Professional Documents

Culture Documents

Drinking Water

Uploaded by

Surajit SamantaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drinking Water

Uploaded by

Surajit SamantaCopyright:

Available Formats

PROJECT PROFILE

PRODUCT

PACKAGED DRINKING WATER

PRODUCT CODE

224103008

QUALITY STANDARD

IS: 14543 - 2004

PRODUCTION CAPACITY :

LITRES)

QUANTITY - 45 LAC BOTTLES (1 LITRE)

33.6 LAC BOTTLES (2

VALUE

- Rs.4,37,70,000/-

MONTH & YEAR OF PREPARATION

DECEMBER, 2010

PREPARED BY -

MSME- DEVELOPMENT INSTITUTE MINISTRY OF MICRO, SMALL AND MEDIUM ENTERPRISES 22 GODOWN INDUSTRIAL ESTATE, JAIPUR 302006 (RAJ.) Phone: (0141)2212098, 2213099, 2215847 Telefax: (0141)2210553 E-mail: dcdi-jaipur.dcmsme@gov.in Website: www.msmedijapiur.gov.in

PROJECT PROFILE ON PACKAGED DRINKING WATER (OTHER THAN MINERAL WATER FROM NATURAL RESOURCE) 1. INTRODUCTION : It is universal truth that water is very essential for sustaining life and survival of mankind including animal and plants. Nature has gifted water to all living things. The water used for potable purpose by mankind should be free from undesirable impurities and contamination. Though the water available on the earth is abundant but fresh water fit for human consumption is hardly 3% of total available water, source of which are river springs, pond, rain water and ground water. The untreated water available from sources like well, bore well and springs is generally not hygienic and unsafe for human consumption. Thus needs treatment and purification to supply hygienic packed water for drinking purpose. As the name implies, the packaged drinking water is the purified water free from contamination, suspended impurities, unwanted colour, diseases causing micro organism and hygienically packed with convenience of use. Water born diseases are cause of concern world over and lot of money spent on the treatment of diseases caused by contaminated water and problem has assumed alarming proportions due to increasing contamination of ground water. This has given boost to demand for hygienically packed purified water and this is growing rapidly. 2.0 MARKET POTENTIAL Fresh water available on the earth is in different sources. Most of river, pond and ground water available for drinking purpose is unfortunately contaminated and unhygienic for human consumption. Level of harmful and toxic chemical is on rise and concentration of pathogenic micro organism has risen beyond safe limit resulting in alarming increase in water born diseases. So it has become imperative to treat the water and pack for safe human consumption. The demand for purified water becomes more during summer season. However, packaged drinking water remain in demand through out the year due to increasing traveling habits of people. The product has wide demand at public places, places of tourist interests. Demand of packaged drinking water is increasing day by day. 3.0 (i) BASIS AND PRESUMPTIONS The Project is based on Ozone Sterilization Technology. Provision of ultraviolet disinfectant for removal of microbial impurities and raw ground water having TDS upto 250 gram.

(ii)

The production capacity is calculated on 3 shifts basis at 70% efficiency and 300 working days a year. The cost of Machinery & Equipment and Raw material as indicated refers to a particular make and prices are approximate and are those prevailing at the time of preparation of this Profile. The rate of interest on investment is taken at 15% on an average and BEP in the Profile has been calculated on the full capacity utilization. IMPLEMENTATION SCHEDULE :

(iii)

(iv)

3.1.

i) ii) iii) iv) v) vi) vii) viii) ix)

4.0 4.1

Selection of Site Preparation of DPR Filing of EM Procurement of Plant & Machinery Construction of Building Power Connection Obtaining BIS licence, Permission from Health Authorities, etc. Appointment of Staff & Labour Trial Run

TECHNICAL ASPECTS : PROCESS OUTLINE :

1 month 2 weeks 1 week 1 month 3 months 1 month 2 months 1 months 1 week

Raw water is treated with measured quantity of alum for removal of heavy metal and insoluble matters and allowed to settle for about an hour. This water is passed through reverse osmosis plant to remove remaining impurities and excess hardness. This water is then treated with chlorine for disinfection followed by passing through carbon filters to remove undesirable odour, colour and excessive chlorine. This water is then passed through series of micro filters comprising 5 micron, 1 micron and 0.4 micron filter followed by ultraviolet disinfection system for terminal disinfection. This purified water is tested for quality standard and then packed in suitable PET bottles of various capacities after treating with ozone. These bottles are packed in corrugated boxes. Capacity of bottle may also be shrink wrapped with printed sealing optionally.

