Professional Documents

Culture Documents

A Criterion For Modelling Initiation and Propagation of Matrix Cracking and Delamination in Cross Ply Laminates Rebiere 2004 Composites Science and Technology

Uploaded by

VU Dinh-QuyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Criterion For Modelling Initiation and Propagation of Matrix Cracking and Delamination in Cross Ply Laminates Rebiere 2004 Composites Science and Technology

Uploaded by

VU Dinh-QuyCopyright:

Available Formats

A criterion for modelling initiation and propagation

of matrix cracking and delamination in cross-ply laminates

J.-L. Rebiere

a,

*

, D. Gamby

b

a

Institut dAcoustique et de Mecanique, Universite du Maine, Avenue Olivier Messiaen 72085 Le Mans Cedex 9, France

b

Laboratoire de Mecanique et Physique des Materiaux, ENSMA, Teleport 2, 1 Avenue Clement Ader, BP 40109,

86961 Futuroscope Chasseneuil Cedex, France

Received 27 November 2003; received in revised form 25 March 2004; accepted 30 March 2004

Available online 14 May 2004

Abstract

A variational approach is used to model the behaviour of composite cross-ply laminates damaged by transverse, longitudinal

cracking and delamination. An energetic criterion is proposed. It is based on the strain energy release rate associated with each of the

three damage modes. The rst part of this paper is concerned with the modelling of the transverse and longitudinal cracking. In the

second part, a model for studying delamination damage is presented. The numerical results showthat these models provide a consistent

level of accuracy for a variety of thin laminate material systems and congurations, with various combinations of delaminations and

matrix cracks. In this paper several numerical simulations meant to describe initiation for each damage mode are proposed. The es-

timationof damage modes contributions is achievedfor twothinlaminates inorder topredict the evolutionof damage mode transition.

2004 Elsevier Ltd. All rights reserved.

Keywords: A. Polymer-matrix composites; B. Matrix cracking; C. Delamination; Damage mechanics; D. Life prediction

1. Introduction

The ultimate failure of a laminate follows the occur-

rence of two or three damage mechanisms and bre

breaking. Usually, these three main damage modes are,

rst, transverse cracking, later longitudinal cracking

and/or delamination. Experimentally, it was observed

that the order and initiation time of each damage mode

are governed by the following parameters: the laminate

geometry, for example the thicknesses of the dierent

layers [1,2], the nature of the bre/matrix constituents,

the loading history and the cycle of fabrication [3,4]. The

rst part of this study investigates the inuence of matrix

cracking (transverse and longitudinal) on the mechanical

properties of a cross-ply laminate. In the second part,

delamination is studied and in the third part examples of

damage mode succession are proposed. This study was

prompted by experimental results [513]. In experimen-

tal loading conditions (monotonic and fatigue tests), the

results [513] show that the rst damage mode is usually

transverse cracking. Two particular states can cha-

racterise this damage mode: its initiation or occurrence

of the rst transverse crack called rst ply failure

(FPF) on one hand and the limiting state when no more

transverse crack can be created, named characteristic

damage state (CDS) on the other. Afterwards, it was

observed that the nature of the second damage mode

depends on the three above parameters. For example, in

a thick laminate, the authors of [59] observed the ini-

tiation and evolution of delamination. Ply separation is

caused by the increase of the normal stress r

zz

and of the

interlaminar stress r

xz

. For thin laminates, the damage

mode succession is dierent. Some authors [5,1014]

observed that the second damage mode, which follows

transverse cracking, is longitudinal cracking. In this

case, local delamination appears between 0 and 90

layers, near the crossing of longitudinal and transverse

cracks, only when longitudinal cracks are widespread. In

each case, the accumulation of the dierent damage

*

Corresponding author. Tel.: +33-2-43-83-34-75; fax: +33-2-43-83-

31-49.

E-mail addresses: jean-luc.rebiere@univ-lemans.fr (J.-L. Rebiere),

gamby@lmpm.ensma.fr (D. Gamby).

0266-3538/$ - see front matter 2004 Elsevier Ltd. All rights reserved.

doi:10.1016/j.compscitech.2004.03.008

Composites Science and Technology 64 (2004) 22392250

www.elsevier.com/locate/compscitech

COMPOSITES

SCIENCE AND

TECHNOLOGY

modes (two or three damage modes present within the

laminate volume) causes bre breaking in the 0 layers.

All bre breaks entail splitting which appears just

before the ultimate failure of the laminate.

For modelling the strain/stress relationship during

damage growth, analytical and numerical approaches

have been proposed. Several models describe the initia-

tion of the rst damage mode. They mainly rely on some

stress eld distribution and a relationship between

loading and crack density is usually proposed. The sim-

plest models, called shear lag analysis [9,1518], are

generally displacement-based approaches. Other models

such as variational approaches, whose principles are

explained in [19,20], use the principle of minimum com-

plementary energy [2126]. Other studies rely on the -

nite element method [2729]. Alternative models are

based on phenomenological approaches [3035], self-

consistent analysis [36,37] or approaches that use specic

aspects of the cracks patterns [38]. Local delamination is

often described by two-dimensional models. This is the

case of the nite element study of Wang et al. [12]. We

can also cite the works of Nairn and Hu [39], based on a

variational approach in which the interaction between

transverse cracks and local delaminations, which appear

near crack tips, is described. Hashin [40] analyses lon-

gitudinal and transverse cracking through a variational

model, with a restrictive hypothesis of constant normal

stress distribution through the thickness of each dam-

aged layer. Binienda et al. [41], who propose a nite el-

ement approach, use the same energy criterion. For

modelling the initiation of the second and/or third

damage mode, several criteria were used. For instance, to

our knowledge, no criterion has been proposed for the

initiation and growth of longitudinal cracking, except in

the works of Binienda et al. [41] who computed the strain

energy release rate in a cross-ply laminate with a pre-

existing longitudinal crack. The main reason for this lack

of attention is that longitudinal damage appears only in

laminates having some specic thickness ratio and

stacking sequence. Moreover, when longitudinal matrix

cracking appears, it is generally shortly before the end of

the laminate life. On the opposite, for describing de-

lamination damage evolution, several criteria have been

proposed. Most of them either involve local stress values

or strain energy release rate associated with the damaged

area (or a parameter related to the damage surface). The

works of Sch on et al. [42] are based on an energy ap-

proach. For these authors, the strain energy release rate

is a good measure of the material resistance to delami-

nation growth. Two dierent delamination modes can be

observed according to the loading history, monotonic

loading (sudden loading) or fatigue loading. The above

authors conducted tests on DCB specimens. They

showed that the strain energy release rate associated with

delamination is not the same for static and fatigue tests.

