Professional Documents

Culture Documents

Blaine Apparatus Procedure

Uploaded by

Vivek PandeyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blaine Apparatus Procedure

Uploaded by

Vivek PandeyCopyright:

Available Formats

Chapter 12-Testing of Cement Part 1

12. TESTING OF CEMENT PART 1.

12.1 Density

The density is the fundamental physical characteristic of the material. Density is defined by mass of a unit volume of a material substance, expressed as kilograms per cubic metre.

=

where

m Vh

-3

is

density in kg.m (g.cm ) mass of the material sample in kg (g) volume of the specimen in m (cm )

3 3

-3

Vh

The mass can be determinate by scale (usually analytic balance), to determine volume of loose material is more difficult. For determination of cement density the pycnometric method is used.

12.1.1 Determination of Density by Pycnometric Method. Pycnometric method is indirect method; the measuring of volume is substituted by several weighing of material in pycnometer. Pycnometer is glass (or metal) bottle with a tight fitting stopper having a small hole in its centre. The hole in the stopper allows excess liquid to escape and the volume of the liquid in the pycnometer is always the same. Density by pycnometry is calculate from basic formula:

=

where

m k m + m4 m3

m is mass of the sample of the tested material (m = m2 m1) m1 mass of dry empty pycnometer including stopper m2 mass of dry pycnometer with sample and stopper m3 mass of closed pycnometer with sample and measuring liquid m4 mass of the closed pycnometer with measuring liquid

density of measuring liquid at tested temperature

Note: Measuring liquid could not be water in case of measuring cement density! Usually is used alcohol. Testing procedure weight mass of the empty pycnometer with stopper - m1 fill the pycnometer with measuring liquid. Replace stopper carefully, allowing excess liquid to escape through the hole in the stopper. Make sure there are no bubbles. Dry outside and weight m4 fill the dry, empty pycnometer about 1/3 full of the sample. Closed it and weight again m2

page 59

Building Materials 10- Testing Methods add measuring liquid to the sample. Fill pycnometer about 2/3 full. Mix up with caution and boil the pyknometer for 2 hours. After cooling refill with the liquid, closed the pycnometer and weight - m3 calculate the mass of the sample from formula: m = m2 - m1 count the density from the basic formula. Fig.:29 Derivation of the formula for density determined pycnometric method

where mk is mass of liquid, volume of which was pushed up by volume of the solid material

12.2 Fineness

Standard EN 196-6 describes two methods of determining the fineness of cement: sieving method air permeability method ( Blaine)

12.2.1 Sieving Method This method serves only to demonstrate the presence of coarse cement particles. This method is primarily suited to checking and controlling production process. The fineness of cement is measured by sieving it on standard sieves. The proportion of cement of which the grain sizes are larger than the specified mesh size is thus determined.

12.2.2 Air Permeability Method ( Blaine Method ) The fineness of cement is measured as specific surface. Specific surface is expressed as the total surface area in square metres of all the cement particles in one kilogram of cement. The higher the specific surface is, the finer cement will be. Principle of air permeability method is in observing the time taken for a fixed quantity of air to flow through compacted cement bed of specified dimension and porosity. Under standardised conditions the specific surface of cement is proportional to t where t is the time for given quantity of air to flow through the compacted cement bed. The number and size range of individual pores in the specified bed are determined by the cement particle size distribution which also determined the time for the specified air flow. The method is comparative rather than absolute and therefore a reference sample of known specific surface is required for calibration of the apparatus.

page 60

Chapter 12-Testing of Cement Part 1 A bed of cement is prepared in special permeability cell and have exact porosity e = 0,500 weight a quantity of cement. The weight of the cement is calculated from

m1 = 0,500 V

where V is the density of the cement [g.cm ]

-3

[g]

volume of the cement bed [cm ]

3

Specific surface S is expressed as

S=

where K e t

K e3 (1 e)

t 0,1

[cm .g ]

2 1

is the apparatus constant porosity of the bed the measured time [s] density of cement [g.cm ]

