Professional Documents

Culture Documents

Design Cleat and Vertical Plate

Uploaded by

Sheik Mohamed LiakathCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Cleat and Vertical Plate

Uploaded by

Sheik Mohamed LiakathCopyright:

Available Formats

Project LIBERTY HOUSE Date 4/3/2008 Details Design cleat angle and Flat Plate to support Stone Cladding

Part APPENDIX TO THE MAIN CALCULATION By Sheik Mohamed Checked Job no. Sheet no. of Rev

ASCO

1 Tel: Fax:

Reference

Calculation

Output

LOAD ASSUMPTIONS

Unit weight of the stone Wind Load Intensity

Wdead

= =

90 2.3 230

Kg/m2 KPa Kg/m2

Wwind

MATERIAL PROPERTIES

Cleat angle, plate and C section are made from Aluminium alloy of 6063 T6 grade Flexural strength Elastic modulus fy = E = 160 70000 N/mm2 kg/cm2

All bolts are of Stainless steel grade SS316 Flexural strength fy = 220 N/mm2

DESIGN CHECK

1. DESIGN CLEAT ANGLE AND ITS FIXTURES

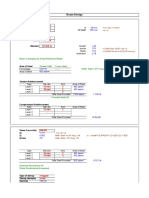

1. CLEAT ANGLE DESIGN (MEMBER - A) Design Philosophy: Cleat shall be designed for the forces maximum of

(1) In-plane bending due to eccentric vertical reaction (2) out of plane bending due to wind pressure acting on the stone face In addition to the above cleat should also be checked for bearing and shear capacities

Size of the cleat (Proposed)

EA 75 x 75 x 5 mm and 275 mm long

Check - 1: Check cleat for In-plane bending

Size of the stone in face A & C Size of the stone in face B

= =

325 260

x x

600 600

mm mm

Project LIBERTY HOUSE Date 4/3/2008 Details Design cleat angle and Flat Plate to support Stone Cladding Part APPENDIX TO THE MAIN CALCULATION By Sheik Mohamed Checked Job no. Sheet no. of Rev

ASCO

1 Tel: Fax:

Reference

Calculation Number of stone pieces along the length of the each segment Weight of the stone Use safety factor of ULS load ULS load carried by each cleat W = = = = 344 1.4 481.6 kg 240.8 kg kg = 7

Output

Moment on the cleat due to eccentric vertical reaction M Where Cleat cross section t =5mm b M Zreq = = = = Wxb 300 72 mm kg.m

4515 mm3

Zx

Zx h =275 mm

Zxx provided

= = =

t h2 / 6 5 x (275)2 / 6 63021 mm3 > 4515 mm3

Check - 2: Check cleat angle for out of plane bending (bending due to lateral loads)

Considering 4m long plate along face-A as two span continuous plate. Cleat at both the ends and a channel section in the middle (as shown in the sketch) provides support (lateral) to the plate

Wind load intensity

Wwind

230

kg/m2

Width of the stone cladding face which is exposed wind

0.325 m

Wind load intensity per m run

74.75 kg/m

(For safety factor of 1.2, ULS wind load intensity

Wwind

89.7

kg/m

Project LIBERTY HOUSE Date 4/3/2008 Details Design cleat angle and Flat Plate to support Stone Cladding Part APPENDIX TO THE MAIN CALCULATION By Sheik Mohamed Checked Job no. Sheet no. of Rev

ASCO

1 Tel: Fax:

Reference

Calculation

Output

Case (1): check cleat for bending due to eccentric axial load

Case (2): check cleat for bending due to wind load

Cleat 2m

Plate

Wwind 90 kg/m

4m 2m

W 241kg b =300

LINE SKETCH SHOWING WIND INTENSITIES ON THE FACE OF STONE

SECTIONAL ELEVATION

End reactions

R R

= = = =

0.5 x 90 x 2 90 kg

Maximum Moment in the plate

coeff x load x span 0.125 x 90 x 2 22.43 kg.m

Cleat b = 325 mm Stone R = 90 kG

PLAN

Project LIBERTY HOUSE Date 4/3/2008 Details Design cleat angle and Flat Plate to support Stone Cladding Part APPENDIX TO THE MAIN CALCULATION By Sheik Mohamed Checked Job no. Sheet no. of Rev

