Professional Documents

Culture Documents

LY-O-31989 RV04 Proposal

Uploaded by

Stavros RoumeliotisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LY-O-31989 RV04 Proposal

Uploaded by

Stavros RoumeliotisCopyright:

Available Formats

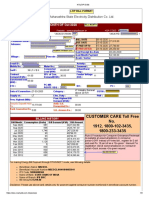

P ROP O SA L : LY- O- 3198 9

REVISION NO.:- 4 Date.:- 25-Jan-12

MAMMUT BUILDING SYSTEMS FZC

CORPORATE ADDRESS

PREPARED BY

V2.9b b

P O Box 41668 Sharjah, UAE. Location : Hamriya Free Zone Direct : +971 4 801 2222 Fax : +971 4 801 2223 E mail : sales@mammut.ae

Diaa El Kenawy Regional Sales Manager Tel : Cell : +20 122 2434 932 Fax : E mail : Diaa.Elkenawy@mammut.ae

www.mammutsteel.ae

25-Jan-12 LY-O- 31989

Al Mansour Diapers Factory Kraimiea, Tripoli libya Phone :Fax :Email :+218 21 5670232 +218 21 5670229 almansour@almansourcorp.com

Attention Subject Project

: : : :

Mr. Mohamed Mansour Bokhdair

(Managing Director)

Supply of Pre-Engineered Building by Mammut Building Systems. Warehouse MBS Quote No:

LY-O- 31989

Reference :

Rev No: 4

Date : 25-Jan-12

Dear Sir, Thank you for giving us the opportunity to submit a proposal for the above noted project. Our proposal is based on Standard Design Criteria, Standard Material Specifications, Standard Terms and Conditions of Sale and Standard Panel Colors of Mammut Building Systems FZC. However, the overall dimensions and layout are in general accordance with your inquiry. Mammuts intent is to comply with your project requirements. Occasionally this may not be possible. Please refer to Section 9 of this proposal offer for specific exceptions, deviations and assumptions that are applicable to this offer. We are very keen to secure the order for this project and we look very much forward to doing business with you. Mammuts policy of continuous improvement and development is adapting the latest Codes and Specifications as possible. We assure you for the superior quality of our buildings. Sincerely yours,

Diaa El Kenawy Regional Sales Manager Mobile: + 20 122 2434 932 Email: Diaa.Elkenawy@mammut.ae

Sheet 2 of 22

Version 2.9

25-Jan-12 LY-O- 31989

PROPOSAL INDEX

SECTION 1: BUILDING DESCRIPTION ........................................................................................................... 4 1.1 BUILDING NO. 01 ............................................................................................................................................. 4 1.1.1 BUILDING NO. 01 AREA NO. 01 ............................................................................................................ 4 1.1.1 BUILDING NO. 01 AREA NO. 01 (CONT) .............................................................................................. 5 SECTION 2: PANEL DESCRIPTION.................................................................................................................. 6 2.1 BUILDING NO. 01 ............................................................................................................................................. 6 2.1.1 BUILDING NO. 01 AREA NO. 01 ............................................................................................................ 6 SECTION 3: DESIGN LOADS.............................................................................................................................. 7 3.1 BUILDING NO. 01 ............................................................................................................................................. 7 3.1.1 BUILDING NO. 01 AREA NO. 01 ............................................................................................................ 7 SECTION 4: SURFACE PREPARATION & PAINT SPECIFICATION......................................................... 8 SECTION 5: STANDARD & SPECIALLY SUPPLIED ITEMS ....................................................................... 9 SECTION 6: SUPPLY DELIVERY AND DISPATCH PERIOD..................................................................... 10 SECTION 7: SUPPLY PRICE AND ALTERNATIVE PRICE OPTIONS ..................................................... 11 SECTION 8: PAYMENT TERMS ...................................................................................................................... 12 SECTION 9: EXCLUSIONS, DEVIATIONS & ASSUMPTIONS................................................................... 13 SECTION 10: CONTRACT FORM FOR SUPPLY OF STEEL & CLADDING ........................................... 14 ANNEXURE - 1 ..................................................................................................................................................... 15 ANNEXURE - 2 ..................................................................................................................................................... 16 ANNEXURE - 3 ..................................................................................................................................................... 17 ANNEXURE - 4 ..................................................................................................................................................... 20 ANNEXURE - 5 ..................................................................................................................................................... 21 ANNEXURE - 6 ..................................................................................................................................................... 22

ENCLOSURES & NOTES:

