Professional Documents

Culture Documents

Sterility Test Failure Investigation Form

Uploaded by

mishannakCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sterility Test Failure Investigation Form

Uploaded by

mishannakCopyright:

Available Formats

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Form 680 Issue date:

Table Contents 1. Purpose of report 2. Batch Details 3. Batch Manufacturing review and Sterility testing 4. Summary of Conclusions found 5. Possible causes 6. Corrective action 7. Preventative action 8. Disposition of filling room 9. Documentation Approval of Investigation

DR____________

1 Purpose of report The purpose of this document is to provide a summary report of the incident investigation conducted into:

2 Batch Details Product Name Date of Manufacturing Product Code Container and size Terminally sterilized Y/N Sterility Test Details Date Test room Time of test session Validated test method Date of results Contaminant/s type

Batch # Filling Room # Filling Machine Autoclave Cycle

Technician Number of products tested Session number that day Tested to Specification Test session results Negative control result

File Location:

Date Printed:

Page 1 of 9

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Form 680 Issue date:

3 Batch review from manufacturing and testing.

Product Manufacturing Review

REVIEW AREA

Dispensing results:

DETAILS & Results Batch # Materials code Validated test method Results of tests Autoclave Cycle# Date Result Time of collection Sample port results Time of collection Validated test method Results of tests Validated test method Results of tests Finished product Water used for manufacture of batch Line # Date Result Vessel # Date Result Holding Tank # Date Result Bioburden reduction filter # Exacta # Date Results

REVIEWED BY

Review of raw materials used for the manufacture Dispensing of the raw materials Sterilization cycles for components

Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No

Solution Preparation results:

Distilled water used for manufacturing Review Bulk solution Bioburden Review of Filled Container Bioburden Review of Bacterial Endotoxin results

Sign: Date: Review Attached: Yes/No

Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No

Line steaming results Vessel steaming results Holding tank results

Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No

Filtering review

Sign: Date: Review Attached: Yes/No

Filling Machine results: Environmental monitoring results

Filling machine Viable

File Location:

Surface plates machine

Sign: Date: Review Attached: Yes/No

Date Printed:

Page 2 of 9

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Form 680 Issue date:

Filling Machine non viable particulates Manufacturing room Viable Air Manufacturing room Viable Surface Manufacturing room Non- Viable particulates Fallout Plates for Batch Review of Prepared plate media

Filling Machine results:

Sterile filling zone, date when last conducted Air L/F Air Filling Room Air Corridor Surface floor Surface wall Filling room, date when last conducted Date Start time of exposure End time of exposure Shift Result Type of Media Batch # Expiry Date

Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No

Sign: Date: Review Attached: Yes/No

Sign: Date: Review Attached: Yes/No

Setting up Procedures Machine steaming results Error log report Filtering review Manufacturing instruction sheet review Interventions Stoppages Reject rate Maintenance log review Product values Pressure testing calibrations Differential pressure excursion review Air shower system Waste tanks Machine # Date Result Report Date Result Sterilisation filter # Date Results

Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No

Sign: Date: Review Attached: Yes/No

Sign: Date: Review Sign: Date: Review Sign: Date: Review Sign: Date: Review Sign: Date: Review Sign: Date: Review

Attached: Yes/No Attached: Yes/No Attached: Yes/No Attached: Yes/No Attached: Yes/No Attached: Yes/No

File Location:

Date Printed:

Page 3 of 9

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Form 680 Issue date:

Filling Process All shifts Cleaning review Disinfectants Chilled water review Product line integrity Work orders Run Sheet Sterile Log Book

Sterile Operator Review

Sign: Date: Review Sign: Date: Review Sign: Date: Review Sign: Date: Review Sign: Date: Review Sign: Date: Review Sign: Date: Review Sign: Date: Review Sign: Date: Review

Attached: Yes/No Attached: Yes/No Attached: Yes/No Attached: Yes/No Attached: Yes/No Attached: Yes/No Attached: Yes/No Attached: Yes/No Attached: Yes/No

Name Name and Number of Operators & Location of working Location

Sign: Date: Review Attached: Yes/No

Interview of Operator Name: for any excursion of procedures: Date Name Training records Training Record Gowning validations Operators Finger Dabs Operators Uniform Name Results Name Results

Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No

Packing Line:

Autoclave cycle finished product

Issues on Inspection / Finishing line

Autoclave # Cycle # Result

Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No

File Location:

Date Printed:

Page 4 of 9

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Form 680 Issue date:

QA Review Manufacturing:

Product Review of past 12 months of results Deviation Reports Review Similar incidents Change control history review Audit of security card swipe Review of Media run reports past 12 months Summary

Sign: Date: Review Attached: Yes/No Sign: Date: Review Sign: Date: Review Sign: Date: Review Sign: Date: Review

Attached: Yes/No Attached: Yes/No Attached: Yes/No Attached: Yes/No

Sign: Date: Review Attached: Yes/No

Micro. Lab. to place a HOLD on adjacent & subsequent batches until establishing a cause which will eliminate their risk of contamination and also;

Date done: Notify QA Manager

Batches on HOLD (Q) Batch # Code

Product & %

Container Size

File Location:

Date Printed:

Page 5 of 9

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Form 680 Issue date:

Sterility Testing Review REVIEW AREA DETAILS Results of known sterile controls Level of false positives in routine testing (previous 12 months) Level false positives in known sterile controls previous 12 months) Review of sampling procedures Review of handling procedures Review of swab method Review of certificate for Steritest unit Review of autoclave cycle for sterility test equipment Media used in sterility test Validation of HEPAs Validation of Laminar Flow unit Review of sterility test session, other batches Training records for sterility technician EM results for the sterility test room Viable EM results for the sterility test room Viable EM results for the sterility test room Non- Viable Review of Prepared plate media LAF Fallout Plate for Session

REVIEWED BY

Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No

Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No

Air L/F Air Sterility Test room Air Change room Surface plates LAF Surface floor Sterility test Room Surface floor Change room Sterility test room Change room Type of Media Batch # Expiry Date

Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No

File Location:

Date Printed:

Page 6 of 9

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Form 680 Issue date:

Sterility Technician Finger Dabs Sterility Technician Uniform Differential pressure excursion review Audit of security card swipe Cleaning review Disinfectants for cleaning Interview of Technician Sterility Log Book Comparison of Isolates Date of Streaking all Isolates:_________________ Technician:________________________________ Source of Isolate Product Finger Dab Plate Uniform Plate Laminar Flow Contact plate Laminar Flow Air Sample Fallout Plate

File Location: Date Printed:

Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No Sign: Date: Review Attached: Yes/No

No. of Colonies N/A

Colony Morphology

Microscopic Appearance

Page 7 of 9

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Form 680 Issue date:

IPA Exp. Date: Bucket 1 Bucket 2

N/A

N/A 4. Summary of Conclusions found

5. Possible cause/ Root Cause

6. Corrective action Task

Responsible

Date Completed

7 Disposition of filling room/batch

8. Documentation Approval of Investigation Prepared by Signature Date

Page 8 of 9

File Location:

Date Printed:

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Form 680 Issue date:

Reviewed by 1 Reviewed by 2 Approved by Quality Assurance Manager

Signature Signature Signature

Date Date Date

Glossary: EM L/F Fallout plates Environmental Monitoring Laminar Flow Also known as Settle Plates

File Location:

Date Printed:

Page 9 of 9

You might also like

- Production of Plasma Proteins for Therapeutic UseFrom EverandProduction of Plasma Proteins for Therapeutic UseRating: 3 out of 5 stars3/5 (5)

- What Is Disinfectant ValidationDocument4 pagesWhat Is Disinfectant Validationrouss1906No ratings yet

- Sterility Testing - Essential Things You Must Know: A White PaperDocument9 pagesSterility Testing - Essential Things You Must Know: A White PaperJeevanend ArumugamNo ratings yet

- Safe Operation of AutoclaveDocument4 pagesSafe Operation of AutoclavesumankatteboinaNo ratings yet

- Sop AutoclavingDocument4 pagesSop AutoclavingXiang LiuNo ratings yet

- A Global Disinfectant Standard For CleanDocument9 pagesA Global Disinfectant Standard For CleanAyman EshraNo ratings yet

- An Inside Look at USP71Document22 pagesAn Inside Look at USP71Dante IulliNo ratings yet

