Professional Documents

Culture Documents

What Is HCDP

Uploaded by

fumerojr5164Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is HCDP

Uploaded by

fumerojr5164Copyright:

Available Formats

WHAT IS HCDP (HYDROCARBON DEW POINT) Principles of Hydrocarbon Dew Point

Dew point is defined as the temperature at which vapor begins to condense. We see it in action every foggy morning. Air is cooled to its water dew point and the water starts condensing and collects into small droplets. We also see it demonstrated by a cold glass "sweating" on a humid day. The cold glass lowers the air temperature below the water dew point temperature and the water condenses on the sides of the cold glass. Water dew point is relatively simple and easy to predict since it is a single component system. It is easily removed using conventional techniques, primarily TEG (Triethylene Glycol) dehydration units. Hydrocarbon dew point (HDP) is similar to the water dew point issue, except that we have a multi-component system. Natural gas typically contains many liquid hydrocarbon components with the heavier components found in smaller amounts than the lighter gaseous ends. It is the heaviest weight components that first condense and define the hydrocarbon dew point temperature of the gas. The dew point temperature also moves in relation to pressure. One of the first questions we are asked by producers with a hydrocarbon dew point issue is: "How can my hydrocarbon dew point be so high?" In return, we ask the producer at what temperature does his high-pressure production separator operate? By definition, a production separator separating oil from gas operates at vapor-liquid equilibrium. Therefore, the gas leaving the separator is in equilibrium with the oil. In other words, the gas leaving the separator is at its hydrocarbon dew point that equals the separator operating temperature (and pressure.) If the separator is operating at 100F, then the gas has a 100F dew point at separator pressure. As the gas leaves the separator and cools flowing through the piping system, liquids condense and the dew point decreases as the heavy ends condense. The TEG dehydration unit will remove some heavy hydrocarbons, in addition to water, and further reduce the hydrocarbon dew point. At the sales meter, (without a conditioning unit) the hydrocarbon dew point is usually close to the lowest temperature the gas has achieved on the location before it was sampled, at operating pressure.

1

Why Control Hydrocarbon Dew Point?

The gas transportation companies have come to the realization that managing hydrocarbon dew point reduces system liabilities, opens up new gas markets and generates operating revenue. By managing hydrocarbon dew point, hydrocarbon condensation can be prevented in cold spots under rivers and lakes where the liquids collect in the low areas and then often move as a slug through the system, over pressuring the pipe, and overpowering liquid handling facilities, flowing into compressors and end user sales points. Most importantly, liquids in burners and pilots onsite and at end user locations at LDCs, can cause fire and explosion hazards. Also, removing pipeline liquids helps prevent pipe corrosion in the low areas where water is trapped under the hydrocarbon liquid layer and slowly destroys the pipe integrity. Proper managing of gas dew point can also prevent liquids from forming as the gas cools while flowing through pressure reduction stations (e.g. citygates) that feed end user supply systems. Controlling dew point is also necessary to qualify the pipeline to market gas to high efficiency gas turbine end users that require a dry and consistent quality fuel.

Specifications for HDP

Pipelines use two main methods to specify contractual natural gas hydrocarbon dew points. 1. Limit on C5+ or C6+ components by analyzing for: o GPM (gallons of liquid per thousand SCF) o Mole % 2. Specifying an actual HDP by: o Setting a hydrocarbon dew point temperature maximum at operating pressure o Setting a maximum cricondentherm hydrocarbon dew point In addition, typical pipeline specifications, or tariffs, almost always specify a maximum GHV (Gross or Higher Heating Value), which is greatly affected by heavy hydrocarbons contained in the gas stream.

Cricondentherm Temperature

2

The cricondentherm temperature is the highest dew point temperature seen on a liquid-vapor curve for a specific gas composition over a range of pressure, e.g. 200-1400 psia. When you look at a hydrocarbon gas dew point temperature curve (phase envelope,) the curve bends with pressure. Shown below is a dew point curve, after conditioning, for a south Texas gas analysis. The transporting pipeline requires a 20F cricondentherm temperature. At the time this sample was taken, the cold separator on the gas conditioning equipment was operating at 9F and 875 psig.