ASCO

1 Tel: Fax:

Reference

Calculation

Output

The above reaction acts at the centre of the plate, i.e., at b

0.325 m

(b is distance between point at which stone is clamped to the plate and to the cleat critical section) and this induces moment on the cleat Moment due to the above eccentric reaction M = M = Length of the cleat Moment per mm width of the cleat = M = Rxb 29.15 kg.m 275 mm

1060 N.mm/mm

Cleat cross section resisting the above moment y

b =275mm

Tp y The required thickness of the plate (out of plane bending) Tp = = sqrt ( 6 M/ fyp) 6.305 mm

Since the proposed thickness of 5mm is found to be unsafe, provide 7mm thick cleat angle Provide WA 75 x 75 x 7mm cleat 275mm Long

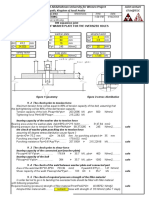

Shear Capacity of the Cleat Ao = 0.9 x net Cross sectional area

Vallow =

0.6 Ao pyp

472.5 mm2 = 45.36 kN > 2.41 kN

Vallow BS 5950-1 Cl 6.3.3.3 3. Bearing capacity of the flat plate Pbs Where kbs d tp pbs e = = = = = =

= kbs d tp pbs 1

< 0.5 kbs e tp pbs

for long slotted holes = nominal diameter of the bolt = cleat thickness = bearing strength of the plate = 0.67 (Us + Ys) = 0.67 x(180+160) edge distance =

mm 7 mm 227.8 N/mm2 25 mm

Therefore,

Pbs Pbs

= =

13 13

kN kN

< >

19.93 kN 2.41 kN

Project LIBERTY HOUSE Date 4/3/2008 Details Design cleat angle and Flat Plate to support Stone Cladding Part APPENDIX TO THE MAIN CALCULATION By Sheik Mohamed Checked Job no. Sheet no. of Rev

ASCO

1 Tel: Fax:

Reference

Calculation

Output

Hence, 7mm thick cleat is safe

2. DESIGN FLAT PLATE (MEMBER - B)

Maximum BM in the plate due to lateral loads

M =

22.43 kg.m

The required sectional modulus

Zreq Zreq

= =

M / fyp 1402 mm3

Dimensions of the plate Width (b)

340

mm

Thickness (t) Sectional modulus of the plate

mm = = b x t2 /6 1417 mm3 > 1402

Z provided Z provided Hence, safe

Block shear capacity of the plate BS 5950-1 Cl. 6.2.4 Beam web Thickness t Lv d Dt k = = = = = 7 240 0 14 0.5 mm mm mm mm

Pr

= 0.6 py t(Lv + Ke(Lt - kDt))

Cl.3.4.3 Py =

For 6063 - T6 grade aluminium alloy 160 N/mm2 Us = . 180 Lt = N/mm2 25 mm

Ke = (Us/1.2)/py Ke = 0.938

Pr = BOLT DESIGN 1. Bolt group A Shear Force Fy Fy = = 241 2.41 90 0.9 kg kN kg kN

172.6 kN

>

2.41

kN

Shear due to lateral load= Fx =

Project LIBERTY HOUSE Date 4/3/2008 Details Design cleat angle and Flat Plate to support Stone Cladding Part APPENDIX TO THE MAIN CALCULATION By Sheik Mohamed Checked Job no. Sheet no. of Rev

ASCO

1 Tel: Fax:

Reference

Calculation Fr Fr = = sqrt( Fx^2 + Fy 62) 3 kN

Output

Number of bolts in a row Resultant Shear per bolt

= Fr =

3 0.858 kN

Tension in the bolt group due to eccentric vertical shear (Fy) T max = F.e . Ymax / m y 2

