Professional Documents

Culture Documents

Abs 2

Uploaded by

ภูเก็ต เป็นเกาะOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abs 2

Uploaded by

ภูเก็ต เป็นเกาะCopyright:

Available Formats

Tech Talk

ANTI-LOCK BRAKING SYSTEMS - PART 2

Review

In part 1 to this article (Dec/Jan issue),we discussed the principles of ABS and that, like all electronic control systems, it consists of sensors, an ECU and an actuator. The wheel speed sensors allow the ECU to determine accurate wheel speed values the ECU uses these values to determine the locking or slipping condition of the wheels through the use of a slip ratio calculation. If excessive slip is detected the ECU uses an ABS actuator (modulator) to control the slip ratio through the regulation of applied braking pressure. Let us now study these systems in more detail.

ABS - the systems

Basic operational overview

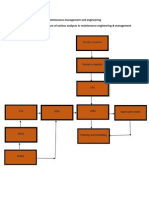

The ABS ECU monitors individual wheel speeds and calculates overall vehicle speed by taking an average of these values. The picture shows a typical layout of an ABS equipped vehicle.

Conventional hydraulic brake circuits appear in various different layouts (often determined by the weight distribution characteristics of the vehicle) and this can have a bearing on ABS hydraulic variances.

Front to rear split circuit

Hydraulic control variations

Diagonally split circuit

The stop light switch provides a signal that the ECU can use to determine that the brakes are being applied. The ECU, through the monitoring of the wheel speed sensor signals, calculates any sudden reduction in wheel speed. The ECU will now control the hydraulic brake actuator to provide optimum brake fluid pressure to each brake to achieve maximum deceleration conditions. The hydraulic brake actuator operates on control signals from the ECU to reduce hold , or increase brake fluid pressure as necessary in order to achieve and maintain an ideal slip ratio of 10% to 30% and avoid wheel lock up. These changes of braking state can be effected at a frequency of up to 60 times per second.

Types of ABS control

It is important to understand that the ABS is an addition to the existing conventional brake system. It does not replace any existing components.

This system is often used on vehicles that have an uneven weight distribution, such as front engine, front wheel drive. This ensures that in the event of a single system failure there is always one loaded wheel that can be braked effectively. As the two rear brakes are not connected directly together (or the two fronts), the ABS actuator has to provide separate hydraulic connections for all four braked wheels. This is known as four solenoid control .

In the case of front to rear split circuits (even weight distribution vehicle layout), the actuator could have just one outlet for the rear brakes. It is important to note that the steered wheels are always controlled independently because of their importance to the maintenance of control (steerability). If just a single hydraulic connection were used for the rear brakes then this would be known as three solenoid control Note: on a . modern motor vehicle, four solenoid control is commonly used regardless of hydraulic layout.

Electrical control variations

In addition, the electrical control of the ABS varies from vehicle to vehicle: individual control of the front wheels whilst controlling the rears together. This is known as three channel control . individual control for all four wheels. This is known as four channel control.