Proposal Drawings

Standard Product Specifications

Standard Panel Color Guide

Product Brochure

Standard Terms & Conditions

Sandwich Panels Write out

Sheet 3 of 22

Version 2.9

25-Jan-12 LY-O- 31989

SECTION 1: BUILDING DESCRIPTION 1.1 BUILDING NO. 01 1.1.1 BUILDING NO. 01

BUILDING PARAMETERS 1 2 3 4 5 6 7 8 9 10 11 Type No. of Interior columns Width Module (m) Roof Slope Width (m) Length (m) Exterior Columns Base Condition Interior Columns Base Condition Height (m) from FFL Bay Spacing (m) Left Endwall Endwalls Right Endwall Bracing At Exterior Walls Type Between Interior Walls Type of Eave Type of Gable Exterior Rigid Frame Columns Fillet Weld of Built up Sections Multi-Span One 2@30.00 1 : 10 60.20//60.60 Out/Out of column outer flange Out/Out of Steel girts Center line to Center line

AREA NO. 01

12 13 14 15 16

102.00 Pinned Pinned 9.50 Clear Height 17@6.00 Frame Type: Bearing Column Spacing : 5@6.00 Frame Type: Bearing Column Spacing : 5@6.00 Diagonal Diagonal Eave Gutters & Downspouts

Girts: Flush Girts: Flush

Gable Trim Tapered Web Double Side Welding for all Built up sections Due to Hot Dip Galvanizing

Note:Additional 2 holes 16mm diameter at every location described below on the lower flange of the roof rafter for fixing light lamps with U bolt by others. Locations of holes: 5m-10m-10m-5m-intrmidiate column centerline-5m-10m-10m-5m from near side wall column exterior flange. These holes will be shown on our approval drawings.

OPEN WALL CONDITIONS 1 2 3 4 Near Side Wall Far Side Wall Left End wall Right End wall

Please refer to section 2 for roof & wall panel description. Open up to 4.50M for Blockwall by others and above sheeted Open up to 4.50M for Blockwall by others and above sheeted Open up to 4.50M for Blockwall by others and above sheeted Open up to 4.50M for Blockwall by others and above sheeted

Sheet 4 of 22

Version 2.9

25-Jan-12 LY-O- 31989

SECTION 1: BUILDING DESCRIPTION 1.1 BUILDING NO. 01 1.1.1 BUILDING NO. 01

LINER PANELS 1 Roof Liner

AREA NO. 01

(CONT)

Please refer to section 2 for interior roof & wall liner panel description. Area (m2) Flange braces Location Area (m2) Flange braces Location Roof is fully lined. Rafter flange braces will be kept Liner panel is located under purlins All sheeted walls are lined Column flange braces will be kept Liner panel is located against girts inside the building For Basic Price Only Quantity per Area 01

Wall Liner

ROOF ACCESSORIES No. Description Roof Insulation. Type: Fiberglass Thick (mm): 50. Density (Kg/m3) = 12 Facing: WMSK (White) Coverage Area (m2) = Full Roof Area Framed openings for power ventilator to be future installed

Full Area

12

WALL ACCESSORIES No. 1 Description Single Skin Clear Translucent Fiberglass Wall lights W (mm) =1000 x L (mm) = 3250. Thk. (mm) =1.5 Double sliding doors with cladding similar as wall cladding Width (mm): 5000 Height (mm): 5000 2 doors will be on LEW 1 doore will be on NSW Wall Insulation. Type: Fiberglass Thick (mm): 50. Density (Kg/m3) = 12 Facing: WMSK (White) Coverage Area (m2) = All sheeted walls

For Basic Price Only Quantity per Area 01 108**

All Sheeted Walls

Note:**Wall light will be double layer interior and exterior same as exterior sheeting and liner. Its length is 54m every side wall continuous for 1 bay of 6m with total of 9 bays on each side wall distribution will be one bay with wall light & the other with out and so one. Fiber glass wall light height is 1.5m height (sheet divided by 2) Height could be adjusted as per girts distribution its location on the wall will be starting from eave

Sheet 5 of 22

Version 2.9

25-Jan-12 LY-O- 31989

SECTION 2: PANEL DESCRIPTION 2.1 BUILDING NO. 01 2.1.1 BUILDING NO. 01

ROOF PANEL ( For buildings ) Profile Material Finish Color M45250. Thickness(mm): 0.5 AluZinc coated steel Polyester Painted Mammut Standard Pale Green) ( RAL 6021)

AREA NO. 01

Single Skin

WALL PANEL ( For buildings ) Profile Material Finish Color M45250. Thickness (mm): 0.5 AluZinc coated steel Polyester Painted Mammut Standard Pale Green ( RAL 6021)

Single Skin

Note:1.0% of total sheeting area will be additionally supplied and its length to be same length as tallest sheet.

