Professional Documents

Culture Documents

18.ijaest Vol No 7 Issue No 2 Performance Evaluation of A Water Treatment Plant 286 289

Uploaded by

Mubasher SaleemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

18.ijaest Vol No 7 Issue No 2 Performance Evaluation of A Water Treatment Plant 286 289

Uploaded by

Mubasher SaleemCopyright:

Available Formats

Sarika M.Mankar* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES Vol No. 7, Issue No.

2, 286 - 289

PERFORMANCE EVALUATION OF A WATER TREATMENT PLANT (CASE STUDY)

Sarika M.Mankar1, Dr. P.B. Nagarnaik2

1 M.Tech(Env.Engg) 4th Sem Student, G.H.Raisoni College Of Engineering, Nagpur, India. 2 Dean, Academic, G.H.Raisoni College Of Engineering, Nagpur, India gpur,

Keywords- Performance evaluation, Water Treatment Plant. -

IJ

ISSN: 2230-7818

Introduction:Study of water treatment plant is carried out with all aspects and considerations including; engineering, physical, chemical & bacteriological to determine its efficiency and to produce water quality [7]. This study will define design and operating problems and gn gn difficulties of the case study that will allow for proper revision of these aspects to redefine and suggest recommendations for proper operations. The findings of work may be applicable for other WTP either under design or operation [1].

@ 2011 http://www.ijaest.iserp.org. All rights Reserved.

ES

Abstract:For providing continuous and good quality of water to all the regions in Maharashtra roviding through out the year, Govt. of Maharashtra has constructed new water treatment plants during the past few years. Performance of these plants is an essential parameter to be monitored and evaluated for the better understanding of design and operating difficulties in water treatment plants.This paper outlines the finding of investigation of the treatment plant in Pawnar,Wardha.The Physico-chemical analysis is proposed to be conducted to investigate water quality. The conclusions drawn from this study will outlines the importance of accurate engineering design and need for continuous monitoring and analysis of each unit performance [1] .

Samples Samples Samples were collected from intake and from all WTPs units of Pawnar, Wardha & analysis were carried out in the Environmental Engineering laboratory of B.D. College of Engineering,Sewagram,Wardha. Analysis were conducted for chemical, physical, bacteriological analysis. All experiments were done and results were determined in accordance to the Standard Methods of American Water Works Association (AWWA) manual, 21st Edition (2009) [1] & CPHEEO manuals[4].

Page 286

Sarika M.Mankar* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES Vol No. 7, Issue No. 2, 286 - 289

Process Description:-

Figure 1 shows the general layout of the WTP. The brief description of all WTP units. components facilities [1] are as follows.

IJ

ISSN: 2230-7818

INTAKE The main source of supply to water treatment plant is Dham river.The river flow from mahakali dam which subsequently arise at pawnar.The Dham river is Perennial in nature.

RAW WATER SUMP AND PUMP HOUSE The sump and pump house has been constructed near the bank of river. The water is first collected in R.C.C.Circular tank having size 4.5 * 9.10m. The capacity of sump is 138 m3. In the pump house two centrifugal pumps (2 nos. + 1 no. stand

@ 2011 http://www.ijaest.iserp.org. All rights Reserved.

ES

The city of Wardha is located on 20045' North latitude and 78039' East longitude in Eastern Maharashtra. The present population of Wardha city is near about 10 lakhs. The Water supply to the city is arranged from Pawnar treatment plant having capacity 10.6 MLD. The Pawnar is located in Wardha Dist. and 7 km away from Wardha on Nagpur Highway. Water treatment plant was constructed in the year 1975 having Capacity 10.6 MLD. Source of water is Dham river. About 10% of total water supplied to the city by this plant. The plant is running for 16 hours and 10.6 MLD water is being treated and supplied to the city. The design and construction of the plant is conventional one and comprises of various units such as flash mixer, clariflocculator, rapid sand filters, chemical house, clear water sump and pump house. The water from this plant mainly supplied to 3 area in the Wardha city namely Snehal Nagar,Civil Line, Mohini Nagar.

PAWNAR: Water Treatment Plant:-

by total 3 nos.) having capacity 25 HP. The diameter of pipe is 400mm.This pipe convey water to clarrifloculator. The total length of this pipe is 10m. FLASH MIXER The flash mixer is 1.4 *1.7 m and 2.63 m deep. The motor of 5 HP has been provided with 80 rpm. The process is done only in rainy season. CLARRIFLOCULATOR Only one clarrifloculator tank is provided in this plant. coagulated water enters at bottom of flocculator has a diameter of 8 m while clarifier has a diameter of 12 m and depth 3.5 m. Desludging are done ones in a day at least 5 min so that the sludge material comes out. RAPID SAND FILTERS Four filter are used, flow through each is about 24 lit/sec. Surface area of each is 18m2.The rate of filtration filtration filtration is 4.8 m3/m2/hr. Sand analysis was conducted conducted on sand samples and it was found that the effective size of the sand is in a range of 0.78 to 1.12 mm where required is 0.45 to 0.55mm. Also uniformity coefficient was found to be 1.025, where standard is 1.3 to 1.7. This shows that sand used inside filters is not as per the standard. POST CHLORINATION The post chlorination is done by using chlorine cylinder having wt. 900 kg. The post Chlorination dose of 1.0 to 3 mg/lit added to the filter water.

