Professional Documents

Culture Documents

Ring and Pinion Construction Details

Uploaded by

havvkxjOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ring and Pinion Construction Details

Uploaded by

havvkxjCopyright:

Available Formats

Differcntiats 25 | front of four-wheel dr.iveaxles.

It's essentiallya mirror image hypoid desigrywhere the pinion is above dre centerlineof the ring gear instead of be1ow.In addition, the teeth are cur.vedin the oppositedirection, so the pinion, which turns in the opposite direction in front-drive applications, dlives on the stronger convex side of the teeth (more on this in a bit). What are tl.repractical differences? The spiral bevel design is noisier.and has more backlash than the hypoid design, but it runs cooler and createslessfriction. The hypoid design createsmore frictiory becausethe gear teeth actually slicle acr.oss each other as they mcsh. Hypoid offset, or the distance lrom the pinion centerlineand thc ring gear centerline,is variable. The advantageto a hypoicl design is

1/1/31-Ringand Pinion Construction Details

The ring gear, also kr-rownas the "crou,n" gear,and the pinion gear come in severalvariations. In curent times, three general types are common in car and light truck tealns-spiral bevei, hypoid, ancl reversecut (a.k.a."high pinion" or "reverse rotation"). In the simplest terms, they differ in that the centerline of the pinion is at the center'line the ring gear on a of spiral bevel design and belotv the centelljnc for a hypoid design. A variant of the hypoid is the reverse-cutling gear, which is designed{or.the

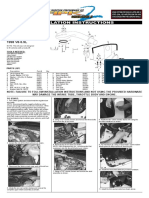

Ringand pinionsets come in everysizeand configuration. Here's Ic$,from DanaSpiccr a and one fromAMC. t-oplql: DanaSpicer (7.7sinch),DanaSpicet (7.12inch),Dafa Spjcer (/.12inch),DanaSpicer 2s 27 l0 fr_ol jf+], Danaspiccr44 (B.sinch), AMC 20 (8.88inch)DanaSpicer (9.2sinch)and DanaSpiccr60 s3 _4] -(9.: l'l 75 irrlhL I generJl,thc lrrser the rinSgcar,the stourer Lrntt. rhe Thatstatement doesn,t alwaysapp y io o)d vs ne$,The DanaSpicer hd! a smaler ringgcarthanthe DanaSpicer for exampte, the 30 is ilronger J0 25, but in everymeasurableway.NotealsothedilferencesinthelinongeJreSurnerreleqcni.rIindicatingalow( i . " l \ \ r 8 l r . l i o O n p a d r p J r B pr o , " i r g , ' g h r . - r r p r i ,I r o , r . o .