- Cleaning Validation in Pharmaceutical IndustriesDocument5 pagesCleaning Validation in Pharmaceutical IndustriesAbhishek RajNo ratings yet

- Testing Compressed Air Lines For Microbiological ContaminationDocument8 pagesTesting Compressed Air Lines For Microbiological Contaminationmuzammil21_adNo ratings yet

- Aseptic ProcessingDocument13 pagesAseptic ProcessingAshok Kumar100% (1)

- Validation of Sterilization: GMP and Qa Class: BDocument50 pagesValidation of Sterilization: GMP and Qa Class: BHikmah Purnama AzaniNo ratings yet

- Autoclave Validation PresentationDocument17 pagesAutoclave Validation PresentationprakhyaatNo ratings yet

- The ABCs of Disinfectant ValidationDocument6 pagesThe ABCs of Disinfectant ValidationSairam EdupugantiNo ratings yet

- Ethylene+oxide+Gas+Sterilization 한신메디칼+ (호환+모드)Document30 pagesEthylene+oxide+Gas+Sterilization 한신메디칼+ (호환+모드)SACHIN KUMARNo ratings yet

- A Final Floor Show For Bugs (Sandle)Document4 pagesA Final Floor Show For Bugs (Sandle)Tim Sandle100% (1)

- 0707-0712 (1117) Microbiological Best Laboratory PracticesDocument7 pages0707-0712 (1117) Microbiological Best Laboratory PracticesDr usama El ShafeyNo ratings yet

- White Paper Tga Audit ReadinessDocument10 pagesWhite Paper Tga Audit ReadinessFaraz Haider100% (1)

- Moist Heat SterilizatiojnDocument16 pagesMoist Heat Sterilizatiojnajitjoshi950No ratings yet

- Cleaning Verification For Intermediate 190612Document8 pagesCleaning Verification For Intermediate 190612Purushothaman SubramanianNo ratings yet

- Multicenter Study On Incubation Conditions For Environmental Monitoring and Aseptic Process SimulationDocument9 pagesMulticenter Study On Incubation Conditions For Environmental Monitoring and Aseptic Process SimulationBLUEPRINT Integrated Engineering ServicesNo ratings yet

- FOB2-3 TS - Technical Manual - Section 2 - Installation SpecificationsDocument10 pagesFOB2-3 TS - Technical Manual - Section 2 - Installation SpecificationsmaghraouiNo ratings yet

- General Chapters - 1222 - Terminally Sterilized Pharmaceutical Products-Parametric ReleaseDocument5 pagesGeneral Chapters - 1222 - Terminally Sterilized Pharmaceutical Products-Parametric ReleaseSuman Katteboina0% (1)

- Use of Chemical & Biological Indicators - 2014 2Document56 pagesUse of Chemical & Biological Indicators - 2014 2jerimiah_manzonNo ratings yet

- Bioproc PDFDocument6 pagesBioproc PDFSrijit KhanNo ratings yet

- Sterility Test Failure Investigations: Peer Review: MicrobiologyDocument8 pagesSterility Test Failure Investigations: Peer Review: MicrobiologyAyman EshraNo ratings yet

- Microbiology Audit Guidance EbookDocument23 pagesMicrobiology Audit Guidance EbookArmando Saldaña100% (1)

- Media Fill Indicador de ColorDocument6 pagesMedia Fill Indicador de Colorsteven correaNo ratings yet

- 143178Document20 pages143178ipatoffNo ratings yet

- Moist Heat Sterilization Validation and Requalification STERISDocument4 pagesMoist Heat Sterilization Validation and Requalification STERISDany RobinNo ratings yet

- Responding To Regulatory InspectionsDocument5 pagesResponding To Regulatory Inspectionspradeep281001No ratings yet

- Disinfectants in Pharmaceutical Industry Tim SandleDocument8 pagesDisinfectants in Pharmaceutical Industry Tim SandleshwampaNo ratings yet

- Sampling Water Table ContentsDocument2 pagesSampling Water Table Contentsraju1559405No ratings yet

- 4 Brading Retrofitting RABS To Existing Aseptic Filling Lines ISPEDocument28 pages4 Brading Retrofitting RABS To Existing Aseptic Filling Lines ISPEsteven correaNo ratings yet

