Professional Documents

Culture Documents

001 Bearing Failure

Uploaded by

HiddenDOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

001 Bearing Failure

Uploaded by

HiddenDCopyright:

Available Formats

Fleet QHSE Alert

No. 001 1st September 2001

ENGINE ROOM MAINTENANCE

Bearing Failure

Confirm that you have the makers updated instructions onboard, and a torque wrench of the appropriate range. 2. Connecting rod bottom end bores should be accurately calibrated to ensure that the inner diameter is above the minimum allowable figure and that the ovality is within limits. The connecting rods should be calibrated without the bearing shells in place, only after tightening the bottom end bearing bolts as specified by the makers.

Bearing white metal wiped out .

Melted down bearings due to lube oil failure

Over the years, we have had a few instances of damage to 3. Carry out dye penetrant crack detection tests on the auxiliary engine main bearings and connecting rod bottom serrations of bottom end bearing keeps and on the end bearings. This has almost always resulted in damage of threaded section of the bottom end bearing bolts. crankshaft beyond repair, necessitating expensive renewals. Check for burrs and distortion at the serrations of the bearing keeps, and at the threaded sections and landing Your attention to the following would greatly help reduce faces or fitted sections of the bolts. Some makers recsuch break-downs: ommend checking the bolts for elongation.

Routine Operation of the Engine

1. Follow correct starting and stopping procedures.

4. Outer diameters of crankpins should be measured along two perpendicular axes, at three locations along the pin.

2. Lube oil pressure of approximately 1.0 Bar must be 5. Maintain a proper record of the service hours of the bottom end bearing bolts and should these be apmaintained continuously by means of hand pump or elecproaching the makers recommended replacement intertric priming pump during starting, until the engine driven vals, ensure that the bolts are renewed during the overpump builds up a pressure exceeding this. Similarly, haul. lube oil pressure must be maintained during the stopping of the engine and for a few minutes thereafter. 6. When using new bolts, it is important to break-in the bolts by tightening and loosening them in the connect3. Maintain the lube oil in good condition and carry out ing rods a couple of times. weekly drop tests as a test of oil quality. Check and clean lube oil filters periodically and ensure that filters 7. When connecting rod bottom end bearing bolts are and coolers are purged after any work is done on them. being re-used, please ensure that they are fitted in the same location from which they were removed. 4. When carrying out crankcase inspections, verify proper lube oil flow. Remember to check for correct end float 8. Only use recommended lubricants/ anti-seize comof bottom end of the connecting rods. pounds on the bolt threads before tightening.

Engine Overhauls

9. Check for correct end float of bottom end of the connecting rods after these are fitted in the engine. 1. In view of a large number of cases of bottom end bearing bolt failure due to incorrect tightening torque, Yanmar and Daihatsu have revised their procedures for tightening 10. Ascertain the zero error of all calibration instruments used, and take this into account as appropriate. bottom end bolts from the torque method to the rotated angle method which require preliminary tightening by torque and further tightening through a specified angle.

IF IN DOUBT, ASK US!

You might also like

- Required Manuals and Documentation: Honda Certified Used Cars 150 Point Inspection ChecklistDocument2 pagesRequired Manuals and Documentation: Honda Certified Used Cars 150 Point Inspection ChecklistKaiser Shaikh100% (2)

- Hi-Rel-10 KVA UPS ManualDocument28 pagesHi-Rel-10 KVA UPS ManualAbdelwhab Elsafty100% (4)

- Butech Catalog PDFDocument206 pagesButech Catalog PDFFIRSON ANDRES SerranoNo ratings yet

- ASIS Chief Sec Officer Asis StandardDocument28 pagesASIS Chief Sec Officer Asis StandardHiddenD100% (1)

- Members Section Timing Chains Tensioning A Timing ChainDocument1 pageMembers Section Timing Chains Tensioning A Timing ChainArun SNo ratings yet