Where - e - distance between the centric of point load and bolt centroid 75 mm e Ymax Y1 Y2 m = = = = = 300 225 mm mm = = 0.3 m 25 112 113 25 1 BOLT GROUP IN CLEAT ANGLE Tmax = 2.57 kN h = 275 mm

0.225 m

0.113 mm 0.225 mm

number of vertical rows =

Design forces that each bolt should resist Fr T = = 0.858 kN 2.57 kN

Suitable type and diameter of expansion bolt which can resist the above forces shall be used

2. BOLT GROUP B Shear Py Fx = = 2.41 0.9 kN kN Fx X e 0.306 kN.m M/b 6.8 3 1 2 kN kN kN

Moment in the bolt group due to eccentric Fx M = Where - e = 340 mm M = T T = =

Tension in the bolt group Where - b = 0.045 mm

Number of bolts in the row Forces per bolt Shear

m = Fy = T =

Project LIBERTY HOUSE Date 4/3/2008 Details Design cleat angle and Flat Plate to support Stone Cladding Part APPENDIX TO THE MAIN CALCULATION By Sheik Mohamed Checked Job no. Sheet no. of Rev

ASCO

1 Tel: Fax:

Reference

Calculation

Output

BOLT CAPACITY CALCULATION Shear capacity of the bolt Ao = cross sectional area of M8 bolt = 0.6 Ao Pyb = 0.9 x3.14 x (8) ^2/4 = Yield strength of Grade SS 316 bolt Shear capacity of the bolt Tension capacity of the bolt = = 45.22 mm2 220 5.97 N/mm2 KN > 1 kN

= 0.8 A Pyb = 7.96 kN > 2 kN

Check for combined Shear and Tension

= V/Vallow + T / Tallow < 1 = 0.4194 < 1 Hence O.k.

3. BOLT GROUP - C Bolt in this group should be designed for (1) vertical shear due to weight of the stone (2) Lateral Shear due to wind load ( wind pressure on the face of C-section)

Reaction / shear due to weight of the stone Fy = = Fy =

(0.325 x 0.600 + 0.260 x 0.600) x 90 31.59 kg 0.32 kN

Shear on the bolts due to lateral loads

Fx = = Fx =

0.260 x 0.600 x230 31.74 kg 0.32 kN

Resultant shear

Fr = Fr =

sqrt( Fx^2 + Fy 62) 0.45 kN

Use M8, SS316 grade bolt Shear capacity of the M8, SS316 grade bolt Pv = 5.97 kN > 0.45 kN Hence, Safe

Project LIBERTY HOUSE Date 4/3/2008 Details Design cleat angle and Flat Plate to support Stone Cladding Part APPENDIX TO THE MAIN CALCULATION By Sheik Mohamed Checked Job no. Sheet no. of Rev

ASCO

1 Tel: Fax:

Reference

Calculation

Output

= f f d r h w

W x [ 1 + 0.075 (d/2r)0.7 ] x [ (6 h / d2) + (0.64 / sqrt(h x d)] = 1450 psi (ultimate) = 1450 psi = 0.394 inch = 1 inch = 0.236 inch = 126.193 pounds per inch

Factor of safety for connection = 12 W ( Maximum Load that Kerf can take safely) = 10.5161 pounds per inch

Reaction on the clamp due to lateral load = = Length of the kerf = = Applied Load per inch along kerf length =

42 92.594 25 9.843 9.40709

+ (0.64 / sqrt(h x d)]

kg pounds cm inch

You might also like

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Base Plate-PinnedDocument34 pagesBase Plate-PinnedSohaibNo ratings yet

- Bracing Design for Asian Paints Phase III Expansion ProjectDocument2 pagesBracing Design for Asian Paints Phase III Expansion ProjectGopi GopinathanNo ratings yet

- PDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDocument29 pagesPDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDEVANG VIJAY SHINDENo ratings yet

