Professional Documents

Culture Documents

Planning and Communicating for Safe SIMOPS

Uploaded by

zineddinmakramOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Planning and Communicating for Safe SIMOPS

Uploaded by

zineddinmakramCopyright:

Available Formats

SIMOPS/OPERATIONS Planning and Communicating for Conducting Safe SIMOPS

Don Ross Pegasus International, Inc.

October 9-10, 2007

Return to Session Directory

Return to Session Directory

INTRODUCTION

Sharing Information Maximizes Our Personal Safety

Definitions: Study the project Identify SIMOPS Meet to discuss SIMOPS Orginze the information Plan our SIMOPS activity Share the plan and information Vessel SIMOPS: Two or more vessels operating in the same or same general area / close proximity to each other. Seafloor SIMOPS: Working in and around hardware (trees, caissons, piles, pipelines, umbilicals, UTAs PLETS, manifolds, etc) on the seafloor. Master/OIM/Officer: Licensed professionals, not titles assigned to individuals, as some construction vessels may call someone an OIM when they are in actuality a Superintendent, and not a licensed OIM.

General Comments: The Master is expressed throughout the document because It has been the authors experience that the masters are often the last people to find out about any of the decisions made by others and at the last minute they have to make decisions under pressure from others about operations involving their vessel. The author is expressing many Masters concerns that have been shared with him over the years throughout the document.

Return to Session Directory

STUDY THE CURRENT PROJECT SCHEDULE AND CREATE A SIMOPS IDENTIFICATION TABLE

Project Example, Results Study 1 - Possible Work to Be Carried Out In The Area

Group Task Year 1 Jan Geology & Geophysical Seismic Drilling New Well Completion Operations Maintenance Workover Construction Group Route Surveys Pipeline - Construction Umbilical Lay Field Development Setting Floater Floater in Place Regulatory Other's Activities Proposed Seismic Spec Shoot Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Year 2 Jan Feb Mar Apr

Review overall project schedule for possible SIMOPS, and assign the SIMOPS a designation for tracking purposes

Possible SIMOPS Number

Table 1: Conceptual Type Schedule, Looking At Long Term Project Goals

E1

April

Drilling

Drilling Vessel

Drilling

DP Acoustic Interference N/A - Propellers Causing Acoustic Noise N/A - Propellers Causing Acoustic Noise Acoustic Interference Others

Acoustic/Navigation

Frequency Management Vessel Movement Plans, DP LBL Array Plans

These vessels may be separated in field These vessels are always coming and going, will use Fan Beam for DP Operations while at Drill ship These vessels may be separated in field, but will be close to the Hull This / these vessels will be running around the 12 mooring pattern

From Schedule above create a SIMOPS identification Table

F3

Supply Vessels / Crew Boats

Bringing Supplies

Drilling

Navigation

Sail Plans / Date / Side to be Set Up On

G 2

Construction Tugs Towing Hull

Navigation

Work plans / sail plans

H 2

Anchor Handlers

Setting Lines

Mooring

to Acoustic/Navigation Work plans / sail plans Frequency Management / Survey Plans / DP LBL Array Plans Frequency Management / Survey Plans / LBL - USBL Plans

I1

Heavy Lift Barge(s)

Setting Hull, Moorings preset

DP Acoustic Interference Acoustic Interference Others

Acoustic/Navigation

These vessels may be separated in field

J2

ROV Vessel (s)

Assisting Lift Barge

Heavy

to Acoustic/Navigation

These vessels may be separated in field

Table 2: Vessel SIMOPS Identification Table

Return to Session Directory

BENEFITS OF EARLY SIMOPS PLANNING

With the implementation of early planning, enough time will be allowed for significant discussion, debate, reasoning etc to create a case for an argument to move all non essential SIMOPS. Furthermore, if the SIMOPS cannot be avoided, this early planning may give some insight as to which contractors/vessels will be more suited to work together. Early Planning Allows Clients and Operators in things such as: Avoiding SIMOPS With early planning, there may be enough time that the construction schedule or vessel schedule can be adjusted where there will SIMOPS can be deleted Vessel Selection The vessel can make choices of vessel depending on the type of SIMOPS that each vessel may be involved in Request For Proposal Details The client now can lay out potential SIMOPS and ask for pertinent information during the request for proposal