Sheet 6 of 22

Version 2.9

25-Jan-12 LY-O- 31989

SECTION 3: DESIGN LOADS 3.1 BUILDING NO. 01 3.1.1 BUILDING NO. 01

DESIGN LOADS 1 2 3 4 5 6 7 8 Design Live Load ( kN/m2 ) on roof Design Live Load ( kN/m2 ) on frame Wind Speed ( km/hr ) ( 3 second gust ) Additional Collateral Load ( kN/m2 ) Roof Snow Load (kN/m2) Seismic Zone as per UBC 1997 Temperature Load Rainfall intensity for design of gutters & downspout (mm/hr) 0.57 0.57 160 None None 2a None 150

AREA NO. 01

Important Notes: Wind speed MBMA 2006 defines the wind speed as the 3 seconds gust wind speed. Seismic Zones Mapped Short Spectral Response ( SDS ) & 1 Second Spectral Response ( S D1 ) are required as per MBMA 2006 ( IBC 2006 & ASCE 7-05 ) in order to calculate the Seismic loads on a structure at a given site. If these values are not available, Mammut will calculate these values by trail and error in order to generate the same base shear as per UBC 1997. Load combinations Load combinations are considered as per MBMA 2006

Sheet 7 of 22

Version 2.9

25-Jan-12 LY-O- 31989

SECTION 4: SURFACE PREPARATION & PAINT SPECIFICATION FOR PRIMARY STEEL

Mammut offers its in-house paint system applied to Primary structural components. Secondary structural members such as roof purlins, wall girts, eave struts, base angles and gable are made out of pre-galvanized steel which is roll formed or press bent. 4.1 Surface Preparation All primary structural components will be Shot blasted to Swedish SA-2.5 standards. 4.2 Paint Specifications:

All steelwork is to be Hot Dip Galvanized to finish zinc layer thickness of 85 microns.

FOR SECONDARY STEEL

Secondary structural members such as roof purlins, wall girts, eave struts, base angles and gable are made out of pre galvanized steel - which is roll formed or press bent.

Sheet 8 of 22

Version 2.9

25-Jan-12 LY-O- 31989

SECTION 5: STANDARD & SPECIALLY SUPPLIED ITEMS

5.1 Standard Supplied Items The following items are supplied with Mammut buildings unless otherwise noted: 5.1.1 Structure Related Hot dip galvanized anchor bolt assembly for rigid frames and end wall posts. Hot dip galvanized high strength connection bolt assembly comprised of bolt, nut and washer. Expansion bolts at base of jambs for wall located framed openings (If any).

5.1.2 Panels Related At Eaves Eave gutters & downspouts at sidewalls Gable trims, corner flashing, drip trims and all necessary flashing & trims.0.5 mm painted AluZinc coated steel. Foam closures (inside & outside). Bead mastic, one row at all side laps and end laps of roof panels. Self drilling fasteners to fix roof and wall panels to secondary members. Carbon steel fasteners (normally used with AluZinc coated steel panels).

5.2 Special Supplied Items for this Project No Special supplied items are included for this project.

Sheet 9 of 22

Version 2.9

25-Jan-12 LY-O- 31989

SECTION 6: SUPPLY DELIVERY AND DISPATCH PERIOD

In this proposal the term Delivery means Dispatch of Materials from Mammuts Factory. 6.1 Within this proposals validity period our Delivery Period for this project is as follows: The whole project will be ready for delivery after 7 to 8 weeks of the delivery trigger date. 6.2 The Delivery trigger date is the latest date of receipt and acceptance of the following at Mammut Head office in Dubai, U.A.E.: Signed Contract (All pages of this proposal document and hand written notes to be initialed by both parties). Final Building(s) Revision/modification irrespective of how insignificant it is. Your written acceptance of price change orders that result from revisions to buildings. Acceptable Letter of Credit (LC) including all amendments requested by Mammut. Signed "Approved as Noted" or "Approved As Is" Approval Drawings

6.3 Approval drawings (detailed proposal drawing ) showing complete building layout dimensions will be submitted after 10-14 days from date of entry of job in Mammuts order register provided that all technical information is available at time of order entry. 6.4 Delivery period may be changed if validity period of this proposal expires and/or if the job is not released for production within 90 days of date of Mammuts first submission of approval drawi gs. n 6.5 Preparation of shop details required for fabrication can only begin after receipt of a signed copy of Mammut Approval Drawings. 6.6 Standard stock of Anchor Bolts takes about 10 days to deliver from the time of receipt of approval drawings approved for fabrication. Any non standard size or grade of anchor bolts needs about 4 weeks for delivery. 6.7 Mammut shall not be responsible for delay in delivery of material due to Force Majeure.

Sheet 10 of 22

Version 2.9

25-Jan-12 LY-O- 31989

SECTION 7: SUPPLY PRICE AND ALTERNATIVE PRICE OPTIONS

7.1 Total Supply Price C & F TRIPOLI Port in USD. BASIC PRICE BREAKDOWN BY BUILDING NUMBER Bldg. No. 01 Total No. of Containers +15 +15 C&F Port Price 383,000 383,000

7.2 Alternative Price Options None 7.3 Important Notes: 7.3.1 Insurance of Materials during transit. Insuring material supplied during transport is an option for the customer at his expenses. 7.3.2 Deliveries to a Sea Port Any expense incurred inside the importing country, including custom duties, taxes, clearance fees or demurrage due to delays in returning containers to shipping line is the Customer responsibility.