3 4 M OTO R I N D U ST RY M AG A Z I N E F E B R UA RY 20 0 6

W W W. M OTO R .O RG .U K

Component overview

DEAR DAVE

Q A Mitsubishi Pajero 1995 2.8 turbo diesel came in with a power loss fault. There is no missing and although the fault does seem to point to the turbo, boost pressure is normal and the engine revs to the redline OK. Theres some black smoke, but I have found this is not unusual for a Pajero. A This could be an exhaust gas recirculation valve sticking open. Clean it and refit with the vacuum pipe off to see if the power loss is still evident. If theres no improvement, the next possibility is a restricted fuel supply to the pump. Change the fuel filter and check that there is no air by substituting some clear plastic pipe in line between the filter and pump. Sometimes, the ability of the pump to suck fuel through the filter from the tank decreases with age, in which case it is cheaper to put in a low pressure electric fuel pump into the fuel line than to change the main pump. Also, there is a wire mesh screen on the inlet union to the injector pump that can get clogged. Dont forget the breathing: the air inlet can get restricted, inlet hoses can collapse and silencers can collapse and restrict the exhaust. I dont think its anything to do with valve timing as I am fairly certain that the valves would have hit the pistons. Q A Toyota Corolla is displaying EML, with fault codes P1346 VVT sensor and P1349 VVT system malfunction. The fault remains, despite fitting a new VVT sensor and checking the wiring for continuity from the VVT sensor back to the ECU. A VVT (variable valve timing) is designed to provide optimum valve timing for all engine conditions by altering the valve overlap using hydraulic oil pressure to activate a link between the inlet and exhaust cams. The link is connected to a sensor that tells the ECU how much overlap is present. If the oil pressure is wrong, or sludge and varnish build up is excessive, then this mechanism will not work correctly; the ECU

ABS ECU

The ECU controls the entire system. It monitors wheel speed and determines wheel lock up. It uses control signals to influence the hydraulic actuator to reduce, hold or increase the brake fluid pressure. It carries out a self-check of- the system at start up and informs the driver of any abnormalities via the dashboard ABS warning light. It stores any diagnostic information for later retrieval by a technician.

Diagnostic check connector

Various types of check connector have been used over the years but they all have basically the same function, which is to allow access to ABS diagnostic codes and other diagnostic data.

Summary

Through this article we have taken the principles studied in Part 1 to a system level. Part 3 will study the sub-systems and components in depth, looking at how the wheel speed sensors actually generate signals and how the ABS actuator controls hydraulic braking pressure. We will then look in detail at diagnostic processes employed in the finding of faults on such systems. If you would like to study anti-lock braking systems in more detail we would be delighted to provide you with a place on one of our technical courses. Please see details below on how to contact us. ProAuto Limited are an automotive technical training company based in Shrewsbury, Shropshire. Our core business is the design and delivery of technical training to the automotive industry, which includes vehicle manufacturers, component manufacturers, diagnostic equipment manufacturers and independent garages. We run courses from numerous select venues nationally, so a course is never too far away. For further details you can visit our website at www.proautotraining.com, email us at info@proautotraining.com, or telephone 01743 709679.

Wheel speed sensors

These enable the ECU to detect individual wheel speed and also calculate vehicle speed.

Sensor rotor

Attached to the hub or drive shaft, it has teeth that when passed in front of the ABS wheel speed sensors cause a signal to be generated.

ABS actuator/modulator

This controls the hydraulic brake fluid pressure to the individual brakes dependent upon control signals generated by the ABS ECU.

ABS warning light

This alerts the driver of system malfunctions. It can also be used as a diagnostic code indicator on some makes of vehicle.

Control relays

Usually two relays are required to facilitate electrical control of the ABS. One relay is the actuator pump relay and the other is for the actuator solenoids. They can be located on the actuator itself or an adjacent fuse/ relay block.

W W W. M OTO R .O RG .U K

F E B R UA RY 20 0 6 M OTO R I N D U ST RY M AG A Z I N E 35

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Business Statistics: Fourth Canadian EditionDocument41 pagesBusiness Statistics: Fourth Canadian EditionTaron AhsanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 6HP26 ZF Transmissions With MechatronicsDocument66 pages6HP26 ZF Transmissions With MechatronicsSalman Eid100% (1)

- SSP 298 Touareg ElectricsDocument29 pagesSSP 298 Touareg Electricsภูเก็ต เป็นเกาะ100% (1)

- SSP 296 1.4 & 1.6 FSi EngineDocument16 pagesSSP 296 1.4 & 1.6 FSi Engineaz3ki3lNo ratings yet

- SSP 296 1.4 & 1.6 FSi EngineDocument24 pagesSSP 296 1.4 & 1.6 FSi Engineภูเก็ต เป็นเกาะ100% (3)