- Media Fill For Validation of A Good Manufacturing - ARTIGODocument9 pagesMedia Fill For Validation of A Good Manufacturing - ARTIGOBiancaNo ratings yet

- Environmental Monitoring Incubation Conditions - JustificationDocument4 pagesEnvironmental Monitoring Incubation Conditions - Justificationveerreddy_157808No ratings yet

- Contamination ControlDocument5 pagesContamination ControlPadmanabhan DhanasekaranNo ratings yet

- CreatingaCleaningValidationPlan TOCDocument1 pageCreatingaCleaningValidationPlan TOCOnichan21No ratings yet

- MICRO 4 SOP For Microbial Monitoring in Drain Point of Pharmaceutical Manufacturing SitesDocument2 pagesMICRO 4 SOP For Microbial Monitoring in Drain Point of Pharmaceutical Manufacturing SitesAjesh Tk100% (1)

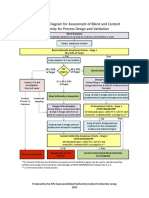

- Blend Content Uniformity Process Flow Diagram Design ValidationDocument1 pageBlend Content Uniformity Process Flow Diagram Design Validationhicham1963No ratings yet

- The Value of Plant Isolates in Pharma Quality (Myatt & Morgan, PDA Letter, JulAug 2011) PDFDocument5 pagesThe Value of Plant Isolates in Pharma Quality (Myatt & Morgan, PDA Letter, JulAug 2011) PDFDholakia100% (1)

- ValidationDocument56 pagesValidationAmit Singh100% (1)

- CCS Guide Attachment3 v2Document34 pagesCCS Guide Attachment3 v2elisabetta ghilardi100% (1)

- Product Catalogue Biological Indicators, Process Challenge Devices and Accessories PDFDocument24 pagesProduct Catalogue Biological Indicators, Process Challenge Devices and Accessories PDFscribdddcNo ratings yet

- Ethylene Oxide Gas Sterilization of Medical Devices: ReviewDocument16 pagesEthylene Oxide Gas Sterilization of Medical Devices: ReviewSHAIK NISHARNo ratings yet

- Validation For Automated Washing Systems: Aaron Mertens, Paul Lopolito, Olivier Van Houtte, and Marcel Dion, SterisDocument2 pagesValidation For Automated Washing Systems: Aaron Mertens, Paul Lopolito, Olivier Van Houtte, and Marcel Dion, SterisVenkatraj CNo ratings yet

- Publications by Tim Sandle - July 2019Document53 pagesPublications by Tim Sandle - July 2019Tim SandleNo ratings yet

- Validation Study and Quality Assurance of Pharmaceutical WaterDocument12 pagesValidation Study and Quality Assurance of Pharmaceutical WaterNguyen TrungNo ratings yet

- 3 2 - MicrobiologicalQualityControl 1Document37 pages3 2 - MicrobiologicalQualityControl 1Tong ChanNo ratings yet

- Cleaning Validation Boot CampDocument7 pagesCleaning Validation Boot Campramin_47No ratings yet

- 2-5a MediaFillDocument37 pages2-5a MediaFillShobha RaniNo ratings yet

- Anti Microbiological Assay Test or Antibiotic Assay Test of Pharmaceutical Preparation Containing Antibiotics Using 'Cylinder Plate Method'Document4 pagesAnti Microbiological Assay Test or Antibiotic Assay Test of Pharmaceutical Preparation Containing Antibiotics Using 'Cylinder Plate Method'Editor IJTSRDNo ratings yet

- Yves MayeresseDocument66 pagesYves MayeressesumankatteboinaNo ratings yet

- Overview of Validation Requirements in Pharmaceutical IndustryDocument56 pagesOverview of Validation Requirements in Pharmaceutical IndustryCarlos Alberto SarriaNo ratings yet

- Pharmaceutical Microbiology LabsDocument27 pagesPharmaceutical Microbiology LabsThuy LeNo ratings yet

- Microbiological Pharmaceutical Quality Control LabsDocument7 pagesMicrobiological Pharmaceutical Quality Control LabsDede Kizzy Black100% (1)

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersFrom EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNo ratings yet