- CHS Base Plate DesignDocument1 pageCHS Base Plate DesignOlusegun S. AjibolaNo ratings yet

- Steel Connections v1.3Document83 pagesSteel Connections v1.3Mateus GehlenNo ratings yet

- Splice HEB 1000 Full StrengthDocument14 pagesSplice HEB 1000 Full StrengthRaveendra Babu CherukuriNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationRajneesh Pratap SinghNo ratings yet

- Anchor Bolt DesignDocument2 pagesAnchor Bolt Designmail2meanwar7865No ratings yet

- Weld ConnectionDocument70 pagesWeld ConnectionSudhakar KrishnamurthyNo ratings yet

- SteelDocument80 pagesSteelAnonymous HJ7hmihhNo ratings yet

- HILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)Document3 pagesHILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)inti lestariNo ratings yet

- Anchor Bolt Design Per IS LSMDocument6 pagesAnchor Bolt Design Per IS LSMdebjyoti_das_6No ratings yet

- Design Calculations For Primary Beam Connections As Welded Connections R2Document6 pagesDesign Calculations For Primary Beam Connections As Welded Connections R2Rajesh PoreNo ratings yet

- Column Base PlateDocument3 pagesColumn Base PlatePurnima ArkalgudNo ratings yet

- Design of Base Plate and Anchor BoltDocument7 pagesDesign of Base Plate and Anchor BoltsavsagarNo ratings yet

- Annexure 3 Anchor Bolt and BaseplateDocument8 pagesAnnexure 3 Anchor Bolt and BaseplateDarshan PanchalNo ratings yet

- Composite Slab DesignDocument6 pagesComposite Slab DesignFranklyn GenoveNo ratings yet

- Buckling H BeamDocument2 pagesBuckling H BeamНемања КараклајићNo ratings yet

- Vessel Supported On 2 PedestalsDocument7 pagesVessel Supported On 2 PedestalsNitesh SinghNo ratings yet

- Anchor Bolt-Pinned ConnectionDocument7 pagesAnchor Bolt-Pinned ConnectionThắngg TrịnhhNo ratings yet

- Column Wall DesignDocument42 pagesColumn Wall DesignCivilax.comNo ratings yet

- Platform Cleat CalculationDocument1 pagePlatform Cleat Calculationmiteshpatel191No ratings yet

- Shear Key DesignDocument2 pagesShear Key DesignmaheshbandhamNo ratings yet

- Welded Connection With I BeamDocument8 pagesWelded Connection With I BeamНемања КараклајићNo ratings yet

- Lifting and Tailing StackDocument42 pagesLifting and Tailing StackSudar MyshaNo ratings yet

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- PEB CalculationsDocument3 pagesPEB CalculationsBhaumik MerchantNo ratings yet

- Rafter-Column Bracing DesignDocument3 pagesRafter-Column Bracing Design4geniecivilNo ratings yet

- Design of Shear KeyDocument13 pagesDesign of Shear KeyRonnie SmithNo ratings yet

- A23.3-04 CorbelsDocument3 pagesA23.3-04 CorbelsDivyesh MistryNo ratings yet

- Pipe Rack Foundation DesignDocument29 pagesPipe Rack Foundation DesignYatendra TyagiNo ratings yet

- UB 610 X 179 - BP - PinnedDocument3 pagesUB 610 X 179 - BP - PinnedArivoli JayaramanNo ratings yet

- Fixed Base Plate-ACI CodeDocument5 pagesFixed Base Plate-ACI CodeMuthukumaran Sivalingam100% (1)

- Moment Connection Design-BS CODEDocument5 pagesMoment Connection Design-BS CODEMuthukumaran SivalingamNo ratings yet

- Design Data: Design For Base Plate (Fixed)Document4 pagesDesign Data: Design For Base Plate (Fixed)Wibawa WorksNo ratings yet

- Design SheetDocument20 pagesDesign SheetPrayush RajbhandariNo ratings yet

- Base Plate Design for Bagging Tower SupportDocument9 pagesBase Plate Design for Bagging Tower SupportbuildconNo ratings yet

