Professional Documents

Culture Documents

Dummy

Uploaded by

thopa_nath100%(2)100% found this document useful (2 votes)

2K views1 pagedummy spread sheet

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdummy spread sheet

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

2K views1 pageDummy

Uploaded by

thopa_nathdummy spread sheet

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

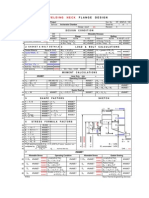

FLUOR

Local Stress Calculation for Dummy Supports

Client Contract Line No. Prepared Checked Node No.

Design Pressure Hydrotest Pressure Design Temperature Material NPS of Pipe(D) Pipe wall thickness(Th) Corrosion allowance Re.pad thickness(Tr) Allowable Stress(Sh) ASTM A106 Gr.B

100 psi 150 psi 425 F

Moment Arm Length(L) NPS of trunnion(d) Trunnion Thickness(Tb) Pipe CL to Support CL(e)

24 inch 4 inch 0.237 Inch 0 Inch

Short Radius

6 inch 0.28 inch 0.125 inch 0.28 inch 19725 psi

Long Radius TRUE

Mill Tolerance(%) Weld Size(optional) 0.237 inch

Loads Radial Circ Long

Deadweight 300 250 300

Thermal 400 350 450

Occasional 100 150 200

Hydrotest 350 300 450

Header Pipe Design Condtion Calculated stress Allowable Result Calculated Stress 8682

Dummy Pipe Allowable Result

Dead Weight Pressure Thermal Dead Weight,Pressure and Occasional Hydrotest

6448

29588

OK

19725

OK

4243

29931

OK

12349

29931

OK

9123

36000

OK

14138

26600

OK

9004

35000

OK

11793

35000

OK

Weld size is OK for the Loads

Note :

This work sheet is based on M .W . Kel log' s Formula

2 L

for local stress S =

1 . 17 f t2

Rt

where f = load per linear length = 1 . 5 ( ( f and f = combined (f

2 L

+ f C2 ) + f A ) in Sus case al and Circumfere ntial components are not

+ f ) + 1 . 5 f A in Thermal

2 C

case . But Longitudin

if f L 3 f C or f C 2 f L

Page 1 of 1

File : 103779128.xls.ms_office

Date :7/18/2012

You might also like

- Pipe CalculationDocument2 pagesPipe CalculationWijayantoNo ratings yet

- Structural TrunnionDocument4 pagesStructural TrunnionecsalomNo ratings yet

- Dummy Leg JacobsDocument1 pageDummy Leg Jacobsananyo_sengupta0% (1)

- Trunnion Calc r6Document4 pagesTrunnion Calc r6Chirag Shah50% (2)

- Reinforcement CalculationDocument2 pagesReinforcement CalculationVekaymech100% (9)

- Trunnion CalculationDocument8 pagesTrunnion CalculationPrashant ChauhanNo ratings yet

- Pipe SupportDocument11 pagesPipe SupportAditya Bagus M100% (3)

- Branch Reinforcement Per Asme B31.4 PipelineDocument1 pageBranch Reinforcement Per Asme B31.4 PipelinegateauxboyNo ratings yet

- Steam Tracing Excel 2007Document74 pagesSteam Tracing Excel 2007cybermineNo ratings yet

- ASME B31.3 Area ReplacementDocument2 pagesASME B31.3 Area ReplacementJahsbuck100% (1)

- Operating Case Trunnion Calculation Sheet: Input DataDocument1 pageOperating Case Trunnion Calculation Sheet: Input DataJagadish JasNo ratings yet

- Pipe Support CalculationDocument2 pagesPipe Support Calculationjsmnjasmines86% (7)

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleNithin ZsNo ratings yet

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- Calculation For Reinforced PadDocument4 pagesCalculation For Reinforced Padjsridhar_34750% (2)

- Trunnion Calculation SheetDocument2 pagesTrunnion Calculation Sheetnirga100% (1)

- Expansion Loop Flexibility Analysis (Weaver)Document3 pagesExpansion Loop Flexibility Analysis (Weaver)bakelly100% (1)

- Pipe Wall Thickness (Complete)Document40 pagesPipe Wall Thickness (Complete)Andri PutraNo ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Stress Sample Calculation On Base EllDocument1 pageStress Sample Calculation On Base EllLionel TorradoNo ratings yet