26 | DiJ.ferentials that the pinion is larger in diameter and provides greater tooth contact, which means the load is spreadout over a larger areaof the teeth. ]n More steelmakesfor a stronter gearset. additiory a larger hypoid oflset changes the load angle on the pinior1 teeth, whjch also adds to gear strength.More or lesshypoid offset results ir-r morc or lesstooth contact,but there are some in disadvantages terms of friction and parasitical More offset is often used in hear'y-duty drag. axleswhere 1ow gear ratios are needed, Thc leverse-cutring geal was designedfor in front axles,whjch totate in the opposite use direction of the rcar.Prior lo this, rear axleswere used up fiont, which meant they were ddving riJe of the ring gc.rr. on the coast (concave) Using it this way makes it flom 15-30percent weaker when driving forward. To give back the lost sbrength,the reversc cut ring gears were dcsignedso that they drive or1the convexside of the geal. The pinion is usually above the ring which may also be an assetto gear centerJine, driveline ang)esin some modified 4x4 setups. Not all manufacturersadopted this desigq but many Ford, Chevy and Jeep 4x4s are so equipped. ln recent years, the amboid gearset has beendevelopedfor large trucks.This type places the pinion abovethe centellinebut in a standard rotation. Arvin-Meritor (formerly Rockwell) is currently using these gearsetson tandem axle applicationsto reduceddveline vibration due to driveshaft angles.We may somedayseeamboid in gearscts light-duty vehicles. The gearratio is determinedby the number of teeth on the ring gear divided by the number of beethon the pinion geal. For example,a ring gear with 43 teeth combined with a pinion that has 13 teeth iesults in a 3.31:1ratio. The variety of ratios is not infinite, but axleswith larger ring gears tend to havc a wider range. There are strengthand size issuesinvolved in too many or too few teethon eitherthe ring or pjrliongears. The ring and pinion gears are constructed of a hard a1loysteelmaterial,most often an SAE 8620alloy that is heat treated to spec according to eachmanufacturer'sstandards.The quality of the 8620steelmay vary as will the heat treating, so there is a quality gap in some cases. There are "Race OnJy" fing and pinions that are made of 9310and the heat treatment is different.They are softer than a standardR&P to be better able to absorbshock loadin& but they wear out much more quickly. For a race car that gets only a few hundred miles per year or an wear is not an issue. overhaul after every season, A streetcar is another story.Unlessyou racetl-re vehicle,stay away from thesegearsets. The designand diameterof the pinion shaft and the method of attachingthe driveshaftyoke is important to strength.Lefs stad with pinion mountings. A pinion that has no support bearings at its gear end is said to be overhung. Most for cut ls The reverse fing gear(right) designed use in the T r r n - ' n . , t s H differentials use an overhung pinion. Higher t , o r n r ( n r- \ h p , l d r l e d p n r i o r . l l o r q u e u n i l . . o m e l i m e " f e a t u r ea r l r a d d l e built to drjve off the stronljerconvexs de of lhe reeih.This avoids a Loss strengththat comes from drjvjng on the oi mounted pinioq which means they have an side coan (concave) of the rifg gearwhen the axle is used a d d i l i o n a l- u p p o r l b e d r i n Sa t t h e g e a r e n d . be on couLd up froni.Depending whomyoutalkto, thalloss Well-known examplesof straddle-mountedpintrom 15 to 30 percent. anywhere

Diffen tiLlts |

)7

In sonre nslanccs/ spilccrs Ltsecl lhc alternrarkct arc by lo nomoloBate carricrb a numberof clilferenl fg gcar ofe I thickfesscs. wofks,anclsot'nct I mes is necessar),, we DUr Lhinkil's af inelegant 5oluliofthal lntroduces sorncprob, l \ ' , 1. e . o l r l r . r l . I r p . : 1 8b , . r L"t r "io , . ., ."rr E o ,- -^r,.,. ,r t. .r. t,t^r ., hp, , . .. t ,. (.1,. .,. to , o exressive gea rlrnoutarld redrctio| ir Lhcc amprg ring a cfleclthat is th. primary ffeansol holding gearr ghrlt thc aganstthe I lange.

i1 :.1r.r'i i88a.-uiir: .,. r,r,'."r'r.

ions t'ould include the Ford 9-inch dropout and the older versjon of the GM/Saginar//AAM "L4-bolt" full-floater These designs 10.S-inch also feature a removablepinion bearing retainer housing. As with axle shafts, the larger the pinion, Lhc more lnput torque the unit can handle (assumingthc rest of the axle is up to the same spec). to splines, same As the rulesapply aswith axles. More splines increase the minor spline cliameieranclmake for a sh.onger piece. Gear ratios actually affect rint and pinion gear strength. The lon'cr (rumerically higher.) you go in a gearsetwith a ring gear of a given diarnetet the weaker the gearsctbecomes.you can make tl-reratio lou,er by having more teeth on both the gears,but you will have to make the teeth smaller and weaker.The ncxt possibiljty is to decrease the number of teeth on the pinion. This reduces tl'te amoultt of tooth conrac, so rnor:estressis being put on less material. In a high ratio gearset,there may effectively be two or more teeth irr nesh wjth the ring gear at any given moment.As the pinion gear getssmalleL the contact may be reduced to the point where you have only one tooth in mesl-r any gtven at time. In the leal world, manufacturers reduce tooth size and number to raise strength,but it,s better io upgrade to an axle with a larger.ring