- Design of Splicing of RafterDocument3 pagesDesign of Splicing of Rafterkeerthivasan_mrvNo ratings yet

- Anchor Bolt CHKDocument17 pagesAnchor Bolt CHKPriya GNo ratings yet

- Combined FootingDocument15 pagesCombined FootingAbhishek GuptaNo ratings yet

- RC Beam - CantileverDocument2 pagesRC Beam - CantilevermayphyoNo ratings yet

- Washer PlateDocument2 pagesWasher PlateНемања Караклајић100% (2)

- End Plate DesignDocument4 pagesEnd Plate DesignAgnon Fung100% (4)

- 8224 Grating No HeaderDocument69 pages8224 Grating No HeadervishalnalwarNo ratings yet

- Punching check of column in column capitalDocument6 pagesPunching check of column in column capitalVikasNo ratings yet

- Vertical Movement Connection-TopDocument2 pagesVertical Movement Connection-TopНемања Караклајић100% (1)

- Design of Beam to Column ConnectionDocument13 pagesDesign of Beam to Column ConnectionGautam SharmaNo ratings yet

- Moment Connection Portal FrameDocument18 pagesMoment Connection Portal Frametmssorin100% (1)

- Shear Connection - Beam - Steel Column - Fin PlateDocument30 pagesShear Connection - Beam - Steel Column - Fin Platekalpanaadhi100% (3)

- Base Plate Dan Anchor Bolt Calculation: Connection DesignDocument21 pagesBase Plate Dan Anchor Bolt Calculation: Connection DesignSurya FahmiNo ratings yet

- Purlin DesignDocument6 pagesPurlin DesignAnonymous mcHqIfbnV1No ratings yet

- 5.15 Swing Barrier v.1.0Document190 pages5.15 Swing Barrier v.1.0rfvz6sNo ratings yet

- Moment ConnectionDocument39 pagesMoment ConnectionRitwick MishraNo ratings yet

- Water Tank Design (With Cover Slab) RDocument13 pagesWater Tank Design (With Cover Slab) RDenishmakvanaNo ratings yet

- Ba Culvertf TestDocument16 pagesBa Culvertf TestsanjuktaacharyyaNo ratings yet

- Base Plate DesignDocument32 pagesBase Plate DesignGautam Sharma50% (2)

- Pile Cap Design - ColumnsDocument6 pagesPile Cap Design - Columnsntah8450% (2)

- Pile Cap Design - ColumnsDocument6 pagesPile Cap Design - Columnssssmou100% (1)

- Project Technical Review Meeting Notes - TRM-J3306-01Document2 pagesProject Technical Review Meeting Notes - TRM-J3306-01Sheik Mohamed LiakathNo ratings yet

- Cantilever Development LengthDocument12 pagesCantilever Development LengthSheik Mohamed LiakathNo ratings yet

- Inspection of Post-Tensioned Concrete - Who and Why - tcm45-348136 PDFDocument4 pagesInspection of Post-Tensioned Concrete - Who and Why - tcm45-348136 PDFSheik Mohamed LiakathNo ratings yet

- Hollow Block Slab Design GuideDocument9 pagesHollow Block Slab Design GuideardabiliNo ratings yet

- PERI Formwork Load Calculator ResultsDocument3 pagesPERI Formwork Load Calculator ResultsfadistaNo ratings yet

- Deflection of Reinforced ConcreteDocument9 pagesDeflection of Reinforced ConcretecklconNo ratings yet

- NS and Contractors Risk Under FIDIC 1987Document8 pagesNS and Contractors Risk Under FIDIC 1987Sheik Mohamed LiakathNo ratings yet

- EIFS System ComponentsDocument2 pagesEIFS System ComponentsSheik Mohamed LiakathNo ratings yet

- Shear Stress in Beams NotesDocument4 pagesShear Stress in Beams NotesMubark Al-haidariNo ratings yet