Sheet 11 of 22

Version 2.9

25-Jan-12 LY-O- 31989

SECTION 8: PAYMENT TERMS MAMMUT BANK INFORMATION & APPLICABLE LAW & DISPUTES

8.1 Payment Terms 20% Down payment on Job confirmation. Down payment may be made either by a Current Dated Cheque in favor of Mammut Building Systems FZC or by Telex Transfer (See bank details as below) 80% Payment by a Sight Irrevocable Letter of Credit (LC) confirmed by a UAE bank.

For Extended payment up to 90 days please add 0.75 % of the C & F price for each month of extension i.e. for 90 days please increase the C & F price by 3 x 0.75 = 2.25 %. The value of LCs opened from a bank outside the UAE should be increased by 0.50 % per quarter to cover confirmation charges in the UAE. Beneficiary shall be : Goods Description : Mammut Building Systems, FZC Pre-Engineered Steel Building Components

8.2 Mammut Bank Information A. Letter of credit should be opened in following bank (Please consult Mammut for Mammuts Pro-forma Invoice, stating the correct bank, at time of opening LC). ACCOUNT TITLE: BANK NAME: BRANCH: ADDRESS: AED ACCOUNT: IBAN NO.: SWIFT CODE: MAMMUT BUILDING SYSTEMS FZC EMIRATES NBD BANK PJSC JEBEL ALI P.O. BOX 2923, DUBAI, U.A.E 101-10642055 01 AE610260001011064205501 EBILAEAD

B. For payment by Telex Transfers (T. T.) please send on below bank details. ACCOUNT TITLE: BANK NAME: BRANCH: ADDRESS: AED ACCOUNT: IBAN NO.: SWIFT CODE: 8.3 Applicable Law & Disputes: This quotation, its application and interpretation shall be governed by The U.A.E. laws; and The U.A.E. Laws, its provisions and executive regulations and decisions shall apply to any matter not provided herein; and Any dispute arising out of the formation, performance, interpretation, nullification, termination or invalidation of this quotation or arising there from or related thereto in any manner whatsoever, shall be settled by arbitration in accordance with the provisions set forth under the Rules of Commercial Conciliation and Arbitration (the Rules) of the Dubai Chamber of Commerce & Industry, by one or more arbitrators appointed in compliance with the Rules. MAMMUT BUILDING SYSTEMS FZC MASHREQ BANK PSC SHARJAH BRANCH P.O. Box 22602, Sharjah, U.A.E. 04 96 305380 AE150330000010496305380 BOMLAEAD

Sheet 12 of 22

Version 2.9

25-Jan-12 LY-O- 31989

SECTION 9: EXCLUSIONS, DEVIATIONS & ASSUMPTIONS

9.1 Standard Exclusions 1. 2. 3. 4. 5. 6. 7. 8. Any approvals and all necessary permits from City, District, State or Federal Agencies as required. Customer to advice / release Mammut to fabricate upon receiving such information. Any design, detailing, coordination, management or building of any architectural features or art works other than what is shown on Mammuts contract or Mammuts proposal drawings. Any design, coordination, management of MEP (Mechanical, Electrical and Plumbing) services. Any site paint, touch-up or fire resistant paints and fire proofing. Any building erection, unless erection is by Mammut. Any doors, windows or other works unless specifically mentioned in the contract and agreed upon in writing with the Customer. Any interior partitions to be made by others unless specifically mentioned in the contract and agreed upon in writing with the Customer. Any inspection and special testing of any Mammut Building element (other than what is in Mammut standard Quality Plan) is excluded. Additional price will be charged if such inspection and special testing is required. However, Mammut will provide customer with a reasonable quantity of material for testing at no cost to customer. Mammut accepts to conduct additional tests (at customer expense) at 3 rd party testing labs selected by customer. Any civil, mechanical and electrical works.

9.

10. Any foundation design and execution. 11. Any non-shrink epoxy grouting under steel columns. 12. Unloading of material at jobsite. 13. Any surety bonds, import taxes and liquidated damages. 14. Customer and their consultants are always welcome to visit Mammut office and factory. This visit should not in anyway obstruct or affect the flow of work process. It can be organized with our area sales office at a mutually agreed prior notice (minimum 48 hours).

Sheet 13 of 22

Version 2.9

25-Jan-12 LY-O- 31989

SECTION 10: CONTRACT FORM FOR SUPPLY OF STEEL & CLADDING

A CONTRACT shall be entered into by the Customer and Mammut. The Contract shall specify the scope of works required from Mammut and the rights and obligations of the contracting Parties. Furthermore, the Contract shall be constituted of the following documents: 1. 2. 3. 4. 5. Mammuts Sales Proposal Quotation No. LY-O-31989 Rev. No. 04 Dated 25-JAN-2012 as described in this contract, with all agreed and initialed amendments, if any. Mammuts Standard Terms & Conditions of Sale. Mammuts Standard Product Specifications. Mammuts Standard Panel Color Chart. Customers PO Number (If any)