Here are very cear visual definitions for ',carrier brea(.,, Because p nion gcargeh srnaller arger Inc axterato the or as changes, location the ring gearface cranges. the you can of compensaie simplt making ringgearthickJr thinner, by the or o b 1^.ir- 1." ,g ga" rorr.i].r' ,,g ur rl-.," i,. '.,14-- boh \.,\, r h. \F{.r n \^T. ,orfJ|i .l-,\dec .l-..1 they preferLosavethe re ativey expensive 8620 al oy i,rB"'r' l",.,rlalr. np

O'tF oTUd t.-. ,Loo..1. to oTp i.dra tlei

by ma<nB and invcntorying several ianiers for each axle

I t. r^*

18 I

ofiset thirn b go to a and,/or rrorc h)'Poic1 Eiear an supel loiv ratio or-r irxlc \\'ith a snall rillg gear' fhe method of attaching the ring g,ear hl the cafriel is 1\'o1th.rfew \vofds. lbda\i viltr-1al b\. 11, everl unit is attachecl bolts ln the not too Eiihel \\'i]\', distant pilst, rivets \\ere also Llsecl. colrlr(\'tionf|1)nr thesepiecesnle pirrt of a clircat the fing qe.rr io the calrier and acceptthe tolque b)'lhe gcar latio Thc! thrt has bccn mr,rliiPliecl Their nLrnllrer arc usuall)' Ell.rLlc,b(tls, or Lretter' .lr1cl sizc is clctcrmirrcrlLrl'thc tlialnetcl ol the line gcaf and ihe nmount of lor'qllc tlle ilxle is clcsignetl io hi'ttrcllc.

l ) r , I r ) ( r ( ( ( i r r r ( 1 l i . r rl r Lr r ,r\ r ' rr ) l r L r1 r , l r r ) r5 5 1r) r ) r1 r r , r | * r , r , r s r ,\ ( l r : . 1 ! ( , l , r L (l1 ) l l r ( l ) l I , r r r I r ( ' \ / ( ' 1 i L r I l L l o f L \ u s r r o r i l r { ' ( l i ! ( ' s l r , r: l , r r r ( 1r { . / ( ' , r r ( l l l l x o r r ( < l r r o r r r r , r r I l r r l r r ' ! i r , r r r t r LrL r l ,i,i,,', ,,,., ,,r' r , , , , l , , " 1 , , r r . r r k r l L r : r 'l ( , , L , r i i r r r ( )s L \ ' ( ' r r r | l n r , r r r ' ,,, l l r ( L l ) , , 1 1 r ' l ( ' L r, r r 1 1 i l r ( ' \,lr ) L ! x ' \ f l r r ' l i r r I i r r i t \ srr' Lil'L l)l)l L!ir'\ , l,Lirullr fri,r,,, I(''\l)r1r1) L!! ( L r l ) 1 ! , L r k l\r ( ' L r l ) i1 ! ( r ) l i { ' rI r, rr rlrrrr L ,,i ri(\ 11, L ' , L t r s L. r r \ ! ( \ ' r r r r r l j r L | r r r r ( j I r ! ( ' r , r \ ! r L r',',', t ( l l \ L l ) r L i r , ! rI r ' ( , i r 1 L r ( ' , , r r ' r r r r | , r l \ r i r r l ' r , r r rl r . rr 1 r ' r , i , , i r L , , l n , r i r r r { 1, r L ( , r l l t L r L ( ) r i n | r ! i l ) r , rllr r j i l ) L r l . r 1 r , c r r r , r ' l r I r , L ) , , 1 ! 1\ i / , 1 \' ! ! , l ! 1 1 llr\ r \ t r 1 )l i t r ( '