- TC BRG and LubDocument3 pagesTC BRG and LubArun SNo ratings yet

- SL00 383Document5 pagesSL00 383bekavacsNo ratings yet

- Members Section Common Rail and Camshaftless Engines The MAN B&W ME Engine Exhaust Valve ActuatorDocument2 pagesMembers Section Common Rail and Camshaftless Engines The MAN B&W ME Engine Exhaust Valve ActuatorArun SNo ratings yet

- A Study On Torque Rich Phenomena in Ship OperationDocument11 pagesA Study On Torque Rich Phenomena in Ship OperationAnonymous XtvvG80zuNo ratings yet

- Actual Sysem Setup Alpha LubricatorDocument7 pagesActual Sysem Setup Alpha LubricatorRanjan DiptanshuNo ratings yet

- Air Start ExplosionDocument12 pagesAir Start ExplosionsahilimuNo ratings yet

- 6 Checking and Adjustment of Exhaust Cam LeadDocument8 pages6 Checking and Adjustment of Exhaust Cam LeadJomari Saligan100% (1)

- Members Section Fuel Oil Fuel Oil TestingDocument3 pagesMembers Section Fuel Oil Fuel Oil TestingArun SNo ratings yet

- Cylinder LubricationDocument8 pagesCylinder LubricationVinay Kumar Neelam100% (1)

- ME Operational Manual MANB&W 7S70MC-CDocument576 pagesME Operational Manual MANB&W 7S70MC-CSamrat ThukralNo ratings yet

- Radial Turbochargers ExplainedDocument3 pagesRadial Turbochargers ExplainedArun SNo ratings yet

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start DistributorDocument1 pageMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start DistributorArun SNo ratings yet

- Calculate Engine Power from Indicator DiagramsDocument6 pagesCalculate Engine Power from Indicator DiagramsArun SNo ratings yet

- vh3372 EnglishDocument20 pagesvh3372 EnglishtonNo ratings yet

- Starting & Reversing Problems in Marine EnginesDocument6 pagesStarting & Reversing Problems in Marine EnginesUjjwal SinghNo ratings yet

- Cylinder Lubrication Marine Engines ArticleDocument10 pagesCylinder Lubrication Marine Engines ArticleVijay Geddada100% (2)

- Two Stroke Crosshead Engine Stuffing BoxDocument6 pagesTwo Stroke Crosshead Engine Stuffing BoxAbhishek Singh ChauhanNo ratings yet

- Puncture ValveDocument1 pagePuncture ValveAnkit DedhiyaNo ratings yet

- RT FlexDocument3 pagesRT FlexGaby CrisNo ratings yet

- Axial Distributor PDFDocument1 pageAxial Distributor PDFArun SNo ratings yet

- 8 Common Problems Found in Steering Gear System of ShipsDocument5 pages8 Common Problems Found in Steering Gear System of ShipsNorman prattNo ratings yet

- 513 613 L28 32H Compressed Air SystemDocument9 pages513 613 L28 32H Compressed Air SystemFlo MarineNo ratings yet

- Indicator Diagrams of Diesel EnginesDocument5 pagesIndicator Diagrams of Diesel EnginesAbdul Anis67% (3)

- Camshaft timing chain drive and reversing mechanismsDocument55 pagesCamshaft timing chain drive and reversing mechanismsMeghanath AdkonkarNo ratings yet

- Common Rail Fuel System and Exhaust Valve ControlDocument12 pagesCommon Rail Fuel System and Exhaust Valve ControlAlagarsamyvenkat ShanmugarajaNo ratings yet

- Piston Ring PDFDocument3 pagesPiston Ring PDFArun SNo ratings yet

- 02 Two Stroke Diesel CycleDocument31 pages02 Two Stroke Diesel CyclenareshNo ratings yet

- Environmentally Friendly Marine Gensets Compliant with IMO RegulationsDocument20 pagesEnvironmentally Friendly Marine Gensets Compliant with IMO RegulationsAjinkya KhamkarNo ratings yet

- 2 Stroke Diesel Engine Components-1Document72 pages2 Stroke Diesel Engine Components-1EdemNo ratings yet