Hydrocarbon Gas Dew Point Curve

The temperature shown in the HDP Dew Point Pressure curve represents the gas dew point at Temperature F PSIA the corresponding pressures. A cricondentherm specification at first seems like the best way a pipeline can protect its assets. The transporting pipeline operator knows if it sets a cricondentherm temperature restriction below the lowest temperature seen in its system, it can raise and lower the gas pressure in the pipeline transportation system, and not have to worry about liquid condensation.

9.0 12.9 15.6 17.5 18.8 19.5 19.7 19.6 19.1 18.2 17.0 15.4 13.5 200 250 300 350 400 450 500 550 600 650 700 750 800

Cricondentherm

11.1 850 The problem a pipeline operator has in 875# using a cricondentherm specification is 8.5 900 in the calculation of the 5.2 950 cricondentherm temperature. The 1.4 1000 -3.3 1050 cricondentherm temperature is -9.4 1100 calculated by obtaining an extended -18.7 1150 gas analysis and then inputting the analysis data into a software package, using equations of state to predict the dew point temperatures at the range of pressures.

3

Operating at 9F and

However, many gas-transporting companies tend to collect gas composition data using on-line chromatographs or composite samples with a grouped C6+ component. The C6+ component does not provide any information on the heavier hydrocarbon (C7+) components that determine the gas hydrocarbon dew point. To calculate a cricondentherm the pipeline operator must make some assumptions. It is these assumptions that are causing problems. The pipeline operator must decide how to distribute the C6+ component for his calculation. The most commonly used distribution assumptions are the Daniels/El Paso distribution (i.e. 48% C6; 35% C7; 17% C8+) and the GPA distribution (i.e. 60% C6, 30% C7, 10% C8+). If the Daniels distribution shown in the previous sentence is used on the gas represented in the dew point curve above, the cricondentherm dew point calculates to be 38.1F, which is 18.4F higher than its actual cricondentherm temperature. The producer would need to operate his cold separator on his conditioning unit at -10F (negative 10F) to meet the system requirements due to the assumptions made in calculating the gas cricondentherm. Another popular mistake is to perform an analysis that groups the C6, C7 and C8+ components, rather than using the detailed component-bycomponent breakdown. Grouping also skews the cricondentherm. If you group the above components, the cricondentherm calculates at 32.6F or 12.9F high. It is DPC's experience that grouping will add a minimum of 3F to 5F to the calculated cricondentherm temperature. To be useful in a commercial environment, pipeline hydrocarbon dew point specifications must be easily measured with existing equipment. The majority of the transporting pipeline systems measure using a C6+ component system. These systems can be used to track cricondentherm based specifications as long as the heavier components are not distributed arbitrarily.

It is DPC is recommendation that when using a C6+ based component analysis system, the following steps should be taken to monitor a sales point location where the transporter is receiving gas that is being dew point controlled based on a cricondentherm requirement. At time of initial delivery, when the receiving gas is meeting pipeline specification, a spot sample should be collected and analyzed with a detailed analysis through C8+. The detailed extended analysis needs to be inputted into a software program using the full analysis to verify the cricondentherm temperature requirement is achieved.

4

The C6+ mole percentage (or GPM) shown on the qualifying extended analysis can then be used as the threshold standard that must be met by the gas being received at this sales meter. Online chromatography or composite samples can then be used to compare against the threshold standard to verify qualification of the cricondentherm specification. The threshold standard should be updated or qualified as needed to handle changing gas compositions.

DPC does not recommend detailed analysis be taken beyond C8+ on dew point conditioned gas streams as it is not useful and results in unnecessary expense.