Return to Session Directory

DETAIL SIMOPS SCHEDULE

August - Year 1 Task Topside Activities 28 29 30 31

September -Year 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

SCR Hang off - Heavy Lift Barge ROV Support - SCR Hang -off Umbilical Lay - Vessel 1 Umbilical Lay - Vessel 2 Array Setting For Heavy Lift Barge's DP system (Acoustic) Supplies Needed Route Survey SIMOPS

A schedule similar to this one should be used in the meetings held to discuss the SIMOPS. The More advanced schedules should have the vessel names included.

Field Completion Drilling Field Array Setting ROV Support Completion

For

Supplies Crew Change - Crew Boat Crew Change - Chopper Route Survey SIMOPS

Table 3: Vessel SIMOPS Identification Schedule for Pre-Construction / Construction / Operations of SIMOPS Number 3 and 4 From Table 1

Return to Session Directory

MEETINGS BOTH ONSHORE AND OFFSHORE

All meetings shall be held in a manner where a truthful, non-biased discussion of each vessel should be held. By truthful, the true health of the vessel and DP system should be stated and handled by Masters and OIMs. Vessel Masters should state what type of DP system they have, number of working redundant systems, if acoustics are listed as a redundant system, then number of working beacons shall be disclosed and working depth of the pole and beacons. Furthermore, vessels should discuss how many officers will be on the bridge while the SIMOPS is being conducted (as one probably already knows this can changes per vessel). Likewise, safety discussions should be held such as emergency breakaway plans. However, all of this should be discussed in detail at the time of the offshore SIMOPS meeting between vessels due to the dynamics of field conditions. Meetings should occur at a minimum: - Conceptual Stage Project Review Meeting - Pre-construction stage Project Review Meeting - Construction Stage/Operations Stage Major Project Kick-off Meeting and Before Each SIMOPS The Meeting Should Have Discussions Such As: - Potential vessel set up in certain wind/sea/and currents - Emergency procedures (break away, drift plans) during the SIMOPS if a vessel or both vessels have issues - SIMOPS communication protocol (radio channels, phone numbers, or satellite phone dedicated to SIMOPS Operations). - Acoustic frequency preferences - Vessel approach methods/protocol - Safety issues

Return to Session Directory

AN UNEXPECTED VESSEL ARRIVES ON SITE

Some recommended questions to be asked by a vessel operator when one of their vessels is picked up in a hurry on a quick charter and things are flying fast for the mobilization: Are there other vessels in the areas? Are there SIMOPS plans in place? Can we have a look at your projects SIMOPS procedures? Is there a possibility of SIMOPS? What is the contact information for other vessels in the area? This is a good one, if one gets this information call the other vessels to let them know that you will be in the field. Can I see a project overview and where will we be working and where are others working at? Do you have a SIMOPS coordinator/manager?

Return to Session Directory

TECHNICAL THOUGHTS / Q&A

Thought 1: Many vessels may claim that they are DP II, However, the only system that may be available is two GPS system, with the weak leak and problem area being the antenna. On most vessels, one can safely bet that the antennas are less than 30 feet apart. Therefore, it would be safe to say that if something masks one antenna, it will mask the other. With this said, the only time that multi-path and/or masking should occur is when a vessel is too close to a structure in which this would be a SIMOPS situation. This is more than likely to occur when a smaller vessel is near a larger vessel or platform.

Thought 2: Along the same lines, if a vessel is in deep water and has a taught line system along with the 2 GPS systems, can the taught line actually be counted as a working part of the DP system for redundancy? Does this reduce the operational class of the DP system at the site?

Thought 3: If a vessel has a hydrophone pole and has only one beacon along with the 2 GPS beacons and is in deepwater to ultra deep water, does the 1% slant rule apply? If it does, is the DP positional foot print good enough call this one beacon set up as a redundant positional system? What if the vessel does not have compatts depth rated? These thought is not questioning the vessels which set out a full array, this is only questioning some of the vessels that have minimal equipment and do not have the capability of setting a full array.