4.2

QUALITY CONTROL AND STANDARDS : The packaged drinking water is essentially has to be BIS Certified. So before marketing the product the enterprise should obtain BIS Certification Licence. Bureau of Indian Standards has laid down following Indian Standard for the product. IS : 14543: 1998 - Packaged Drinking Water other than Packaged Natural Mineral Water Specification.

4.3

PRODUCTION CAPACITY (ANNUAL) : Quantity Value : : 45 lac Bottles (1 litre) & 33.6 lac Bottles (2 litre) Rs.4,37,70,000/-

4.4

MOTIVE POWER : The unit would need approx.25,000 kwh electric motive power per month.

4.5

POLLUTION CONTROL : Although the enterprise is non-polluting but it is advisable that NOC must be obtained from the competent authority i.e. State Pollution Control Board and proper utilization of waste water generated by RO plant should be ensured.

4.6

ENERGY CONSERVATION : Suitable measures should be adopted to optimize the use of energy and provision of energy saving devices are advised to conserve energy and to have check on this regular energy auditing must be carried out. Proper ventilation and arrangement of natural light in working shed are advisable.

5.0 5.1 5.1.1

FINANCIAL ASPECTS : Fixed Capital : Land & Building Land Total Covered Area for filteration, R.O. unit. Packing Material Storage, Laboratory, Office & Godown etc. 2000 Sq. Meters 600 Sq.Mtrs. 400 Sq.Mtrs. __________ 40 lacs. --------------7.0 lacs 33.0 lacs

5.1.2 PLANT & MACHINERY (All indigenous): Qty (i) (i) (iii) (iv) (v) (vi) (vii) (viii) (ix) Alum treatment tanks Chlorination tanks SS 3 Nos. 2 Nos. 1 No. 1 Set 1 No. 1 No. 1No. Total (Rs.) 1,50,000 1,00,000 8,50,000 75,000 40,000 37,500 37,500 3,90,000 4 Nos. 2,00,000

Reverse Osmosis Plant Cap. 5000 litre/hr. Filters (Sand, Carbon and Micro filters)(5, 1and 0.4 mic mm size) Ultra Violet disinfectant system Electronic doser for alum Electronic doser for chlorine Ozone Generator Capacity -

Raw and purified water collection tanks with motor/ pump and other accessories. Automatic bottle rinsing, filling and capping machine Shrink Wrapping machine for bottle labeling Misc. tools and equipment Laboratory equipments and analytical instruments Electrification and installation charges @ 10% of Plant & Machinery. Cost of Office Equipment and furniture including computer & printer Deep Bore Tube well as water source

(x) (xi) (xii) (xiii) (xiv) (xv) (xvi)

2 Nos. 2 Nos. L.S. L.S.

17,75,000 37,000 1,75,000 2,25,000 4,19,200 1,00,000 1,75,000 -------------

Total :

47,86,200 ------------Rounded to 47,86,000

5.1.3

TOTAL FIXED CAPITAL : 1. 2. 3. Land & Building Plant & Machinery Pre-operative expenses including Delivery Van Total 40,00,000 47,86,000 12,04,000 ________ 99,90,000

5.2 B. WORKING CAPITAL (Per Month) 5.2.1 STAFF & LABOUR : No. Salary 1 10,000 1 1 1 1 1 1 1 15 4 3 ---24 4,000 3,000 3,500 2,500 8,000 5,000 2,500 3,500 2,500 2,500 Amount (Rs.) 10,000 4,000 3,000 3,500 2,500 8,000 5,000 2,500 52,500 10,000 7,500 ----------1,08,500 16,275 1,24,775 1,25,000

(i) (ii) (iii) (iv) (v) (vi) (vii) (viii) (ix) (x) (xi)

Works Manager Accountant cum Cashaier Clerk cum Typist Store cum Purchase Officer Sweeper / Cleaner Production Manager Chemist cum Supervisor Lab Assistant

Skilled Worker including Maintenance Staff Unskilled Workers Watchman/ Peon -

Add 15% perquisites Total Rounded to 5.2.2 RAW MATERIAL (Per Month) : 1. PET Bottles with Cap (i) 1 litre size - 3,78,000 Nos. (ii) 2 litre size - 2,82,000 Nos.