-3

the viscosity of air at the test temperature taken from Tab.:27

The apparatus constant is determinate by measuring permeability of reference cement of known specific surface. The procedure repeats three times for three samples of cement bed. For each sample is calculated constant K from formula:

K = S0 0

(1 e) e3

0,10 t0

2 -1

where S0 0 t0 0

is the specific surface of the reference cement [cm .g ] density of the reference cement [g.cm ]

-3

measured time [s] air viscosity at the test temperature [Pa.s]

With the specified porosity of e = 0,500

K = 1,414 S0 0

0,10 t0

The mean of three values of K is the constant K for the apparatus.

page 61

Building Materials 10- Testing Methods Fig.:30 Blaine apparatus

CONICAL SOCKET STOPCOCK MANOMETER

PERMEABILITY CELL

PLUNGER

ETCHED LINES

COMPACTED CEMENT BED

PERFORATED DISC

RUBBER BULB

Testing procedure Place the perforated disc on the ledge at the bottom of the cell and place on it a new filter paper disc. Place the weighed quantity of cement, m1, in the cell. Place a second new filter paper disc on the levelled cement. Insert the plunger and press it gently but firmly until the lower face of the cap is in contact with the cell. Slowly withdraw the plunger, rotate it through 90 and press once again. The bed is now compacted and ready for the permeability test. Test is performed on the Blaine apparatus (see Fig.:30). It is practically manometer in the U-tube form. One arm of the manometer is provided at the top with conical socket to form an airtight fit with the conical surface of the cell. The same arm has four etched lines M1 to M4 and T-joint, which lead to an airtight stopcock beyond which is attached aspiration rubber bulb. Manometer is filled to the level of the lowest etched line with non-volatile, non-hygroscopic liquid of low viscosity and density (such as dibutylphthalate or light mineral oil). Insert the conical surface of the cell into the socket at the top of the manometer. Open the stopcock and with gentle aspiration raise the level of the manometer liquid to that of the highest etched line. Close the stopcock and the manometer liquid will begins to flow. Start the timer as the liquid reaches the second etched line and stop it when the liquid reaches the third etched line. Record the time, t, and the temperature, T. The procedure repeats three times Calculate three values of the specific surface and the mean of them.

page 62

Chapter 12-Testing of Cement Part 1 Tab.:27 Viscosity of air and 0,1 [C] Air viscosity 0.00001800 0.00001805 0.00001810 0.00001815 0.00001819 0.00001824 0.00001829 0.00001834 0.00001839 [Pa.s]

Temperature 16 17 18 19 20 21 22 23 24

0,1

0.001342 0.001344 0.001345 0.001347 0.001349 0.001351 0.001353 0.001354 0.001356

linear interpolation can be used for the determination of the intermediate values

12.3 Determination of Setting Time

The setting time is determined by observing the penetration of needle into cement paste of standard consistence until it reaches a specified value. The laboratory shall be maintained at a temperature of 20 2 and a relative humidity of not less C than 65 %.

12.3.1 Standard Consistence Test Cement paste of standard consistence has a specified resistance to penetration by a standard plunger. The water required for such a paste is determined by trial penetrations of pastes with different water contents. Content of water is expressed as percentage by mass of the cement. Vicat apparatus (see Fig.:31) with the plunger is used for the test. The plunger shall be of noncorrodible metal in the form of a right cylinder of 50 1mm effective length and of 10,00 0,05 mm diameter. The total mass of moving parts shall be 300 1 g. Part of the Vicat apparatus is the mould from hard rubber (of truncated conical form) on the glass base-plate. Procedure calibrate the Vicat apparatus by lowering the plunger to rest on the base-plate to be used and adjusting the pointer to read zero on the scale. Raise the plunger to the stand-by position. weight 500 g of cement (to the nearest 1g). Weight a quantity of water (distilled or deionized), e.g. 125 g, in the mixer bowl or measure the water from the graduated cylinder into the mixer bowl. ad the cement carefully to the water in order to avoid loss of water or cement. The time of addition shall be not less than 5 s nor more than 10 s. Note the time of completion of the addition as zero time, from which later measurements of time shall be made. start the mixer immediately and run at low speed. stop the machine after 90 s for 15 s during which remove with a suitable scraper any paste adhering to the bowl outside the mixing zone and return it to the mix. Restart the machine and run at low speed for further 90 s. The total mixer running time shall be 3 min. page 63