Return to Session Directory

CASE STUDY EXAMPLE 1:

SETTING AN ACOUTIC ARRAY, BOXING IN COMPATTS AND COLLECTING ACOUSTIC BASELINES IN THE NEAR VICINITY OF A DP DRILLSHIP

LEGEND

PR OP EX IS

OS ED

UM BIL

TIN G

IC AL

PIP EL

We tried to avoid this SIMOPS as best as possible. However due to a drilling schedule slip and the pipelay advancing, this work had to be performed. This plan and sketch was created offshore

IN E

BLOCK 4

ED UM BILICA L

PROPOS

BLOCK 3

GULF OF MEXICO SAMPLE AREA BLOCK 1

EXIS TIN

GP

A frequency list was gathered, reviewed, checked for clashes and shared before discussions began.

IPE LINE

SIMOPS NUMBER 5 - A

SAMPLE SIMOPS BETWEEN ROV VESSEL PERFORMING LBL COMPATT ARRAY SETTING, COMPATT BOX-IN, AND ARRAY BASELINE COLLECTION, AND A DP DRILL SHIP DRILLING AND OR COMPLETING A WELL USING A LBL ARRAY FOR DP ACOUSTIC POSITIONING. DISCUSSED DATE: 00/00/00 APPROVED DATE: 00/00/00 SIMOPS NUMBER 5-A REV A DRAWING 1 OF 1 DATE: 00/00/00

BLOCK 2

LEGEND

After information was gathered and the plan was created, the plan was sent to the drill ship for comments, revisions and approval. We had meeting aboard the drill ship before operations began.

PROP

EXISTIN

OSED UMBIL ICAL G PIP ELINE

BLOCK 4 BLOCK 3

UMBILICAL PROPOSED

Operations moved slowly and we had constant communications between both vessels This was completed with no issues.

GULF OF MEXICO SAMPLE AREA BLOCK 1

EXIS TIN

GP IPE LINE

SIMOPS NUMBER 5 - A

SAMPLE SIMOPS BETWEEN ROV VESSEL PERFORMING LBL COMPATT ARRAY SETTING, COMPATT BOX-IN, AND ARRAY BASELINE COLLECTION, AND A DP DRILL SHIP DRILLING AND OR COMPLETING A WELL USING A LBL ARRAY FOR DP ACOUSTIC POSITIONING. DISCUSSED DATE: 00/00/00 APPROVED DATE: 00/00/00 SIMOPS NUMBER 5-A REV A DRAWING 1 OF 1 DATE: 00/00/00

BLOCK 2

Return to Session Directory

CASE STUDY EXAMPLE 2:

SURPRISE VESSEL WORKING NEAR THE DRILLSHIP

LEG END

VESSEL 1 T Y P E / D P C L A S S : D R IL L S H IP / 3 P R IM A R Y R E F E R E N C E : G P S -1 S E C O N D A R Y R E F E R E N C E : G P S -2 T E R T IA R Y R E F E R E N C E : A C O U S T IC A R R A Y VESSEL 2 TYPE / DP C LASS: FAST CR EW BO AT / 2 P R IM A R Y R E F E R E N C E : G P S -1 S E C O N D A R Y R E F E R E N C E : G P S -2 T E R T IA R Y R E F E R E N C E : N /A VESSEL 3 T Y P E / D P C L A S S : S U P P L Y V E S S E L - D R IL L M U D / 2 P R IM A R Y R E F E R E N C E : F A N B E A M S E C O N D A R Y R E F E R E N C E : G P S -1 T E R T IA R Y R E F E R E N C E : G P S 2 V E S S E L 4 - S IM O P S W A R N IN G - U S E S U S B L T O T R A C K R O V TYPE / DP C LASS: RO V VESSEL / 2 P R IM A R Y R E F E R E N C E : G P S -1 S E C O N D A R Y R E F E R E N C E : G P S -2 T E R T IA R Y R E F E R E N C E : N O N E VESSEL 5 TYPE / D P C LASS: SU PPLY - CREW CHANG E P R IM A R Y R E F E R E N C E : G P S -1 S E C O N D A R Y R E F E R E N C E : G P S -2 T E R T IA R Y R E F E R E N C E : F A N B E A M VESSEL 6 TYPE / D P C LASS: SUPPLY P R IM A R Y R E F E R E N C E : G P S -1 S E C O N D A R Y R E F E R E N C E : G P S -2 T E R T IA R Y R E F E R E N C E : F A N B E A M

