Professional Documents

Culture Documents

Welcome To Alligator Ready Set Staple

Uploaded by

Denn Sopan0 ratings0% found this document useful (0 votes)

76 views23 pagesLIGHT-DUTY BELT FASTENER SYSTEMS Features and Benefits One-piece fastener strips prevent individual parts from getting into conveyed product. Pre-inserted staples reduce installation time by eliminating the need to handle and load individual staples.

Original Description:

Original Title

Alligator Staple

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLIGHT-DUTY BELT FASTENER SYSTEMS Features and Benefits One-piece fastener strips prevent individual parts from getting into conveyed product. Pre-inserted staples reduce installation time by eliminating the need to handle and load individual staples.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

76 views23 pagesWelcome To Alligator Ready Set Staple

Uploaded by

Denn SopanLIGHT-DUTY BELT FASTENER SYSTEMS Features and Benefits One-piece fastener strips prevent individual parts from getting into conveyed product. Pre-inserted staples reduce installation time by eliminating the need to handle and load individual staples.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 23

LIGHT-DUTY BELT FASTENER SYSTEMS

Welcome to Alligator Ready SetTM Staple

LIGHT-DUTY BELT FASTENER SYSTEMS

Applications

Ideal for light- and medium-duty conveyor applications including: Package Handling Baggage Handling Cased Goods Parts Food Agricultural Products

LIGHT-DUTY BELT FASTENER SYSTEMS

Selection Guide

Fastener Size Operating Tension Range kN/m (P.I.W.) 17 (100) 28 (160) 35 (200) Belt Thickness Range mm (in.) 1.5-3.2 (1/16-18) 3.2-4.8 (1/8-3/16) 4.8-6.4 (3/16-1/4) Minimum Pulley Diameter mm (in.) 50 (2) 75 (3) 100 (4)

RS62 RS125 RS187

LIGHT-DUTY BELT FASTENER SYSTEMS

Fastener Metal Selection

Steel Standard fastener material is suitable for most applications. Plated for rust and corrosion resistance. Stainless Steel Type 316 provides extra resistance to abrasion, magnetic attraction, and corrosion from acids and chemicals. Also excellent for high-sanitary requirements.

LIGHT-DUTY BELT FASTENER SYSTEMS

Fastener Metal Selection

MegAlloy - Superior resistance to wear and abrasion, providing several times the service life of steel. Not recommended where subject to impact or corrosion. Magnetic Stainless Type 430 For use with magnetic separators, and provides resistance to wear and abrasion. Plate, staples and hinge pins are all constructed from magnetic stainless steel.

LIGHT-DUTY BELT FASTENER SYSTEMS

Hinge Pin Selection

Wide selection makes it easy to match the correct hinge pin to the needs of your application. Nylon Covered Steel Cable Nylon covering reduces corrosion and simplifies hinge pin insertion. Nylon Covered Stainless Steel Cable For greater corrosion resistance. Steel Spring Wire For flat belt conveyors carrying abrasive or gritty materials. Stainless Steel Spring Wire For use with stainless steel fasteners.

LIGHT-DUTY BELT FASTENER SYSTEMS

Features & Benefits

One-piece fastener strips prevent individual parts from getting into conveyed product. Pre-inserted staples reduce installation time by eliminating the need to handle and load individual staples.

LIGHT-DUTY BELT FASTENER SYSTEMS

Features & Benefits

Smooth, unrippled joint simplifies hinge pin insertion. Extended plate design separates the point of staple penetration from the line of belt flexing, eliminating splice fatigue. Strong splice that resists impact damage.

LIGHT-DUTY BELT FASTENER SYSTEMS

Features & Benefits

Staples penetrate between carcass fibers without severing them. Staples are clinched crosswise to prevent belt tension from pulling against and unclinching staples.

LIGHT-DUTY BELT FASTENER SYSTEMS

Features & Benefits

Installation requires only a hammer and lightweight installation tool. Tool can easily be carried to and from the job site. Simply fit the fastener strip onto the belt ends and secure the tool.