Building Materials 10- Testing Methods transfer the paste immediately to the mould and fill it to excess. Remove the excess gently and make a smooth upper surface immediately after levelling the paste, transfer the mould and base-plate to the Vicat apparatus and position it centrally under the plunger. Lower the plunger gently until it is in contact with the paste. Pause in that position for between 1s and 2s. Than release the moving part quickly and allow the plunger to penetrate vertically into the centre of the paste. The release of the plunger shall occur 4 min after zero time. Read the scale when penetration has ceased or 30 s after the release of the plunger, whichever is the earlier. record the scale reading, which indicates the distance between the bottom face of the plunger and the base plate. Clean the plunger immediately after each penetration. repeat the test with pastes containing different water contents until one is found to produce a distance between plunger and base-plate of 6 1 mm. Record the water content of that paste to the nearest 0,5% as the water for standard consistence.

Fig.:31 Vicat apparatus with plunger and needle

PLUNGER FOR STANDARD CONSISTENCE

NEEDLE

VICAT APPARATUS WITH HARD RUBBER MOULD

12.3.2 Setting Time Test Cement paste of standard consistence is used for this test. Vicat apparatus is used, but the plunger is replaced by the steel needle in the form of a right cylinder of effective length 50 1 mm and diameter 1,13 0,05 mm. The total mass of moving part is 3001 g. Procedure calibration of Vicat apparatus with the needle is the same as for the apparatus with the plunger. mould, filled by paste of standard consistence and base plate transfer to the Vicat apparatus. procedure of penetration is the same as by using plunger.

page 64

Chapter 12-Testing of Cement Part 1 repeat the penetration test on the same specimen at conveniently spaced position, not less than 10 mm from the rim of the mould or from each other, at conveniently spaced intervals of time, e.g. at 10 min intervals. clean the Vicat needle after each penetration initial setting time is time measured from zero at which distance between the needle and the base-plate is 4 1 mm . Record it to the nearest 5 min. final setting time is time measured from zero at which the needle first penetrates only 0,5 mm into the specimen Automatic setting time machines are commercially available and may be used provided that they can be shown to give the same test results as the specified apparatus and procedure.

Vocabulary

cement paste coarse density final setting time fine fineness initial setting time mesh mould porosity setting time sieving specific surface standard consistence test specimen to harden hardening time to set cementov kae hrub hustota konec tuhnut jemn jemnost mlet potek tuhnut sto forma porozita, mezerovitost dobya tuhnut prosvn mrn povrch normln hustota zkuebn vzorek, zkuebn tleso tvrdnout doba tvrdnut tuhnout doba tuhnut

page 65

You might also like

- Test For Properties of Cement: Physical & ChemicalDocument4 pagesTest For Properties of Cement: Physical & ChemicalmuqeetNo ratings yet

- Cement PDFDocument70 pagesCement PDFhamza2k19No ratings yet

- Cement IndustryDocument27 pagesCement IndustryAhmed Mahmoud100% (1)

- KILN Hot SpotDocument4 pagesKILN Hot Spotabdulfetah100% (1)

- Clinker CoolersDocument12 pagesClinker CoolersAkhilesh Pratap SinghNo ratings yet

- 7-Mineral Phases of Portland CementDocument28 pages7-Mineral Phases of Portland CementzamriseramikNo ratings yet

- Production Process of CementDocument2 pagesProduction Process of CementMarwaNo ratings yet

- Alite Modification by SO3 in Cement Clinker - An Industrial TrialDocument7 pagesAlite Modification by SO3 in Cement Clinker - An Industrial TrialRaúl Marcelo Veloz100% (2)

- Interpreting Cement Science Since 2005: Understanding Cement Book/ebookDocument14 pagesInterpreting Cement Science Since 2005: Understanding Cement Book/ebookVirat ChintuNo ratings yet

- 4 Cement TechnologyDocument43 pages4 Cement TechnologySomu AdityaNo ratings yet