9,00,000 9,85,000

2. 3.

Corrugated Boxes, tape, labels, etc. Misc. Chemicals Total :

7,85,000 30,000 ----------------27,00,000

5.2.3

UTILITIES (Per Month) : (i) (ii) Electricity Fuel & Others Total: 1,37,500 2,500 ---------------1,40,000

5.2.4

OTHER CONTINGENT EXPENSES (Per Month) : (i) (ii) (iii) (iv) (v) (vi) Postage & Stationery Phone Advertisement & Publicity Consumable Stores & Maintenance Transport Charges / Conveyance Charges Sales Expenses/ Sales Commission 750 750 2,000 3,000 5,000 8,000 1,875 2,000 1,000 ------------------Total : 24,375 Rounded 24,500

(vii) Insurance & Taxes (viii) Licence & Other fee (ix) Miscellaneous Expenses

5.2.5

WORKING CAPITAL (Per Month) : (i) (ii) (iii) (iv) Staff & Labour Raw Materials/ Packaging Materials Utilities Recurring Expenses 1,25,000 27,00,000 1,40,000 24,500 ----------------Total : 29,89,500 -----------------

6.0

WORKING CAPITAL FOR 3 MONTHS: 29,89,500 X 3 = Rs.89,68,500

7.0

TOTAL CAPITAL INVESTMENT : (i) (ii) Fixed Capital Working Capital (for 3 months) 99,90,000 89,68,500 ------------------1,89,58,500 -------------------

8.0 8.1

FINANCIAL ANALYSIS : COST OF PRODUCTION (Per Annum) : (i) (ii) (iii) Total Recurring Expenses Depreciation on Building @ 5% of Cost Depreciation on Plant & Machinery @ 10% per annum Depreciation on Office Equipment & furniture @ 20% Interest on Total Capital Investment @ 15% Total : Say : 3,58,74,000 1,65,000 4,68,000

(iv)

20,000

(v)

28,43,775 -----------------3,93,70,775 3,93,71,000

8.2

TURN OVER (Annual) : By sale of 45 lakh bottles of 1 litre @ 4.5 3360000 bottles of 2 litre @ 7.00

2,02,50,000 2,35,20,000 ------------------4,37,70,000 -------------------

8.3 8.3.1 8.3.2

PROFITABILITY : Total Profit Per Annum Net Profit Ratio 43,99,200 10.0%

8.2.3 8.3.4

Rate of Return on Investment Break Even Point B.E.P = FC x 100 FC + P (A) (i) (ii) (iii) (iv) (v) FIXED COST (FC) :

23.2% 48.9%

Depreciation on Plant & Machinery and Building Interest on Investment 40% of Salary & Wages 40% of Other Expenses other than Insurance Insurance

6,33,300 28,43,775 6,00,000 1,08,000 22,500 --------------------42,07,275 ---------------------

(B)

PROFIT (P) : FC X 100 FC + P = 42,07,275 x 100 86,06,275 = 48.9 %

9.0

NAME & ADDRESSES OF MACHINERY & EQUIPMENT SUPPLIERS : (1) M/s Rays Water Technology, CRT, 111 AM, No.25-B, 1st Floor, Laxmipuram, Ganapathy, Coimbatore 641 006 Phone: 0422-2523765 M/s Masseach Associates, No.13, Manohar Mahal, Moghal Lane, Mahim, Mumbai 400 016. Phone: 022-24377702 M/s Cristal Mineral Water Systech, No.107, Thirupathi Complex, M.G. Road, Paradise Circle, Hyderabad 500 001. Phone: 040-65160390 , FAX: 040-66486905

(2)

(3)

(4)