- Guidelines Use of The Word AnzacDocument28 pagesGuidelines Use of The Word AnzacMichael SmithNo ratings yet

- Project Management: Chapter-2Document26 pagesProject Management: Chapter-2Juned BhavayaNo ratings yet

- Bug Head - Fromjapanese To EnglishDocument20 pagesBug Head - Fromjapanese To EnglishAnonymous lkkKgdNo ratings yet

- Delta PresentationDocument36 pagesDelta Presentationarch_ianNo ratings yet

- Portfolio Report Zarin Tasnim Tazin 1920143 8Document6 pagesPortfolio Report Zarin Tasnim Tazin 1920143 8Fahad AlfiNo ratings yet

- Aman 5Document1 pageAman 5HamidNo ratings yet

- VoLTE KPI Performance - E2EDocument20 pagesVoLTE KPI Performance - E2EAnway Mohanty100% (1)

- Floor Paln ModelDocument15 pagesFloor Paln ModelSaurav RanjanNo ratings yet

- Income Tax Calculator 2023Document50 pagesIncome Tax Calculator 2023TARUN PRASADNo ratings yet

- A Winning Formula: Debrief For The Asda Case (Chapter 14, Shaping Implementation Strategies) The Asda CaseDocument6 pagesA Winning Formula: Debrief For The Asda Case (Chapter 14, Shaping Implementation Strategies) The Asda CaseSpend ThriftNo ratings yet

- Vodafone M2M Integrated M2M Terminals Overview BrochureDocument4 pagesVodafone M2M Integrated M2M Terminals Overview BrochureJamie JordanNo ratings yet

- Preventive Maintenance - HematologyDocument5 pagesPreventive Maintenance - HematologyBem GarciaNo ratings yet

- DR-2100P Manual EspDocument86 pagesDR-2100P Manual EspGustavo HolikNo ratings yet

- Agreement Deed BangladeshDocument8 pagesAgreement Deed BangladeshVabna EnterpriseNo ratings yet

- Dr. Li Li Prof. Feng Wu Beijing Institute of TechnologyDocument20 pagesDr. Li Li Prof. Feng Wu Beijing Institute of TechnologyNarasimman NarayananNo ratings yet

- Fletcher Theophilus Ato CVDocument7 pagesFletcher Theophilus Ato CVTHEOPHILUS ATO FLETCHERNo ratings yet

- Go Ask Alice EssayDocument6 pagesGo Ask Alice Essayafhbexrci100% (2)

- Outage Analysis of Wireless CommunicationDocument28 pagesOutage Analysis of Wireless CommunicationTarunav SahaNo ratings yet

- Service ManualDocument30 pagesService ManualYoni CativaNo ratings yet

- Pro Tools ShortcutsDocument5 pagesPro Tools ShortcutsSteveJones100% (1)

- Labor CasesDocument47 pagesLabor CasesAnna Marie DayanghirangNo ratings yet

- Admissibility of Whatsapp Messages in Court For Family MattersDocument3 pagesAdmissibility of Whatsapp Messages in Court For Family Mattersnajihah adeliNo ratings yet

- Historical DocumentsDocument82 pagesHistorical Documentsmanavjha29No ratings yet

- Automatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Document7 pagesAutomatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Abdelrahman MahmoudNo ratings yet

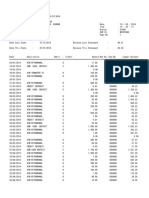

- Bank Statement SampleDocument6 pagesBank Statement SampleRovern Keith Oro CuencaNo ratings yet

- Milestone 9 For WebsiteDocument17 pagesMilestone 9 For Websiteapi-238992918No ratings yet

- Beam Deflection by Double Integration MethodDocument21 pagesBeam Deflection by Double Integration MethodDanielle Ruthie GalitNo ratings yet

- QuizDocument11 pagesQuizDanica RamosNo ratings yet

- Proposal For Chemical Shed at Keraniganj - 15.04.21Document14 pagesProposal For Chemical Shed at Keraniganj - 15.04.21HabibNo ratings yet

- Insurance Smart Sampoorna RakshaDocument10 pagesInsurance Smart Sampoorna RakshaRISHAB CHETRINo ratings yet