LIGHT-DUTY BELT FASTENER SYSTEMS

Alligator RSC187 Installation Tool

Holds fasteners securely in proper alignment. Guides staples as they are driven. Installs two staples simultaneously. Provides a solid anvil surface for initial staple clinching.

LIGHT-DUTY BELT FASTENER SYSTEMS

Alligator RSC187 Installation Tool

RSC187 comes complete with guide blocks and driver. Standard tool can be used to install all three fastener sizes. Available in sizes to match a variety of belt widths. Wider tools available for production lacing and fabrication shops.

LIGHT-DUTY BELT FASTENER SYSTEMS

Alligator Quad Staple Driver

The Quad Staple Driver allows for the installation of four staples at one time. Allows installers to reduce their installation time by 50%.

LIGHT-DUTY BELT FASTENER SYSTEMS

Alligator Ready Set Tool Kit

Everything needed to install Alligator Ready Set fasteners in a lightweight, easy-tocarry toolbox. Includes RSC187 tool, staple set plate, hand skiver, belt nippers and a 0.5kg (1 lb.) hammer.

LIGHT-DUTY BELT FASTENER SYSTEMS

Staple Setting Plate

Use the staple setting plate to achieve a smooth, finished splice. Heat-treated steel plate puts the finishing set on staples. Features countersunk bolt holes for easy mounting.

LIGHT-DUTY BELT FASTENER SYSTEMS

Rough-Top Belt Skiver

For quick and clean removal of rough top from light- and medium-duty belting. Permits lower fastener installation to minimize splice profile. Durable. Hand-operated tool.

LIGHT-DUTY BELT FASTENER SYSTEMS

Alligator Hinge Pin Cutter

Cuts bulk hinge pin cable quickly and easily. Provides a clean cut with no frayed ends.

LIGHT-DUTY BELT FASTENER SYSTEMS

Hinge Pin Retaining Washers

Retaining washers prevent migration of nylon covered cable hinge pins.

LIGHT-DUTY BELT FASTENER SYSTEMS

Hinge Pin Bender

For use with steel spring wire pins. Bends hinge pin end to prevent pin migration.

LIGHT-DUTY BELT FASTENER SYSTEMS

Ready Set Staple Guide Blocks

It is easy to convert the standard C187 Alligator Installation Tool to Alligator Ready Set. Simply replace standard guide blocks with the ST5-5 staple guide block.

LIGHT-DUTY BELT FASTENER SYSTEMS

Clipper 845LD Belt Cutter

For straight, clean and safe cuts on belts up to 12mm (1/2) thick. Shielded, doubleedged safety blade. Blade can be chaindrive from either end of the cutter. Removable clamp bars hold belts securely.

LIGHT-DUTY BELT FASTENER SYSTEMS

Alligator 300 Series Belt Cutter

Delivers clean, straight cuts quickly and safely. Double-edged blade cuts in either direction. For belts of any width up to 28mm (1-1/8) thick. Extra-long blade can be special ordered for belts up to 39mm (1-9/16) thick.

LIGHT-DUTY BELT FASTENER SYSTEMS

You might also like

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Chainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyFrom EverandChainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyRating: 5 out of 5 stars5/5 (4)

- ALUMIL - Accessories Guarantee Guidelines - EN-2019.V3Document11 pagesALUMIL - Accessories Guarantee Guidelines - EN-2019.V3Aleksandar Sasa DjurkovicNo ratings yet

- Regency Drawn Bonnet... Pattern and Tutorial: Draw by GridDocument12 pagesRegency Drawn Bonnet... Pattern and Tutorial: Draw by GridFlorenciaNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Alcoa Fastening SystemsDocument131 pagesAlcoa Fastening SystemsWanbo LiuNo ratings yet

- The The Art of Fashion IllustrationDocument147 pagesThe The Art of Fashion IllustrationAswathy Unnikrishnan100% (11)