S IM O P S N U M B E R S - 1

C A U T IO N : V E S S E L S U S IN G F A N B E A M B E A W A R E T H A T T H E Y M A Y H A V E P E O P L E W O R K IN G W E A R IN G C O V E R A L L S W IT H R E F L E C T IV E T A P E . T H IS M A Y C A U S E A D P R U N O F F S IM O P S O F A V E S S E L C A L L E D IN A T L A S T M IN U T E T O A ID T H E D R IL L S H IP D U E T O IT S R O V B R E A K IN G D O W N T H E V E S S E L U S E D IS T H E O N L Y V E S S E L A V A IL A B L E T O B E S O U R C E A T T H E T IM E O F T H E O P E R A T IO N S . D IS C U S S E D D A T E : 0 0 /0 0 /0 0 A P P R O V E D D A T E : 0 0 /0 0 /0 0 S IM O P S N U M B E R S -1 R E V A D R A W IN G 1 O F 1 D A T E : 0 0 /0 0 /0 0

Return to Session Directory

MORE CASE STUDY EXAMPLES

Case 3:

An AUV Survey Was Needed In And Around A Drill Ship Due To Pipeline/Flowline Route Deviations An AUV operating in the vicinity of a Drill Ship. We began discussion weeks before hand to discuss how close we could get to the drillship. The master set the rules, and they were followed. The early on discussions allowed for better survey planning to get data that was in the restricted area. What is great about this was at first they said no way this is going to happen, but with a little discussion, and time to prepare, it became possible. There were some conversations held in the field shortly before the work initiated and this was due to some slight changes in the program which were not relayed to the master of the drill ship. Case 4:

SIMOPS at a Floating Platform, this was totally amazing The project demanded a huge array in the area of the floating facility to all for all of the umbilical and pipeline risers to be positioned using the array. By planning ahead and using forward thinking we were able to have 2 lay vessels using LBL in the same array, while a Heavy lift ship was starting up and setting their array and had 2 other ROV vessels positioning their ROVs without anyone stepping on anybody else. This worked well because of forward planning and allowing the vessels to have some flexibility in the field to adjust accordingly to work around each other.

Return to Session Directory

CONCLUSION

Things to think about as we close this presentation No mater what happens, safety is most important.

I would like to give special thanks for the clients, employers and mostly all of the vessels and crews that I have worked with over the past years. Without the knowledge that they shared with me and allowed me to gain, this paper could have never been created. Furthermore, the inspiration of this paper was from the time that I spent offshore working with different vessels in different parts of the world and hearing the masters and DP officers complaints and concerns, which was mostly that they are kept in the dark about all or most operations.

You might also like

- Planning Communicating SIMOPSDocument26 pagesPlanning Communicating SIMOPSantonNo ratings yet

- HSE Practice SIMOPS ProcedureDocument17 pagesHSE Practice SIMOPS ProcedureAjay Krishnan80% (5)

- HSE Plan - FPSO Topside PDFDocument48 pagesHSE Plan - FPSO Topside PDFdndudc100% (3)

- COSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsDocument2 pagesCOSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsPaulSwinbankNo ratings yet

- Simops Risk AssessmentDocument3 pagesSimops Risk Assessmentzineddinmakram100% (1)

- Welding HabitatDocument12 pagesWelding HabitatDesmond Chang100% (3)

- SIMOPS Check ListDocument8 pagesSIMOPS Check ListWawan Setiawan100% (2)

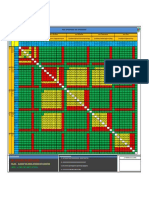

- SIMOPs Matrix - Combined - Rev-1Document1 pageSIMOPs Matrix - Combined - Rev-1DebadityachatterjeeNo ratings yet

- HSE - Operational Safety of FPSO Initial Summary ReportDocument41 pagesHSE - Operational Safety of FPSO Initial Summary Report고병석100% (1)

