Professional Documents

Culture Documents

Flow Regimes

Uploaded by

cakzinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow Regimes

Uploaded by

cakzinCopyright:

Available Formats

Flow Regimes - TWO-PHASE FLOW

TWO-PHASE FLOW There are situations, in practice, where more than one fluid face is transported simultaneously through a pipeline. In fact, there is an expanding application for two-phase flow to transport offshore products. Examples of two phase flow are found in pipelines transporting: Natural gas and condensate Crude oil and associated gas Such conditions occur when, produced fluids, especially crude oil produced from a reservoir below the bubble point or natural gas produced above dew point is transported in the pipeline. Often, two-phase flow is further complicated by the presence of a second liquid phase, such as water with oil and gas or glycol with a gas and condensate system. Designing a pipeline for two-phase or multi-phase flow is complex because the properties and flow patterns of two or more fluids must be considered in the design. Two-phase Flow Parameters To evaluate the behavior of a two-phase flow pipeline, a number of parameters must be considered. These include: Liquid Volume Fraction, Pipeline Profile, Flow Regime, Two-phase Pressure Loss. Liquid Hold-up, and Knowing how much liquid and gas is present in a hydrocarbon mixture is very important in designing a two-phase flow pipeline. The two-phase liquid-gas composition of a hydrocarbon mixture is best illustrated by what is called a phase envelope. A phase envelope is a graphical representation of the relative quantities of liquid and gas present in a mixture at various pressures and temperatures. Examples of typical pressure-temperature operating profiles for a pipeline with varying flow-rates are shown in Figure 1 . The phase envelope of a gas indicates the liquid percentage in the fluid at each point. For the examples, we can see that at the pipeline operating range, the liquid percentage changes from about 3% at the inlet to about 5% at the outlet.

Liquid Volume Fraction Liquid volume fraction is the fraction of fluid flowing as a liquid present at a local point in the pipeline. The phase envelope just described in Figure 1 graphically represents this. It is determined by assuming that thermodynamic equilibrium exists between the two phases at the local pressure and temperature. The equation for liquid volume fraction is shown in Figure 2 .

Another parameter shown in this figure is Superficial Liquid Velocity. This is the velocity the liquid would have in the pipeline, if only the liquid phase was present. Likewise, the superficial gas velocity is the velocity the gas would have, if only the gas phase was present. Pipeline Profile Changes in elevation of the pipeline route play an important role in two-phase flow pipeline design and operation. The elevation profile, which represents the angle of inclination in every point of a pipeline, influences the liquid hold-up and determines the flow regime. This in turn impacts the pressure loss incurred during the two-phase flow. Liquid Hold-up Liquid hold-up is the accumulation of liquid in the pipeline because of the difference in velocity (slip) between the phases and the influence of gravity (See Figure 3 ). Liquid holdup is usually larger than the liquid volume fraction. The only exception might be during a downward sloping flow at low velocity.

Two-phase Flow Regimes The way in which liquid and gas simultaneously flow within a pipeline is characterized by what is known as flow regimes. Flow regimes indicate the distribution of the phases over the cross sectional area of the pipeline. Many investigators, including a special institute at the University of Tulsa, have extensively analyzed two-phase flow patterns and regimes. Some of the most commonly occurring two phase flow regimes in pipeline are: Bubble flow Annular dispersed flow Stratified or laminar flow Plug or churn flow Slug flow The relative positions of the liquid and gas as they move along the pipeline depend on whether the flow is horizontal or vertical. Figure 4

and Figure 5 illustrate the different flow regimes for horizontal and vertical flow.

Figure 6 exhibits a flow pattern map, which shows how flow behavior depends on the gas and liquid loading.