Other models involve critical stress values. Marion

et al. [43] propose a quadratic stress criterion using the

value of the interlaminar stress at a characteristic dis-

tance of the interface. Leguillon et al. [44] compare the

stress criterion of [44] with a stress criterion based on the

mean shearing stress value only. There is a major ob-

stacle to the use of a delamination criterion based on a

maximum stress value along a debonding edge [44]. In a

model with homogenised layers and perfect interfaces,

the stress eld is singular as already mentioned: stress

components take on innite values at the intersection of

the interface and free edges. Even if these values remain

nite when computed, they are irrelevant. To overcome

this problem, Whitney and Nuismer [45] introduce a

characteristic length like Marion et al. [43]. Kim and

Nomenclature

a longitudinal half crack spacing

A

d

interlaminar delaminated area

A

f

intralaminar cracked area

b transverse half crack spacing

d

x

delamination length in the longitudinal di-

rection

d

y

delaminationlengthinthe transverse direction

k constraint parameter

h ply thickness

G strain energy release rate

G

FT

strain energy release rate associated with

transverse cracking

G

FL

strain energy release rate associated with

longitudinal cracking

G

dx

, G

dy

strain energy release rate associated with

delaminated length d

x

or d

y

G

c

critical strain energy release rate

G

crf

cracking critical strain energy release rate

G

crd

delamination critical strain energy release

rate

k ply index

L

1

laminate length in x direction

L

2

laminate length in y direction

m number of longitudinal cracks

n number of transverse cracks

S

ijkl

local compliances

t

0

0 layer thickness

2t

90

90 layer thickness

U

d

deformation energy of the whole laminate

U

cel

deformation energy of the unit damaged

cell

V volume of the half unit cell

2240 J.-L. Rebiere, D. Gamby / Composites Science and Technology 64 (2004) 22392250

Sony [46] connect this distance with the layer thickness

modied by a factor varying from one to two. Brewer

and Lagace [1] and Lecuyer [47] assume that this distance

should be independent of the layer thickness, and that

the factor must be determined from experimentations.

We can also cite the works of Diaz-Diaz and Caron [48]

who propose a model for laminates with free edges in

uniaxial loading. In their approach, the edge singularity

is smoothed out. A simple shear stress criterion is pro-

posed and validated for two h

n

s

laminates. These

authors obtain critical values of the interlaminar shear

stress that depend on the thickness ratio of the layers but

do not depend on the layer orientations. To conrm this

result, they also performed a calculation with a criterion

based on the strain energy release rate.

In this section, we report experimental observations

concerning the dierent damage modes. Various ana-

lytical and numerical models are proposed for the

analysis of the stress eld during the evolution of the

damage. Some damage criteria, a stress based approach

and an energetical approach are described. In this arti-

cle, a damage initiation and growth is proposed.

A variational approach gives the stress eld necessary to

derive the strain energy release rate associated to each

damage mode. The inuence of the three damages

modes (transverse cracking, longitudinal cracking and

delamination) is studied. Using the proposed model, our

objective is to predict the successive occurrence of sev-

eral damage mechanisms during the life of a laminate.

We also studied the inuence of laminate architecture on

damage mechanisms and life prediction.

2. Matrix cracking modelling

The proposed analytical model is based on a varia-

tional approach for 0

m

; 90

n

s

cross-ply laminates

(Fig. 1). The parameter related to the lay up architecture

is kk t

0

=t

90

m=n where t

0

is the thickness of the 0

layer and 2t

90

is the thickness of the 90 layer. Experi-

mentally, as explained in the previous section, the fol-

lowing succession of damage modes can be observed.

The transverse cracking is the rst damage mode oc-

curring in the 90 layers. The cracks are supposed to

have a rectangular plane geometry and all cracks span

the whole width of the laminate plate and the whole

thickness of the 90 layers. Dierent damage mecha-

nisms are observed in the second damaging step which

occurs in this type of laminate. It can be delamination or

longitudinal cracking. Under some circumstances, lon-

gitudinal cracks appear in the 0 layers and they are

supposed to obey the same hypotheses as transverse

cracks. The distribution of longitudinal and transverse

cracks as well is supposed to be uniform in the two

x and y directions.

With the previous hypotheses related to the trans-

verse and longitudinal distributions and geometry of the

cracks the laminate damage can be described by the

unit damaged cell displayed in Fig. 2. This unit

damaged cell is situated between two consecutive

transverse cracks and two consecutive longitudinal

cracks. The geometrical hypotheses will be described

later.

The variational approach is based on the proper

choice of a statically admissible stress eld. The starting

point is the distribution used rst by Vasilev and

Duchenco [21], later by Hashin [22] and then by Varna

and Berglund [25]. However, we also take into account

the variation of the stress eld through the thickness of

the laminate damaged by transverse and longitudinal

cracks.

The stress eld in the two layers of the laminate has

the following form:

2 a

2 b

t

0

2 t

90

2 h

Longitudinal

Cracks

Transverse

Cracks

Triangular

Delaminated

Area

Uniaxial loading

z

y

x

Fig. 1. Laminate damaged by transverse and longitudinal cracks and delamination.

J.-L. Rebiere, D. Gamby / Composites Science and Technology 64 (2004) 22392250 2241

r

Tk

ij

r

0k

ij

r

Pk

ij

: 1

For an undamaged laminate loaded in the x direction,

the layers are in an uniform plane stress state r

0k

ij

ob-

tained by the laminate plate theory, where k is the ply

index k 0; 90. Orthogonal cracks induce stress

perturbations in the 0 and 90 layers which are denoted

r

Pk

ij

.

In order to verify all the following boundary condi-

tions, we must use the hypothesis of uniform stress

distribution in the thickness of the 90 damaged layer. In

the 0 layers, the stress distribution through the thick-

ness is not uniform. The normal stresses have the fol-

lowing form:

r

90

xx

r

090

xx

1 /

1

x; r

90

yy

r

090

yy

1 w

1

y;

r

0

xx

r

00

xx

1 /

2

xuz; r

0

yy

r

00

yy

1 w

2

y:

2

The unknown functions are /

1

x, /

2

x, w

1

y, w

2

y

and uz. The overall equilibrium conditions in the

damaged laminate give:

r

090

xx

t

90

r

00

xx

t

0

r

90

xx

t

90

r

0

xx

t

0

r

0

h;

r

090

yy

t

90

r

00

yy

t

0

r

90

yy

t

90

r

0

t

0

0:

_

3

Using dimensionless quantities, x x=t

90

, y y=t

90

,

z z=t

90

,

h h=t

90

, a a=t

90

,

b b=t

90

and k t

0

=t

90

in

the previous Eqs. (2) and (3), we obtain:

r

90

xx

r

090

xx

1 /x; r

90

yy

r

090

yy

1 wy;

r

0

xx

r

00

xx

r

090

xx

k

/xuz; r

0

yy

r

00

yy

r

090

yy

k

wy:

4

Eq. (3) will be veried if the following condition is

imposed

_

h

1

uz dz k: 5

The three sets of boundary conditions presented in

Fig. 2 are:

Antisymmetric shear stress distribution:

r

90

xz

x; y; 0 r

90

yz

x; y; 0 0: 6

Traction continuity across the 0/90 interface:

r

90

xz

x; y; 1 r

0

xz

x; y; 1;

r

90

yz

x; y; 1 r

0

yz

x; y; 1;

r

90

zz

x; y; 1 r

0

xz

x; y; 1:

7

The upper face of the laminate at z h is stress free:

r

0

xz

x; y;

h 0; r

0

yz

x; y;

h 0;

r

0

zz

x; y;

h 0:

8

In this model, r

xy

is neglected in the whole laminate.