- 2006 Slag Grinding With MPS Vertical Roller MillsDocument4 pages2006 Slag Grinding With MPS Vertical Roller Millslijosh_rexy1983No ratings yet

- GM 1.4 GrindabilityDocument6 pagesGM 1.4 GrindabilityJosé UrdayNo ratings yet

- Cement Mill: History Materials Ground Temperature Control Ball MillsDocument5 pagesCement Mill: History Materials Ground Temperature Control Ball MillsAli HadiNo ratings yet

- Chemical Technology Subject Code: CH2001Document13 pagesChemical Technology Subject Code: CH2001U SANKAR TEJONo ratings yet

- Physical Testing of Clinker & CementDocument61 pagesPhysical Testing of Clinker & CementDineshNo ratings yet

- Quailty Assurance of CementDocument30 pagesQuailty Assurance of Cementabdullah100% (3)

- Pre-Homogenization Factor PDFDocument6 pagesPre-Homogenization Factor PDFAfqan B-v0% (1)

- Grinding Systems and Cement Composition Optimisation-Cement Additives Added Value - Laurent GuillotDocument15 pagesGrinding Systems and Cement Composition Optimisation-Cement Additives Added Value - Laurent Guillotnathaniel villanuevaNo ratings yet

- Cement Manufacturing ProcessDocument26 pagesCement Manufacturing ProcessZubair KhanNo ratings yet

- Raw Meal Grinding Aids: Improving BurnabilityDocument3 pagesRaw Meal Grinding Aids: Improving BurnabilityfaheemqcNo ratings yet

- Snowman CompositionDocument7 pagesSnowman CompositionSunil MohanNo ratings yet

- Cement KilnsDocument26 pagesCement KilnsEngr Nabeel AhmadNo ratings yet

- A To ZDocument126 pagesA To ZMohamed Osama RagaaNo ratings yet

- Cement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Document14 pagesCement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Senthilkumar PragasamNo ratings yet

- Cement Process Engineering Vade-Mecum: 3. QualityDocument22 pagesCement Process Engineering Vade-Mecum: 3. QualityRaúl Marcelo VelozNo ratings yet

- Quality & Composition of Cement Clinker - INFINITY FOR CEMENT EQUIPMENT PDFDocument74 pagesQuality & Composition of Cement Clinker - INFINITY FOR CEMENT EQUIPMENT PDFSiddharth Singh100% (1)

- Calculation of The Formation Process of Clinker inDocument7 pagesCalculation of The Formation Process of Clinker inYounas BugtiNo ratings yet

- Clinker. Kiln Design and ProcesDocument7 pagesClinker. Kiln Design and Procesrrvc25100% (1)

- Training - Cga ApplicationDocument34 pagesTraining - Cga ApplicationSubhan MuhammadNo ratings yet

- Cement Ball-Mill-Heat-BalanceDocument3 pagesCement Ball-Mill-Heat-Balanceanurag soni100% (1)

- Circulation of Inorganic Elements in Combustion of Alternative Fuels in Cement PlantsDocument85 pagesCirculation of Inorganic Elements in Combustion of Alternative Fuels in Cement PlantsBetonÇimento100% (3)

- The Effects of Limestone Addition, Clinker Type and Fineness PDFDocument5 pagesThe Effects of Limestone Addition, Clinker Type and Fineness PDFHazem DiabNo ratings yet

- Chemical AnalysisDocument8 pagesChemical Analysisصفاء رجبNo ratings yet

- Cement Kiln RefractoryDocument166 pagesCement Kiln RefractorySyed Kazam RazaNo ratings yet

- Cement Technology Cement ChemistryDocument22 pagesCement Technology Cement Chemistryshani5573No ratings yet

- 1 - Grinding Media Catalogue PDFDocument14 pages1 - Grinding Media Catalogue PDFmahreza189No ratings yet

- Cement Grinding OptimizationDocument9 pagesCement Grinding OptimizationFran JimenezNo ratings yet

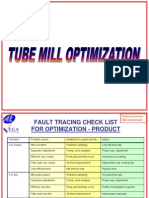

- Tube Mill OptimisationDocument7 pagesTube Mill OptimisationJoko DewotoNo ratings yet