Bubble flow In this type of flow, bubbles of gas flow along with the liquid at about the same velocity. In horizontal pipelines gas bubbles move along the upper part of the pipe. Annular dispersed flow In this flow regime, the liquid flows along the wall of the pipe, while the gas flows at high velocity in the center of the pipe. Stratified flow In stratified flow both gas and liquid flow separately with a distinct and relatively smooth interface between them. Gas flows in the upper part and liquid moves in the lower part of the pipe. Sometimes a wave is formed; it is then called stratified wavy flow. Plug or Churn flow This is similar to bubble flow, except that the gas bubbles coalesce into large bubbles or plugs. In horizontal flow the plugs flow on the upper part of the pipe, while, in vertical flow, they tend to flow in the center of the pipe.

Slug flow Slug flow is similar to stratified wavy flow, except that the top of some waves touches the pipe wall and the flow tend to be alternative slugs of liquid and gas. In vertical flow, alternative slugs of liquid flow in the center of the pipe along with gas. Two-phase Flow Pipeline Pressure Loss The pressure drop in a pipeline for two-phase flow is higher than that of single-phase flow. The increased pressure loss is essentially caused by the additional friction loss due to the formation of waves and slugs. A number of different correlation's have been developed by different authors to predict pressure loss in a pipeline for two-phase flow. Some are more suitable than others for specific fluid types, giving varying levels of uncertainty. Usually companies develop their own correlation's for two-phase flow that can be generally applied. The behavior of a two-phase pipeline is normally evaluated using specialized process simulation computer packages. The simulation package will take the input parameters and use two-phase flow equations and correlation's to determine the flow regimes, pressure loss and liquid hold-up for the pipeline. The graph in Figure 7 shows the required pipeline inlet pressure to achieve a fixed outlet pressure for a range of throughputs and pipeline diameters. This is a typical output and is invaluable in determining the optimum pipeline diameter.

Two-phase Liquid Hold-up When designing a two-phase pipeline system, usually, a graph is generated showing how liquid hold-up volume varies with throughput and with varying pipeline diameters (See Figure 8 ). This is an invaluable piece of information. In a two-phase pipeline, one must first predict the amount of liquid expected to be present and then manage it.

An understanding of how the anticipated liquid hold-up in a pipeline will vary with flow-rates will greatly help in formulating a suitable liquid management system. This could perhaps include slug-catcher, pigging facilities or operational limits on ramp-up times. Two-Phase Applications Although it is more challenging to design and operate two-phase flow pipelines, they have been successfully built and operated throughout the world. It used to be that in typical operations, two separate lines would automatically be built for gas and oil, transporting from the same source and often delivering to the same delivery point. However, where, construction costs are high, such as offshore, building a single two-phase pipeline rather than two separate lines is often the most economical approach. Figure 9 illustrates an example of a two-phase pipeline system built offshore Denmark.

This very large production system handles many fluid combinations. To be able to operate such a complex transport system one must be able to accurately predict and manage the pipelines.

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IEA SHC Task60 D5 Basic Concepts of PVT TechnologiesDocument26 pagesIEA SHC Task60 D5 Basic Concepts of PVT TechnologiesKARAM KNo ratings yet

- (Biofuels and Biorefineries 2) Zhen Fang, Chunbao (Charles) Xu (Eds.) - Near-Critical and Supercritical Water and Their Applications For Biorefineries-Springer Netherlands (2014)Document481 pages(Biofuels and Biorefineries 2) Zhen Fang, Chunbao (Charles) Xu (Eds.) - Near-Critical and Supercritical Water and Their Applications For Biorefineries-Springer Netherlands (2014)MZ100% (1)

- Mud TestDocument8 pagesMud TestNakkolopNo ratings yet

- Effect of Temperature On Invertase ActivityDocument3 pagesEffect of Temperature On Invertase ActivityElizar Nepomuceno Gonzales100% (2)

- Thermal Physics: Solid ExpansionDocument3 pagesThermal Physics: Solid ExpansionBilly BlattNo ratings yet

- Chapter 15-4811-ElectroanalyticalmethodsDocument137 pagesChapter 15-4811-ElectroanalyticalmethodsMustafa KamalNo ratings yet