This hypothesis was brought out after several numerical

simulations with a nite element model and other

models [4]. So, with this hypothesis, the stress eld in the

two layers of the damaged laminate is as follows:

The stress eld in the 90 layer is such that

r

90

xx

r

090

xx

1 /x;

r

90

yy

r

090

yy

1 wy;

r

90

zz

r

090

xx

d

2

/x

dx

2

R

z

2

2

_ _

r

090

yy

d

2

wy

dy

2

h z

2

;

r

90

xy

0;

r

90

yz

r

090

yy

dwy

dy

z;

r

90

xz

r

090

xx

d/x

dx

z:

9

The stress eld in the 0 layers has the following form:

r

0

xx

r

00

xx

r

090

xx

k

/xuz;

r

0

yy

r

00

yy

r

090

yy

k

wy;

r

0

zz

r

090

xx

k

d

2

/x

dx

2

u

II

z

r

090

yy

2k

d

2

wy

dy

2

h z

2

;

r

0

xy

0;

r

0

yz

r

090

yy

k

dwy

dy

h z;

r

0

xz

r

090

xx

k

d/x

dx

u

I

z:

10

The constant R is obtained with the continuity Eq. (4)

and is such that R

u

II

1

k

1

2

with u

I

_

uzdz and

u

II

_

u

I

zdz.

2 a

2b

t

0

2 t

90

Transverse Cracks

Longitudinal Cracks

Fig. 2. Unit damaged cell with transverse and longitudinal cracks.

2242 J.-L. Rebiere, D. Gamby / Composites Science and Technology 64 (2004) 22392250

The boundary conditions for the stress eld in the

damaged unit cell are:

/a w

b 1; /

0

a w

0

b 0;

where

/

0

x

d/x

dx

; /

00

x

d

2

/x

dx

2

and

w

0

y

dwy

dy

; w

00

y

d

2

wy

dy

2

; 11

u

I

h u

II

h 0; u

I

1 k; u

II

1 k R

1

2

_ _

:

The complementary energy functional has the fol-

lowing form for a half unit cell, in a laminate subjected

to a tensile loading in the 0 direction

U

c

_

v

S

ijkl

r

ij

r

kl

dv; 12

where S

ijkl

are the local compliances, r

ij

is the admissible

stress eld and V is the volume of the half unit cell such

that jxj 6a, jyj 6b and jzj 6h. Hashin [22] showed that

for any elastic body containing cracks, the comple-

mentary energy can be expressed in the form

U

d

U

c

U

0

. All the details concerning the expressions

of the complementary energy and the /, w and u

functions are given in Appendix A.

The strain energy release rate G associated with the

initiation and development of damage for a given stress

state is dened by:

G

d

~

U

d

dA

_ _

r

; 13

where

~

U

d

is the strain energy of the whole laminate and

A is the damaged area. Let L

1

denote the length of the

laminate in the x direction, L

2

being its width in the y

direction. The strain energy of the whole laminate and

the numbers n and m of transverse and longitudinal

cracks, respectively, are such that

~

U

d

nmU

cel

; 14

where

n

L

1

2at

90

; m

L

2

2

bt

90

: 15

The intralaminar (transverse and longitudinal) cracked

area A

f

is such that

A

f

L

1

L

2

1

a

_

1

b

_

: 16

We will distinguish between the strain energy release

rates associated with dierent damage mechanisms. The

strain energy release rate associated with transverse

cracking is denoted G

FT

. The strain energy release rate

related with longitudinal cracking is denoted G

FL

. The

G

FT

and G

FL

expressions are:

G

FT

d

~

U

d

dA

f

d

~

U

d

da

da

dA

f

; G

FL

d

~

U

d

dA

f

d

~

U

d

d

b

d

b

dA

f

: 17

Using Eqs. (14)(17), the strain energy release rates

associated with transverse or longitudinal damage are

such that

G

FT

1

2

bt

2

90

U

cel

_

a

dU

cel

da

_

;

G

FL

1

2at

2

90

k

U

cel

_

b

dU

cel

d

b

_

:

18

3. Delamination modelling

Experimentally, local delamination can also appear in

some laminates [43,46]. According to the proposed

model, the delaminated area is supposed to have a tri-

angular shape (Figs. 3 and 4). This damage occurs at the

intersection of the longitudinal and transverse cracks.

Experimental results conrm that the initiation of local

delamination takes place at the 0/90 interface, near

transverse and longitudinal crack tips and the intensity

of the interlaminar stresses is enhanced close to the

crack planes. The damaged laminate can be represented

by the unit delaminated damaged cell displayed in

Fig. 3. In the unit delaminated damaged cell the del-

aminated area consists of two distinct areas at the 0/90

interface: In Fig. 4, area I is the undamaged area and

delaminated area II has a triangular shape. The dela-

minated area is dened by the d

x

and d

y

parameters. The

hypotheses and derivation are explained in [49]. In [47],

the authors used the same hypotheses in a multipartic-

ular model.

With the previous hypotheses, the stress eld in the

delamination area is such that

r

90

xx

r

90

yy

r

90

zz

r

90

xz

r

90

yz

0: 19

Therefore, the stress eld in the delamination area

(triangular area II) is such that

/x wy 1; /

0

x w

0

y 0; /

00

x w

00

y 0:

20

2 a

2 t90

t0

2 b

Transverse

Cracks

Longitudinal

Cracks

4 Triangular Delaminated

areas

Fig. 3. Unit damaged cell with transverse and longitudinal cracks and

triangular areas of the delaminated 0/90 interface.

J.-L. Rebiere, D. Gamby / Composites Science and Technology 64 (2004) 22392250 2243

Taking into account the boundary conditions in the

triangular area, the stress eld is reduced to the single

component:

r

0

xx

x; y; z r

00

xx

r

090

xx

k

uz: 21

To summarise, when the three damage modes are

present, the stress eld has one non-zero component

only (21) in the delaminated zone. In the rest of the

laminate the stress eld is given by Eqs. (10) and (11).