- Parts ListDocument179 pagesParts ListWilson PalacioNo ratings yet

- Air Assist For Starting and Lambda ControllerDocument2 pagesAir Assist For Starting and Lambda ControllerKalai selvanNo ratings yet

- Exhaust ValvesDocument3 pagesExhaust ValvesJitendra Kumar100% (1)

- Exhaust Valve System (Set 2015)Document42 pagesExhaust Valve System (Set 2015)Fernando SouzaNo ratings yet

- Overview Management and Exploitation of Fishery Resources of CameroonDocument32 pagesOverview Management and Exploitation of Fishery Resources of CameroonHiddenDNo ratings yet

- MAN Diesel and Turbo SL2014-571 PDFDocument20 pagesMAN Diesel and Turbo SL2014-571 PDFhiiiNo ratings yet

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Local ControlDocument3 pagesMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Local ControlArun SNo ratings yet

- TURNOMATDocument2 pagesTURNOMATArun SNo ratings yet

- Cylinder Liner Cold Corrosion ControlDocument8 pagesCylinder Liner Cold Corrosion ControlarunNo ratings yet

- Chapter 21 - Starting Air SystemDocument16 pagesChapter 21 - Starting Air Systemsezar100% (1)

- Joern Andersen - MAN B&W2Document29 pagesJoern Andersen - MAN B&W2Flo MarineNo ratings yet

- X Head LubricationDocument3 pagesX Head LubricationArun SNo ratings yet

- Slide Fuel Valves Reduce EmissionsDocument5 pagesSlide Fuel Valves Reduce EmissionsParthiban NagarajanNo ratings yet

- Grone PDFDocument25 pagesGrone PDFthis9999No ratings yet

- Cylinder Liner Types, Materials, Problems and InspectionDocument7 pagesCylinder Liner Types, Materials, Problems and InspectionRicardo Garing100% (2)

- Parts Catalog: 0CK10-M37402ENDocument102 pagesParts Catalog: 0CK10-M37402ENMarcell AgungNo ratings yet

- Sust Capex-Aluminium Julaug2016Document4 pagesSust Capex-Aluminium Julaug2016HiddenDNo ratings yet

- Techno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVADocument6 pagesTechno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVASrivatsanNo ratings yet

- The Turnomat Valve RotatorDocument5 pagesThe Turnomat Valve RotatorBharatiyulam100% (1)

- Instruction of Adjustment For Tacho System: 2016.03.10 Diesel Engine DepartmentDocument8 pagesInstruction of Adjustment For Tacho System: 2016.03.10 Diesel Engine DepartmentDurgesh k singhNo ratings yet

- SN183Document18 pagesSN183papaki2No ratings yet

- Man Diesel 2015Document38 pagesMan Diesel 2015LelosPinelos123No ratings yet

- c1 1Document301 pagesc1 1Liza Cabalquinto LorejoNo ratings yet

- RTX Piston Running GuideDocument32 pagesRTX Piston Running GuideDaniel TsvetilovNo ratings yet

- E20100617739 - 1 Removal Tool For F.inj - ValveDocument13 pagesE20100617739 - 1 Removal Tool For F.inj - ValveIvanciu Ionut-FabianNo ratings yet

- Thrust BlockDocument2 pagesThrust Blockkyaw yaNo ratings yet

- Guidelines - CE 2EDocument14 pagesGuidelines - CE 2ESUNILNo ratings yet

- EKM Dec 2016Document2 pagesEKM Dec 2016Arun SNo ratings yet

- Piston Kit InstructionsDocument2 pagesPiston Kit InstructionsMoto ExpertNo ratings yet

- Camshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLDocument12 pagesCamshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLGabriel ChiavettoNo ratings yet

- Emat PDFDocument2 pagesEmat PDFJaymart Hernandez MojicaNo ratings yet

- Oh LolDocument5 pagesOh Lolrhomel hamoyNo ratings yet

- Hyundai Coupe 2.0Document11 pagesHyundai Coupe 2.0BrandonHiDudNo ratings yet

- Fact Sheet: Basis of DesignDocument4 pagesFact Sheet: Basis of DesignHiddenDNo ratings yet