M/s Sai Aquafresh, X-10, 2nd Floor, Mani Market, West Patel Nagar, New Delhi 110 008. Phone: 011-25881093 , FAX: 011-25880739 M/s Neel Hydrotech, 1992, Udhai Sadan, Madi Wale Colony, Sadashiv Path, Pune 411030 (Maharashtra) Phone: 020 -24476611, FAX: 020-24476611 M/s Aquatech Systems, S.No.247/2/2D, Plot No.2 & 3, New Ganesh Nagar, Chinchwad Pune, Pune 411 001 (maharashtra) Phone: 020-27453395, FAX: 020-27453395 M/s N.B Industries, A-23,Meladi Estate, Opp. Meladi Mata Mandir, Near Gota, Railway Crossing, Gota Road, Ahmedabad 382 481 M/s E.C Packaging Pvt. Ltd., 14/7, Milestone, Mathura Road, Faridabad 121 003. Phone: 0129-4192900/2277698, FAX: 0129-2255602. M/s Ozone Technologies, C-225, Sector-63, Noida 201 301 Phone: 0120-4227679, FAX: 0120-4259442 M/s Numatik Engineers Pvt. Ltd., Shop No.6, Bobby Pathak Avenue, Opp. Rotary Garden, Dahisar East, Mumbai 400 068. Phone: 022-26480866/28483848 M/s Ion Exchange India Ltd., Ticcon House Road, Mahalaxmi, Mumbai 400 011.

(5)

(6)

(7)

(8)

(9)

(10)

(11)

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- From Wastewater To Drinking WaterDocument15 pagesFrom Wastewater To Drinking WaterSurajit SamantaNo ratings yet

- Franchising A BusinessDocument2 pagesFranchising A BusinessSurajit SamantaNo ratings yet

- Nuvo 8 BrochureDocument2 pagesNuvo 8 BrochureSurajit SamantaNo ratings yet

- Rain Water HarvestingDocument1 pageRain Water HarvestingSurajit SamantaNo ratings yet

- Water Treatment Handbook by ADILDocument134 pagesWater Treatment Handbook by ADILscribd8421100% (10)

- ListOfElements PDFDocument1 pageListOfElements PDFlata sirohiNo ratings yet

- 45MLD TTRO Plant at KoyambeduDocument3 pages45MLD TTRO Plant at KoyambeduSurajit SamantaNo ratings yet

- 45mldtertiarytreatment PDFDocument3 pages45mldtertiarytreatment PDFSurajit SamantaNo ratings yet

- Lecture 1 ETP Textile - verIIDocument44 pagesLecture 1 ETP Textile - verIIAshok ThakkarNo ratings yet

- Acm & Mini Pumps Technical SpecificationDocument5 pagesAcm & Mini Pumps Technical SpecificationSurajit SamantaNo ratings yet

- Water Treatment Handbook by ADILDocument134 pagesWater Treatment Handbook by ADILscribd8421100% (10)

- History and Types of Derivatives MarketsDocument2 pagesHistory and Types of Derivatives MarketsSurajit SamantaNo ratings yet

- NGO PresentationDocument5 pagesNGO PresentationSurajit SamantaNo ratings yet

- Reverse Osmosis Water Treatment PlantDocument11 pagesReverse Osmosis Water Treatment PlantSurajit SamantaNo ratings yet

- Drinking WaterDocument11 pagesDrinking WaterSurajit SamantaNo ratings yet

- Luetjens AbacusDocument8 pagesLuetjens Abacussainath_karetiNo ratings yet

- NarrationDocument1 pageNarrationSurajit SamantaNo ratings yet

- Abacus Mystery of The BeadaDocument40 pagesAbacus Mystery of The BeadaChitra KumaravelNo ratings yet

- Gita For MeDocument219 pagesGita For MeSurajit Samanta100% (1)

- 100% To Pass NCFM Dealers Mod If You Do Cash100Document17 pages100% To Pass NCFM Dealers Mod If You Do Cash100Surajit SamantaNo ratings yet

- NarrationDocument1 pageNarrationSurajit SamantaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Drawdown Testing and Semilog AnalysisDocument35 pagesDrawdown Testing and Semilog AnalysisAssholeNo ratings yet