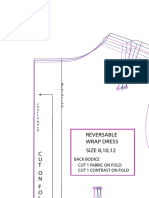

- Wrap Around Dress Pattern PDFDocument8 pagesWrap Around Dress Pattern PDFStefaniaRosatiNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Sop On Sewn Button Snap Fastener Safety PDFDocument58 pagesSop On Sewn Button Snap Fastener Safety PDFAri RamadhanNo ratings yet

- Crizaf Catalog 2004Document69 pagesCrizaf Catalog 2004ArmandoDias100% (1)

- Papua Yarn: "Lea" DressDocument2 pagesPapua Yarn: "Lea" DressVeritoo VeroNo ratings yet

- Kitchen UL 300Document18 pagesKitchen UL 300Special_DonkNo ratings yet

- Worksheet #3 - Supply and DemandDocument2 pagesWorksheet #3 - Supply and Demandhuhu4545No ratings yet

- Project 2017-2019Document30 pagesProject 2017-2019RAJAVEL ANAND0% (1)

- Horizontal SystemsDocument8 pagesHorizontal SystemsJohn Jairo CamachoNo ratings yet

- Entrepreneur Chapter 12Document8 pagesEntrepreneur Chapter 12CaladhielNo ratings yet

- IQF Frost AB Power Point PresentationDocument61 pagesIQF Frost AB Power Point PresentationKB NilkanthNo ratings yet

- Heli-Coil Catalog HC2000 Rev12Document40 pagesHeli-Coil Catalog HC2000 Rev12anon_512891835No ratings yet

- Side by Side 2 Chapter 1 Test PDFDocument62 pagesSide by Side 2 Chapter 1 Test PDFSa-rah Joie69% (16)

- Pirate Pencil Skirt: By: Patterns For PiratesDocument27 pagesPirate Pencil Skirt: By: Patterns For PiratesssakreNo ratings yet

- Reminton CatalogoDocument20 pagesReminton CatalogoGustavo Javier Ramírez100% (1)

- Ringlock Scaffolding SystemDocument9 pagesRinglock Scaffolding SystemJyles SirabNo ratings yet

- Brochure Tubular DragDocument2 pagesBrochure Tubular DragIvo KovachevNo ratings yet

- Bucket Elevator ConveyorDocument7 pagesBucket Elevator ConveyorJuan Carlos RNo ratings yet

- Manejo de Catalogo Reductores Montados Sobre Eje DODGEDocument56 pagesManejo de Catalogo Reductores Montados Sobre Eje DODGEPedro Julio PérezNo ratings yet

- SR Working 07 EN PDFDocument34 pagesSR Working 07 EN PDFrfzebralNo ratings yet

- SR Working 2013 EN PDFDocument72 pagesSR Working 2013 EN PDFDie Medienwerkstatt GmbHNo ratings yet

- Protocatalog p20800 14.specialtytoolsDocument18 pagesProtocatalog p20800 14.specialtytoolsdionisio emilio reyes jimenezNo ratings yet

- Unilift de DGDDocument36 pagesUnilift de DGDLove SemsemNo ratings yet

- Close Tolerance Stop Collar: ProductDocument1 pageClose Tolerance Stop Collar: Productber allamNo ratings yet

- The Advantages at A Glance: The Unique & Versatile SystemDocument2 pagesThe Advantages at A Glance: The Unique & Versatile SystemVikrant MapuskarNo ratings yet

- BELTWALL BrochureDocument6 pagesBELTWALL Brochurejurilika100% (1)

- CS1-014 A4 BrochureDocument4 pagesCS1-014 A4 BrochureLuc TellierNo ratings yet

- Speed Flooring SystemDocument31 pagesSpeed Flooring SystemAbhijit BhattacharjeeNo ratings yet

- 2020 DGCL Mining BrochureDocument8 pages2020 DGCL Mining BrochureCAT MINING SHOVELNo ratings yet