You might also like

- Principles of Hydrocarbon Dew PointDocument4 pagesPrinciples of Hydrocarbon Dew PointRowan BalajiNo ratings yet

- 03 Dew Point Measurements Andy Benton Michell EngezerDocument64 pages03 Dew Point Measurements Andy Benton Michell EngezerccdumitraNo ratings yet

- A Systemic Optimization Approach For The Design of Natural Gas Dehydration PlantDocument9 pagesA Systemic Optimization Approach For The Design of Natural Gas Dehydration PlantInternational Journal of Research in Engineering and ScienceNo ratings yet

- CMPAPPP Separator Vessel and Filter Design GuideDocument18 pagesCMPAPPP Separator Vessel and Filter Design GuideJWilson73No ratings yet

- AX5 Vaporizer Electric Water Bath Type LPG VaporizerDocument2 pagesAX5 Vaporizer Electric Water Bath Type LPG VaporizerRicky DermawanNo ratings yet

- Ethylene PipesDocument8 pagesEthylene Pipesingbarragan87No ratings yet

- Teg ContactorDocument4 pagesTeg ContactorrepentinezNo ratings yet

- Pressurized Glycol Dehy SystemsDocument11 pagesPressurized Glycol Dehy SystemsJagan BoseNo ratings yet

- Line Sizing: Liquid Phase CaseDocument13 pagesLine Sizing: Liquid Phase CaseEngr Theyji0% (1)

- 17-ApGreid - Pump Sizing Rev.2Document14 pages17-ApGreid - Pump Sizing Rev.2Dhanny MiharjaNo ratings yet

- Energy Performance Assessment of Heat ExchangersDocument22 pagesEnergy Performance Assessment of Heat ExchangersShailesh PatelNo ratings yet

- Simulation Compresseur PDFDocument85 pagesSimulation Compresseur PDFyamakunNo ratings yet

- CryoStar PresentationDocument26 pagesCryoStar PresentationLelosPinelos123No ratings yet

- Thermal Analysis of Exposed Pipeline Under Natural ConvectionDocument6 pagesThermal Analysis of Exposed Pipeline Under Natural ConvectionSyahrizalYusoff100% (1)

- Teg PDFDocument5 pagesTeg PDFElena RicciNo ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- Blowdown of LPG PipelinesDocument10 pagesBlowdown of LPG PipelinesBehnam HosseinzadehNo ratings yet

- X ViberDocument4 pagesX ViberHenry CruzNo ratings yet

- Liquid Monopropellant CombustionDocument4 pagesLiquid Monopropellant Combustionherdi sutanto adigunaNo ratings yet

- Treater Mohandesi Shimi 87-3-16 A SyDocument7 pagesTreater Mohandesi Shimi 87-3-16 A Syrahul84803No ratings yet

- Curve Char ADocument3 pagesCurve Char AvantaNo ratings yet

- Simulation of Natural Gas Production in Hydrate ReservoirsDocument5 pagesSimulation of Natural Gas Production in Hydrate ReservoirsGAURAV KUMARNo ratings yet

- Ekoplastik PPR Catalogue of Products PDFDocument36 pagesEkoplastik PPR Catalogue of Products PDFnamNo ratings yet

- Steam Tracing AppendixDocument13 pagesSteam Tracing AppendixAmin BagheriNo ratings yet

- Joule-Thomson (JT) Assembly: Oil and Gas Process and Production EquipmentDocument2 pagesJoule-Thomson (JT) Assembly: Oil and Gas Process and Production Equipmentpedro100% (1)

- Transfer of Liquefied Natural Gas On Long Insulated Lines PDFDocument6 pagesTransfer of Liquefied Natural Gas On Long Insulated Lines PDFIgnacio ChaparroNo ratings yet

- 1 s2.0 S0263876299717624 MainDocument7 pages1 s2.0 S0263876299717624 Mainryan123459No ratings yet

- Performance Optimization of Low-Temperature Power Generation by Supercritical ORCs Using Low GWP Working FluidsDocument14 pagesPerformance Optimization of Low-Temperature Power Generation by Supercritical ORCs Using Low GWP Working Fluidsmonsterh5No ratings yet

- Water Vapor Content of Gaseous Fuels by Measurement of Dew-Point TemperatureDocument11 pagesWater Vapor Content of Gaseous Fuels by Measurement of Dew-Point TemperatureDIAZCORDOBANo ratings yet

- New Correlation For Water Content of Sour NGDocument4 pagesNew Correlation For Water Content of Sour NGromdhan88No ratings yet

- JEWEL T Hydrocarbon Dew Point ControlDocument2 pagesJEWEL T Hydrocarbon Dew Point ControljojeecaresNo ratings yet