SUMP AND PUMP HOUSE The chlorinated water is collected in sump having size 7.6*6.08*4.56 and having capacity 210m3. In the pump house 3 pumps are used (2 nos. + 1no standby) of 300 HP for pumping pure water.

Page 287

Sarika M.Mankar* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES Vol No. 7, Issue No. 2, 286 - 289

LABORATORY ANALYSIS Table: Laboratory analysis & comparison of raw water, Tap water & Permissible Limits

`Particulars

pH Turbidity Dissolved Oxygen Total Solids. Suspended Solids Total coliform

7.1 to 8.4 43 to 5.2 6.1 to 7.8 245 to 109 22 to 64 45.23 to 9200

Observations

Before Treatment Tap Water

7 to 8.6 3.1to 5.2 6.7 to 8.2 12 to 48 4 to 20 78 to 5.3

Permissible Limits (BIS Standard/CPEEO)

Desirable 6.5 to 8.5 5 NTU max 9.2 mg/lit ----10No/100ml max Permissible 6.5 to 8.5 10 NTU max 5.0 mg/lit ----10No/100ml max

Remark

Within the limit Within the limit Moderate

Contamination in the pipe.

Observations at Water Treatment plant

A thick scum layer is accumulated at the bottom of the coagulation tanks. Dose of coagulant are decided arbitrarily on the basis of turbidity.Coagulants are not added regularly in raw water. In the flash mixer motor is not in working condition and hence operation of uniform mixing is hampered.. The sludge from the clariflocculator is discharged into a river . The scraping of sludge is not done due to which lot of sludge is accumulated at bottom. Sometime the water in clarifier is over discharged. The Place where Alum is kept is not hygienic due to which there is possibility of bacterial growth. The Quality of river water gets affected due to transfer of backwashing water into river.

CONCLUSIONS

The overall performance of Water Treatment Plant is found to be satisfactory with the scope for improvement in following aspects. Coagulant dose is determine arbitrarily without any laboratory study on Jar test. Jar test shall be conducted for calculations of optimum dose. Sand in Rapid sand filters should be according to standards. Rapid sand filters, sand should be replaced every year.

IJ

ISSN: 2230-7818

@ 2011 http://www.ijaest.iserp.org. All rights Reserved.

ES

REFERENCES

The flash mixer is not found in working condition this is necessary to repair and keep in working. Thickness of sand in every bed is not as per design. Transfer of backwashing water into river should be prevented.

1) M. A. Eldib and Mahmoud A. Azeem ElbayoumyEvaluation Of A Water Treatment Plant Performance Case Study in Seventh International Water Technology Conference (IWTC-7) held in Egypt 1-3 April 2003.p.p. 471-478. 2) Sujit Kumar Bhattacharya & Ratan Kishore Choudhary Performance of Engineering Parameter of a water Treatment Plant A Case Study paper published in 28th WEDC conference on Sustainable Environment Sanitation and Water Survices at Kolkata (Culcutta), India, 2002. 3) Dhaneshwar R. S., Sharma V.P., Raut T., Gupta R. K., Kelkar P.S. and Paramasivam R Performance Evaluation of Five Urban Water Treatment Plants in Utter Pradesh paper published in Indian Water Works Association Journal, edition-Jan-March, 1991.p.p. 23-30 4) CPHEEO Manual on Water Supply and Treatment Third Edition published by Ministry of Urban 5) www.iwwa.info/index.htm 6) www.tsawatersystems.in/index.asp 7) www.iwtc.info/2003_pdf/07-5.pdf

Page 288

Sarika M.Mankar* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES Vol No. 7, Issue No. 2, 286 - 289

8).www.oregon.gov/DHS/ph/dwp/swt.shtml 9).www.deq.state.or.us/WQ/dwp/links.htm

Figure: Schematic Representation of Water Treatment Plant, Pawnar

IJ

ISSN: 2230-7818 @ 2011 http://www.ijaest.iserp.org. All rights Reserved. Page 289

ES

You might also like

- Down To Earth - Complete - UnlockedDocument125 pagesDown To Earth - Complete - UnlockedMubasher SaleemNo ratings yet

- Basics GenchemDocument31 pagesBasics GenchemMubasher SaleemNo ratings yet

- Khizar e RahDocument60 pagesKhizar e RahMubasher SaleemNo ratings yet

- Dars e Masnavi Maulana RoomDocument374 pagesDars e Masnavi Maulana Roombinarymind100% (3)