- Catalogo SINGING ROCK Working 2014 2015 en 150dpiDocument106 pagesCatalogo SINGING ROCK Working 2014 2015 en 150dpikerocorpNo ratings yet

- Pro Rod BrochureDocument9 pagesPro Rod BrochureMIRCEA1305No ratings yet

- 1 Power Band and Circular SawsDocument51 pages1 Power Band and Circular SawsJiggy Lawrence BathanNo ratings yet

- The Advantages at A Glance: The Unique & Versatile SystemDocument2 pagesThe Advantages at A Glance: The Unique & Versatile SystemAdnan KunicNo ratings yet

- Locking DevicesDocument28 pagesLocking Devicesraj mohan100% (1)

- Lintech CatalogDocument75 pagesLintech CatalogElectromateNo ratings yet

- Udyogi PPT FPDocument41 pagesUdyogi PPT FPAniruddha GujarNo ratings yet

- Pipe Purging BrochureDocument19 pagesPipe Purging BrochurejmsmechNo ratings yet

- Kerk Catalog 2008 PDFDocument74 pagesKerk Catalog 2008 PDFhexapodoNo ratings yet

- Catálogo Rexnord IngenieríaDocument152 pagesCatálogo Rexnord IngenieríaCésar VásquezNo ratings yet

- Motion Transmission Mechanisms: Emergency Door: Presented byDocument33 pagesMotion Transmission Mechanisms: Emergency Door: Presented byJohan GuerreroNo ratings yet

- Bearing Maintenance ToolsDocument20 pagesBearing Maintenance Toolscaryll_27No ratings yet

- Lorbrand Return Roller V1Document2 pagesLorbrand Return Roller V1PaulRamosNo ratings yet

- BSA Lead Screws: Easy Running, Precise and Cost-Effective PositioningDocument16 pagesBSA Lead Screws: Easy Running, Precise and Cost-Effective PositioningDavid FrazãoNo ratings yet

- NL Superbolt Standard-Range-Brochure 70186EN 2013-07Document15 pagesNL Superbolt Standard-Range-Brochure 70186EN 2013-07dassoumennNo ratings yet

- Well HandyDocument6 pagesWell HandymtonellyNo ratings yet

- PowerCoil Sell Sheet 2page DistDocument2 pagesPowerCoil Sell Sheet 2page Distthoma111sNo ratings yet

- Duro Dyne CableDocument16 pagesDuro Dyne CablemaxxhaloNo ratings yet

- Avdel LockboltSystems enDocument16 pagesAvdel LockboltSystems enkamaleshaiahNo ratings yet

- Clamping & Clamping DevicesDocument17 pagesClamping & Clamping DevicesJunaid YNo ratings yet

- Marbett Component Solutions For BeverageDocument48 pagesMarbett Component Solutions For Beverageabsalon_jarvNo ratings yet

- Scaffolding: Smart Scaffolding For Innovative ConstructionDocument5 pagesScaffolding: Smart Scaffolding For Innovative ConstructionEbrahimAbuZaidNo ratings yet

- Slick Swivel Rope SocketDocument1 pageSlick Swivel Rope SocketDeans BoogElzzNo ratings yet

- Super Clamps-General Clamp Industries IncDocument19 pagesSuper Clamps-General Clamp Industries IncTagor SianiparNo ratings yet

- HRT Catalog 11 2014 Low Res PDFDocument11 pagesHRT Catalog 11 2014 Low Res PDFEdgar Barrientos VilcasNo ratings yet

- Automatic ArmsDocument4 pagesAutomatic ArmsAlvaro VillabonaNo ratings yet

- Stressing CatalogueDocument24 pagesStressing CatalogueAdinarayana RaoNo ratings yet

- Tools For Cable InstallationDocument16 pagesTools For Cable InstallationKhaled ElshubriouaNo ratings yet