- Atb1128 DodgeDocument6 pagesAtb1128 Dodgeภูเก็ต เป็นเกาะNo ratings yet

- 4T65R Erratic Shift, 1 2 ShuddleDocument1 page4T65R Erratic Shift, 1 2 ShuddleAlitar HersongollsNo ratings yet

- SSP 315 Eobd DieselDocument60 pagesSSP 315 Eobd Dieselภูเก็ต เป็นเกาะNo ratings yet

- Article 0001 Ravigneaux Planetary TransmissionDocument9 pagesArticle 0001 Ravigneaux Planetary Transmissionthisisjinesh100% (1)

- 4T65R Erratic Shift, 1 2 ShuddleDocument1 page4T65R Erratic Shift, 1 2 ShuddleAlitar HersongollsNo ratings yet

- SSP 269 d1 PDFDocument60 pagesSSP 269 d1 PDFAdrian BuzasNo ratings yet

- SSP 300 6 SP Auto Box 09DDocument12 pagesSSP 300 6 SP Auto Box 09Dภูเก็ต เป็นเกาะNo ratings yet

- SSP 298 Touareg ElectricsDocument31 pagesSSP 298 Touareg Electricsภูเก็ต เป็นเกาะ100% (3)

- SSP 297 TouaregDocument56 pagesSSP 297 Touaregภูเก็ต เป็นเกาะ100% (1)

- SSP 300 6 SP Auto Box 09DDocument22 pagesSSP 300 6 SP Auto Box 09Dภูเก็ต เป็นเกาะ100% (1)

- SSP 299 6 SP Manual Gearbox 08DDocument44 pagesSSP 299 6 SP Manual Gearbox 08DvasilealexandruNo ratings yet

- SSP 280 Phaeton Auxillary HeaterDocument25 pagesSSP 280 Phaeton Auxillary HeaterButnaru EmanuelNo ratings yet

- SSP 286 New Data Bus SystemsDocument30 pagesSSP 286 New Data Bus Systemsภูเก็ต เป็นเกาะNo ratings yet

- SSP 286 New Data Bus SystemsDocument26 pagesSSP 286 New Data Bus Systemsภูเก็ต เป็นเกาะ100% (1)

- SSP 276 Phaeton Proximity ControlDocument40 pagesSSP 276 Phaeton Proximity Controlภูเก็ต เป็นเกาะ100% (1)

- SSP 294 VAS 5051 On Line Link, Immobilizer 4Document24 pagesSSP 294 VAS 5051 On Line Link, Immobilizer 4ภูเก็ต เป็นเกาะNo ratings yet

- SSP 281 New Beetle CabrioletDocument40 pagesSSP 281 New Beetle Cabrioletภูเก็ต เป็นเกาะNo ratings yet

- SSP 279 2.0 FSiDocument44 pagesSSP 279 2.0 FSiภูเก็ต เป็นเกาะ0% (1)

- SSP 280 Phaeton Auxillary HeaterDocument27 pagesSSP 280 Phaeton Auxillary Heaterภูเก็ต เป็นเกาะNo ratings yet

- SSP 277 Phaeton ChassisDocument60 pagesSSP 277 Phaeton Chassisภูเก็ต เป็นเกาะNo ratings yet

- SSP 275 Phaeton Air SuspensionDocument21 pagesSSP 275 Phaeton Air Suspensionภูเก็ต เป็นเกาะ100% (1)

- SSP 273 Phaeton ConvenienceDocument29 pagesSSP 273 Phaeton Convenienceภูเก็ต เป็นเกาะNo ratings yet

- SSP 275 Phaeton Air SuspensionDocument17 pagesSSP 275 Phaeton Air Suspensionภูเก็ต เป็นเกาะNo ratings yet

- SSP 275 Phaeton Air SuspensionDocument21 pagesSSP 275 Phaeton Air Suspensionภูเก็ต เป็นเกาะNo ratings yet