Due to symmetry with respect to the laminate mid-

plane z 0, the complementary energy of the half unit

cell 0 < z < h, for a laminate subjected to traction

boundary conditions, is still dened by:

U

c

1

2

_

V

S

ijkl

r

ij

r

kl

dv; 22

where S

ijkl

are the local compliances, r

ij

is the admissible

stress eld and V is the volume of the half unit cell such

that jxj 6a, jyj 6b and jzj 6h.

The unit damaged cell, where the three damage modes

are present, is schematised in Fig. 3. The strain energy in

the unit cell is the sum of the strain energies in the non-

delaminated portion (area I) and in the delaminated

portion (triangular area II). In the non-delaminated por-

tions (area I), sub-regions are used for calculating the

energy. The strain energy expressions are detailed in [49].

In the non-delaminated region, the strain energy expres-

sion appears in Eq. (23). In the delaminated portion (area

II), the complementary energy is given by Eq. (24), using

the normal stress expression (21):

U

I

d

1

2

U

d

a;

b: U

d

a;

b

d

y

U

d

a

d

x

;

b

U

d

a

d

x

;

b

d

y

; 23

U

II

d

d

x

d

y

t

3

90

E

L

kr

00

2

xx

_

2r

00

xx

r

090

xx

r

090

2

xx

k

2

_

h

1

u

2

zdz

_

:

24

For a laminate degraded by the three damage modes,

the strain energy of the half unit cell is

U

cel

U

I

d

U

II

d

: 25

As in Section 2, pertaining to transverse cracking

damage, the strain energy release rate G associated with

the initiation and development of the delamination

damage for a given stress state is dened by:

G

d

~

U

d

dA

_ _

r

; 26

where

~

U

d

is the deformation energy of the whole lami-

nate, and A is the delaminated area. Let L

1

denote the

length of the laminate in the x direction, L

2

being its

width in the y direction.

The strain energy of the whole laminate is such that:

~

U

d

nmU

cel

: 27

The numbers n and m of transverse and longitudinal

cracks are dened in (15). The delaminated area A

d

is

such that:

A

d

d

x

;

d

y

A

d

L

1

L

2

d

x

d

y

2a

b

_ _

: 28

The strain energy release rates associated with de-

lamination in the x and y directions are denoted G

d

x

and

G

d

y

respectively. They mainly depend on the delami-

nated lengths d

x

and d

y

. When d

x

(respectively d

y

) alone

is varied, we get

G

dx

d

~

U

d

d

d

x

d

d

x

dA

d

; G

dy

d

~

U

d

d

d

y

d

d

y

dA

d

: 29

d

y

d

y

b-dy

b-dy

d

x

d

x

a-d

x

x

y

Area I

triangles

Area II

a-d

x

4 delaminated

Fig. 4. Schematic triangular areas of the delaminated 0/90 interface.

2244 J.-L. Rebiere, D. Gamby / Composites Science and Technology 64 (2004) 22392250

From Eqs. (16), (25), (28), (29), we obtain the strain

energy release rates associated with delamination in the

x and y directions denoted G

d

x

and G

d

y

, respectively:

G

dx

1

2

d

y

t

2

90

dU

cel

d

d

x

; G

dy

1

2

d

x

t

2

90

dU

cel

d

d

y

: 30

4. Results

4.1. Initiation of the rst damage mode

The results of Table 1 show the inuence of the 90

ply thickness on the rst ply failure in a cross-ply lam-

inate as computed with the proposed model. Several

numerical simulations were achieved with other models

and the analyses of the results converge to the same

conclusion. It is easier to create transverse cracking in a

laminate containing thicker 90 layer. A lot of experi-

mental results, on cross-ply laminates submitted to axial

loading, show that during the loading progression, a

second damage mode usually appears after the trans-

verse cracking.

4.2. Initiation of the second damage mode

First of all, the second damage mode can succeed

transverse crack damage or coexist with it. This second

damage mode is generally delamination at the 0/90

interface or longitudinal matrix cracking in the 0 layers.

All the studies conducted on this subject prove that the

nature of the second damage mode is strongly inuenced

by the architecture of the laminate (ply thickness and

constraint parameter) and the nature of the laminate

system constituents (bre and matrix). When studying

the inuence of the damage process on the degradation

of the laminate mechanical properties, it is necessary to

propose a model which is able to predict the initiation

and the propagation of the dierent damage mode

during loading development. The numerical results dis-

played in Tables 2 and 3 give the mean strain value

necessary for the initiation of longitudinal matrix

cracking or delamination computed for a 0

2

; 90

n

s

laminate made of the carbon/epoxy T300/934 material

system. The numerical simulations pertaining to the

model are compared with experimental results from

Wang et al. [12] and the nite elements results of [12].

4.3. Thickness ply inuence on initiation of longitudinal

matrix cracking

The experimental results related to the ultimate fail-

ure of the 0

2

; 90

s

laminate (Table 2) show that the

second damage mode does not appear in this laminate.

For other types of laminates containing a more impor-

tant number of 90 plies, the initiation of a second

damage mode is observed. It can be longitudinal matrix

cracking or delamination. As is well known, the initia-

tion of delamination or longitudinal matrix cracking is

easier in a laminate containing a thick 90 layer. The

numerical results from the model are in good agreement

with the experimental results from Bailey et al. [50] who

studied the ply thickness inuence on the initiation of

longitudinal cracks in a glass/epoxy laminate. On Fig. 5,

numerical results from our model are compared with

experimental data from [50]. For a given thickness of the

0 layer, it is easier to create a longitudinal cracking

damage in a thick 90 layer (Fig. 5(a)). A similar remark

can be made for 0 plies. For a given thickness of the 90

layer, the risk to initiate a longitudinal cracking in-

creases with the 0 layer thickness (Fig. 5(b)).

4.4. Life prediction in [0

2

; 90

2

]

s

and [0

2

; 90

4

]

s

laminates

The deformation thresholds pertaining to the initia-

tion of the three damage modes are displayed in Figs. 6

and 7 for an equilibrated laminate 0

2

; 90

2

s

and in Figs.