- Effect of Raw Meal Fineness On Quality of ClinkerDocument6 pagesEffect of Raw Meal Fineness On Quality of ClinkerPrasann R Namannavar100% (1)

- Mombasa: WR 2954 Raw Materials Study and KFUI Improvement PlanDocument22 pagesMombasa: WR 2954 Raw Materials Study and KFUI Improvement PlanmustafNo ratings yet

- Monolithics - Basten 2018Document69 pagesMonolithics - Basten 2018Yhane Hermann BackNo ratings yet

- 6.1 Determination of Raw Mixture BurnabilityDocument2 pages6.1 Determination of Raw Mixture BurnabilityVipan Kumar DograNo ratings yet

- Optimization of Kiln Plants: Activities and Technical DetailsDocument10 pagesOptimization of Kiln Plants: Activities and Technical DetailsPaulo VidasNo ratings yet

- Free LimeDocument10 pagesFree LimeHazem DiabNo ratings yet

- VDZ-Onlinecourse 7 3 enDocument20 pagesVDZ-Onlinecourse 7 3 enAnonymous iI88LtNo ratings yet

- Unwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyDocument5 pagesUnwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyharyantoaditNo ratings yet

- Sulphur Release From Alternative Fuel FiringDocument6 pagesSulphur Release From Alternative Fuel FiringElwathig BakhietNo ratings yet

- Cement Grinding PlantsDocument30 pagesCement Grinding PlantsChalbelaro100% (2)

- Clinker FormationDocument120 pagesClinker FormationDragos PlaesuNo ratings yet

- Duoflex BurnerDocument6 pagesDuoflex Burnersinghite100% (1)

- 1.0 General Plant Information: Existing Cement Mill Process Data SheetDocument6 pages1.0 General Plant Information: Existing Cement Mill Process Data SheetBùi Hắc HảiNo ratings yet

- Cement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Document17 pagesCement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Salah Romdani100% (1)

- 031 Introduction Cement Grinding With Ball Mill SystemsDocument4 pages031 Introduction Cement Grinding With Ball Mill SystemsCesar Orlando Guarniz JustinianoNo ratings yet

- Grinding and Milling in Cement Manufacturing: 1.2 Fineness RequirementsDocument6 pagesGrinding and Milling in Cement Manufacturing: 1.2 Fineness RequirementsJosé UrdayNo ratings yet

- Boulder Formation in Cement Silos by Chettinad Cement CoDocument11 pagesBoulder Formation in Cement Silos by Chettinad Cement CoWaka OngetiNo ratings yet

- Chapter12 - Testing of Cement 1Document7 pagesChapter12 - Testing of Cement 1piratekANo ratings yet

- Sci1103 Unit 4notesDocument84 pagesSci1103 Unit 4notesSalin RajNo ratings yet

- BlainsDocument3 pagesBlainsShivakumara M JNo ratings yet

- Tests On CementDocument24 pagesTests On CementIan BondocNo ratings yet

- Determination of Specific Gravity of CementDocument1 pageDetermination of Specific Gravity of CementSyed Mohd MehdiNo ratings yet

- Is 1489 - Portland CementDocument14 pagesIs 1489 - Portland CementVivek PandeyNo ratings yet

- Properties of CementDocument14 pagesProperties of CementVivek PandeyNo ratings yet

- Constitution of India-Complete Full TextDocument471 pagesConstitution of India-Complete Full TextDaras Bir Singh67% (6)

- Chapter10 PDFDocument14 pagesChapter10 PDFyazidNo ratings yet

- Andy Nguyen 1 PDFDocument6 pagesAndy Nguyen 1 PDFPhin WNo ratings yet

- CoolBLUE Inductive Absorbers PresentationDocument49 pagesCoolBLUE Inductive Absorbers PresentationmauriciojjNo ratings yet

- Course Detail FMDocument13 pagesCourse Detail FMsidyantNo ratings yet

- St. Joseph Academy San Jose, Batangas SY 2019 - 2020 NAME: - GRADE and SECTIONDocument2 pagesSt. Joseph Academy San Jose, Batangas SY 2019 - 2020 NAME: - GRADE and SECTIONArnold Paombong0% (1)