- Flexco MSP-Standard Duty - PreCleanerDocument2 pagesFlexco MSP-Standard Duty - PreCleanerNaser Hasan FauziNo ratings yet

- AVE Conveyor PartsDocument30 pagesAVE Conveyor PartsSerhat DoğuNo ratings yet

- Caidas - Arnes A032 TRACTEL 3 ANILLOS PDFDocument2 pagesCaidas - Arnes A032 TRACTEL 3 ANILLOS PDFEvy Ezquerra BernardoNo ratings yet

- Elliot-Recon 1500 Vacuum Tube Tester Catalog 2017Document4 pagesElliot-Recon 1500 Vacuum Tube Tester Catalog 2017naidu60606No ratings yet

- Drillstring Hardbanding: Arcraft Plasma IndiaDocument10 pagesDrillstring Hardbanding: Arcraft Plasma Indiapavi32No ratings yet

- Engineered Steel ChainsDocument140 pagesEngineered Steel ChainsCarlos Castañeda HernándezNo ratings yet

- Recycling GuideDocument1 pageRecycling GuidejimleydonNo ratings yet

- FT Carbon ActivadoDocument2 pagesFT Carbon ActivadoAndreita AceroNo ratings yet

- Cwts103 A10 Project-Work-Plan Fat AdrianneedeniseDocument2 pagesCwts103 A10 Project-Work-Plan Fat AdrianneedeniseJulieth MaeNo ratings yet

- 2-Sharp Points and Sharp EdgesDocument2 pages2-Sharp Points and Sharp EdgesAndreeaNo ratings yet

- Amara SamiraDocument35 pagesAmara SamiraHassinaNo ratings yet

- 16 CFR Part 423 (Up To Date As of 4-10-2023)Document10 pages16 CFR Part 423 (Up To Date As of 4-10-2023)Jigna PatelNo ratings yet

- Team MONKS' - NITIE, Mumbai (NIIE8240) : LIME 5 ChallengeDocument38 pagesTeam MONKS' - NITIE, Mumbai (NIIE8240) : LIME 5 Challengersriram84No ratings yet

- About Iban: Sarawak BidayuhDocument4 pagesAbout Iban: Sarawak BidayuhAmanda HazsmahNo ratings yet

- We Accept All Major Credit Cards... : Retail Buy & SellDocument2 pagesWe Accept All Major Credit Cards... : Retail Buy & SellDigital MediaNo ratings yet

- CatalogueDocument104 pagesCataloguefoxkonnNo ratings yet

- (June 2011) CAS 100 Informative Speech #2 - Technology Meets FashionDocument3 pages(June 2011) CAS 100 Informative Speech #2 - Technology Meets FashionLaura Wake-RamosNo ratings yet

- Anu ShankdharDocument3 pagesAnu ShankdharAbhay PareekNo ratings yet

- Meets BC Regulatory Requirements: Sample Food Safety PlanDocument9 pagesMeets BC Regulatory Requirements: Sample Food Safety PlanKhalid MehboobNo ratings yet

- Company Case. Trap-Ease America: The Big Cheese MousetrapDocument2 pagesCompany Case. Trap-Ease America: The Big Cheese MousetrapakmushaNo ratings yet

- Virgin and Coca Cola Case Study A - Abdur-Rehman QureshiDocument4 pagesVirgin and Coca Cola Case Study A - Abdur-Rehman QureshiAbdur-Rehman QureshiNo ratings yet

- 2.1 DMR - OdalarevuDocument67 pages2.1 DMR - OdalarevuSanjay Kumar GhadaiNo ratings yet

- Newsletter: Rockwell Family Tree Donation Program Spirit Wear Sale Begins September 24th!!Document4 pagesNewsletter: Rockwell Family Tree Donation Program Spirit Wear Sale Begins September 24th!!Erin O'Meara GaitaNo ratings yet

- Science and Technology For Physically Abled PersonDocument10 pagesScience and Technology For Physically Abled PersonDHILSHIYA DHAS100% (3)