Contract scope: Supply of Mammut Steel Building(s) Contract Price: AED. 383,000USD Three Hundred And Eighty Three Thousands United State Dollars. ___________________________________, hereby defined as the Buyer On behalf of the Buyer, Name Title Signature Date : ______________________ : ______________________ : ______________________ : ______________________ Company Stamp:

We, the Buyer, hereby acknowledge having read this proposal document and accepted all the terms and conditions of this Contract, the proposal document including the annexure, and irrevocably undertake hereby to be bound by it. AND MAMMUT BUILDING SYSTEMS, FZC hereby defined as the Seller On behalf of the Seller, Name Title Signature Date Endorsed by Name Title Signature Date : Diaa El Kenawy : Regional Sales Manager : ______________________ : ______________________ : : Achraf Kassem : General Sales Manager : ______________________ : ______________________ Company Stamp:

Sheet 14 of 22

Version 2.9

25-Jan-12 LY-O- 31989

ANNEXURE - 1

The following is the list of the material standards and specifications for which the building components have been designed:

MATERIAL SPECIFICATIONS No.

1

Structural Components

Built-up Sections Tubes Grade 50 /345 Structural Quality Grade 50 /345 Grade 50 /345 Grade 50 /340

Material Specifications

Hot Rolled Sections I-sections Channels

Cold formed secondary members Aluzinc coated steel Bare & Pre-painted

Grade 50 /340 Class 1 Aluzinc Coating: AZM 150 Grade AA 3105 Grade 50 /340 Class 1: Zinc Coating Z180 Extra High Strength Class A Breaking Load = 120 kN Grade 36 /250 Grade 50 /345 Grade 36 /250 High Strength Bolts Grade 36 /250

Sheeting Panels

Aluminum Mill finish & Pre-painted

Mezzanine Decking Panels Cable

Diagonal X Bracing

Rods HR Angles

7 8 9

Anchor Bolts High Strength Bolts Sag Rods

Important Note:Subject to market conditions and material availability, Mammut reserves the right to substitute equivalent or better material.

Sheet 15 of 22

Version 2.9

25-Jan-12 LY-O- 31989

ANNEXURE - 2

Deflections Limitations:

Deflection design greatly influences the weight and price of a building. Applying stringent deflection criteria necessarily will increase the weight and price of the building. Mammut uses the deflection criteria recommended in MBMA 2006

DEFLECTION TABLE

Sr. No. 1 2 3 4 5 6 1 2 3 4 5 6 7 8 Structural Members Rigid Frame and Endwall Rafters Vertical Deflection With fully sheeted walls With Blockwall and sheeting of equal heights With full height Blockwall With glazing & sheeting of equal heights With full height glazing With pendant operated crane Rigid Frame and Portal Frame Sway (Horizontal) With fully sheeted walls With Blockwall and sheeting of equal heights With full height Blockwall or Precast walls With glazing & sheeting of equal heights With full height glazing With pendant operated crane Special Cranes, Service Class E & F category Special Residential Buildings (JAFZA, DM) EH / 50 EH / 75 EH / 100 EH / 150 EH / 240 CBH / 100 CBH / 240 <= 50 mm EH / 500 Span / 240 Span / 360 Span / 240 Span / 360 Span / 60 Span / 150 Span / 180 Span / 120 Span / 150 Span / 60 Span / 90 Span / 120 Span / 180 & Span / 120 L or S or W & D + (L or S) Standard Allowable Deflection Load Case

W or E or Cr

W or E (D + L) or (D + W) L or S or W (D + L) or (D + W) L or W Total L or S W D+L D+L Total W

Mezzanine, Jack Beams, Panels & Purlins, Grating, Chequered Plates 1 2 3 4 5 1 2 3 4 Legend EH Denotes Eave Height CBH Denotes Crane Beam Height D Denotes Dead Load L Denotes Live Load S Denotes Snow Load W Denotes Wind Load E Seismic Load Cr Crane Load Beams & Joists of Mezzanine, Roof Platform, walkway etc. Jack Beams Roof Panel Roof Purlins Grating, Chequered Plates Wall Panels & Girts, Wind Columns, Horizontal Beams Wall Panels Wall Girts with Metal Sheeting Wind Columns Blockwall Supporting lateral beams, etc

For cantilevers L shall be taken as twice the length of cantilever

Sheet 16 of 22

Version 2.9

25-Jan-12 LY-O- 31989

ANNEXURE - 3

Claims for Short Shipped, Damaged & Quality Non Conforming Materials Claims may result from any of the following: Short shipped material (Material on the shipping list but not received at site) Damaged material (Material received damaged before unloading of material at jobsite) Quality Non Conformance (Defective Material, BOM error, etc)