- Ch07 PrecipDocument34 pagesCh07 PrecipPa Loma B. SantosNo ratings yet

- Diesel HydrotreatingDocument6 pagesDiesel HydrotreatingArchana RaviNo ratings yet

- Terrestrial Ionosphere - Part1/2Document31 pagesTerrestrial Ionosphere - Part1/2voidnamexxxNo ratings yet

- Elements in Power Plant and Industrial Plant EngineeringDocument19 pagesElements in Power Plant and Industrial Plant EngineeringRc Tuppal75% (8)

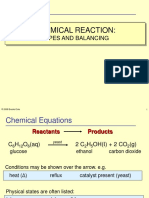

- Types of Chemical Reactions and Balancing Chemical Equations.Document15 pagesTypes of Chemical Reactions and Balancing Chemical Equations.Joshua Del Pilar100% (1)

- Half Cell ReportDocument47 pagesHalf Cell Reportraja qammarNo ratings yet

- Chemistry Atoms First 2nd Edition Burdge Test Bank 1Document154 pagesChemistry Atoms First 2nd Edition Burdge Test Bank 1lillian100% (33)

- 64ecc6943427510018731934 - ## - Chemical Bonding Short NotesDocument2 pages64ecc6943427510018731934 - ## - Chemical Bonding Short NotesShlok MishraNo ratings yet

- Unit 3. Mixtures and Pure SubstancesDocument36 pagesUnit 3. Mixtures and Pure SubstancesArman VillagraciaNo ratings yet

- Physics Exam SS 1 CambridgeDocument3 pagesPhysics Exam SS 1 CambridgesunliasNo ratings yet

- Combustion R.ADocument39 pagesCombustion R.ARitanshu Anand100% (1)

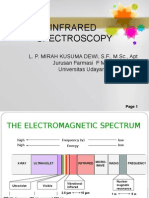

- Infra Red SpectroscopiDocument42 pagesInfra Red SpectroscopiMade PrimaNo ratings yet

- Question 15Document3 pagesQuestion 15maniNo ratings yet

- Worksheet 5 (Acids-Bases III) With AnswersDocument2 pagesWorksheet 5 (Acids-Bases III) With AnswersDelilah StephenieNo ratings yet

- Durable Modification of Segmented Polyurethane For Elastic Blood-Contacting Devices by Graft-Type 2-Methacryloyloxyethyl Phosphorylcholine CopolymerDocument17 pagesDurable Modification of Segmented Polyurethane For Elastic Blood-Contacting Devices by Graft-Type 2-Methacryloyloxyethyl Phosphorylcholine CopolymerDinca ValentinaNo ratings yet

- Laboratory Activities QC2Document14 pagesLaboratory Activities QC2ampay ayubNo ratings yet

- Atomic Structure Worksheet - 1 KeyDocument2 pagesAtomic Structure Worksheet - 1 KeyJoana Marie Pabilona DueñosNo ratings yet

- Sulfaflux - Oilfield H2S Scavenger'sDocument6 pagesSulfaflux - Oilfield H2S Scavenger'sben7251No ratings yet

- Molarity of Concentrated Reagents 2Document2 pagesMolarity of Concentrated Reagents 2srikanthdip007No ratings yet

- RE1 Dr. Ayoub Assignment 2 John Kevin de CastroDocument2 pagesRE1 Dr. Ayoub Assignment 2 John Kevin de CastroJohn Kevin de CastroNo ratings yet

- Chen 2005Document10 pagesChen 2005varsha patilNo ratings yet

- Created by C. Mani, Principal, K V No.1, AFS, Jalahalli West, BangaloreDocument3 pagesCreated by C. Mani, Principal, K V No.1, AFS, Jalahalli West, BangaloreAñoop GāurNo ratings yet

- PPT II Plastics Materials and Its Applications II 20 221Document1 pagePPT II Plastics Materials and Its Applications II 20 221Raj ThakurNo ratings yet