- Simultaneous Operations (SIMOPS)Document156 pagesSimultaneous Operations (SIMOPS)Ahmed Lepda100% (3)

- Simultaneous OperationsDocument22 pagesSimultaneous OperationsOgbadiboNo ratings yet

- East Wind Simops MatrixDocument2 pagesEast Wind Simops MatrixkhaledNo ratings yet

- Confined Space Entry Procedure for SPM Inner Floating Hose Onshore InspectionDocument23 pagesConfined Space Entry Procedure for SPM Inner Floating Hose Onshore InspectionAizat Najib100% (3)

- BP Golden Rules - Download From Step Change Web Site PDFDocument16 pagesBP Golden Rules - Download From Step Change Web Site PDFDerouich2019No ratings yet

- Crisis ManagementDocument3 pagesCrisis ManagementAsad UllahNo ratings yet

- GP 00 02 Engineering Technical Practice (ETP) Governance and Management PrinciplesDocument10 pagesGP 00 02 Engineering Technical Practice (ETP) Governance and Management PrinciplesSHANZAY21111111No ratings yet

- Behavioural Based SafetyDocument1 pageBehavioural Based SafetyHarthwell CapistranoNo ratings yet

- I. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17Document15 pagesI. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17KehindeNo ratings yet

- Managing HSE in A Geophysical ContractDocument88 pagesManaging HSE in A Geophysical ContractRameeSahibaNo ratings yet

- 12 Life Saving ShellDocument12 pages12 Life Saving ShellMd Amirul75% (4)

- Offshore Technical Safety FAQDocument12 pagesOffshore Technical Safety FAQPillai Sreejith100% (15)

- Standard Safety Practices ManualDocument350 pagesStandard Safety Practices Manualrs_hendarsah100% (13)

- Document Title: HSE Standard Manual Management of ChangeDocument12 pagesDocument Title: HSE Standard Manual Management of ChangeDhimaz Yudi100% (3)

- Process Safety ManagementDocument74 pagesProcess Safety ManagementShankarMukherjeeNo ratings yet

- 3S HSE MS Docs ContentDocument85 pages3S HSE MS Docs Contentrashid zamanNo ratings yet

- 03a-Simultaneous Operations Operational ProcedureDocument11 pages03a-Simultaneous Operations Operational Proceduremichel louis friedman100% (1)

- OGP Life-Saving RulesDocument24 pagesOGP Life-Saving RulesInternational Association of Oil and Gas Producers100% (3)

- South Pars Permit System ExplainedDocument25 pagesSouth Pars Permit System ExplainedAntonne E. PhillipNo ratings yet

- ZETODocument24 pagesZETOKimberly Jinn100% (1)

- Scaffolding SafetyDocument58 pagesScaffolding Safetychaymaa MRHARNo ratings yet

- HSE Directive 7 ChemicalsDocument9 pagesHSE Directive 7 ChemicalsakubestlahNo ratings yet

- Handouts PTW Standard Rev. 00Document173 pagesHandouts PTW Standard Rev. 00Francis AlmiaNo ratings yet

- Safety in PlantsDocument18 pagesSafety in PlantsVikas NigamNo ratings yet

- fpso-USCG RequirementsDocument17 pagesfpso-USCG RequirementsAji VasudevanNo ratings yet

- GU-612 - v3.1 - Guidelines - Incident Investigation and Reporting v1Document185 pagesGU-612 - v3.1 - Guidelines - Incident Investigation and Reporting v1rwerwerw100% (3)

- Loss of ContainmentDocument68 pagesLoss of Containmentpetrolhead1No ratings yet

- E-C.2.4-HQ-PRO-001 Process and Mechanical Valving and Isolation PhilosophyDocument16 pagesE-C.2.4-HQ-PRO-001 Process and Mechanical Valving and Isolation Philosophyagaricus100% (2)

- 6.63 Pipeline Hazid Envid ReportDocument17 pages6.63 Pipeline Hazid Envid ReportGaluh Pramudipto100% (7)

- Compressed Gas Cylinders PowerPointDocument20 pagesCompressed Gas Cylinders PowerPointInspire KharianNo ratings yet