- PTA Guidance Note GN02Document2 pagesPTA Guidance Note GN02Sheik Mohamed LiakathNo ratings yet

- Guidelines and Rules For Detailing Ofreinforcement in Concrete StructuresDocument403 pagesGuidelines and Rules For Detailing Ofreinforcement in Concrete Structuresamino222No ratings yet

- The Designers' Guide To The Use of Expamet Hy-RibDocument34 pagesThe Designers' Guide To The Use of Expamet Hy-Ribprasad perkaNo ratings yet

- Deflection Calculation of Concrete Floors TN292 PDFDocument38 pagesDeflection Calculation of Concrete Floors TN292 PDFSheik Mohamed LiakathNo ratings yet

- Span To Depth Various Codes PDFDocument5 pagesSpan To Depth Various Codes PDFAhmed Ben HmidaNo ratings yet

- PT Slab Design Review Check ListDocument2 pagesPT Slab Design Review Check ListSheik Mohamed LiakathNo ratings yet

- Long-Term Deflection Three Times Dead P... ACI (Concrete) Code Issues - Eng-TipsDocument4 pagesLong-Term Deflection Three Times Dead P... ACI (Concrete) Code Issues - Eng-TipsSheik Mohamed LiakathNo ratings yet

- P-Delta Analysis ParametersDocument2 pagesP-Delta Analysis ParametersjachoijachoiNo ratings yet

- Span To Depth Various Codes PDFDocument5 pagesSpan To Depth Various Codes PDFAhmed Ben HmidaNo ratings yet

- Coupled Shear Wall DesignDocument18 pagesCoupled Shear Wall DesignSheik Mohamed LiakathNo ratings yet

- Building Drifts in EtabsDocument5 pagesBuilding Drifts in EtabsSheik Mohamed LiakathNo ratings yet

- Strip WizardDocument15 pagesStrip WizardSheik Mohamed LiakathNo ratings yet

- HB Ground Improvement Solutions MatrixDocument3 pagesHB Ground Improvement Solutions MatrixSheik Mohamed LiakathNo ratings yet

- Cost Comparison: PT vs RCC Flat Slab SystemsDocument5 pagesCost Comparison: PT vs RCC Flat Slab SystemsSheik Mohamed Liakath50% (2)

- 1st Yelgip Workshop ReportDocument17 pages1st Yelgip Workshop ReportDestiar Ultimaswari Adi KartikaNo ratings yet

- What Is Glass Reinforced ConcreteDocument2 pagesWhat Is Glass Reinforced ConcreteSheik Mohamed Liakath100% (1)

- Rebar Size and Weight ChartDocument1 pageRebar Size and Weight ChartSheik Mohamed LiakathNo ratings yet

- Construction LoadingDocument0 pagesConstruction Loadingrami1964No ratings yet

- Advantages of GGBS in ConcreteDocument2 pagesAdvantages of GGBS in ConcreteSheik Mohamed Liakath60% (5)

- Concrete Mix Design Specifications for Structural and Non-Structural ElementsDocument3 pagesConcrete Mix Design Specifications for Structural and Non-Structural ElementsSheik Mohamed LiakathNo ratings yet

- ADAPT T904 Stress Losses PDFDocument16 pagesADAPT T904 Stress Losses PDFignacio_vazquez_18No ratings yet

- Bend Table Samples For SheetmetalDocument24 pagesBend Table Samples For SheetmetalsuperalitosNo ratings yet

- Safeguarding Against Warpage and Distortion During Hot-Dip Galvanizing of Steel AssembliesDocument3 pagesSafeguarding Against Warpage and Distortion During Hot-Dip Galvanizing of Steel AssembliesInti Gacitúa CampoloNo ratings yet

- Design and Structural Analysis of 3 Axis CNC Milling Machine TableDocument6 pagesDesign and Structural Analysis of 3 Axis CNC Milling Machine Tablewai phyoeNo ratings yet