8 and 9 for a 0

2

; 90

4

s

laminate. The numerical simula-

tions are achieved for a carbon/epoxy T300/934 system;

see Table 4 for the constant of the material. Once more,

it can be conclude that it is easier to damage a laminate

containing a thick 90 layer. The initiation of the three

damage modes appears later in the 0

2

; 90

2

s

laminate

than in the 0

2

; 90

2

s

laminate. In Fig. 7, we can observe

the initiation of delamination during the propagation of

the transverse cracking damage (Fig. 6). Before the ul-

timate failure of the specimen, longitudinal matrix

cracking appears in the 0 plies. At the end of the test,

Table 1

Mean stress value (MPa) at initiation of transverse matrix cracking

n in 0; 90

n

; 0 Model Experimental [12]

n 1 908 915

n 2 537 540

n 3 418 430

n 4 297 305

Table 2

Applied mean strain value e

0

% at initiation of longitudinal matrix

cracking in a 0

2

=90

n

s

carbon/epoxy T300/934 laminate system

n in 0

2

; 90

n

s

Model FEM [12] Experimental [12]

n 1 1.35 >1.2

n 2 0.98 1.05 0.92

n 4 0.74 0.78 <0.8

Table 3

Applied mean strain value e

0

% at delamination initiation in a

0

2

=90

n

s

carbon/epoxy T300/934 laminate system

n in 0

2

; 90

n

s

Model FEM [12] Experimental [12]

n 1 1.35 >1.2

n 2 0.95 1.09 >0.92

n 4 0.65 0.75 <0.8

J.-L. Rebiere, D. Gamby / Composites Science and Technology 64 (2004) 22392250 2245

0

2

4

6

8

10

12

14

16

18

20

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

0

(%)

C

r

a

c

k

D

e

n

s

i

t

y

(

c

m

-

1

)

Longitudinal Cracks

Transverse Cracks

Fig. 6. Damage mechanism in a 0

2

=90

2

s

carbon/epoxy T300/934

laminate: matrix cracking.

0

2

4

6

8

10

12

14

16

18

20

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

0

(%)

C

r

a

c

k

D

e

n

s

i

t

y

(

c

m

-

1

)

Longitudinal Cracks

Transverse Cracks

Fig. 8. Damage mechanism in a 0

2

=90

4

s

carbon/epoxy T300/934

laminate: matrix cracking.

0

5

10

15

20

25

30

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

0

(%)

D

e

l

a

m

i

n

a

t

i

o

n

(

m

m

)

Delamination width d

Delamination length d

x

y

Fig. 9. Damage mechanism in a 0

2

=90

4

s

carbon/epoxy T300/934

laminate: delamination in x and y directions.

0.8

1

1.2

1.4

1.6

1.8

0.5 1 1.5

t 0 (mm)

F

L

(

%

)

Experiment Bailey [50]

3D Model

Bailey [50]

0.8

1

1.2

1.4

1.6

1.8

0.50 0.75 1.20 1.25

t 90 (mm)

F

L

(

%

)

3D Model

Bailey [50]

Experiment

Bailey [50]

(a) (b)

Fig. 5. Mean strain value e

0

% at initiation of longitudinal cracking in a glass/epoxy laminate. (a) 0

2;5

=90

n

s

laminate with t

0

0:5 mm (b)

0

m

=90

2:5

s

laminate with t

90

0:5 mm.

0

5

10

15

20

25

30

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

0

(%)

D

e

l

a

m

i

n

a

t

i

o

n

(

m

m

)

Delamination width d

Delamination length d

y

x

Fig. 7. Damage mechanism in a 0

2

=90

2

s

carbon/epoxy T300/934

laminate: delamination in x and y directions.

2246 J.-L. Rebiere, D. Gamby / Composites Science and Technology 64 (2004) 22392250

the longitudinal crack density is about 5 cm

1

for the

0

2

; 90

2

s

laminate and about 10 cm

1

for the 0

2

; 90

4

s

laminate. The delamination evolution is not the same for

the two laminates. In the 0

2

; 90

2

s

laminate, the evolu-

tion is dierent in the x and y directions. At the end of

the test, for this 0

2

; 90

2

s

laminate, the delaminated

length is 16 mm in the x direction and 10 mm in the y

direction (Fig. 7), contrary to the 0

2

; 90

4

s

laminate

where delaminated lengths are equivalent (Fig. 9).

5. Conclusion

Using the proposed energetic model, our objective

was to predict the occurrence of several damage mech-

anisms in cross-ply laminates. The beginning of the

damaging process is well described when compared to

Wangs experiments [12]. We propose some results about

the initiation and propagation of the dierent damage

modes, longitudinal matrix cracking in the 0 plies and

delamination. As an example, the lifes of an equilibrated

0

2

; 90

2

s

laminate and a 0

2

; 90

4

s

laminate have been

described and the successive damage mechanisms for

these laminates have been predicted. We have also been

able to bring out the propagation of transverse cracks

during the initiation of delamination, the development of

the triangular shape of delamination and the fact that the

delaminated length is not the same in the x and y direc-

tions of the laminate. Other examples, not presented

here, showed that the damage mechanism succession can

be dierent. The nature of the material system and the

laminate architecture, represented here by 90 and 0

layers thicknesses, are very important parameters.

Appendix A

U

c

_

v

S

ijkl

r

ij

r

kl

dv:

S

ijkl

are the local compliances, r

ij

is the admissible stress

eld and V is the volume of the half unit cell such that

jxj 6a, jyj 6b and jzj 6h.

U

d

U

c

U

o

;

where U

o

denotes the constant complementary energy of

the uncracked laminate, and U

c

is the variation of en-

ergy due to damage in the laminate. Using the density of

complementary energy W

k

in each layer, the energy

perturbations due to cracks can be written as:

U

c

_

V

90

W

90

dv

_

V

0

W

0

dv:

Substituting Eqs. (9) and (10) into these expressions, we

obtain:

U

c

1

2

r

2

0

t

3

90

_

a

a

_

b

b

A

0

k

2

x

/

2

_

2B

0

k

x

k

y

/w C

0

k

2

y

w

2

A

1

k

2

x

/

02

B

1

k

2

y

w

02

A

21

k

2

x

//

00

A

21

k

x

k

y

/w

00

B

12

k

x

k

y

w/

0

B

22

k

2

x

/

02

B

1

k

2

y

ww

0

C

01

k

2

x

/

002

C

02

k

2

y

w

002

C

03

k

x

k

y

w

00

/

00

_

dxdy

with

A

0

1

E

T

1

E

L

; A

0

m

TT

E

T

k

_

2

3

_

m

LT

E

L

2I

5

k

2

;

B

0

m

LT

E

L

1

_

I

3

k

2

_

; B

21

2

m

LT

E

L

k

_

1

6

_

2

m

TT

0

E

T

I

6

k

2

;

C

0

1

E

L

1

kE

L

; B

22

m

LT

E

L

k

_

2

3

_

m

TT

0

E

T

k

3

A

1

1

3G

TT

0

I

2

k

2

G

LT

; C

01

1

E

T

k

2

_

k

3

1

20

_

I

7

20k

2

E

T

;