- SSP 274 Phaeton InfotainmentDocument40 pagesSSP 274 Phaeton Infotainmentภูเก็ต เป็นเกาะNo ratings yet

- SSP 273 Phaeton ConvenienceDocument28 pagesSSP 273 Phaeton Convenienceภูเก็ต เป็นเกาะNo ratings yet

- Assignment 5 WarehousingDocument4 pagesAssignment 5 WarehousingabbasNo ratings yet

- Distillation Column DesignDocument42 pagesDistillation Column DesignAakanksha Raul100% (1)

- Answer:: Exercise-IDocument15 pagesAnswer:: Exercise-IAishika NagNo ratings yet

- RV900S - IB - Series 3Document28 pagesRV900S - IB - Series 3GA LewisNo ratings yet

- Catálogo StaubliDocument8 pagesCatálogo StaubliJackson BravosNo ratings yet

- History Homework Help Ks3Document8 pagesHistory Homework Help Ks3afetnjvog100% (1)

- Electronics 12 00811Document11 pagesElectronics 12 00811Amber MishraNo ratings yet

- ECON 401/601, Microeconomic Theory 3/micro 1: Jean Guillaume Forand Fall 2019, WaterlooDocument3 pagesECON 401/601, Microeconomic Theory 3/micro 1: Jean Guillaume Forand Fall 2019, WaterlooTarun SharmaNo ratings yet

- Jungles & SavannasDocument80 pagesJungles & SavannasJessica100% (1)

- Overview of MEMDocument5 pagesOverview of MEMTudor Costin100% (1)

- 2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessDocument11 pages2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessOne PlusNo ratings yet

- Formula Renault20 Mod00Document68 pagesFormula Renault20 Mod00Scuderia MalatestaNo ratings yet

- Hooke's LawDocument1 pageHooke's LawAnan BarghouthyNo ratings yet

- SL 4001Document2 pagesSL 4001ardiNo ratings yet

- Relay G30 ManualDocument42 pagesRelay G30 ManualLeon KhiuNo ratings yet

- Review Rachna WasteDocument9 pagesReview Rachna WasteSanjeet DuhanNo ratings yet

- Gastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterDocument9 pagesGastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterPier Pasquale TrausiNo ratings yet

- Eurocode Conference 2023 Seters Van Eurocode 7Document33 pagesEurocode Conference 2023 Seters Van Eurocode 7Rodolfo BlanchiettiNo ratings yet

- Static Power Conversion I: EEE-463 Lecture NotesDocument48 pagesStatic Power Conversion I: EEE-463 Lecture NotesErgin ÖzdikicioğluNo ratings yet

- Using Impact IX49 and 61 With Nektar DAW Integration 1.1Document21 pagesUsing Impact IX49 and 61 With Nektar DAW Integration 1.1Eko SeynNo ratings yet

- Climatol GuideDocument40 pagesClimatol GuideFressiaNo ratings yet

- A. Premise Vs Conclusion NotesDocument8 pagesA. Premise Vs Conclusion NotesEmma PreciousNo ratings yet

- An Overview and Framework For PD Backtesting and BenchmarkingDocument16 pagesAn Overview and Framework For PD Backtesting and BenchmarkingCISSE SerigneNo ratings yet

- BS 07533-3-1997Document21 pagesBS 07533-3-1997Ali RayyaNo ratings yet

- EE360 - Magnetic CircuitsDocument48 pagesEE360 - Magnetic Circuitsبدون اسمNo ratings yet

- Tools of Persuasion StudentsDocument4 pagesTools of Persuasion StudentsBelén Revilla GonzálesNo ratings yet

- Dynamic Shear Modulus SoilDocument14 pagesDynamic Shear Modulus SoilMohamed A. El-BadawiNo ratings yet

- Research Paper On N Queen ProblemDocument7 pagesResearch Paper On N Queen Problemxvrdskrif100% (1)

- Catalog NeosetDocument173 pagesCatalog NeosetCarmen Draghia100% (1)