- Practice Midterm ProblemsDocument4 pagesPractice Midterm ProblemsAnonymous Ms8nYcbxY2No ratings yet

- Erc 500-1000 - GBDocument2 pagesErc 500-1000 - GBtram 11100% (1)

- Piping Design CalculationsDocument16 pagesPiping Design Calculationsrahult19100% (1)

- P and H Chapter 3Document42 pagesP and H Chapter 3Noor UL AaienNo ratings yet

- Bab Bahasan Buku QasimDocument2 pagesBab Bahasan Buku QasimRd Nur MuhammadNo ratings yet

- Check Valves for Inline and Manifold MountingDocument4 pagesCheck Valves for Inline and Manifold MountingSamad A BakarNo ratings yet

- 2018-05 KRAL Z Series En-UsDocument16 pages2018-05 KRAL Z Series En-UsartyyNo ratings yet

- Jefferson CatalogDocument100 pagesJefferson Catalogmonky80No ratings yet

- Control Valve Sizing GuideDocument23 pagesControl Valve Sizing GuideEnerprec SASNo ratings yet

- Basic Viscometry TrainingDocument47 pagesBasic Viscometry TrainingMohamed AbouelhassanNo ratings yet

- Desalination Plant Feed Water ArrangementsDocument11 pagesDesalination Plant Feed Water ArrangementsSooraj Surendran SugathaNo ratings yet

- FMEADocument3 pagesFMEAJoseph FloresNo ratings yet

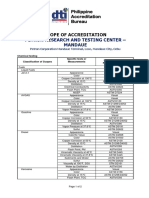

- Scope of Accreditation PRTC MandaueDocument2 pagesScope of Accreditation PRTC MandaueKent DoyuhimNo ratings yet

- Flow Through Circular PipesDocument105 pagesFlow Through Circular PipesArchangel VenantNo ratings yet

- 29 DALRYMPLE ROGERS Numerical Modeling of Water Waves With The SPH Method.Document7 pages29 DALRYMPLE ROGERS Numerical Modeling of Water Waves With The SPH Method.Anonymous HijNGQtNNo ratings yet

- Static & Rotating EquipmentDocument6 pagesStatic & Rotating EquipmentAnonymous ZPV7AKaBANo ratings yet

- Derivation of The Dupuit Equation - Unconfined FlowDocument15 pagesDerivation of The Dupuit Equation - Unconfined Flowyaseen90azizNo ratings yet

- Water GatesDocument11 pagesWater GatesEhlma LacuarenNo ratings yet

- Nanofiltration - WikipediaDocument7 pagesNanofiltration - WikipediaSrinivas DsNo ratings yet

- Industrial Lubricants Product GuideDocument29 pagesIndustrial Lubricants Product GuideChandra Kaladhara Rao KuntamukkalaNo ratings yet

- Volvo H Series Wheel Loader Periodic ServiceDocument35 pagesVolvo H Series Wheel Loader Periodic ServiceJoshua Simamora100% (2)

- CHE 503 Power Consumption in AgitatorDocument16 pagesCHE 503 Power Consumption in AgitatorNurtasha AtikahNo ratings yet

- Fundamentals of Orifice Metering FMCDocument7 pagesFundamentals of Orifice Metering FMCapply19842371No ratings yet

- MEP2133 Combined SheetsDocument19 pagesMEP2133 Combined SheetsAbdallah GamalNo ratings yet

- 0302 14 PDFDocument3 pages0302 14 PDFRony CruzNo ratings yet

- Report On Water Supply System Improvement Activities Siddhipur Integrated Water and Sanitation ProgrammeDocument30 pagesReport On Water Supply System Improvement Activities Siddhipur Integrated Water and Sanitation ProgrammeTsihatesfaNo ratings yet

- Thermal EOR screening criteria for oil recovery processesDocument4 pagesThermal EOR screening criteria for oil recovery processesanon04100% (1)

- 000 SLT2101316 Pe PiDocument27 pages000 SLT2101316 Pe PijaidikarimNo ratings yet

- Swimming Pool Circulation System Sizing SheetDocument2 pagesSwimming Pool Circulation System Sizing SheetTrang Ngo97% (30)