Reporting of Claims Claims for short shipped, damaged or defective material must be reported to Mammuts local area office and simultaneously to Mr. Satheesh Kumar, Manager, Order Management at Mammuts head office: Email: Satheesh.Kumar@mammut.ae, Phone: (971-4) 801-2222 Fax: (971-4) 801-2223 CLAIMS FROM MUST BE REPORTED WITHIN THE NO. OF DAYS NOTED IN COL. 3 OF THE TABLE BELOW. Must be Claims reported Mammut Event within Response From For (days) (Territory) 5 Mammut will ship Date of Receipt of replacement material All Damaged Material 30 Material at Job Site within 7 days of Quality Non Conformance 60 receiving a claim Failure to report a claim within the no. of days noted above will make your claim invalid. 3.1 Backordered Material (These do not require the filling of a claim) Mammut ships its jobs in phases with a deliberate intent to ship complete phases. We make a great effort to avoid Backorders. A backorder is an item that is deliberately excluded from Mammut FZC supply because of its unavailability at Mammut FZC at the time of shipping a phase. A phase may occasionally be shipped incomplete because of a customers insistence to receive material on site. When a shipped phase has Backorders, Mammut FZC will inform you of each item that is Backordered, its quantity and the approximate date when it will be shipped. No claim needs to be filled for Backorders. Backordered material does not show in Mammuts shipping list. 3.2 Short Shipped Material Short shipped material is material that is on Mammuts shipping list but not received at jobsite. It is the responsibility of the customer (or his erector) to check the material received at jobsite to ensure th at all material mentioned in Mammuts shipping list is accounted for. 1 2 Short Shipped Material 3 30 4

Sheet 17 of 22

Version 2.9

25-Jan-12 LY-O- 31989

ANNEXURE 3 (CONT)

3.3 Damaged Material Damaged material is material that is received damaged prior to unloading it from trailers/containers at the jobsite. Container shipments must be unloaded at jobsite only. Mammut is not responsible for material that is damaged during unloading or during storage at jobsite while awaiting erection. Guidelines for unloading material and storing it at site may be requested from Mammut Head Office Order Management Department. It is the responsibility of the customer (or his erector) to unload Mammut material at the jobsite in a safe and orderly manner in order to avoid damage to Mammut material during unloading; and to store Mammut material at the jobsite in a manner that will protect it from the environment as well as from mechanical damage. A claim for damaged material must be backed up by proof that the material was damaged during transit and not during unloading of material at the jobsite or during storing of material at jobsite. The ideal proof is a digital video/digital pictures of the unloading of each trailer/container. Once a claim is accepted by Mammut, Mammut will determine whether the damaged material can be rectified by the customer or whether the damaged material should be replaced altogether by Mammut. When rectification is practical Mammut will ask the customer/erector to rectify the damaged material in accordance with a Mammut method statement and Mammut will pay for the cost of rectification on the basis of UAE material and labor rates. 3.4 Quality Non Conformance (includes defective material) Defective Material can be of 2 main types: 1. A fit problem such as a clip welded in the wrong location, missing holes, wrong size of hole, wr ong length of a member, etc Such defects are easy to discover and report. Mammut can quickly check them against shop drawings or manufacturing records. A technical problem such as a welding defect, excessive sway, camber, tolerance, deviation from specs, etc

2.

Normal erection operations include the corrections of minor misfits by moderate amounts of reaming, chipping, welding or cutting, and the drawing of elements into line through the use of drift pins. Errors which cannot be corrected by the foregoing means or which require major changes in member configuration are to be reported immediately to Mammut by the BUYER / END USE CUSTOMER to enable whoever is responsible either to correct the error or to approve the most efficient and economical method of correction to be used by others. (Section 7 AISC Code of Standard Practices, 13th Edition) Claims for defective material must specify the Mammut part no. that is defective and a detailed description of the defect. Digital photos clearly showing the defect must be attached to the claim. Defects may be minor in which case it is the responsibility of the erector to fix them without liability to Mammut or they can be more serious which may require rectification or replacement. Mammut will determine whether a par t no. can be rectified by the erector or whether a replacement is required. When rectification is an acceptable option Mammut will pay for the cost of the rectification on the basis of UAE material and labor rates and will provide a method statement for the rectification. Other quality non conformance includes BOM errors (Material that is required and shown on Mammut Erection Drawings but was missed in the BOM), Missing details on erection drawings, etc

Sheet 18 of 22

Version 2.9

25-Jan-12 LY-O- 31989

ANNEXURE 3 (CONT)