- Flare Gas Recovery PDFDocument13 pagesFlare Gas Recovery PDFSadad MohamadNo ratings yet

- PPR Products Technical InformationDocument26 pagesPPR Products Technical InformationJoe VergheseNo ratings yet

- 750-326 Blowdown Separator 11 2015Document10 pages750-326 Blowdown Separator 11 2015osamaNo ratings yet

- Clesse, Comap, NovacometDocument60 pagesClesse, Comap, NovacometVivek RajanNo ratings yet

- Cavitational FlowDocument11 pagesCavitational FlowriemannNo ratings yet

- Level Gauges Definition Types Measuring Range Ordering InformationDocument3 pagesLevel Gauges Definition Types Measuring Range Ordering Informationkamala 123No ratings yet

- Application of Genetic Algorithm For Optimization of Separator Pressures in Multistage Production UnitsDocument14 pagesApplication of Genetic Algorithm For Optimization of Separator Pressures in Multistage Production UnitsAbbas AlkhudafiNo ratings yet

- Delivering Excellence in Combustion and Process HeatingDocument11 pagesDelivering Excellence in Combustion and Process HeatingsajjadyasinNo ratings yet

- CHEN 4470 - Process Design Practice: Dr. Mario Richard Eden Department of Chemical Engineering Auburn UniversityDocument23 pagesCHEN 4470 - Process Design Practice: Dr. Mario Richard Eden Department of Chemical Engineering Auburn UniversityRachele PiovanelliNo ratings yet

- Optimizing Pumping Systems P-IDocument4 pagesOptimizing Pumping Systems P-Imatrix69No ratings yet

- Economic N2 Removal Hydrocarbon EngineeringDocument8 pagesEconomic N2 Removal Hydrocarbon EngineeringSergio JavierNo ratings yet

- Tutorial Topic 2 2020 RevisedDocument3 pagesTutorial Topic 2 2020 RevisedTara PillayNo ratings yet

- Best Practices For Steam Control Valve InstallationDocument4 pagesBest Practices For Steam Control Valve InstallationBen MusimaneNo ratings yet

- Brochure - Valves For Oil & Gas Industries (En) .Document28 pagesBrochure - Valves For Oil & Gas Industries (En) .ABULARA2K6No ratings yet

- 10 1016@j Jngse 2016 01 016Document37 pages10 1016@j Jngse 2016 01 016saiful bahriNo ratings yet

- PSSCV ZixxingDocument2 pagesPSSCV ZixxingShashi Kant KumarNo ratings yet

- Piping Workbook PIDesignDocument73 pagesPiping Workbook PIDesignUrsula MoeringsNo ratings yet

- M004 & E004 Basic Safety in Process DesignDocument66 pagesM004 & E004 Basic Safety in Process DesignebsmsartNo ratings yet

- Reliability of Instrumentation Systems for Safeguarding & Control: Proceedings of the IFAC Workshop, Hague, Netherlands, 12-14 May 1986From EverandReliability of Instrumentation Systems for Safeguarding & Control: Proceedings of the IFAC Workshop, Hague, Netherlands, 12-14 May 1986No ratings yet

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- HCDP Danalyzerdan An 42 NGC An HDCP 700xaDocument4 pagesHCDP Danalyzerdan An 42 NGC An HDCP 700xakenangrok2009No ratings yet

- Determination of Hydrocarbon Dew Point Measurement in Natural GasDocument13 pagesDetermination of Hydrocarbon Dew Point Measurement in Natural GasgabowinerNo ratings yet

- HCDPDocument92 pagesHCDPMuddassar SultanNo ratings yet

- Liquid RecoveryDocument87 pagesLiquid Recoveryrkumar_225No ratings yet

- Hydrocarbon Dewpoint DeterminDocument8 pagesHydrocarbon Dewpoint Determineng20072007No ratings yet

- Favour PROJECT PRESENTATIONDocument20 pagesFavour PROJECT PRESENTATIONockiyacliffcNo ratings yet