B

1

1

3

1

G

LT

_

1

G

TT

0

_

; C

02

3k

3

15k

2

20k 8

60E

T

;

A

21

m

TT

0

E

T

R

_

1

6

_

2

m

LT

E

L

I

4

k

2

;

C

03

1

E

T

Rh

_

1

3

R

_

h

2

_

1

10

_

I

8

k

2

E

T

;

and

k

x

r

090

xx

r

0

; k

y

r

090

yy

r

0

;

/

0

o/

ox

; /

00

o

2

/

ox

2

; /

0

o/

ox

; /

00

o

2

/

ox

2

:

The parameters I

i

i 1; 8 are dened by:

I

1

_

h

1

u

2

zdz; I

2

_

h

1

u

I

2

zdz; I

3

_

h

1

uzdz;

I

4

_

h

1

uzu

II

zdz;

Table 4

Material constants for a T300/934 unidirectional ply [12]

Property SI unit

E

LL

144.8 GPa

E

TT

, E

zz

11.7 GPa

m

LT

, m

Lz

0.3

m

Tz

0.54

G

LT

, G

Lz

6.5 GPa

G

Tz

3.5 GPa

t, nominal ply thickness 0.132 mm

G

crf

228 J m

2

G

crd

158 J m

2

J.-L. Rebiere, D. Gamby / Composites Science and Technology 64 (2004) 22392250 2247

I

5

_

h

1

uz

h z

2

dz; I

6

_

h

1

u

II

zdz;

I

7

_

h

1

u

II

2

zdz; I

8

_

h

1

u

II

z

h z

2

dz:

The EulerLagrange dierential equations are:

d

4

/

dx

4

p

1

d

2

/

dx

2

q

1

/

k

x

k

y

B

0

C

01

1

2

b

_

b

b

wydy 0;

d

4

w

dy

4

p

2

d

2

w

dy

2

q

2

w

k

x

k

y

B

0

C

02

1

2a

_

a

a

/xdx 0;

where

p

1

A

21

A

1

C

01

; q

1

A

0

C

01

; p

2

B

22

B

1

C

02

; q

2

C

0

C

02

;

/x D

1

f

1

x F

1

g

1

x m

1

w;

wy D

2

f

2

y F

2

g

2

y m

2

/:

The constants D

i

, F

i

,

/ and

w are such that:

D

1

1 m

1

wg

0

1

a

f

1

ag

0

1

a f

0

1

ag

1

a

;

F

1

1 m

1

wf

0

1

a

f

1

ag

0

1

a f

0

1

ag

1

a

;

D

2

1 m

2

/g

0

2

b

f

2

bg

0

2

b f

0

2

bg

2

b

;

F

2

1 m

2

/f

0

2

b

f

2

bg

0

2

b f

0

2

bg

2

b

;

/

x

1

m

1

1 x

1

x

2

1 m

1

m

2

1 x

1

1 x

2

w

x

2

m

2

1 x

2

x

1

1 m

1

m

2

1 x

1

1 x

2

;

and

m

1

k

y

B

0

k

x

A

0

; m

2

k

x

B

0

k

y

C

0

:

The functions f

i

, g

i

and x

i

depend of the signe:

4q

1

p

2

i

i 1; 2

If 4q

1

Pp

2

i

f

i

u

i

cosha

i

u

i

cosb

i

u

i

;

g

i

u

i

sinha

i

u

i

sinb

i

u

i

;

x

i

2a

i

b

i

cosh2a

i

r

i

cos2b

i

r

i

r

i

a

2

i

b

2

i

a

i

sin2b

i

r

i

b

i

sinh2a

i

r

i

:

If 4q

1

6p

2

i

with p

i

< 0:

f

i

u

i

cosha

i

u

i

;

g

i

u

i

coshb

i

u

i

;

x

i

b

2

i

a

2

i

sinha

i

r

i

sinhb

i

r

i

a

i

b

i

r

i

b

i

cosha

i

r

i

sinhb

i

r

i

a

i

sinha

i

r

i

coshb

i

r

i

;

where:

a

i

q

1=4

i

cos

h

i

2

_ _

; b

i

q

1=4

i

sin

h

i

2

_ _

;

h

i

Arctg

4q

i

p

2

i

1

; a

i

; b

i

p

i

2

1

1

4q

i

p

2

i

_ _

_

with u

1

x, u

2

y, r

1

a, r

2

b and i 1, 2.

A.1. Model I

The function uz can be taken in the form:

uz kD

cosh D

h z

sinhDk

;

u

I

z k

sinh D

h z

sinhDk

;

u

II

z k

cosh D

h z 1

DsinhDk

;

the parameter R is such that:

R

1

2

cosh Dz

h 1

DsinhDk

:

This function is independent of the damage state of

the laminate. The problem is thus reduced to mini-

mizing a function with only one unknown parameter

U

c

D.

A.2. Model II

In order to analyse the inuence of function uz on

the stress eld distribution in the unit cell, this function

is taken in the form of a second order polynomial in z

with only one unknown parameter D. Taking into ac-

count the boundary and continuity conditions, the

function uz is such that:

uz

3D

k

2

z

h

2

1 D;

u

I

z

D

k

2

z

h

3

1 Dz

h;

u

II

z

D

4k

2

z

h

4

1 Dz

h

2

:

The related parameter R is now: R

1k

2

Dk

4

.

As in Model 1, the determination of uz is reduced

to minimizing a function of only one parameter

U

c

D.

2248 J.-L. Rebiere, D. Gamby / Composites Science and Technology 64 (2004) 22392250

References

[1] Brewer J-C, Lagace PA. Quadratic stress criterion for initiation of

delamination. J Compos Mater 1988;(22):114155.

[2] Leguillon D. A method based on singularity theory to

predict edge delamination of laminates. Int J Fract 1999;

(10):10520.

[3] Sicot O, Gong X, Cherouat A, Lu J. Importance des contraintes

residuelles sur le comportement mecanique dun composite

stratie. Ann Compos (AMAC) 1991;(1):659.

[4] Rebiere J-L, Ma^atallah M-N, Gamby D. Initiation and growth of

transverse and longitudinal cracks in composite cross-ply lami-

nates. Compos Struct 2001;53(2):17387.

[5] Urwald E. Inuence de la geometrie et de la stratication sur

lendommagement par fatigue de plaques composites carbone/

epoxyde. These de doctorat, Universitede Poitiers; 1992 [in

French].

[6] Wang ASD, Crossman FW. Initiation and growth of transverse

cracks and edge delamination in composite laminates Part I: An

energy method. J Compos Mater 1980;Suppl 14:7187.

[7] Xu LY. Interaction between matrix cracking and edge delamina-

tion in composite laminates. Compos Sci Technol 1994;(50):469

78.