- Decommission and Removal of Offshore O Amp G Facilities 1997Document68 pagesDecommission and Removal of Offshore O Amp G Facilities 1997Linh TranNo ratings yet

- Hazard Analysis ProcedureDocument26 pagesHazard Analysis ProcedureRaghu Venkata100% (5)

- 0310-10 Rev 2 CBTA Gas Tester TRAINING PDFDocument16 pages0310-10 Rev 2 CBTA Gas Tester TRAINING PDFfaltekxNo ratings yet

- Hazid Presentation (Fso Preparation Work) 1Document34 pagesHazid Presentation (Fso Preparation Work) 1Afriansyah100% (1)

- How UGDC Can Improve Performance with Human FactorsDocument8 pagesHow UGDC Can Improve Performance with Human FactorsTFattah100% (1)

- PDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Document255 pagesPDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Syed AmzarNo ratings yet

- BPcrane LiftingDocument56 pagesBPcrane Liftingheppy51710% (1)

- Permit To Work CBT (Chevron) Training PresentationDocument45 pagesPermit To Work CBT (Chevron) Training Presentationkanakarao1100% (4)

- Manta To Richmond SIMOPS Risk Matrix FINALDocument1 pageManta To Richmond SIMOPS Risk Matrix FINALDesmond Chang50% (2)

- Onshore Design Safety PhilosophyDocument61 pagesOnshore Design Safety Philosophyrahman196011100% (3)

- 8 - RJN NAD HSE Management PlanDocument45 pages8 - RJN NAD HSE Management PlanMartahanManurung100% (1)

- Client: BMT India Document: Terms of References For Quantitative Risk Assessment StudyDocument10 pagesClient: BMT India Document: Terms of References For Quantitative Risk Assessment StudyAnurag BholeNo ratings yet

- Tech Safety Vs HSE EngineerDocument5 pagesTech Safety Vs HSE EngineerIrsyad Ilhami100% (1)

- Emergency Response and Rescue Vessel Survey GuidelinesDocument41 pagesEmergency Response and Rescue Vessel Survey Guidelinesokandandin100% (1)

- Planning and Communicating For Conducting Safe SIMOPS: Dynamic Positioning Conference October 9-10, 2007Document26 pagesPlanning and Communicating For Conducting Safe SIMOPS: Dynamic Positioning Conference October 9-10, 2007DiegoNo ratings yet

- Dynamic PositioningDocument31 pagesDynamic PositioningU Zaw Aung100% (3)

- 1978 - Harvald - Shipyard Needs For Model TestDocument26 pages1978 - Harvald - Shipyard Needs For Model Testhamedullah mNo ratings yet

- Openhole Wireline Logging PDFDocument0 pagesOpenhole Wireline Logging PDFyoyi yuniasNo ratings yet

- Multibeam-Surveying-LINE SPACINGDocument6 pagesMultibeam-Surveying-LINE SPACINGjasper richardsNo ratings yet

- Fischer SessionH4Document62 pagesFischer SessionH4eff offNo ratings yet

- Fiche Fonction Ingénieur ContratDocument1 pageFiche Fonction Ingénieur ContratzineddinmakramNo ratings yet

- Introduction To CFD BasicsDocument21 pagesIntroduction To CFD BasicsVijay KrishnanNo ratings yet

- Es-10 Flowrate Chart: Inlet Pressure (Barg)Document1 pageEs-10 Flowrate Chart: Inlet Pressure (Barg)zineddinmakramNo ratings yet

- Arbre Défaillance - ESP - REV01Document2 pagesArbre Défaillance - ESP - REV01zineddinmakramNo ratings yet

- SCHEDLOG Ver01Document4 pagesSCHEDLOG Ver01zineddinmakramNo ratings yet

- X English Book Back Solution by Arunachalam KDocument14 pagesX English Book Back Solution by Arunachalam KPorkodi Amirthalingam AmirthalingamNo ratings yet

- Lee Scratch PerryDocument11 pagesLee Scratch PerryrizkisembiringNo ratings yet

- Excercises For Jazz 2019Document11 pagesExcercises For Jazz 2019filipdinev150% (2)