- Process Modelling and System Dynamic Project 1 Gas Processing SimulationDocument14 pagesProcess Modelling and System Dynamic Project 1 Gas Processing SimulationHusaini ZaidanNo ratings yet

- BoilersDocument3 pagesBoilersatikulNo ratings yet

- Tablas ft2 PDFDocument3 pagesTablas ft2 PDFJunior Alexander Lazo ZeladaNo ratings yet

- Ethylene Glycol PlantDocument18 pagesEthylene Glycol Plantezasukekun50% (2)

- SB / SBH / Sbi Series Instruction and Maintenance ManualDocument24 pagesSB / SBH / Sbi Series Instruction and Maintenance ManualErkan TakNo ratings yet

- 0 - Mains Water Pipe SizingDocument4 pages0 - Mains Water Pipe SizingstarykltNo ratings yet

- HGDocument156 pagesHGJosè Helì Vallejos CoronadoNo ratings yet

- Electrohydrodynamic Atomization (EHDA)Document15 pagesElectrohydrodynamic Atomization (EHDA)Ananya SinghNo ratings yet

- 4 Contacting EquipmentDocument40 pages4 Contacting EquipmentBiswa JitNo ratings yet

- Course O-5003 Centrifugal Pump Analysis For Petroleum ApplicationsDocument70 pagesCourse O-5003 Centrifugal Pump Analysis For Petroleum ApplicationsPok Jak Salleh100% (1)

- Soal Latihan PompaDocument1 pageSoal Latihan PompaAdi Wijaya0% (1)

- Chemical EngineeringDocument287 pagesChemical EngineeringSleek KastrowNo ratings yet

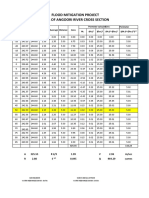

- Flood Mitigation Project Area of Angoori River Cross SectionDocument8 pagesFlood Mitigation Project Area of Angoori River Cross SectionankitNo ratings yet

- Turbomachanies & ClassificationDocument7 pagesTurbomachanies & ClassificationVinay ChandwaniNo ratings yet

- Meshless Methods in LS-DYNA: An Overview of EFG and SPHDocument43 pagesMeshless Methods in LS-DYNA: An Overview of EFG and SPHLe Anh TuanNo ratings yet

- Brochure RheologyDocument6 pagesBrochure RheologyPaoloMMNo ratings yet

- CH 18Document11 pagesCH 18jay mishraNo ratings yet

- Design of Distillation Column of Nitric AcidDocument20 pagesDesign of Distillation Column of Nitric Aciddhoom 760No ratings yet

- MANICA BOARDS and DOORS Tawanda Report On Boiler FinalDocument22 pagesMANICA BOARDS and DOORS Tawanda Report On Boiler FinalRobin BushuNo ratings yet

- Drift Model For Two Component FlowsDocument7 pagesDrift Model For Two Component Flowsfatjon31No ratings yet

- Air OverviewDocument20 pagesAir OverviewOlefile Mark MolokoNo ratings yet

- HDP 502 S 110050Document311 pagesHDP 502 S 110050Reciclando ChatarraNo ratings yet

- Everpure Filtre Apa Fisa TehnicaDocument2 pagesEverpure Filtre Apa Fisa TehnicaPreot Andreana CatalinNo ratings yet

- A - Day 2Document3 pagesA - Day 2Astra BeckettNo ratings yet

- Java FoilDocument27 pagesJava FoilJúlio Cesar RodriguesNo ratings yet

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2151909Document3 pagesGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2151909onikNo ratings yet

- Gas Adsorption Apparatus PosterDocument1 pageGas Adsorption Apparatus PosterEdgar PuenteNo ratings yet

- 2017 - Review of Nature-Inspired Heat Exchanger TechnologyDocument17 pages2017 - Review of Nature-Inspired Heat Exchanger TechnologyCarlos Fernando Rojas TovarNo ratings yet

- Phase Changes WorksheetDocument4 pagesPhase Changes WorksheetAndrea Jarani LinezoNo ratings yet

- Midland AcsDocument4 pagesMidland AcswolverulNo ratings yet

- 3D Lift DistributionDocument43 pages3D Lift DistributionabcesarNo ratings yet