- Guidelines Annex A Statement of WorkDocument10 pagesGuidelines Annex A Statement of WorkHiddenDNo ratings yet

- Oakajee Strategic Industrial Area: Western Australia Midwest: GeraldtonDocument2 pagesOakajee Strategic Industrial Area: Western Australia Midwest: GeraldtonHiddenDNo ratings yet

- Careers GuideDocument48 pagesCareers GuideHiddenDNo ratings yet

- 2018-09-27 Project Map Oakajee SIADocument1 page2018-09-27 Project Map Oakajee SIAHiddenDNo ratings yet

- 2018-10-02 SIA Land Allocation Process For Strategic Industrial AreasDocument1 page2018-10-02 SIA Land Allocation Process For Strategic Industrial AreasHiddenDNo ratings yet

- Oakajee Master Plan 2Document8 pagesOakajee Master Plan 2HiddenDNo ratings yet

- Oakajee Master Plan 2Document8 pagesOakajee Master Plan 2HiddenDNo ratings yet

- MWT ONIC BrochureDocument3 pagesMWT ONIC BrochureHiddenDNo ratings yet

- Oakajee Structure PlanDocument1 pageOakajee Structure PlanHiddenDNo ratings yet

- 2017-02-08 Mid West Investment Opportunities Brochure LAND6435 - Single-PagesDocument28 pages2017-02-08 Mid West Investment Opportunities Brochure LAND6435 - Single-PagesHiddenDNo ratings yet

- Oakajee Structure Plan ReportDocument72 pagesOakajee Structure Plan ReportHiddenDNo ratings yet

- Committee of Council Agenda Apr 16Document150 pagesCommittee of Council Agenda Apr 16HiddenDNo ratings yet

- Cape Alumina Limited: Annual Report 2009Document39 pagesCape Alumina Limited: Annual Report 2009HiddenDNo ratings yet

- ExecutiveSummary EnglishDocument35 pagesExecutiveSummary EnglishHiddenDNo ratings yet

- Cape Alumina Limited: Annual Report 2009Document39 pagesCape Alumina Limited: Annual Report 2009HiddenDNo ratings yet

- Dean's Study Guide For CPPDocument27 pagesDean's Study Guide For CPPHiddenDNo ratings yet

- SingaporeDocument9 pagesSingaporeHiddenDNo ratings yet

- Management and Exploitation of Fisheries Resources in CameroonDocument70 pagesManagement and Exploitation of Fisheries Resources in CameroonHiddenDNo ratings yet

- 9 Alumina ProjectDocument13 pages9 Alumina ProjectHiddenDNo ratings yet

- Contractor Travel GuidelinesDocument4 pagesContractor Travel GuidelinesHiddenDNo ratings yet

- Dean's Study Guide For CPPDocument27 pagesDean's Study Guide For CPPHiddenDNo ratings yet

- Ostrich Nutrition and Management: Model To Form The Skeleton For Nutritional ResearchDocument14 pagesOstrich Nutrition and Management: Model To Form The Skeleton For Nutritional ResearchHiddenDNo ratings yet

- 2012004-Personnel Security in Remote WorkingDocument19 pages2012004-Personnel Security in Remote WorkingHiddenDNo ratings yet

- Management Problems in The Farming Ostrich PDFDocument7 pagesManagement Problems in The Farming Ostrich PDFamct1No ratings yet

- Manufacture of Sulfuric AcidDocument9 pagesManufacture of Sulfuric AcidDiajeng M.100% (1)

- Manufacture of Sulfuric AcidDocument9 pagesManufacture of Sulfuric AcidDiajeng M.100% (1)

- HL 5340D - HL 5350DN - HL 5350DNLT - HL 5370DW - HL 5370DWT - HL 5380DNDocument36 pagesHL 5340D - HL 5350DN - HL 5350DNLT - HL 5370DW - HL 5370DWT - HL 5380DNefreedunk6257No ratings yet

- Microcontrolador PIC16F628 - DatasheetDocument160 pagesMicrocontrolador PIC16F628 - DatasheetNandoNo ratings yet

