Analysis: M. SrinathromaNo ratings yet

- Transistor Amplifier Operating ParametersDocument21 pagesTransistor Amplifier Operating ParametersReddyvari VenugopalNo ratings yet

- MAN 2 Model Medan Introduction to School Environment ReportDocument45 pagesMAN 2 Model Medan Introduction to School Environment ReportdindaNo ratings yet

- Community Development A Critical Approach PDFDocument2 pagesCommunity Development A Critical Approach PDFNatasha50% (2)