- Water Risk Management-WHODocument108 pagesWater Risk Management-WHOmmoosaniNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Buffer Zone Guidelines For Wetlands, Rivers and Estuaries. Part 1: Technical ManualDocument183 pagesBuffer Zone Guidelines For Wetlands, Rivers and Estuaries. Part 1: Technical ManualShewa Lemma TekleNo ratings yet

- Physiography of India: Northern Mountain Region and Great PlainsDocument32 pagesPhysiography of India: Northern Mountain Region and Great PlainsKartik Vishwakarma100% (1)

- Module 3: Irrigation Multiple ChoiceDocument9 pagesModule 3: Irrigation Multiple ChoiceRafaella ManaloNo ratings yet

- Infiltration and Soil Moisture MG3Document14 pagesInfiltration and Soil Moisture MG3trisha tanglaoNo ratings yet

- 1-Farmers ProblemDocument7 pages1-Farmers ProblemApple Ermida BanuelosNo ratings yet

- Unit 4 Social Issues-2 5 17 PDFDocument17 pagesUnit 4 Social Issues-2 5 17 PDF1020-Santhosh kumar. JNo ratings yet

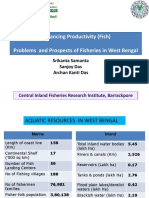

- Samanta CIFRIDocument17 pagesSamanta CIFRIashisbhuniyaNo ratings yet

- Texas State Water Plan 2012Document314 pagesTexas State Water Plan 2012Patricia DillonNo ratings yet

- 8 Solar Panels at Boston College PaperDocument22 pages8 Solar Panels at Boston College PaperJovan StoimenovskiNo ratings yet

- Abengoa Hugoton Fact Sheet enDocument2 pagesAbengoa Hugoton Fact Sheet enLaperaNo ratings yet

- ProjectDocument3 pagesProjectKimzee kingNo ratings yet

- Carrying Capacity of Cox's BazarDocument11 pagesCarrying Capacity of Cox's BazarJakiya SultanaNo ratings yet

- Reading and Writing Waste Not Want NotDocument11 pagesReading and Writing Waste Not Want NotLarbi NadiaNo ratings yet

- Cross Drainage Works: by Santosh Kumar GargDocument25 pagesCross Drainage Works: by Santosh Kumar GargUmer Waheed100% (1)

- World Water in 2025Document49 pagesWorld Water in 2025Francois BornmanNo ratings yet

- A History of Energy SourcesDocument40 pagesA History of Energy SourcesKhánh JuuNo ratings yet

- Modernizing Romania's Tractor Fleet & Agricultural MachineryDocument6 pagesModernizing Romania's Tractor Fleet & Agricultural MachineryAnonymous p52JDZOdNo ratings yet

- AJAD 2005 2 1 2 6brionesDocument13 pagesAJAD 2005 2 1 2 6brionesHaruki AkemiNo ratings yet

- 4.chapter IDocument12 pages4.chapter IMARIAN TIMTIMANNo ratings yet

- Shankarpur (Bhatgaon II) Extn, BLOCK SUMMARY: Part ADocument2 pagesShankarpur (Bhatgaon II) Extn, BLOCK SUMMARY: Part AAkhil AnandNo ratings yet

- Analisis Laju Infiltrasi Pada Sub Das (Daerah Aliran Sungai) Siak Kota PekanbaruDocument10 pagesAnalisis Laju Infiltrasi Pada Sub Das (Daerah Aliran Sungai) Siak Kota Pekanbarutheyaponz agraotek2015No ratings yet

- KupwaraDocument18 pagesKupwaraMuzamil RatherNo ratings yet

- Assignment 2 BWTDocument9 pagesAssignment 2 BWTSonam TenzinNo ratings yet

- Fishing Industry - Laguna de BayDocument32 pagesFishing Industry - Laguna de BayReign CuyosNo ratings yet

- Upcoming Sour Gas Project (Source: Wood Mackenzie Business Consulting)Document4 pagesUpcoming Sour Gas Project (Source: Wood Mackenzie Business Consulting)グレイロレンス シロシ プトラNo ratings yet

- Soil Taxonomy ShaluDocument6 pagesSoil Taxonomy Shalushalini shuklaNo ratings yet

- Biogas Production in China - Current Status and Future Development, DR Xiujin LiDocument41 pagesBiogas Production in China - Current Status and Future Development, DR Xiujin LiDio PambudiNo ratings yet

- 11baku Mutu Pupuk OrganikDocument14 pages11baku Mutu Pupuk Organikikhsan07No ratings yet

- Kuno CAG REPORTDocument126 pagesKuno CAG REPORTkshipra soniNo ratings yet

- UOP Hydrorefining Green Diesel Tech Paper PDFDocument5 pagesUOP Hydrorefining Green Diesel Tech Paper PDFalisonlsleeNo ratings yet