- Wrench Manufacturing Process Optimized for Strength and PrecisionDocument5 pagesWrench Manufacturing Process Optimized for Strength and PrecisionM. RazaNo ratings yet

- Peb Kbsil Rev 1Document57 pagesPeb Kbsil Rev 1prabhakarsunku100% (2)

- Caracteristicas PS360CDocument12 pagesCaracteristicas PS360COscarNo ratings yet

- Flakiness ElongationDocument4 pagesFlakiness ElongationrisrizNo ratings yet

- SSM HandbookDocument20 pagesSSM HandbookOng Hendra100% (2)

- VISI Progress PDFDocument8 pagesVISI Progress PDFjeeva72100% (1)

- Manufacturing Hygiene PracticesDocument56 pagesManufacturing Hygiene Practicesmohamed sabryNo ratings yet

- Krantz: Multifunction Exposed Ceiling Solutions With SystemDocument20 pagesKrantz: Multifunction Exposed Ceiling Solutions With SystemjimmiilongNo ratings yet

- Tender9 Vol II o II Pig Launcher and Receiver by MeconDocument31 pagesTender9 Vol II o II Pig Launcher and Receiver by MeconVeena S VNo ratings yet

- Master Thesis Dusko Ruzicic English VersionDocument3 pagesMaster Thesis Dusko Ruzicic English VersionРужичић ДушкоNo ratings yet

- Ssab Tube HandbookDocument190 pagesSsab Tube HandbookMerygouNo ratings yet

- Forming Assessment Questions - SanfoundryDocument5 pagesForming Assessment Questions - SanfoundryrahmaNo ratings yet

- Punch and DieDocument16 pagesPunch and DieNani DatrikaNo ratings yet

- India Machine Tools IndustryDocument33 pagesIndia Machine Tools IndustryTejas ShahNo ratings yet

- Operation Manual TruTool N700 (1A1)Document26 pagesOperation Manual TruTool N700 (1A1)Catalin VladNo ratings yet

- Metal Craft BrochureDocument2 pagesMetal Craft BrochureViswa BhuvanNo ratings yet

- Welding, Forming, Casting Seminar TopicsDocument2 pagesWelding, Forming, Casting Seminar Topicsyagnesh50% (2)

- Decorative Metal (MS - FL)Document10 pagesDecorative Metal (MS - FL)walid abou kachfeNo ratings yet

- Technical SpecificationDocument63 pagesTechnical Specificationgopvij1No ratings yet

- F1472 1479757-1Document5 pagesF1472 1479757-1Thaweekarn Changthong100% (1)

- The Impact of Technical Aspects of Kitchen Equipment Selection On The Occupational Safety of Hotel Sector EmployeesDocument141 pagesThe Impact of Technical Aspects of Kitchen Equipment Selection On The Occupational Safety of Hotel Sector EmployeesCliffordNo ratings yet

- ASTM D5147 - Sampling and Testing Modified Bituminous Sheet Material1Document5 pagesASTM D5147 - Sampling and Testing Modified Bituminous Sheet Material1jothi vel muruganNo ratings yet

- Blank Size Formula For Sheet Metal Forming - Google SearchDocument2 pagesBlank Size Formula For Sheet Metal Forming - Google SearchJebin AbrahamNo ratings yet

- Zinc Coating (Hot-Dipped) On Steel Plates and Steel Strips For AutomobilesDocument22 pagesZinc Coating (Hot-Dipped) On Steel Plates and Steel Strips For AutomobilesMike Fioren100% (3)

- Manufacturing Process 4 PDFDocument2 pagesManufacturing Process 4 PDFVijayalaxmi MudhigondaNo ratings yet

- Semi-Automatic Boiled Potato Peeling and Smashing MachineDocument4 pagesSemi-Automatic Boiled Potato Peeling and Smashing MachineVIVA-TECH IJRINo ratings yet

- TG7-15 Scaffold Board NailplatesDocument1 pageTG7-15 Scaffold Board NailplatesMohammed HafizNo ratings yet