Building Revisions/ Price Change Orders 3.5 Building Revisions A Building Revision is defined as a change that is made by the Customer to the building parameters, material specifications, design loads, etc. after a job is entered at Mammuts Head office orders register. Some Building Revisions (such as a change in the building parameters, design loads or material specifications) will result in a price increase/decrease which necessitates a price change order. Some Building Revisions such as relocating a sliding door or a roof accessory will most likely not result in a price change but may affect the delivery period of a building especially if it is intimated to Mammut after return of Mammuts Approval Drawings to Mammut Head Office. 3.6 Price Change Orders If a Building Revision results in a price increase, Mammut will put the job on hold until a written price change order accepting the additional price is signed by the Customer and returned to Mammut. A price change order must not be a cause to hold payment for work already completed in the original contract. Proposal Validity, Contract Price Validity & Contract Signature Authority 3.7 Proposal Validity This proposal is valid for 15 days from the date of this proposal. Any extension of validity by Mammut must be in writing. 3.8 Contract Price Validity For Mammuts price and delivery period to remain valid for this job, the job must be Released for Production within 90 days from the date of signing of this contract. Mammut reserves the right to re-price that portion of the project (that has not been released for production within 90 days from the date of signing of this contract) on the basis of Mammuts prevailing price list at time of its release for production. Release for Production Means Technical Release for production i.e. the return of Mammuts Approval Drawings to Mammut duly signed by the Customer with any of the following notes: approved as is or approved as noted within 30 days of the date of job entry in Mammuts orders register. Financial Release for Production by Mammuts Finance Department within 90 days of the date of job entry in Mammuts orders register. Such Financial Release is conditional to the receipt of a Letter of Credit (LC) and all its amendments at Mammuts bank (any of the banks mentioned below) within 90 days of the date of job entry in Mammuts orders register. No hold notice is put on the job by the Customer in a way that prevents Mammut from starting production after receiving the above noted Technical and Financial Releases.

3.9 Contract Signature Authority Contracts may be signed by a Mammut Authorized Regional Sales Manager or Authorized Representative but must be indorsed by the General Sales Manager of Mammuts Building Systems FZC.

Sheet 19 of 22

Version 2.9

25-Jan-12 LY-O- 31989

ANNEXURE - 4

All structural components in buildings included in this proposal are designed in accordance with the following design codes. 4.1 Design Codes Hot rolled sections and built up sections are designed in accordance with: Manual of Steel Construction Allowable Stress Design American Institute of Steel Construction, Inc. ( ISC) A 1 East Wacker Drive, Suite 3100, Chicago, Illinois 60601 -2001, USA Phone: (001-312) 670-2400 Fax: (001-312) 670-5403 Edition used in this project: 2005 (Latest), 1989 Cold formed members are designed in accordance with: North American Specification for the Design of Cold -Formed Steel Structural Members American Iron and Steel Institute (AISI) 1140 Connecticut Avenue, NW Suite 705, Washington DC 20036, USA Phone: (001-202) 452-7100 Fax: (001-202) 463-6573 Edition used in this project: 2007 (Latest), 2001 Welding is applied in accordance with: Structural Welding Code Steel Manual (AWS D.1.1/D.1M:2008) American Welding Society (AWS) 550 NW LeJeune Road, Miami, FL 33126, USA Phone: (001-800) 443-9353 Fax: (001-305) 443-5647 Edition used in this project: 2008 (Latest) 4.2 Building Codes The buildings in this proposal are designed in accordance with the following building co de: Metal Building Systems Manual Metal Building Manufacturers Association, Inc. (MBMA) 1300 Summer Ave., Cleveland, Ohio 44115, USA Phone: (001-216) 241-7333 Fax: (001-216) 241-0105 Edition used in this project: 2006 (Latest) International Building Code IBC Formerly called Uniform Building Code (UBC) The last version was in 1997. 4051 West Flossmoor, Country Club Hills, IL 60478-5795 Phone: (001-800) 214 4321 Fax: (001-800) 214 7167 Edition used in this project: 2009 (Latest), 2006

Sheet 20 of 22

Version 2.9

25-Jan-12 LY-O- 31989

ANNEXURE - 5

Building Revisions/ Price Change Orders 5.1 Building Revisions A Building Revision is defined as a change that is made by the Customer to the building parameters, material specifications, design loads, etc. after a job is entered at Mammuts Head office orders register. Some Building Revisions (such as a change in the building parameters, design loads or material specifications) will result in a price increase/decrease which necessitates a price change order. Some Building Revisions such as relocating a sliding door or a roof accessory will most likely not result in a price change but may affect the delivery period of a building especially if it is intimated to Mammut after return of Mammuts Approval Drawings to Mammut Head Office. 5.2 Price Change Orders If a Building Revision results in a price increase, Mammut will put the job on hold until a written price change order accepting the additional price is signed by the Customer and returned to Mammut. A price change order must not be a cause to hold payment for work already completed in the original contract.

Sheet 21 of 22

Version 2.9

25-Jan-12 LY-O- 31989

ANNEXURE - 6

Proposal Validity, Contract Price Validity & Contract Signature Authority 6.1 Proposal Validity This proposal is valid for 15 days from the date of this proposal. Any extension of validity by Mammut must be in writing. 6.2 Contract Price Validity For Mammuts price and delivery period to remain valid for this job, the job must be Released for Production within 90 days from the date of signing of this contract. Mammut reserves the right to re-price that portion of the project (that has not been released for production within 90 days from the date of signing of this contract) on the basis of Mammuts prevailing price list at time of its release for production. Release for Production Means Technical Release for production i.e. the return of Mammuts Approval Drawings to Mammut duly signed by the Customer with any of the following notes: approved as is or approved as noted within 30 days of the date of job entry in Mammuts orders register. Financial Release for Production by Mammuts Finance Department within 90 days of the date of job entry in Mammuts orders register. Such Financial Release is conditional to the receipt of a Letter of Credit (LC) and all its amendments at Mammuts bank (any of the banks mentioned below) within 90 days of the date of job entry in Mammuts orders register. No hold notice is put on the job by the Customer in a way that prevents Mammut from starting production after receiving the above noted Technical and Financial Releases.