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- Saddle Dimension CalculationDocument2 pagesSaddle Dimension Calculationrinabiswas50% (2)

- Blow Off Pipe SizingDocument13 pagesBlow Off Pipe Sizinggopaltry100% (1)

- Trunnion Calculation SheetDocument3 pagesTrunnion Calculation Sheetsudhisnair67% (3)

- Pipe Span Without Point LoadsDocument36 pagesPipe Span Without Point Loadsbakelly100% (4)

- FLANGEDocument1 pageFLANGEscrbdgharavi50% (2)

- Pipe Reinforcement Calculation (ASME-B31.3)Document3 pagesPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Line Stop Welded To Shoe CalculationDocument16 pagesLine Stop Welded To Shoe CalculationmohdnazirNo ratings yet

- ASME B31.3 - 2008 PipeCalculationDocument6 pagesASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Flange CalculationsDocument5 pagesFlange CalculationsswapnavattemNo ratings yet

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Document17 pagesNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoNo ratings yet

- API 650-RF Pad CalculationDocument1 pageAPI 650-RF Pad CalculationSudhanshu67100% (2)

- Pipeline Expansion Loop CalculationsDocument2 pagesPipeline Expansion Loop CalculationsthehraoNo ratings yet

- Imperial Piping Weight Load Calculation WorkbookDocument13 pagesImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- SPAN Calc.Document48 pagesSPAN Calc.yoi_123No ratings yet

- New - Reinforcement of NozzleDocument24 pagesNew - Reinforcement of NozzleVaniya GoelNo ratings yet

- Sif B31.3Document10 pagesSif B31.3Rob Gillespie100% (1)

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 pagesASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Sif B31 3Document10 pagesSif B31 3Sergio SmithNo ratings yet

- Saddle Design at Operating ConditionDocument17 pagesSaddle Design at Operating ConditionGanesh Bhardwaj100% (2)

- ASME B31 4 Calculator V1 1Document11 pagesASME B31 4 Calculator V1 1vazzoleralex6884100% (1)

- Pipe Design Thikness For PipingDocument1 pagePipe Design Thikness For PipingKanit ChobNo ratings yet

- Calculator ASME B31 4Document11 pagesCalculator ASME B31 4Denstar Ricardo Silalahi50% (2)

- Hot Tapping CalculationsDocument17 pagesHot Tapping CalculationsVikash Tiwari100% (3)

- Retiring Wall Thickness Calculation For PipeDocument4 pagesRetiring Wall Thickness Calculation For PipeFares JawadNo ratings yet

- Pipe Bend Againts Coating 3LPE AnalisisDocument25 pagesPipe Bend Againts Coating 3LPE Analisisraditia2205100% (1)

- CCK VNT Tank Cal DataDocument1 pageCCK VNT Tank Cal Datachompink6900No ratings yet

- ASME B31.3 Pipe Wall ThicknessDocument33 pagesASME B31.3 Pipe Wall Thicknessaike_5No ratings yet

- Weight CalculatorDocument12 pagesWeight CalculatorShafqat AfridiNo ratings yet

- BoltDocument39 pagesBoltHarmeet SinghNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Heat HXerDocument2 pagesHeat HXerGade JyNo ratings yet

- API 530 Tube Thickness Design: CV. Alpha Omega Mohammad FirmansyahDocument3 pagesAPI 530 Tube Thickness Design: CV. Alpha Omega Mohammad FirmansyahagusnurcahyoNo ratings yet

- INERGENDocument1 pageINERGENMihai STANNo ratings yet

- Gas Pipeline SpecDocument4 pagesGas Pipeline SpecA_bener100% (1)

- Boq For RSP Ccas PipingDocument3 pagesBoq For RSP Ccas Pipingkoushikdey_2011No ratings yet

- Data Sheet: DescriptionDocument6 pagesData Sheet: DescriptionEDUARDONo ratings yet

- Cone Design Tool: Pressure Vessel Engineering LTDDocument1 pageCone Design Tool: Pressure Vessel Engineering LTDkedubhajjiNo ratings yet

- Product Range DN 32+: Standard or CustomizedDocument2 pagesProduct Range DN 32+: Standard or CustomizedViale ElvioNo ratings yet