- Web Duster HR 13 Aug 2020 12 Pager BrochureDocument7 pagesWeb Duster HR 13 Aug 2020 12 Pager BrochureTop TamilNo ratings yet

- Installation Instructions: Suzuki Samurai 1.3L Sidekick/Tracker Power Steering KitDocument44 pagesInstallation Instructions: Suzuki Samurai 1.3L Sidekick/Tracker Power Steering KitEdward GálvezNo ratings yet

- Smartglcd 240x128 Manual v151Document36 pagesSmartglcd 240x128 Manual v151garguz94100% (1)

- Product Recommendation John Deere 6020 Series 6420 ( - Nr. 398790) (2002-2003)Document3 pagesProduct Recommendation John Deere 6020 Series 6420 ( - Nr. 398790) (2002-2003)la la lalaNo ratings yet

- Datavideo MCU-100PDocument22 pagesDatavideo MCU-100PTomas VeteveNo ratings yet

- MTRL MasterDocument386 pagesMTRL MasterSourav MaitraNo ratings yet

- Hoists Spare PartsDocument46 pagesHoists Spare PartsWiesław WarnelNo ratings yet

- Compact & Supersilent: Elb43SdDocument2 pagesCompact & Supersilent: Elb43SdRodolfo Hernandez A.No ratings yet

- Activity 1.1.4 Pulley Drives and SprocketsDocument4 pagesActivity 1.1.4 Pulley Drives and SprocketsNate FrieslNo ratings yet

- 6 HeidolphDocument7 pages6 HeidolphCeleynes RTNo ratings yet

- Bi Cmos TechnologyDocument26 pagesBi Cmos Technologyjeevan432No ratings yet

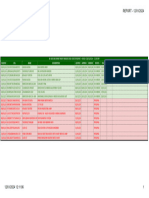

- Re-Refurb Parts Daily Status Report - Dated 12-01-2024-12-30-PMDocument1 pageRe-Refurb Parts Daily Status Report - Dated 12-01-2024-12-30-PMshylesh.raveendranNo ratings yet

- Parts Catalogue: CD DeluxeDocument52 pagesParts Catalogue: CD DeluxeJonathan FiquitivaNo ratings yet

- Control up to 4 or 6 speaker pairs with PSLSW4-PSLSW6 Multi-Zone Speaker SelectorDocument8 pagesControl up to 4 or 6 speaker pairs with PSLSW4-PSLSW6 Multi-Zone Speaker SelectorRosmiNo ratings yet

- Automatic Irrigation SystemDocument3 pagesAutomatic Irrigation SystemVijay MNo ratings yet

- Service Manual: Mobile TerminalDocument132 pagesService Manual: Mobile Terminalosmar rafael monsalve valenciaNo ratings yet

- CAT 2 ECE SchemeDocument2 pagesCAT 2 ECE SchemeLaaria ChrisNo ratings yet

- HI-8421, HI-8424: 6-Channel / 8-Channel Discrete-to-Digital Interface Sensing 28V / Open SignalsDocument5 pagesHI-8421, HI-8424: 6-Channel / 8-Channel Discrete-to-Digital Interface Sensing 28V / Open SignalsAnonymous 3mJfZENo ratings yet

- Powerrex BulletPro-BP40M-2-post-clear-floor-lift-4-ton-240V-user-manualDocument18 pagesPowerrex BulletPro-BP40M-2-post-clear-floor-lift-4-ton-240V-user-manualCykhong KhongNo ratings yet

- Technical Data Sheet For Air Washer Unit 10000 CFM AND 25000 CFMDocument3 pagesTechnical Data Sheet For Air Washer Unit 10000 CFM AND 25000 CFMSupport aeronomNo ratings yet

- All Wiring Diagrams For Nissan Sentra CA 2002Document63 pagesAll Wiring Diagrams For Nissan Sentra CA 2002tellossaposNo ratings yet

- Control BoardsDocument19 pagesControl BoardsRaul quispe quispeNo ratings yet