[8] Highsmith A-L, Reifsnider K-L. Internal load distribution eects

during fatigue loading of composite laminates. Composite mate-

rials: fatigue and fracture. In: Hahn HT, editor. ASTM STP 907,

Philadelphia; 1986. p. 23351.

[9] Han YM, Hahn HT. Ply cracking property degradation of

symmetric balanced laminates under general in-plane loading.

Compos Sci Technol 1989;35:37797.

[10] Jamison R-D, Schulte K, Reifsnider K-L, Stinchcomb W-W.

Characterization and analysis of damage mechanisms in tension

tension fatigue of graphite/epoxy laminates, ASTM STP 836;

1984. p. 2155.

[11] Stinchcomb W-W. Non destructive Evaluation of Damage Accu-

mulation Process in Composite Laminates. Compos Sci Technol

1986;25:10318.

[12] Wang ASD, Kishore NM, Li CA. Crack development in graphite-

epoxy cross-ply laminates under uniaxial tension. Compos Sci

Technol 1985;24:131.

[13] Takeda N, Ogihara S. Initiation and growth of delamination from

the tips of transverse cracks in CFRP cross-ply laminate. Compos

Sci Technol 1994;52:30918.

[14] Ogihara S, Takeda N. Interaction between transverse cracks and

delamination during damage process in CFRP cross-ply laminate.

Compos Sci Technol 1995;54:395404.

[15] Steif PS. Parabolic shear-lag analyses of a 0=90

s

laminate. In

Transverse crack growth and associated stiness reduction during

the fatigue of a simple cross-ply laminate. Ogin SL, Smith, PA,

Beaumont, editors. Report CUED/C/MATS/TR 105, Cambridge

University; 1984.

[16] Law N, Dvorak GJ. Progressive transverse cracking in composite

laminates. J Compos Mater 1988;22(Oct.):90016.

[17] Lim SG, Hong CS. Eect of transverse cracks on the thermome-

chanical properties of cross-ply laminated composites. Compos

Sci Technol 1989;34:14562.

[18] Lee JW, Allen DH, Harris CE. Internal state variable approach

for predicting stiness reduction in brous laminated composites

with matrix cracks. J Compos Mater 1989; 23:127391.

[19] Reissner E. On a variational theorem in elasticity. J Math Phys

1950;29:905.

[20] Lema^tre J, Chaboche J-L. Mecanique des materiaux solides. 2nd

ed. Paris: DUNOD; 1988.

[21] Vasilev VV, Duchenco AA. Analysis of the tensile deformation of

glass-reinforced plastics. Translated from Mekhanica Polimerov,

Jan/Feb. 1970;(1):1447.

[22] Hashin Z. Analysis of cracked laminates: a variational approach.

Mech Mater 1985;(4):12136.

[23] Nairn JA. The strain energy release rate of composite micro

cracking: a variational approach. J Compos Mater 1989;23:1106

29.

[24] Pijaudier-Cabot G, Dvorak GJ. A variational approximation of

the stress intensity factors in cracked laminates. Eur J Mech A:

Solids 1990;9(6):51735.

[25] Varna J, Berglund LA. Thermo-elastic properties of composite

laminates with transverse cracks. J Compos Technol Res

1994;16(1):7787.

[26] Rebiere J-L. Modelisation du champ des contraintes cree par des

ssures de fatigue dans un composite stratie carbone/polymere.

These de doctorat, Universite de Poitiers; 1992 [in French].

[27] Herakovich CT, Aboudi J, Lee SW, Strauss EA. Damage in

composite laminates: eects of transverse cracks. Mech Mater

1988;(7):91107.

[28] Talreja R, Yalvac S, Yats LD, Wetters DG. Transverse cracking

and stiness reduction in cross ply laminates of dierent matrix

toughness. J Compos Mater 1992;26(11):164463.

[29] Gamby D, Hena-Gardin C, Rebiere J-L. Modelling of the

damage distribution along the width of a composite laminate

subjected to a tensile fatigue test. In: Proceedings of localized

damage II. Southampton, UK: Elsevier Applied Science; 1992. p.

31525. 13 July.

[30] Talreja R. Internal variable damage mechanics of composite

materials. Symposium on Yielding, Damage and Failure of

Anisotropic Solids Grenoble, France; 1987. p. 248.

[31] Pyrz R. A micromechanically-based model for composite mate-

rials with matrix cracks. Compos Eng 1992;2(8):61929.

[32] Allen DH, Groves SE, Harris CE. A thermomechanical consti-

tutive theory for elastic composites with distributed damage. Part

I theoretical development. Report MM-5023-85-17, Mechanics

and Materials Center, Texas A&M University; 1985.

[33] Allix O, Ladeveze P, Le Dantec E. Modelisation de lendomm-

agement dun pli elementaire des composites stratie s. In:

Fantozzi G, Fleishman P, editors. Proceedings of the 7th Jurnees

Nationales des Composites, Lyon, Nov. Paris: AMAC; 1990. p.

111524.

[34] Thionnet A. Prevision de lendommagement sous chargements

quasi-statiques et cycliques des structures composites stratie s.

These de doctorat, Universite de Paris 6; 1991 [in French].

[35] Chow CL, Yang F. Elastic damage analysis of interlaminar stress

distribution in symmetrical composite laminates with edge delam-

ination cracks. Proceedings of the Institution of Mechanical

Engineering, Part C. J Mech Eng Sci 1994;208(1):111.

[36] Adali S, Markins RK. Eect of transverse matrix cracks on the

frequencies of unsymmetrical, cross-ply laminates. J Franklin Inst

1992;329(4):65565.

[37] Yeh JR. The mechanics of multiple transverse cracking in

composite laminates. Int J Solids Struct 1992;25(12):144555.

[38] Kaw A, Bestereld GH. Mechanics of multiple periodic brittle

matrix cracks in unidirectional ber-reinforced composites. Int J

Solids Struct 1992;29(10):1193207.

[39] Nairn JA, Hu S. The initiation and growth of delamination

induced by matrix microcracks in laminated composites. Int J

Fract 1992;57:124.

[40] Hashin Z. Analysis of orthogonally cracked laminates under

tension. J Appl Mech 1987;25:8729.

[41] Binienda WK, Hong A, Roberts GD. Inuence of material

parameters on strain energy release rates for cross-ply laminate

with pre-existing transverse crack. Compos Eng 1994;4(12):1167

210.

[42] Sch on J, Nyman T, Bom A, Ansell H. A numerical and

experimental investigation of delamination behaviour in the

DCB specimen. Compos Sci Technol 2000;60:17384.