6.3 Contract Signature Authority Contracts may be signed by a Mammut Authorized Regional Sales Manager or Authorized Representative but must be indorsed by the General Sales Manager of Mammuts Building Systems FZC.

Sheet 22 of 22

Version 2.9

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Normanhurst Boys 2017 Year 9 Maths Yearly & SolutionsDocument29 pagesNormanhurst Boys 2017 Year 9 Maths Yearly & SolutionsPriscaNo ratings yet

- SCALP Handout 040Document2 pagesSCALP Handout 040Cher NaNo ratings yet

- Foreign Grantor Trust 13-6-07Document3 pagesForeign Grantor Trust 13-6-07Harpott Ghanta90% (10)

- Homework Assignment 1 KeyDocument6 pagesHomework Assignment 1 KeymetetezcanNo ratings yet

- Chapter 1 & 2: Entrepreneurship: Chapter 1: Definition and EvolutionDocument21 pagesChapter 1 & 2: Entrepreneurship: Chapter 1: Definition and EvolutionKey OnNo ratings yet

- Assessment of Operational BADocument26 pagesAssessment of Operational BAFaruk HossainNo ratings yet

- Class - 4 TransactionDocument8 pagesClass - 4 TransactionAkshay SinghNo ratings yet

- Problem Set 3 (Duration II) With AnswersDocument5 pagesProblem Set 3 (Duration II) With Answerskenny013No ratings yet

- Cost Estimation: (CHAPTER-3)Document43 pagesCost Estimation: (CHAPTER-3)fentaw melkieNo ratings yet

- DocumentDocument26 pagesDocumentLorraine Miralles33% (3)

- Road Chart: Kakinada-Rajahmundry Road From KM 0/0 To 27/0Document4 pagesRoad Chart: Kakinada-Rajahmundry Road From KM 0/0 To 27/0Phani PitchikaNo ratings yet

- WP10 2013 Distribution Income and Fiscal Incidence 18062013Document49 pagesWP10 2013 Distribution Income and Fiscal Incidence 18062013akinky3sumNo ratings yet

- What..? How..? and What Nextǥ?Document19 pagesWhat..? How..? and What Nextǥ?Amit BhardwajNo ratings yet

- Final Answer KeyDocument13 pagesFinal Answer Keysiva prasadNo ratings yet

- MSQ-01 - Cost Behavior & CVP AnalysisDocument10 pagesMSQ-01 - Cost Behavior & CVP AnalysisDanica Reyes QuintoNo ratings yet

- Gibson10e ch02Document23 pagesGibson10e ch02SHAMRAIZKHANNo ratings yet

- Class 8 NotesDocument48 pagesClass 8 NotesHamza FayyazNo ratings yet

- Akixxxxx0p c15 PDFDocument1 pageAkixxxxx0p c15 PDFGanesh DasaraNo ratings yet

- Trading Riot Auction Market Theory - Understanding of Market andDocument13 pagesTrading Riot Auction Market Theory - Understanding of Market andJ100% (2)

- Letter From Sacred Heart Cathedral Preparatory President To FacultyDocument4 pagesLetter From Sacred Heart Cathedral Preparatory President To FacultyNational Catholic ReporterNo ratings yet

- Grant Thornton On Credit Rating AgenciesDocument105 pagesGrant Thornton On Credit Rating AgenciesMoneycontrol News60% (5)

- Draft Operating Agreement (LLC)Document10 pagesDraft Operating Agreement (LLC)haspiNo ratings yet

- 3441 Fulton ST TeaserDocument1 page3441 Fulton ST TeaserZach FirestoneNo ratings yet

- LTIP E Bill Oct 20 For WebDocument3 pagesLTIP E Bill Oct 20 For WebRabbul RahmanNo ratings yet

- ALDI ManagerDocument1 pageALDI ManagerRahul SinghNo ratings yet

- Sample Problems INTACC-3 - PART-2Document6 pagesSample Problems INTACC-3 - PART-2Angela AlarconNo ratings yet

- Final MBA-suragDocument84 pagesFinal MBA-suragSurag VsNo ratings yet

- RR 13-2018Document20 pagesRR 13-2018Nikka Bianca Remulla-IcallaNo ratings yet

- SSRN Id4187217Document70 pagesSSRN Id4187217luminous blueNo ratings yet

- Stock Market of IndiaDocument37 pagesStock Market of IndiaSonia NarangNo ratings yet