1/1 /3K- Differential Construction Details

r s L l i l l ' t ' r e r t t i cr l) t t s i s t ( ) l n l l L l n l L ) co f r( r l i l l ' f f ( ' r l t i , lrrl , l sh ) L r ( ' A \ p . r r i s . s x n . r s s t ' n r b 1L'l,l c if's slouI be..rLrsL' ihr' io(ltlc corlrlc.li(]llbcl!{c('n l L h cr i r r gg , r ' . r r . r nttlll c . r r l c s .I i c n l c n r b e r , r l s tL lra t Ltrlvt h c f i r r g. r r l . l h t l r i sl { r f r l u c r s b e e r rn r L r l t i P l i L ' g c r| [ r i i o . pini()n fhc aarricf is i c.lsi of 1(rrgL'd l)lcce l() il l r l ! l i l . ( ) r l l ; 1 i r r s r ! h i c h i h c r i n g g c a r 1 sr t t n a h c c singlc piccc, thc tlil'fcrcniialgcals. lt's r.rsrrallv,r that Lrolt Lnl sL)lIccarricrsdlL'of rrlultiPlcPjc'cc's icrgcilrc.r'. rc rliffcrcntill Pirlions, of "sPrder ' L i r l . . | | . | . . . ,I r . r t , t l r " . lr' ' Lritr i.'r " r ' l .l ifiL'r'er1or "spiclel sh.ii." \lost stanll.fcl oPen iials car|v t$ro pinjorls, u,hilc hcavv clLriv.ules morc spoceln tht'calwith l.lrge ring geals (arrcl '' '1 ' i . r . ' f l .r r . r f ) "' In I llrc. -\'. r1 .'i Lrestout and ihey arc folgecl,heilt trcaied, high made of Irigh Ihc crossshaft is .t1so qu;r1itv stccL. clualitv allo,v sieel thirt is surfacc haldcnccl. The side geals arc splinctl to the arLesancl ale of ihe samc matefial ils tllc pilliolls 'l'hc

,F

t l ' e r h . t r sh e L r s L. . f n f r l o r b e t \ r r f r L r e d i ! u s h n i t a n r t ; q i o l ' . eL , i t ' * , n n t e dr . rr g e sm . ii f i ( r r a s t r oq ' , ' , r o i i e no n a t e r . o . l e l F o r l r ! . l L r 1 s , r r . li n l r o ' T r . l

i h . r r r r i o l r s l h e ' o n r ' l n o r i l i f , q e f o ! s l o u tl r o l c . r n . lt h c c . r1 1 l lrss':ofr no rll ce-'f . rrr runr ) I g"'r r "ee\rc'i\!erfd f e d r o rn ' o L P o oi n iierent.lt veqhiil I r ' 8 r ' f \ "L r f q rl r r r e e l

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- How To Make An Effective PowerPoint PresentationDocument12 pagesHow To Make An Effective PowerPoint PresentationZach Hansen100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Vertical Cutoff WallsDocument18 pagesVertical Cutoff WallsMark LaiNo ratings yet

- Categories of Cargo and Types of ShipsDocument14 pagesCategories of Cargo and Types of ShipsVibhav Kumar100% (1)

- Chapter S1 (Celestial Timekeeping and Navigation)Document28 pagesChapter S1 (Celestial Timekeeping and Navigation)Марко Д. Станковић0% (1)

- NCPDocument6 pagesNCPJoni Lyn Ba-as BayengNo ratings yet

- AVH-X8700BT Manual ENDocument164 pagesAVH-X8700BT Manual ENhavvkxjNo ratings yet

- Spis Czesci Skrzynie A518 A618 46re 46rh 47re 47rh 48reDocument7 pagesSpis Czesci Skrzynie A518 A618 46re 46rh 47re 47rh 48rehavvkxjNo ratings yet

- KNN 57 1506 2 - InstDocument2 pagesKNN 57 1506 2 - InsthavvkxjNo ratings yet

- Axle Shaft Strength ChartDocument1 pageAxle Shaft Strength CharthavvkxjNo ratings yet

- Common Steel Groups For AxlesDocument3 pagesCommon Steel Groups For AxleshavvkxjNo ratings yet

- Axle Shafts Construction DetailsDocument5 pagesAxle Shafts Construction DetailshavvkxjNo ratings yet

- M.Sc. Steel Structures LEC. #7 Plastic Analysis and Design: Dr. Qasim Shaukat KhanDocument43 pagesM.Sc. Steel Structures LEC. #7 Plastic Analysis and Design: Dr. Qasim Shaukat KhanSSNo ratings yet