- Matter Flipbook With PictureDocument3 pagesMatter Flipbook With Pictureapi-376074224No ratings yet

- Assignment 1: Introduction To Aircraft StructuresDocument4 pagesAssignment 1: Introduction To Aircraft StructuresLv NanhengNo ratings yet

- Canadian Association of Physicists 1999 Prize Exam Part A: Multiple ChoiceDocument5 pagesCanadian Association of Physicists 1999 Prize Exam Part A: Multiple Choiceelty TanNo ratings yet

- Roof Our PrjectDocument33 pagesRoof Our PrjectHundeejireenyaNo ratings yet

- Applications of Lie Groups To Differential Equations, by Peter J. Olver. GraduateDocument6 pagesApplications of Lie Groups To Differential Equations, by Peter J. Olver. GraduateNilesh SinghalNo ratings yet

- T SC 2550160 Ks2 Year 5 Properties and Changes of Materials Revision Activity Mat Ver 4Document6 pagesT SC 2550160 Ks2 Year 5 Properties and Changes of Materials Revision Activity Mat Ver 4khushbakhtNo ratings yet

- 11 DP Physics - Topic 2 Mechanics ProgramDocument13 pages11 DP Physics - Topic 2 Mechanics ProgrampixelhoboNo ratings yet

- 3 2 EnthalpyDocument14 pages3 2 EnthalpymahmoudNo ratings yet

- JEE ADVANCED Track Sheet (2024)Document3 pagesJEE ADVANCED Track Sheet (2024)MAHESWARA RAO ThotaNo ratings yet

- Atomic Structure History Dalton-BohrDocument28 pagesAtomic Structure History Dalton-BohrFabrielle RafaelNo ratings yet

- Psychrometrics: United States Standard AtmosphereDocument17 pagesPsychrometrics: United States Standard AtmosphereYuti PasaribuNo ratings yet

- Chapter 2 Force and Motion (Answer)Document108 pagesChapter 2 Force and Motion (Answer)Nadia SaidonNo ratings yet

- PHYS Module 2 WorksheetsDocument16 pagesPHYS Module 2 WorksheetsPrathmesh Sinha100% (1)

- Advanced 3D Modelling For Anode Baking FurnaceDocument6 pagesAdvanced 3D Modelling For Anode Baking Furnacefariza_yunitaNo ratings yet

- Transmission Lines & Termination Techniques: SAED VLSI GroupDocument17 pagesTransmission Lines & Termination Techniques: SAED VLSI GrouplusinNo ratings yet

- CH 10Document13 pagesCH 10patilamardip0078122No ratings yet

- B.TECH IT FinalDocument135 pagesB.TECH IT Finalk dharshiniNo ratings yet

- Bob Long Part 2Document296 pagesBob Long Part 2padalakirankumar100% (4)

- Hsslive-XI-Chemistry-Simplified Notes For 1 Improvement ExamDocument35 pagesHsslive-XI-Chemistry-Simplified Notes For 1 Improvement ExamLingesh Waran100% (3)

- Electromagnetic I EELE 3331: Electrostatic FieldsDocument84 pagesElectromagnetic I EELE 3331: Electrostatic Fieldsmae100% (1)

- Problem Set No. 1Document4 pagesProblem Set No. 1Marc MathieuNo ratings yet

- Stephen Mumford David Armstrong Philosophy Now Press 2007Document217 pagesStephen Mumford David Armstrong Philosophy Now Press 2007DjLuga Ayd100% (3)

- ACTRAN Modules OverviewDocument10 pagesACTRAN Modules OverviewGirish BellurNo ratings yet

- Fundamentals of Engineering Exam Sample Math Questions: X z+6 zx+6 ZDocument9 pagesFundamentals of Engineering Exam Sample Math Questions: X z+6 zx+6 ZinspectorsufiNo ratings yet

- Quantum Computing NotesDocument57 pagesQuantum Computing Notesjelena_luzija9197No ratings yet