J.-L. Rebiere, D. Gamby / Composites Science and Technology 64 (2004) 22392250 2249

[43] Marion G, Rospars C, Harry R, Lecuyer F. Prediction de

lamorc age du delaminage des straties croise s. Ann Compos J

Sci Tech: Delaminage AMAC 2000;(1):2935.

[44] Leguillon D, Marion G, Harry R, Lecuyer F. The onset of

delamination at stress-free edges in angle-ply laminates

analysis of two criteria. Compos Sci Technol 2001;61(3):377

82.

[45] Whitney JM, Nuismer RJ. Stress fracture criteria for laminated

composites containing stress concentration. J Compos Mater

1974;8:25365.

[46] Kim RY, Sony SR. Experimental and analytical studies on the

onset of delamination in laminated composites. J Compos Mater

1984;18:706.

[47] Lecuyer F. Etude des eets de bord dans des structures minces

multicouches. These de doctorat, Universite de Paris 6; 1991 [in

French].

[48] Diaz-Diaz A, Caron J-F. Criterion of delamination initiation in

multilayered composites. Ann Compos J Sci Tech: Delaminage

AMAC 2000;(1):3744.

[49] Rebiere J-L, Ma^atallah M-N, Gamby D. Analysis of damage

mode transition in a cross-ply laminate under uniaxial loading.

Compos Struct 2002;55(2):11526.

[50] Bailey J-E, Curtis PT, Parvizi A. On the transverse cracking and

longitudinal splitting behaviour of glass and carbon bre rein-

forced epoxy cross ply laminates and the eect of Poisson and

thermally generated strain. Proc R Lond A 1979;(366):599623.

2250 J.-L. Rebiere, D. Gamby / Composites Science and Technology 64 (2004) 22392250

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- AJODO Eliades2006 - Orthodontic Materials Research and Applications Part 1-Current Status and Projected Future Developments in Bonding and Adhesives.Document7 pagesAJODO Eliades2006 - Orthodontic Materials Research and Applications Part 1-Current Status and Projected Future Developments in Bonding and Adhesives.drgeorgejose7818No ratings yet

- Brosur Baja Gunung Raja Paksi Welded BeamDocument2 pagesBrosur Baja Gunung Raja Paksi Welded BeamRobbi Shobri RakhmanNo ratings yet

- ECOTherms Feed Water TanksDocument4 pagesECOTherms Feed Water TanksFadzil NorNo ratings yet

- 1 Rectangular NotchDocument4 pages1 Rectangular NotchAshlin Augusty80% (5)

- Bonding Types Lab #1: Ionic vs. Covalent Solids Teacher'sDocument3 pagesBonding Types Lab #1: Ionic vs. Covalent Solids Teacher'sEsther SparksNo ratings yet

- On The Resonances and Polarizabilities of Split Ring ResonatorsDocument9 pagesOn The Resonances and Polarizabilities of Split Ring ResonatorsNabil DakhliNo ratings yet

- Nde Request - RTDocument1 pageNde Request - RTSam RajaNo ratings yet

- CHEMICAL ANALYSIS (Max Values) : Hardness Range (Delivery Condition) : 370-430 HBW Heat ResistanceDocument4 pagesCHEMICAL ANALYSIS (Max Values) : Hardness Range (Delivery Condition) : 370-430 HBW Heat ResistanceFilipe CordeiroNo ratings yet

- Science Quiz: WaterDocument4 pagesScience Quiz: WaterSARANGMUMBAINo ratings yet

- Dynamics of Soils and Their Engineering Applications (Swami Saran) (Z-Library)Document587 pagesDynamics of Soils and Their Engineering Applications (Swami Saran) (Z-Library)juan carlos molano toroNo ratings yet

- Hydraulic TransientsDocument58 pagesHydraulic TransientsjulianvillajosNo ratings yet

- Investigation On Properties of Steel Fibre Reinforced Concrete IJERTV9IS120220Document4 pagesInvestigation On Properties of Steel Fibre Reinforced Concrete IJERTV9IS120220Ricky RickxNo ratings yet

- 3rd Q Science 2022-2023Document2 pages3rd Q Science 2022-2023Richard CruzNo ratings yet

- Large Binocular Telescope 2008Document15 pagesLarge Binocular Telescope 2008王轩No ratings yet

- Kishen Hydormechanics in Dentine Role of Dentinal Tubules and Hydrostatic Pressure On Mechanical Stress-Strain DistributionDocument11 pagesKishen Hydormechanics in Dentine Role of Dentinal Tubules and Hydrostatic Pressure On Mechanical Stress-Strain DistributionОлександр БайдоNo ratings yet

- Progress of PV Cell TechnologyDocument17 pagesProgress of PV Cell TechnologysriNo ratings yet

- Microsoft Word - CH 12 Worksheet 2-2 - DocDocument7 pagesMicrosoft Word - CH 12 Worksheet 2-2 - DocAhmad RezaNo ratings yet

- Assignment 3 - Mechanics 3 SolutionDocument10 pagesAssignment 3 - Mechanics 3 SolutionSamriddhi SinglaNo ratings yet

- API Dispersal Through Hot Melt ExtrusionDocument3 pagesAPI Dispersal Through Hot Melt ExtrusionKhaled Abdel-Ghaffar SalamaNo ratings yet

- Exp7 Calcite CrystalDocument9 pagesExp7 Calcite Crystalctremblaylcsd150No ratings yet

- The Direct Stiffness Method: BreakdownDocument11 pagesThe Direct Stiffness Method: BreakdownShubhankar BhowmickNo ratings yet

- Bridge Deck BehaviourDocument327 pagesBridge Deck BehaviourJunwhan KimNo ratings yet

- Quiz 2 Retake GuideDocument1 pageQuiz 2 Retake Guideapi-213645632No ratings yet

- Nikon ECLIPSE LV100N POLCi-POLDocument8 pagesNikon ECLIPSE LV100N POLCi-POLvictorNo ratings yet

- Chaubey 2019Document38 pagesChaubey 2019ranim najibNo ratings yet

- Odisha Public Service Commission: Odisha The Vacancy Position Is Given BelowDocument15 pagesOdisha Public Service Commission: Odisha The Vacancy Position Is Given BelowJeshiNo ratings yet

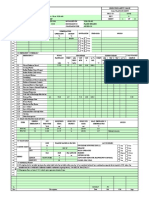

- PSV Calculation Sheet APIDocument10 pagesPSV Calculation Sheet APIionutlaur86100% (2)

- Basic InstrumentationDocument59 pagesBasic Instrumentationjudegj100% (1)

- Plate Load Soil Test ReportDocument5 pagesPlate Load Soil Test ReportJoseph Cloyd L. LamberteNo ratings yet

- Presentation DehumidifierDocument22 pagesPresentation Dehumidifiershubham mhatreNo ratings yet