- Prepositions of Time QuizDocument1 pagePrepositions of Time Quizthx1138gaNo ratings yet

- Coltrane Pentatonic PDFDocument45 pagesColtrane Pentatonic PDFJose Melo100% (3)

- High School Story of My Life Essay PDFDocument2 pagesHigh School Story of My Life Essay PDFJr YansonNo ratings yet

- IVCS3 User GuideDocument19 pagesIVCS3 User GuideJimmy Watt AbarcaNo ratings yet

- Knowledge Organiser: Properties of Waves Sound Waves HearingDocument1 pageKnowledge Organiser: Properties of Waves Sound Waves HearingLuisGamesNo ratings yet

- Patient Monitors 2010Document1 pagePatient Monitors 2010albertoNo ratings yet

- The BUSINESS of MUSIC - A Summary of Contracts Governing Music Industry DealsDocument15 pagesThe BUSINESS of MUSIC - A Summary of Contracts Governing Music Industry Dealsgshearod2u50% (2)

- 19 - RLC Circuits & Resonance PDFDocument13 pages19 - RLC Circuits & Resonance PDFRAJESHNo ratings yet

- Andante (From Concerto in G For 2 Mandolins) by Antonio VivaldiDocument5 pagesAndante (From Concerto in G For 2 Mandolins) by Antonio VivaldiumitNo ratings yet

- At The Five Spot, Vol. 2 - BookletDocument6 pagesAt The Five Spot, Vol. 2 - BookletBenjamín Poblete100% (2)

- Philippine ILLINI Fall-Winter, 2013Document34 pagesPhilippine ILLINI Fall-Winter, 2013christphilippineNo ratings yet

- Rule 37 - Distress SignalsDocument27 pagesRule 37 - Distress SignalsMitch Speeder100% (2)

- Imagine Tab by John LennonDocument3 pagesImagine Tab by John LennonjonjammyNo ratings yet

- CBSE Class XII Physics Sample PaperDocument7 pagesCBSE Class XII Physics Sample PaperAbhimanyu MalhotraNo ratings yet

- Technical ReportDocument9 pagesTechnical Report27051977100% (3)

- Little Women: by Louisa May AlcottDocument330 pagesLittle Women: by Louisa May AlcottLuis Gabriel Luna CuadroNo ratings yet

- Bonnie TylerDocument7 pagesBonnie TylerRinaldo TravagliniNo ratings yet

- What Is A Time Signature?: About Those NumbersDocument10 pagesWhat Is A Time Signature?: About Those NumbersNaluminoNo ratings yet

- 2019-10-11 Proof of Licensing For Luis Miguel Matta Rios (LPL194494) PDFDocument2 pages2019-10-11 Proof of Licensing For Luis Miguel Matta Rios (LPL194494) PDFLuis Matta RiosNo ratings yet

- Proper Cello Maintenance and CareDocument10 pagesProper Cello Maintenance and CareFebie DevinaNo ratings yet

- Antenna Used in IndiaDocument5 pagesAntenna Used in IndiaShiv ChaudharyNo ratings yet

- Viewsonic VA2026W1Document79 pagesViewsonic VA2026W1Raul AlfaroNo ratings yet

- Global System For Mobile CommunicationDocument53 pagesGlobal System For Mobile CommunicationJahan ZaibNo ratings yet

- Animesh Karandikar Meghna Mahak Jaspreet Gaurang ShubhamDocument9 pagesAnimesh Karandikar Meghna Mahak Jaspreet Gaurang ShubhamShaun NevilleNo ratings yet

- Peter Grimes and The Rumor of HomosexualityDocument10 pagesPeter Grimes and The Rumor of HomosexualityAllison Q. KessingerNo ratings yet

- Owner Manual - AVR 158 (English EU)Document42 pagesOwner Manual - AVR 158 (English EU)Romeo MoranoNo ratings yet

- Grammar - Be Past Simple: Affirmative and Negative: 10 / 11 Points (90%)Document19 pagesGrammar - Be Past Simple: Affirmative and Negative: 10 / 11 Points (90%)Sheyla Armas FloresNo ratings yet