- Dash8 200 300 Electrical PDFDocument35 pagesDash8 200 300 Electrical PDFCarina Ramo LakaNo ratings yet

- Load Schedule: DescriptionDocument1 pageLoad Schedule: Descriptionkurt james alorroNo ratings yet

- B.e.eeeDocument76 pagesB.e.eeeGOPINATH.MNo ratings yet

- A Tall Order - Cooling Dubai's Burj Khalifa: FeatureDocument2 pagesA Tall Order - Cooling Dubai's Burj Khalifa: FeatureMohsin KhanNo ratings yet

- Teal Motor Co. Vs CFIDocument6 pagesTeal Motor Co. Vs CFIJL A H-DimaculanganNo ratings yet

- Phenomenology of The SelfDocument5 pagesPhenomenology of The SelfGuilherme CastelucciNo ratings yet

- Motion To Dismiss Guidry Trademark Infringement ClaimDocument23 pagesMotion To Dismiss Guidry Trademark Infringement ClaimDaniel BallardNo ratings yet

- MPPSC ACF Test Paper 8 (26 - 06 - 2022)Document6 pagesMPPSC ACF Test Paper 8 (26 - 06 - 2022)Hari Harul VullangiNo ratings yet

- Different Principles Tools and Techniques in Creating A BusinessDocument5 pagesDifferent Principles Tools and Techniques in Creating A BusinessLuna LedezmaNo ratings yet

- 377 Situational Expression Advanced Level Test Quiz Online Exercise With Answers 1Document7 pages377 Situational Expression Advanced Level Test Quiz Online Exercise With Answers 1zdravkamajkicNo ratings yet

- Chapter 3 Depreciation - Sum of The Years Digit MethodPart 4Document8 pagesChapter 3 Depreciation - Sum of The Years Digit MethodPart 4Tor GineNo ratings yet

- Chandigarh Distilers N BotlersDocument3 pagesChandigarh Distilers N BotlersNipun GargNo ratings yet

- LP MAPEH 10 1st Quarter Printing Final.Document29 pagesLP MAPEH 10 1st Quarter Printing Final.tatineeesamonteNo ratings yet

- Certificate of Attendance: Yosapat NashulahDocument2 pagesCertificate of Attendance: Yosapat NashulahStrata WebNo ratings yet

- Catch Up RPHDocument6 pagesCatch Up RPHபிரதீபன் இராதேNo ratings yet

- Tutorial 3 MFRS8 Q PDFDocument3 pagesTutorial 3 MFRS8 Q PDFKelvin LeongNo ratings yet

- ADMT Guide: Migrating and Restructuring Active Directory DomainsDocument263 pagesADMT Guide: Migrating and Restructuring Active Directory DomainshtoomaweNo ratings yet

- Assignment 4 Job Order Costing - ACTG321 - Cost Accounting and Cost ManagementDocument3 pagesAssignment 4 Job Order Costing - ACTG321 - Cost Accounting and Cost ManagementGenithon PanisalesNo ratings yet

- CNC - Rdmacror: Public Static Extern Short Ushort Short Short ShortDocument3 pagesCNC - Rdmacror: Public Static Extern Short Ushort Short Short ShortKession HouNo ratings yet

- EvolutionCombatMedic 2022Document17 pagesEvolutionCombatMedic 2022smith.kevin1420344100% (1)

- Coc 1 ExamDocument7 pagesCoc 1 ExamJelo BioNo ratings yet

- Crusader Castle Al-Karak Jordan Levant Pagan Fulk, King of Jerusalem MoabDocument3 pagesCrusader Castle Al-Karak Jordan Levant Pagan Fulk, King of Jerusalem MoabErika CalistroNo ratings yet

- Course: Introduction To Geomatics (GLS411) Group Practical (2-3 Persons in A Group) Practical #3: Principle and Operation of A LevelDocument3 pagesCourse: Introduction To Geomatics (GLS411) Group Practical (2-3 Persons in A Group) Practical #3: Principle and Operation of A LevelalyafarzanaNo ratings yet

- Rate If Iodine and PropanoneDocument3 pagesRate If Iodine and Propanoneshareef1No ratings yet